Adjusting the oil supply to the chain of the Husqvarna chainsaw

Fake bought, what’s next?

What if you are in a hurry and have already bought a Chinese chainsaw called “Husqvarna” 5200? The main thing is not to get upset and prepare for the fact that you will have to carry out all the repair and adjustment work yourself. Most likely, you will not find the operating instructions in the kit for the saw, therefore, in order to start the tool correctly, refer to the video instructions:

As for the repair and adjustments of the carburetor, lubricants and others. the design of the internal combustion engine and other systems is identical for all chainsaws, with the exception of some nuances, so you can be guided by similar devices. The characteristics are also not fully presented, the Chinese manufacturer indicated only the most basic ones:

| Model | Husqvarna 5200 |

| Cylinder volume | 25 cm3 |

| Idling speed | 3 thousand rpm. |

| Bus length | 40 cm. |

| Fuel tank capacity | 550 ml. |

| Chain oil tank volume | 260 ml. |

| Weight in ready-to-use form | 5.3 kg. |

As a consolation, we can say that this tool also works, with proper maintenance, the chainsaw can work for a long time before the first repair. Spare parts are inexpensive. this is also a big plus.

Adjusting the carburetor of a Husqvarna 5200 chainsaw

Repairs are often necessary due to poor saw handling.

The most common signs of damage are:

- The motor is unstable;

- The number of exhaust emissions has increased;

- The power of the tool has significantly decreased;

- The amount of consumed fuel mixture has increased.

The problems described can be eliminated by adjusting the carburetor of the power tool.

The algorithm for this procedure:

- The adjusting screws are turned to the factory settings indicated in the instructions;

- The engine starts and warms up for ten minutes;

- The saw operation is adjusted at low speeds. Screw “L” turns counterclockwise to the maximum. After that, it twists in the other direction until the engine runs stably;

- Screw “H” turns counterclockwise until it stops. After that, it twists in the other direction by a quarter of a turn;

- If the chain moves along the bus, you need to turn the screw “T” until the chain stops moving;

- A tachometer is connected to the saw, the tool starts, you need to hold the gas until the maximum number of revolutions is reached. If the data on the tachometer is above the norm (indicated in the operating instructions), the screw “H” turns counterclockwise.

If you follow all the manufacturer’s recommendations, the troubleshooting process is straightforward. All repair work can be done by yourself.

The chainsaw is a great helper for any man living in his home. The chainsaw device is a complex system that requires careful maintenance and requires increased attention. Today you will learn how to adjust the carburetor of a Husqvarna 137 chainsaw with your own hands in the garage.?

Preparing the chainsaw for work

The algorithm of actions is as follows:

- assemble a chainsaw;

- put on and fasten the headset, pull the chain;

- prepare and pour fresh fuel mixture;

- fill the oil container with universal oil;

- start the chainsaw;

- check the brake performance;

- make sure that the chain is stationary at idle (otherwise, carburetor adjustment is required);

- check the oil supply to the chain.

Important! The mixture is prepared from unleaded gasoline with an octane rating of at least 90 and no more than 93 and synthetic oil (2T) for 2-stroke air-cooled engines. Ratio 50/1.

Equipment

The kit includes:

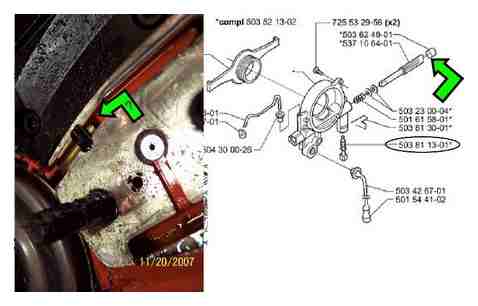

Husqvarna Chain Oiler repair and Easy Clutch Removal Hack

- Chainsaw 5200 with Husqvarna logo;

- chain with 72 links;

- tire 52 cm long;

- key;

- packaging.

Chainsaw Husqvarna 5200 carburetor adjustment

The Husqvarna 5200 chainsaw is not an original product of the world famous Swedish company Husqvarna. This is a natural Chinese counterfeit. the miracle technology of the Middle Kingdom, not distinguished by either special quality or assembly, which does not have a guarantee of the Husqvarna trademark. If you check the Internet catalog “Husqvarna”, then there is no such model at all! The Chinese deliberately display other names that are incomprehensible to the broad masses of the consumer who only reacts to the well-known brand logo.

The most attractive and wonderful thing about these models is the price. The manufacturer did not even bother to attach instructions to his product, so the Internet is teeming with questions and requests to get a link to this very instruction, which is unknown whether it actually exists.

Do-it-yourself Husqvarna carburetor adjustments?

In order to correctly adjust the carburetor of the chainsaw, you need to stock up on the appropriate tool in advance.

You will need the following list:

- The most common screwdriver, with which you can unscrew or tighten the adjusting screws;

- A tachometer designed to count the revolutions of the crankshaft. It is necessary when adjusting the idle speed, since it is quite problematic to determine the number of revolutions per minute by ear;

- Phillips screwdriver. It is needed to be able to unscrew the screw (T);

- Compressor with a special gun connected to them. The blowing device will help get rid of excess debris and dirt, since the carburetor must always be clean.

Many Husqvarna chainsaws use a special section adjusting bolt. See in advance which ones you have installed and purchase the appropriate kit. This will help to avoid many difficulties at the initial stage.

What is the factory setting of a Husqvarna chainsaw carburetor?

In order for the saw to start anyway, even if the setting is incorrect, the factory settings of the screws H and L are applied. Most Husqvarna chainsaws can be started by unscrewing both screws exactly one and a half turns. Only then can the position of the screws be changed in order to achieve the desired fuel consumption and maximum efficiency. It is regulated by XX also after these manipulations.

If you still have questions about adjusting the carburetor on the Husqvarna 137 chainsaw and other models of this line, I recommend watching this

Not Lubricated On Stihl Chainsaw

If a fuel mixture is found on the spark plug, it means there is an excess of fuel. Chain (14 ″; 1.3 mm for stihl 180 saws 14 rezer ps-9-1,3-50 low price, chainsaws (536. The reason may be a poorly adjusted carburetor or a violation of starting rules. See if the access through which gasoline is supplied is open.

To do this, open and close the fuel tank cap. It is also necessary to check the combustion chamber. After the work done, check the condition of the spark plug and change it if necessary.

Description of common malfunctions of the Stihl 180 chainsaw and how to fix them. A clogged breather may be the cause of the breakdown. Here I am telling and showing the proportion of mixing oil and gasoline for the Stihl chainsaw ms 180. Not only I am telling but also showing. Thus, when working in the fuel tank, a vacuum is formed, which affects the fuel supply. This can be due to an unregulated carburetor, clogged passages or air filter.

To correct the problem, the valve must be repaired, due to which the pressure is equalized when fuel is supplied. To do this, the breather should be carefully cleaned with a needle.

To adjust the carburetor, you need to use three screws. the highest and the lowest speed. Adjustment should be carried out strictly according to the instructions for repairing a chainsaw.

the main reasons why oil verse 180.

A quick overview of why the oil in the chainsaw stopped being presented on the bus from the tank Support our channel with what you can.

main prerequisites why oil is not supplied stihl 180.

- difficulties with air leaks;

- breakdown of the oil pump drive.

The main characteristics of the chainsaw chain.

The main reason for the breakdown is air leaks. This can happen due to the depressurization of the oil hose during the operation of the chainsaw. In this case, you need to remove the hose from the hole. This must be done in the area where it is connected to the crankcase. Then the hose sits on the sealant and is set to its normal position. If this did not help, most likely, elasticity was lost. For the upcoming operation of the chainsaw, it is purposeful to change the hose.

Another reason is a breakdown of the oil pump drive. In the common people, this part is called a worm. When the drive fails, no oil will flow to the chain. The oil pump drive is a round plastic ring with grooves inside. The constant introduction of the chainsaw leads to wear of the internal parts, and as a result, the iron hook inside the drive is chipped. After this breakdown, oil stops flowing to the chain.

the main reasons why stihl 180 oil is not fed.

Self-repair of the stihl ms 180 chainsaw. The chainsaw chain is not lubricated. Find and eliminate the cause of samos

Recommended to watch

- Stihl chainsaw: supplying oil to the chain

- The device and repair of the oil pump of the chainsaw

- How to thin your chainsaw gasoline?

- Stihl chainsaw oil

- Chainsaw oil Husqvarna

- Chainsaw Hopper Farmer

main reasons why oil is not supplied stihl 180.

Stihl chainsaw chain lubrication system consists of:

- guide rail;

- saw chain;

- oil pump.

The oil supply by the pump has a special regulation. Chainsaw chain lubrication occurs constantly during the operation of the machine. Therefore chainsaw chains have a long service life.

During operation, the chain requires a constant supply of lubricant. Its continuous supply must be ensured. This is required by the design of the device. During the operation of the chainsaw, the oil leaves the groove of the tire, instantly absorbed by the sawdust.

For this reason, the chain is lubricated automatically. Some chainsaw chains are equipped with a system that regulates the exact amount of lubricant supplied. The cheapest devices are equipped with a hand pump, which is powered by a drive located on the handle.

Scheme for checking the operation of the chain lubrication system.

Transmission grease is absolutely not suitable for work. In winter, it freezes, as a result, the oil system clogs up, you have to completely clean it.

In winter, chain lubrication requires special attention. Branded oil “M-20” thickens in severe frost and resembles petroleum jelly. Therefore, to work in winter, it is necessary to lubricate chainsaws with special winter oil, which has a more liquid consistency.

It is not always possible to purchase such a lubricant. To solve the problem, diesel fuel is mixed with oil, the viscosity is lowered. However, if the previously filled oil remains in the crankcase, then the addition of diluted oil will not have a positive effect, the system channels will remain clogged. There is only one way out. heating the chainsaw in a warm room.

If the chain oil does not solidify too much, you can try to melt it by running the saw at low idle.

Stihl 180 oil repair should be done when you see your chain dry. Take a close look at the oil passages and clean them thoroughly. Channel clogging occurs quite often.

Stihl 180 oil supply repair video instruction for the user of the STIHL MS180 chainsaw

Self-repair of the stihl ms 180 chainsaw. The chainsaw chain is not lubricated. Find and eliminate the cause of samos.

The Stihl 180 chainsaw has a characteristic malfunction, which consists in insufficient sealing of the place where the oil hose is installed in the chainsaw body and the appearance of a leak in this place. To eliminate it, just remove the Stihl MS 180 saw handle, disconnect the hose itself, rinse and degrease the seat in the body and the hose shank, then apply sealant and reinstall the hose.

As we have already found out, it is necessary to carry out additional diagnostics. For this we disassemble the lubrication system. Please note that in some saw models this is possible when the tool is completely disassembled. So, just in case, arm yourself with the proper repair tools. If you do not have experience in parsing a saw, entrust this business to a professional.

When the lubrication system is disassembled, you can find one of these failures:

- the oil hose is cut off (sometimes visible with the naked eye during a preliminary study of this part of the assembly), which needs to be replaced;

- there is no thread of the shaft where the oil pump is located (you need to attach, replace);

- damaged thread of the main pump gear (a new one is installed);

- there is no corkscrew of the main shaft (this problem is often observed with Homelite chainsaws), which can be solved by installing the original corkscrew, a nail in place (ideal in size, if there is a need to cut it);

- clogged line, this is solved by blowing (mechanically or with the help of compressed air, sometimes the wire helps);

- clogged filter element (clean or replace).

Please note that for some Stihl power units (for example, for the MS 180 model), the pump cannot be disassembled, but it will periodically clog up. In this case, it is washed with gasoline or, if necessary, completely replaced.

Chinese saws often “suffer” from the sheared grooves of the main gear, through which the force is transmitted.

Another common problem, again typical for Stihl products, is the leakage of the line. You need to look for the problem at the point where the oil line that goes from the reservoir enters the equipment case. Such a breakdown is indicated by oil leaks at the bottom of the power unit.

Operating principle

The main unit of the system is the pump. The principle of its operation is as follows. When the engine speed increases, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oily mowing line, which causes the oil to move along it towards the tire.

Chainsaw chain oils. which are better and how to use?

Chainsaw. a tool equipped with a two-stroke carburetor engine. For high-quality and long-term operation of a chainsaw, you need not only fuel. gasoline, but also lubricants, that is, oil. All technical oils, regardless of the principle of operation and scope of application, serve the same purpose. high-quality engine operation, lubrication of the leading parts of the engine, durability of parts, and a decrease in the degree of wear of parts.

The ideal chain saw oil should meet the following requirements:

- be of high quality, preferably a well-known world brand or “native”, which the manufacturer produces for his chainsaws;

- have good adhesive properties, that is, evenly and densely distributed over the entire area of the chain and the point of contact of the chain with the bar;

- meet the viscosity standards for the season;

- not be smoke-generating;

- withstand low temperatures and do not freeze in frost, which is especially important for work in the winter season.

Do not lubricate the chain saw if the chainsaw chains are not lubricated. This has a negative effect on the bar, drive sprocket and chain, and can also lead to serious repair costs.

- Chainsaw chain is dry and has a pale shade without shine.

- The chain stretches relatively quickly.

- The tire is very hot and even paint may be partially melted.

- The oil from the tank hardly decreases.

- Sharp chain cutting efficiency has decreased