At what degree to sharpen the chain of a chainsaw

Sharpening angles and chainsaw tooth configuration

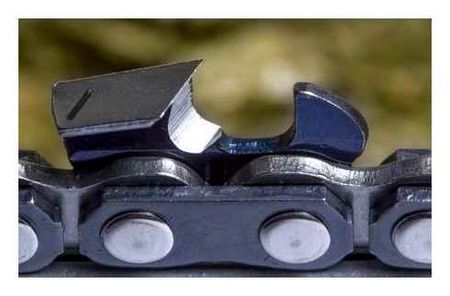

The tooth blades, or cutting edges, must be sharpened at a certain angle, otherwise it will be difficult to achieve the optimum cutting performance of the chain. The upper blade (horizontal) performs the function of cutting the tooth into the wood and forming a groove. The side or end blade (vertical) helps trim the fibers on the side.

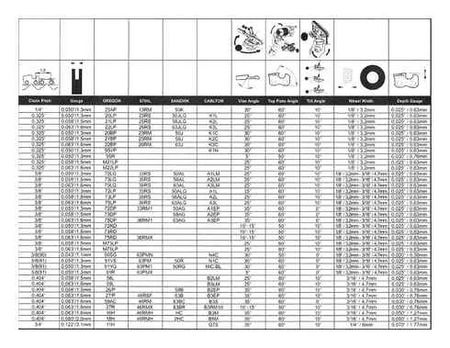

The most important thing when sharpening a chainsaw is to achieve the correct angle of the top blade, which should be between 60-50 degrees. The angle of the end blade should be kept between 85-60 degrees. It is also worth adhering to the angle in plan (sharpening angle), namely the one that is clearly visible when you look at the chain link from above. it departs from the side edge along the mowing line in front and should be 10-15 degrees.

Productivity of cross-cutting wood sawing operations is increased by increasing the chain saw’s sharpening angle to the maximum possible and vice versa. Chains to be sharpened lengthwise in the tree trunk should be filed at an angle of about 10 degrees.

Never touch the depth stop unnecessarily, as an incorrect grinding operation may cause the tool to vibrate. Finishing is done using a special template.

How to sharpen with an angle grinder (angle grinder)

The method of grinding the saw chain with the angle grinder is the least popular because of its insecurity. To dress chain teeth using angle grinder as a sharpening tool, it is necessary to put it in a vice and clamp it firmly. Next, the tool is turned on and the tooth edge to be sharpened is placed against the rotating surface of the disc. A similarly sharpened tooth is quite different from a file sharpened with a fine file.к. during dressing with an angle grinder, it is quite difficult to control the grinding angle.

The big disadvantage can be considered the possibility of notching the disc angle grinder lug fastening chain link, which will subsequently lead to a break, when carrying out work. If during work with a chain saw the need for sharpening it is better to use a special tool than to come up with different tricks that can lead not only to financial losses, but also to serious injuries at their implementation.

To sharpen a chain is not as difficult as it may seem at first sight. Anyone, after learning the process of dressing chains, can sharpen the cutting equipment of his tool by himself. Even if you get it wrong the first time, don’t despair.к. with each new attempt the result will be better and better.

Chainsaw chain sharpening. it’s easy!

To sharpen the chain, perhaps, do not need a lot of effort, because it is not very difficult, in this article we will consider how to properly sharpen the chain on a chainsaw, and consider all the fine details.

First you need to find out why the chain gets blunt.

How to sharpen a chain on a chainsaw?

The chain saw tooth you want to sharpen has a heavy geometry.

It has two edges that cut. one on the side and one on the top. one of them is beveled at an angle that determines how the chain should move, and it makes the operation a little difficult.

A chainsaw with a lot of power cuts through all the wood, and you can use the limiter to control how thick the chips are, whether they are small or large.

Why does the chain get blunt??

- If you work a lot with your chainsaw, it will get blunt very soon. And you have to sharpen it a couple of times a day.

- Also the main problem why the chain gets blunt is the ground. If you accidentally snag the soil, you can go immediately to sharpen it, because it will not cut as well as it should, chainsaw will not cut into wood, and you will see that the chips get much finer than it was.

Tooth chainsaw after hitting the ground or sand with a stone

You have to sharpen it as soon as possible to get a longer life, as soon as you see that the saw isn’t cutting as hard, go and sharpen the teeth, because if you tighten it, you have to take more material off of it.

The best way to check if you have to sharpen the tines is to give a bit more feed.

If the chain is sharpened, it cuts into the wood very quickly. Well, when you’re constantly maxing out your feed, you definitely need to sharpen it.

A chain that’s already blunt is very easy to figure out as written above. it’s a fine chip.

Reasons why you should not use a chain saw with blunt teeth:

- Your body is very tense, because there is a great deal of vibration

- Cyclic load

- You can immediately see a deterioration in cutting

- Of course, it reduces performance

- It increases fuel and oil consumption a lot

- There is also a lot of wear and tear on all parts of the chainsaw, which will soon lead to repairs

How to sharpen the saw, what tools to sharpen, and at what angle correctly?

Let’s start one by one, chain sharpening angle, measured from your case for use, let’s say the higher you take the angle, correspondingly stronger and more productive it is for sawing soft wood.

Sharpening angle for the link which cuts, it affects the chain, on average it should be from 50 ° to 60 °

When we decrease the angle then the saw will go very smoothly into the hard wood and accordingly the vibration is much less and does not recoil in your body.

Now we take a protractor and measure, it is strictly forbidden to sharpen the chain more than 35 degrees or less than 25 degrees (the exception is the chain for a longitudinal saw, which has an angle of 10 °)

Now you need to know what tools you need to sharpen the chain. As the contour of the tooth itself is similar in shape. You have to use a (round) file with small diameter.

The sharpening needs to be done very precisely, you should clearly hold the file, without changing the angle, its upper edge of the file, it should protrude in the upper edge of the tooth, about 1/5 of the diameter of the file.

The important step is what parameters of teeth (chain), because it is necessary to hammer files for a chain pitch. In standard cases this diameter is 4-5.5 mm.

And the file is held at a precise angle of 90° in the (vertical) plane, and 30-10° in the (horizontal) plane.

To sharpen the teeth using files only is a very time consuming process, and many people undertake other tools for sharpening, these are also kits that go in addition to the chainsaw, or if not going together, you can buy them in a gardening equipment store.

Now we will consider in more details tools with which it is possible to sharpen chains:

- A file (round) that is attached in a round holder.

- Flat file to be used for sharpening the limiter.

- A template to be used for the last operation.

- Hook, with which we clean the saw from sawdust.

On a file (round) which is fixed in a holder, there are special mowing cords due to what it is correctly located in relation to the chain, and does not go aside, and the plate rests against the crown of a tooth as much as possible, and thereby the file becomes the cutting edge at the bottom.

Thanks to the file holder you will know exactly where the file fits on the saw tooth with the right height. And there are many holder options available for each file with a holder.

If you choose a file and a holder correctly you will know exactly, that on 20 % or on 1/5 of diameter it comes in contact with a back of a tooth.

When sharpening carefully strengthen the bar, and with smooth movements with a file and a holder make 2-3 movements from itself, for maximum effect.

To sharpen the file even more, put as much effort as possible on the file to sharpen it even more. Also, to save it from wear, make turns, so that it is used from all sides.

We do so with all the teeth on one side, then we turn the saw and do the same on the other side.

Teeth also need to be made at the same length, you do not need to sharpen one tooth 5-6 times, and the rest 2-3 times, make everywhere the same, so that the saw cut well, also can be due to uneven running, often can prick.

When we have finished sharpening the chain, you need to sharpen the depth stop.

On it it is necessary to impose a template, namely that it got straight in a kerf, then we take a flat file and it already, we sharpen the end acting from the kerf.

When you sharpen the limiter, the template should be close to where it says “Soft” or “Hard” wood.

And it should enter clearly into the kerf, and at sharpening as with round, we do smooth movements, and with a flat file do the same movements from him.

Examples of a couple of machines for sharpening chain saws

The whole chain, all the teeth can be resharpened with files, if you hit the ground or the sand, but if you find this process time-consuming you can use special machines for sharpening.

A company like STIHL makes two types of machines and two modifications of manual machines, the first is mobile (FG1) the second is stationary (FG2).

These machines are very similar to crab saws but they have a file (round) instead of the blade.

These machines are sharpening machines according to their principle (FG1, FG2). and that is how you mend them, by adapting the edges to the same size, taking the smallest tooth at the head.

So we do on one tooth and we pass on the following, thus adjustment which you have put remain not named, after you have adjusted on the first tooth, this sharpening to you provides uniform sharpening of all teeth on the correct size.

When we get to the stop we have to change the file (round) to a flat.

How the Pro’s sharpen a chainsaw

Also available are automatic (electret) machines, it has a system for adjusting, which presses the chain immediately takes the desired angle, and brings the blade to the stern, which is sharpened, there are also machines that make the clamping on the machine when you lower the blade on the chain.

Files and jigs

The main one used for sharpening the saw’s working tooth is round. Flat file is used for height adjustment of the tooth. depth of cut limiter.

Round file

The round ones vary in diameter. The basic diameters are:

Depending on tooth size, you choose the optimal diameter. To facilitate the process special file holders or supporting rollers with the indication of the sharpening angle of the tooth can be used.

Flat file

The flat one should not be more than 1 cm wide. It’s convenient to sharpen the limiter tooth with the help of a special bar (file gauge) which is installed on the chain and shows the maximum depth of sharpening required to achieve optimum performance of a chainsaw.

File holder for a file

A circular file is mounted in a holder and secured with special clamps. There are several markings on the plane of the holder, indicating the specific sharpening angle. When dressing a chain with a file holder, the markings on the fixture are parallel to the guide bar of the chainsaw, which allows the required angle to be maintained quite accurately.

Using the jig at all times is quite inconvenient. It is possible to use this fixture from time to time to control the correct angle of the tooth.

Sawing gauges

These tools are used to control the angle of sharpening teeth, as well as the distance to the depth stop along with a flat file.

How to tell when a chain is blunt?

There are some indications that a chain is not very serviceable at the moment:

- physical effort for the same operation.

- Stretching of the chain.

- Vibrations you feel when using the tool.

- Unevenness of the sawdust, which, in addition, becomes more like dust.

Opinion of the expert Kuznetsov Vasily Stepanovich

According to many experts a well sharpened chain is more important than engine power.

There are many reasons why a chain can become blunt:

- Improper handling.

- coming into contact with very hard objects, e.g. stones.

- Overextended and time-consuming work.

Sharpening with files

files are an excellent handheld tool that can be used to sharpen the teeth.

When using them, it is important to remember to observe the sharpening angle of chainsaw chains.

But it is still a good idea to start with another question. It concerns how to choose the right file for sharpening chain from a chainsaw.

The choice of tool largely determines the quality of the future work done. If you choose the wrong file, at best the efficiency of the teeth will drop even further. In the worst case, you will damage the chain so badly that there is no way to repair it.

To sharpen a chainsaw chain with a file, use the pitch of the chain teeth as a guide.

For them, respectively, files of such a diameter are suitable:

There are rarer exclusive saw chains. They require a cylindrical counterpart with a diameter of 3.2 millimeters.

For comfortable work, it is worth to use tools with a size of 200 mm.

Sharpening technology

It is recommended to properly sharpen a chain from a chainsaw with a round and a flat file.

In general, for the work should be prepared such a set:

The round file will be used to finish the edges on the saw teeth, which have a rounded shape. Mainly take hand tools with a diameter of 4 to 5.5 millimeters.

The flat file is needed for sharpening depth stops. Because the chain’s ability to penetrate or gnaw into the machined material’s structure depends on them. It is mostly wood. But chainsaws can be used for cutting and sawing in other materials.

The very correct sharpening of a worn chain from a chainsaw involves carrying out the work without removing the element from the structure of the tool. Place the saw on a flat, horizontal surface and sharpen the cutter. Make sure the brake is on beforehand.

Before sharpening, the chain should be carefully inspected along its entire length. It is possible that cracks, chips, or fractures may have developed. Some faults turn out to be so serious that it is pointless to sharpen such a chain.

When sharpening the chain teeth of a chainsaw, the following special procedures should be taken into account:

- The teeth should be sharpened from the inside out;

- The degree of sharpening depends on the marks applied by the chain manufacturer;

- The tooth to be sharpened must be centered.

Such work, done by hand, necessarily involves the use of heavy protective gloves, as well as a mask and goggles. Otherwise you might cut yourself on the teeth or get hurt because of flying metal chips.

The craftsman can greatly simplify his task. But you will need to buy a special holder designed for sharpening. But with its help you can clearly select the depth of the limiter and find the right angle for sharpening.

the right machine (with emphasis on the “I”) is clamped to the guide rail. Then the guideways are set at an angle, and the degree of sharpening is determined on the basis of these guideways.

The tooth to be sharpened must be secured with the stop. A file is placed on top of it.

Regardless of the tools used, first you need to sharpen the edges and only then align the depth limiters.

Step-by-step process

The process of sharpening, where the main role played by the file, is performed in this sequence:

- The saw is then clamped in place so that it can be machined more accurately and to a higher standard;

- the holders are mounted, referring to the scale readings;

- determine the sharpening angle by raising the sharpening block 1/5 higher than the point;

- The minimum size of the sharpening is determined by the bluntest prongs;

- processing is performed with the help of a round file;

- It is important to make smooth movements from yourself;

- 2 to 3 slow movements per tooth.

It is obligatory to turn the file during sharpening. This is to avoid uneven draining.

It is also important to sharpen the teeth on both sides. only after finishing the first side, the chainsaw can be turned.

A good solution is to install a template for the limiter. The indexing part is placed between the teeth. The protrusion formed above the template must be ground with a flat file.

Ways to solve current problems

Inexpensive chainsaws are equipped with relatively short-lived budget level saw headsets. in the long term such bars and chains will be replaced by more prestigious and durable models.

Practitioners offer an original way to improve the strength and wear resistance of budget devices, known as stabilization of the internal structure of the metal.

To do this, the new tire for a week and a half to two weeks at 55-65 ° C is heated in an oil bath. The effectiveness of this technology is confirmed by the positive feedback from the owners of household models.

Grinding as a business service. what you need for it

To provide mass sharpening services, that is, to create a business in this area, requires a mass of equipment and conditions. Below are the basic materials, equipment and supplies that will be needed to create a mini-workshop:

- a room, heated, with electricity, space for a machine tool, a chair, racks (minimum area 2 sq. m.);. a room, heated, with power supply, a place for a machine tool, a chair, racks (minimum area 2 sq. m.).the room is heated, the power supply is 220 volts);

- Machines with washers for different disks (electric grinder);

- sharpening discs, including diamond discs;

- grinding wheel;

- Fixings for tools such as skates, scissors, chain saws;

- a slicer. a die for manual sharpening;

- hammers;

- small tools (hacksaws, screwdrivers, keys, etc.).д);

- vise;

- spindle oil;

- lights;

- puncher;

- storage boxes, baskets, furniture.

How to correctly sharpen chain on a chainsaw chain sharpening machine

It is much quicker and more accurate to sharpen a chain on a machine than by hand. Many different electric sharpeners are available. Household units are compact, run on 220 V. They are easy to replace abrasive wheels, they can be easily reconfigured for different parameters of the chain: the pitch of the teeth, the thickness of the top edge, the sharpening angle. All machined cutting edges are obtained with the same. Fast sharpening process.

Electric chain sharpening machine for chainsaws

The electric motor is the main part of the machine, on the shaft of which the sharpening disc is mounted. There are controls on its handle. Clamping clamp for securing machine to the chain is available. Adjustment of pressing force on the sharpened element is provided by a spring clip. Differentiated clamping provides for self-centering of the product in the machine. Hinged safety guard for safe working.

Electric tool for sharpening saw chains

The saw chain is fitted into a special guide mounted on a turntable. A clamping device holds the tooth to be sharpened and an electric grindstone is mounted at a prescribed angle. Operator switches on the motor and controls the plunge of the blade

Machines with manual drive

There are devices designed for sharpening, but without electric drive. These are manual machines for straightening saw chains. An ordinary file is used as a sharpening tool. Machine mounted directly on the bar. Special stop, holds the tooth to be sharpened. Grinding angle can be adjusted.

Stationary machine shown here with the sharpening disk rotated by a crank via a gear unit. The saw chain itself is clamped in a bench vice. The machine has a frame that can be bolted to a table.

Machine with manual drive for sharpening chain saws

Machine for sharpening chainsaw chains: selection criteria, design features, technical and operational characteristics of the equipment, the principle of operation of manual and automatic devices, review of popular models of sharpening machines.