Backhoe for a motocultivator with their own hands

Maintenance

What is meant by maintenance? This is a series of measures that ensure the proper operation and proper storage of equipment. Under the maintenance of the cultivator “Mole” understand the following works:

- washing;

- cleaning;

- lubrication;

- inspection;

- filling;

- inspection;

- fasteners;

- adjustment of all units and systems

Such work should be done as often as possible, especially if you have to work in adverse conditions.

Before you start the cultivator engine, you must check the fuel, oil, etc. д. The mixtures must be filled to a certain level; if necessary, the fuel and oil must be changed. For cultivators we use oil Avtol (M-8B), which has proved itself back in the days of the Soviet Union.

If it is difficult to get it, you can use analogues:

Check that all parts are in good working order before beginning any maintenance or repair work. д.

Cleaning operations include cleaning of the filter, working surfaces, housing and all clogged parts on the surface of the Mole Tiller. When malfunctions occur, or for preventive purposes (less often), it is necessary to clean the internal parts of the machine.

Before replacing a part, check that it is in good condition.

Installation or replacement of any attachments must take place with the engine completely off. The machine needs to be conserved before it can be stored for a long time. For this purpose it is necessary to prepare the engine in a certain way (see the manual), then to clean (rinse) and dry all external parts of the Mole, wipe them with a rag, drying well. After that it is necessary to grease all accessible parts of the cultivator with grease. The machine is now ready for a long rest.

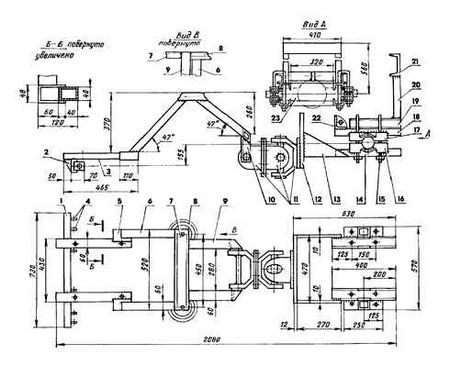

How to make a homemade differential for a power tiller with his own hands. drawings

How to make a differential for a motor-block with your own hands? As a rule, the operation of a power tiller does not require a long rotation of the wheel relative to the drive axle.

Due to this, often called “semi-differential” schemes are common, which provide the possibility of free rotation of the wheel relative to the axle by a certain angle.

For more information on “semi-differentials,” see

The simplest mechanism in this case looks like a sleeve mounted on the axle of the motoblock with a transverse slit. A short axle is inserted inside the hub and secured against falling out by a bolt wrapped through a slot in its body, and the wheel is attached directly to the axle.

When the power harrow is in motion, the drive axle turns the hub freely until the rear edge of the slot hits the bolt, and then transmits the torque to the axle through the bolt.

Snowmobile allows you to quickly and comfortably move through the snow from one point to another, while also carrying a passenger or some cargo. Here’s the 2016 Yamaha snowmobile lineup and prices.

The quality of grown products, their productivity, and, ultimately, the return on financial and physical investment depends on the timely and quality application of special means in growing crops. Here you will learn how to make a sprayer with your own hands.

When turning, the wheel, in an effort to overtake the drive, moves the bolt forward along the slot, breaking the transmission of torque, and the angle of the easy turn of the motorized machine depends on the length of the slot.

These extensions are extremely simple and can be made by low skilled machinists, and are therefore cheap and widespread. Usually they are made with a few extra holes, allowing you to vary the track width of the motoblock and rigidly link the wheel to the drive axle if necessary.

Blueprints of these self-made differentials are widely distributed on the Internet.

The disadvantage of the described design is a relatively small angle of free rotation of the wheel (no more than 240 degrees), as the cross-slot greatly reduces the overall strength of the mechanism, and a lot of internal friction, especially with the inevitable ingress of mud inside the hub.

The most common extensions with free running are used on lightweight power tillers, like VAZ 2121.

Differential for power tillers Salyut and the like Texas, Proab, VIKING, Forza, Sadko, Don, Huter, Profi, having a relatively large mass, has a slightly more complicated design, but also a larger angle of free throw. within 330 degrees.

This is ensured by the fact that the meshing is carried out by the protrusions on the extension of the drive axle and on the freely rotating hub mounted on it, equipped with ball bearings. Accordingly, the hub can make almost a full turn in relation to the axis, until it rests against the opposite edge of the ledge.

It is much easier to turn a single-axle tractor with such differentials.

A number of designs allow the wheels to turn freely against the axle and more than one turn. For example, the differential of “Farmer” power tillers consists of two clutches, controlled by levers on the handlebar.

If necessary, the owner of the power tiller can disengage the desired clutch, allowing the corresponding wheel to rotate for as long as needed.

The device

Lightweight hand-held cultivators are the most in demand among farmers and dacha farmers. As a rule, they weigh about 20 kilograms, are small in size and high performance. Cultivator can loosen the soil, remove weeds, thin plants. It is even used to apply fertilizer. With this unique device simplifies not only planting, but also the process of caring for the plants.

Of course, a single-axle tractor is more powerful, but for such small tasks a cultivator is better, as it has more maneuverability and lighter weight. In addition, it is perfectly suited for areas with difficult terrain or located in inaccessible places.

The work of cultivators depends largely on what burrs are included in it, because they perform loosening and a number of other operations. Among the working attachments on manual models, the following are quite often used:

For breaking a strong earth crust (special needle disk);

When it will be clear what kind of cultivator is needed for certain tasks, you can choose what parts it will consist of. The drawings of a homemade device can help in this. The main part of the cultivator is the engine, which can be electric or internal combustion. It is best to give preference to reliable and durable installations. If necessary, it is necessary to provide a cooling system, as it is not always built-in.

Gearbox is responsible for engine torque control. This detail reduces the speed and also contributes to the operation of the power takeoff shaft. And for the frame and the headstock, you can make it out of whatever you have on hand. Even the simplest two-wheeled wheelbarrow will do for this. The main thing is to think in advance about the scheme, so that you have a good idea of how and where the individual elements will be placed.

Comfort and adjustability are important parameters for the control lever. It should not only be convenient, but also adjustable.

As a rule, handles are equipped with all the elements responsible for controlling the device. So it is important to imagine beforehand how the complete unit will look like to make it easy to use.

Modernization of the KROT power tiller

Mole type power tillers have been produced in Russia for a long time. The first model of the MK-1 mole cultivator was manufactured as a single-purpose machine for tilling the soil. To date, technical capabilities of motocultivators have been significantly expanded and even mini forage harvesting equipment has been developed in the set of machines. Outwardly, motocultivators look like power tillers and their basic structural units are the same.

Description of KROT motocultivator

MK-1 “Krot” motocultivator:

operating device (rotor); 2. gearbox; 3. operating device knife; 4. gas tank; 5. “stop” button to stop the engine; 6. clutch control lever; 7. carburetor throttle control lever; 8. engine; 9. coulter; 10. support; 11. frame; 12. transport wheel

The main units of MK-1 (see. Fig.) consists of engine with built-in reducer (described below), transmission, control system, operating elements, coulter, wheels.

Transmission provides the torque transmission from the single-stage engine gearbox to the working elements and consists of a V-belt transmission and a lower two-stage gearbox. V-belt drive also has a clutch function. Operating elements are installed on the output shaft of the gearbox chain drive.

The throttle trigger consists of two levers that are adjustable in length and width. The left-hand throttle lever of the carburettor and the right-hand clutch lever. The control system has a stop button to stop the motor.

Operating elements are designed as rotors, each with four specially shaped blades. The milling drum with 320 mm diameter is assembled from two or four rotors. Width of the working area is 330 mm in the first case and 580 mm in the second case. Two additional rotors enable a working width of 830 mm, depending on design. The milling drum rotates at 85 rpm and cuts the soil up to 20 cm deep (depending on the setting).

The power tiller moves forward by rotating the working elements. rotors that simultaneously perform the technological process.

Retroescavadora para tractor. homemade backhoe project 2ª parte

Coulter is fitted behind the working elements and acts as a depth control on soil tillage. Coulter height is set in steps.

A pair of wheels in the form of discs with a rubber rim has no drive and serves only for moving the cultivator, and during operation the wheels are lifted upwards.

Productivity of MK-1 at milling the soil to the depth of 20 cm is 0,017 ha/h, and at cultivation to the depth of 10-12 cm. 0,05 ha/h, i.e. its application on the most labor-intensive operations of tillage. more than 5 times more productive than manual cultivation. The MK-1 power tiller is supplied with additional devices: harrows with L-shaped blades with a wedge-shaped blade; discs that protect from damage during rotary tillage; hiller. These units can be used to put together a machine for combined tillage of potato row-spacing, for example: the share discs are mounted instead of the rotors, and the cover discs on the share shafts; the planter is mounted instead of the bottom disc on the back of the frame. When the unit is in operation, the opener blades loosen the soil, trim weeds and simultaneously help move the power tiller, and the ridging bar on the loosened soil plunges two adjacent seedbeds into one pass, each on one side. Such a unit processes 0.14 hectare/h, which is 18 times more productive than doing similar work by hand.

Dimensions MK-1. 1300 X 800 X 810 mm, weight 50 kg, it can be easily placed in the trunk or on the roof of the car.

In general, for all versions of motocultivators such as “Mole” are produced, except for the already mentioned for MK-1 working bodies, a small plow, mower, semi-trailer with a carrying capacity of 200 kg, a water pump. A front attachment is designed to form a motorized cart when connected to the power pack of the power tiller. Sprayer, home sawmill and other devices are created to be used with this power pack.

Modifications MK-2 and MK-3 have 320 mm wheel diameter, ground clearance of 90 mm, track 285 or 600 mm, overall dimensions 1960X800X1170 mm. MK-2 model has one forward gear, which provides up to 7 km/h driving speed, weight 50 kg. MK-3 model has two forward gears, providing travel speed of 4.7 and 7.1 km/h and two reverse gears (2.8 and 4 km/h), weight 60 kg. This model has an additional option of pulley installation, and it is equipped with rear and front linkage. The pulley can be used to drive a variety of small machines, including those used in livestock farming. To the rear linkage are attached or hitched implements related to use of traction force (plough, ridger, semi-trailer, etc.).). implements and machines with active implements (mower, feed mill, pump and others) are mounted on front linkage and driven through V-belt drive.

Modification of the KROT power tiller

For better performance suggest to install on a MC 4-stroke engine manufactured in China LIFAN 160F, with a capacity of 4 hp. This increases the power of the MC at low rpm. Now do not need to increase the engine speed to handle the depth of the soil 20cm (in the passport). Besides at the expense of power working depth has increased by 1,5 times and was about 30 cm. (up to belt slippage). The motor can easily perform this task.

One more not unimportant plus of this replacement. the engine starts in a cold or hot condition. The rpm is automatically maintained at a predetermined level. At greater power gasoline consumption remained approximately the same as that of a regular engine, besides now there is no need to add oil to gasoline (4-stroke engine).

The new motor can be installed with little effort and without any modifications. Engine mounts fit into the standard place. The pulley is taken from the old engine, a little bit drilled inside the hole and the keyway.

After suffering a lot with the old engine, now the new engine gives a completely different feeling when working with power tillers!

Used literature: Small-scale mechanization in the household and farming industry. Ed. И.П.Oil. 1996г.

How to reduce the size of a power tiller with your own hands drawings

The days when you could work a small area of land all day long and were worn out. Whoever had a single-axle tractor was the envy of the neighborhood? This is not the case today. Mini-motorised agricultural vehicles have the highest sales figures on the market. The additional equipment that is used in power tillers and the power of the mini-tractor allow for the successful treatment of large areas of the homestead plots. When working on heavy soils, extra strength is needed. A reduction gearbox or so-called travel-decreasing machine on a single-axle tractor is widely used for this purpose.

They are installed together with pneumatic wheels and are practically not used on a wheel set with trailing feathered wheels. Reducing rotational speed and power train speed increases tractive power of the machine. It is not very difficult to make it yourself.

Stalker will allow you to work any soil on your power tiller