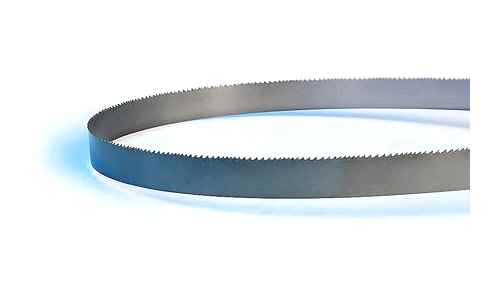

Band Saw Blades. Bimetal Band saw blades

Band Saw Blades

Band saw blades are a common tool used in various industries, such as woodworking and metalworking. They are specifically designed to cut through materials like wood, plastic, and metal. The blade is typically attached to a Band saw machine that allows the user to adjust the tension of the blade and make precise cuts.

Types of Band Saw Blades

There are several types of Band saw blades that can be used for different purposes. For instance, wood cutting Band saw blades have teeth with sharp points which help them cut through softer materials like wood more easily. Metal cutting Band saw blades have teeth that are more widely spaced so they can cut through harder materials like steel or aluminum. Additionally, there are also specialty Band saw blades available for specific applications such as resawing or creating intricate shapes.

How Band Saw Blades Are Made

Band saw blades are typically made from high-quality steel alloys with a variety of compounds added to increase strength and durability. The teeth on the blade may also be hardened using heat treatment processes to ensure they remain sharp longer. Additionally, some manufacturers use carbide tips on their bandsaw blades for increased performance when cutting through harder materials.

Industries That Use Band Saw Blades

Band saw blades can be found in many industries including construction, manufacturing, automotive repair shops, and even art studios. Professionals in these industries rely on the precision and accuracy provided by these tools when making cuts in various materials. Additionally, some bandsaw accessories such as guides or clamps may be needed depending on the application.

Find the Band Saw Blades You Need at Zoro

Looking for a specific item? Use our robust search tool to find it by name or keyword, or use our handy filters to narrow down our full assortment. You can also check out our whole selection of Band Saw Blades along with other tools or equipment to ensure you have all you need to tackle the job, especially if you’re taking on a DIY project for the first time.

Plus, when you shop at Zoro, you’ll always enjoy competitive on tons of great brands you know and trust. We make the shopping experience as fast and seamless as possible with free shipping on orders over 50 for registered users, Net 30 payment terms for qualifying customers, and an unparalleled customer service experience.

Bimetal Band saw blades

- Back

- Open Ticket

- Recent Tickets

- FAQ

- Back

- Reciprocating Saw Blades

- Back

- 4IN 18TPI BI METAL Reciprocating Saw Blades

- 6IN 3TPI Reciprocating Saw Blade

- 6IN 6TPI HCS Reciprocating Saw Blade

- 6IN 14TPI Bi Metal Reciprocating Saw Blade

- 6IN 18TPI BI Metal Reciprocating Saw Blades

- 8IN 14TPI Bi Metal Reciprocating Saw Blade

- 8IN 14TPI Bi Metal Reciprocating Saw Blades for METAL 200x19x125mm

- 9IN 3TPI HCS Reciprocating Saw Blade

- 9-in 5-TPI HCS Reciprocating Saw Blade

- 9IN 18TPI Bi Metal Reciprocating Saw Blade

- 9IN 14TPI Bi Metal Reciprocating Saw Blade

- Back

- 14″ Ring Saw Blade

- Back

- 4in Diamond Blade

- 4.5in Diamond Blade

- 5in Diamond Blade

- 6in Diamond Blade

- 7in Diamond Blade

- 9in Diamond Blade

- 10in Diamond Blade

- 12in Diamond Blade

- 14in Diamond Blade

- 16in Diamond Blade

- 18in Diamond Blade

- 20in Diamond Blade

- 22in Diamond Blade

- 24in Diamond Blade

- Hot Pressed Diamond Saw Blades

- Tuck Point Saw Blades

- Super Thin Diamond Saw Blades

- 26in Diamond Blade

- Back

- 7.25in Carbide

- 10in Carbide

- 12in Carbide

- 14in Carbide

- 16in Carbide

- 18in Carbide

- 20in Carbide

- 22in Carbide

- 24in Carbide

- For WOOD with NAILS

- For Plastic

- For Steel

- For Metal

- Back

- 15’4″ (184″) BandSaw Blade

- 15’9″ (189″) BandSaw Blade

- 16’2″ (194″) BandSaw Blade

- 16’6″ (198″) BandSaw Blade

- 18’2″ (218″) BandSaw Blade

- 18’4″ (220″) BandSaw Blade

- 18’6″ (222″) BandSaw Blade

- 19’8″ (236″) BandSaw Blade

- 19’10” (238″) BandSaw Blade

- 20′ (240″) BandSaw Blade

- 20’6″ (246″) BandSaw Blade

- 21′ (252″) BandSaw Blade

- 21’6″ (258″) BandSaw Balde

- 22′ (264″) BandSaw Blade

- 22’4″ (268″) BandSaw Balde

- 22’6″ (270″) BandSaw Blade

- 22’10” (274″) BandSaw Blade

- 23′ (276″) BandSaw Blade

- 23’4″ (280″) BandSaw Blade

- 23’6″ (282″) BandSaw Blade

- 23’8″ (284″) BandSaw Blade

- 23’9″ (285″) BandSaw Blade

- 24′ (288″) BandSaw Blade

- 24’6″ (294″) BandSaw Balde

- 25’4″ (304″) BandSaw Blade

- Back

- Glass. Bevels

- Back

- 3/4-in on Quarter Glass

- 1-in on 8mm Glass

- Circle Bevel

- Half Circles

- Circles on 1-in Stock

- Circles on 1.5-in Stock

- Corner Bevel

- Inside Corner

- Diamond Shaped

- Diamond Glue Chip

- Quarter Diamond

- Side Diamond

- House Shaped

- Double House

- Double House Glue Chip

- Half Double House

- Pair Half House

- Heart Shaped

- Oval Shaped

- Side Oval

- Oval Top

- Pencil Cut

- Peach Glass

- Square Rectangle

- Square Rectangle Glue Chip

- Star Shaped

- Triangle Shaped

- Triangle Glue Chip

- Back

- 10mm.

- 14mm.

- 30mm.

- Back

- Acrylic Crystals

- Faceted Drop Glass Crystal

- Flower Crystal

- Heart Crystal

- Faceted Bead Crystal

- Moon Star Crystal

- Icicle Crystal

- Ball Crystal

- Leaves Crystal

- Oval Crystal

- Bar Crystal

- Square Crystal

- Raindrop Crystal

- Back

- Glass Marbles

- Back

- 11mm.

- 14mm.

- 16mm.

- 25mm.

- 50mm.

- Back

- 16mm

- 25mm

- 35mm

- Back

- 10mm.

- 14mm.

- 30mm.

- Back

- Circle Jewels

- Octagon

- Square

- Oval

Band Saw Blade Replacement 22’4″ (268″) Bi metal M42 Cobalt 8%, 34 x1.1mm(1-1/4 x.042 in.) 5/8 TPI (Back quality X32 Cr 4. 270 gr./m)

Customers have said that our bandsaw blades are: “As good as or better than other products they have used”

Shipping is FREE to all business addresses.

Addresses that are not considered “business”, according to FedEx, will be charged a flat fee of 20 for shipping. Please note that FedEx does not deliver to PO BOX addresses.

My account

McGills Warehouse is a premiere supplier of saw blades, glass bevels, tools hardware, DIY arts craft materials, stained glass supplies and other quality products at discount every day. From circular saw, table saw, chop saw and bandsaw blades to a wide assortment of glass products, we are proud to offer sale all year long. We specialize in bandsaw blade replacements with a wide selection of sizes. Enjoy extra savings on bulk orders and free shipping on select items!

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

LENOX Bimetal Band Saw Blade

In our wide range of products, we are offering superior quality Bi-Metal Band Saw Blade which is manufactured using premium quality raw material and advanced technology. This blade is designed with high precision in order to meet the international quality standards. Apart from this, this is rigorously tested on various parameters of quality in order to deliver flawless range at clients end. Available in various specifications, this can be availed at market leading prices. Features:Fine finishRust resistanceDurability

Product Details

Product Description

In our wide range of products, we are offering superior quality Bi-Metal Band Saw Blade which is manufactured using premium quality raw material and advanced technology. This blade is designed with high precision in order to meet the international quality standards. Apart from this, this is rigorously tested on various parameters of quality in order to deliver flawless range at clients end. Available in various specifications, this can be availed at market leading prices.

Increased Wear Resistance Delivers Longer Blade Life

New HSS edge wire increases tooth hardness for better abrasive wear resistance

Patent pending chip controlling design reduces heat and wear

Improved Chip Formation Helps Penetrate Difficult To Cut Materials

Variable tooth heights and multi-level set creates deeper, narrower chips

High Rake angles reduce cutting forces

Optimized Design For Straighter Cuts On Large Blocks

Shallow gullet construction increases beam strength

Company Details

About the Company

We are the authorized dealer of these company Lenox, Miranda, Irwin, Trumax Machine Tools Accessories SAK Abrasives Ltd.Established in the year 1983, at Ahmedabad (Gujarat, India), we, “Minal Tools Traders”, are a leading trader and supplier of a superior quality range of Bi-Metal Band Saw Blades, Carbide Band Saw Blades, Jobber Drills, SPC Cables, Vernier Calipers, Industrial Gauges, Collet Chucks, Revolving Centers, Industrial Spanners, HSS Products, Carbide Products, Industrial Tools, Bonded Abrasives, Coated Abrasives, Super Abrasives and many more. Sourced from authentic vendors, these products are manufactured using excellent quality raw material and cutting-edge technology in compliance with international standards. The offered products are also available in varied finishes, material and sizes as per the specific requirements of clients. These products are extensively acknowledged by our clients for their features like high tensile strength, durable finish standards, corrosion resistant finish, sturdy construction and dimensional accuracy. Owing to such features, the offered products are extensively demanded in the varied industry segments.

Understanding the Types and Benefits of Carbide Tipped Band Saw Blades

In Band sawing, shops can typically choose between three types of blades: carbon, bi-metal and carbide tipped. Bi-metal and carbide tipped blades offer better performance and longer life expectancy than carbon steel blades; however, choosing the correct type can be a challenge. In this article, we will explain the benefits of carbide tipped Band saw blades and when to use them.

Types of Band Saw Blades

Band saw blades can be divided into three general types: carbon, bi-metal and carbide tipped.

- Carbon blades are composed of entirely carbon steel and have induction hardened teeth. The use of carbon blades is quite limited in modern operations.

- Bi-metal blades are made with two different types of metals. The blade backing is made with a flexible spring steel which allows the blade to bend and flex during use. A high-speed steel wire is electron-beam welded onto the blade backing, which the teeth of the blade are milled into. High speed steel (e.g. M42) provides durability in the cutting edge, contributing to a much longer blade life compared to a carbon blade.

- The backing for carbide tipped blades is made of a flexible spring steel. The teeth s are milled into the backing material, and the carbide tip is brazed into the s and finish ground. The carbide tip is stronger and can resist more heat.

Carbide Tipped Band Saw Blades

The main reasons a shop would switch to carbide Band saw blades are longer life and faster cutting. The reason these blades can deliver such results is the carbide itself, a popular material for cutting tools because of its high durability and high heat resistance. These two factors are why carbide blades outperform the bi-metal blades.

Carbide is best suited for use in solid materials because the continuous cut faces less vibration than when cutting structural or thin wall tubing, for example.

Carbide blades can be divided into four basic categories:

- General Purpose: generally recommended for cutting operations that frequently change the materials being cut. These blades are engineered to be versatile, working on a wide range of materials and limiting the need to change blades.

- Hard-to-Cut Metals: blades optimized for aerospace alloys containing high amounts of nickel, such as stainless steel and Inconel.

- Extreme Performance: coated carbide blades – applying a thin film coating to the tooth edge of a blade helps transfer the heat from the cutting edge of the blade to the chips. This protection enables the blade to stay cool, cut faster and provide much longer blade life.

- Specialty: blades engineered with specific cutting operations in mind.

When To Use a Carbide Tipped Band Saw Blade

In order to get the most of a carbide tipped blade, it is important to consider some key elements: the Band saw machine, the operator, and the operating costs.

The first step of evaluating when to use carbide tipped is the machine itself. It’s commonly understood that carbide tipped blades should only be run on new, high end Band saw machines. In fact, carbide tipped blades can be run on a wide variety of saws. But there are some key elements to maximize the output of your carbide blade: a) the more rigid the saw, the better as it will help prevent vibration which helps protecting the carbide teeth; b) the machine must run at elevated Band speeds; and c) the machine must be well maintained to extend the benefits of a carbide tipped blade and help prevent premature failure.

A key component of running a carbide tipped blade is the experience of the operator. An experienced or well-trained operator will help to get the most out of a carbide tipped blade. A trained operator is more likely to safely install the blade without breaking teeth, break-in the blade properly to achieve faster rates, run the job at the correct sawing parameters, and perform preventative machine maintenance to keep the machine in optimal condition.

Another key element is the cost per cut. Reducing cut times directly affects the use of overhead in making the cut. This is particularly obvious in difficult to cut materials, using a carbide tipped blade with higher speed and feed rate can reduce the cost per cut when compared to bi-metal.

Our Supplier

Lenox, a Division of Stanley Black Decker, is our Supplier Partner for Band saw blades. They offer a comprehensive range of high-quality carbon, bi-metal, and carbide tipped Band saw blades.

Choosing the correct blade is crucial for the success of the job. For more information about carbide tipped Band saw blades and how to choose the correct blade for your job, contact us.