Band Saw Tooth Step Selection For Metal

The length of the saw is selected depending on the model of the band saw, each model of the machine has its own length. The length of the tape is indicated in millimeters, for example 3300mm.

Also, each model of a band saw has its own dimensions along the width of the tape used. The width of the band saw for metal is indicated in millimeters, for example 20 mm.

The thickness of the band saw is usually constant and depends on the parameters of the rolled steel, for example, for a saw 13 mm wide, the thickness of the tape is 0.9 mm (designation 130.9), for a saw 20 mm wide, the thickness of the tape is 0.9 mm (200.9) and respectively 27×0.9mm; 34×1.1mm; 41×1.3mm; 54×1.6mm

By type of material

Depending on the steel grades, the saw grade is selected.

The M42 brand band saw is used for sawing the following metals: carbon steels, alloy steels, stainless steels, structural steels, tool steels, non-ferrous metals, aluminum, etc.

The M51 brand band saw is used for sawing the following metals: stainless steels, heat resistant steels, titans, nimonics, inconickel, etc.

In appearance and size of the workpiece to be sawn.

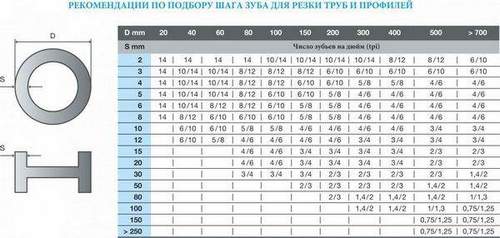

Depending on the type and size of the workpiece, the tooth pitch is selected. The step values are determined by the number of teeth per inch (TPI), for example, a 2/3 step means 2-3 teeth per inch (25.4 mm). The tooth pitch is variable. this provides a reduction in vibration and noise during cutting.

There is a rule. when sawing, you need at least 3 teeth in the body of the workpiece, the best option is 10-12 teeth, up to a maximum of 22 teeth in the body of the workpiece.

For example, to cut a workpiece with a diameter of 90 mm, you can choose the tooth pitch 3 / 4TPI, 4 / 6TPI.

Video: Band Saw Tooth Step Selection For Metal

To facilitate the selection of tooth pitch, you can use the table

Circular saws WST (Wood Steel Tools)

Circular saws WST (Wood Steel Tools) Germany.

WST circular saws are designed for sawing various types of wood, including hardwood and frozen wood. The casing of circular saws is made of tool steel 75CR1 (Germany), the hardness of the casing of the saw is 44-46 HRC. The saw body undergoes a tempering operation (heat treatment, as a result of which material stability and high hardness are achieved), sheet dressing, and rolling.

On WST circular saws, carbide brazing of the CERATIZIT brand (Luxembourg) is used. The soldering hardness is 80HRC. Silver solder is used to install soldering. The melting point of silver solder is lower than that of brass and therefore the soldering does not overheat and microcracks do not occur, which can lead to tooth breakage. When brazing carbide teeth and cutting knives, Brazatec brand flux (Germany) is used.

At the production of WST circular saws, an automatic Kirshner robot (Germany) is used for brazing carbide teeth. For sharpening circular saws, Vollmer machines (Germany) are used.

At each stage of manufacturing WST circular saws, diagnostic instrumental and visual quality control is performed. Selective laboratory tests are also carried out, and studies in each batch of saws produced.

Design features of wood saws

Design features of circular saws for wood:

Wood saw blades are made of carbon tool steel. To increase the hardness of the teeth of the saw, hard alloy brazing is used.

Circular saws can be without cutting knives (the body of a circular saw is continuous) and cutting knives. Cutting knives are made of hard alloy. Cutting knives do not allow the carriage to clamp the circular saw. perform the function of wedging. As a result, due to scoring (proppant knife-teeth) friction of the surface of the saw body against the cut walls is reduced. During the sawing process, the side faces of scoring knives increase the amount of heat loss that comes from the cutting zone to the air (vortex) stream and the environment. all this contributes to a significant reduction in the heating of such saw blades and, as a consequence, their high-quality and continuous operation. It is advisable to use circular saws with cutting knives on multisaw machines and sawmills when sawing round wood.

Circular saw without cutting knives

Carbide tipped saw with cutting blades