Bewildered by weed eaters? Here s the difference between automatic and bump…

Why Does My Trimmer Line Keep Breaking?

Keep reading to learn the easy remedies for these common weed trimmer problems as well as why they happen to begin with.

Low Quality Line

The easiest problem to fix is a low-quality line. Look, for some things, you have to just buy the good stuff.

If you bought a cheap line from the big box store, it is cheaply made with inferior materials.

That means it is going to break way faster than it should. Here are some qualities you should look for in a good roll of trimmer line:

- Round cut is the strongest, then star. Square is the weakest.

- Try to buy line that comes pre-rolled on an attachable reel. That way you do not have to roll it yourself and risk damage.

- Look for a thicker line. The thinner it is, the easier it is going to break.

- If none of the pre-rolled lines fit your trimmer, go for a bigger reel. The more you have, the better.

The Line Is Not Designed for Your Weed Trimmer

Of course, if buying a higher quality trimmer line did not work, it could also be possible that you are using one that is not designed for your trimmer in the first place.

If the line is too thick, it will break at slower speeds and without feeding more line through. If it is too thin, will feed through and cut off way too easily.

Either way, that line is going to keep breaking and you are going to keep running out.

Consult your instruction manual for exact line specifications for your trimmer after you use up the factory installed line.

Your Line is Not Rolled Properly

Another possibility is that you did not roll the line properly. As trimmer line weakens at the ends, it is meant to naturally fall off.

With the extra space now under the grass guard, more line will automatically feed out of the reel. Ideally, you actually should never have to “tap” out more line.

However, in practice, occasionally having to tap out more line is perfectly normal. But of course, if you have to do it every few minutes because the line keeps breaking, that understandably becomes annoying.

It is most likely because the line is bound around the reel incorrectly, meaning it cannot automatically slip out. Follow these steps to properly roll up your trimmer line:

- Detach the spool from the weed trimmer head. Usually these can be popped off with a push and twist. If you are not sure, consult your owner’s manual for removal instructions.

- Pull off roughly 20 feet of line from your reel.

- Grab one end and find the hole in the middle of the spool.

- Stick the end into the hole.

- Pull on the line until you reach the middle of it. Now you should have two equal lengths, like shoelaces.

- Take both ends and start winding the around the spool at the same time.

- The most important thing to remember when winding the line: try to avoid crossing as much as possible. Keep wrapping straight on, and only cross slightly over when you need to start a new row. The more you cross, the more risk of the line becoming caught and causing feeding issues.

- When you have about 8 inches of line left on both sides, feed both ends through the holes on the side of the trimmer head.

- Latch the spool in place and you should be good to cut those weeds!

You can check out this video from Mr. Hardware to see how it’s done:

Too Much or Not Enough Line is Being Used at Once

If none of that works, the problem might just be with your trimming habits. Do not worry, this is easy to fix.

Either of two things are happening here: either you are letting the line become way too long, or you just are not using enough.

If your line is too long, say about a foot, it is essentially going to start slapping walls and becoming caught on fences, rather than just powering through the grass cut and moving on.

Any excess wear and tear on your line is going to break it at a much faster rate.

On the contrary, if your line is only a couple inches short, the grass tends to win the battle, not the line.

That is because without enough line and the resulting torque, it does not have enough strength to cut. Instead, the string wears out and needs to be replaced faster.

In general, it is best to keep about 8 inches of trimmer line showing for the perfect combination of an easy cut and low line usage.

The Line May be Worn Out

For most weed trimmers, whether it breaks often or not, more line can be tapped back into place. However, this is not the case with certain weed trimmers.

How to Fix the Ego Auto Load Feature and Bump Feed Problems

Some require a much stronger type of line that is precut and simply placed into the head. (No wrapping necessary.)

If you have this kind of trimmer and the line is breaking too often, keep the following in mind:

- It is absolutely essential you buy the highest quality line, as replacement is a bigger hassle.

- Be careful to avoid hitting objects like sidewalks and walls, as this will make the line wear out faster.

- Make sure you are not cutting the line too long. Even in these kinds of trimmers, if the line is too long, it just takes more damage.

- Too much power. You should not constantly run this type of trimmer at the highest possible setting. Doing so may cut a little faster, but it also makes the line take a lot more abuse.

The Best Weed Trimmer Brands

If all else fails, it might just be that your trimmer is not producing enough power anymore, which hurts the effectiveness of the line. You may want to check out one of these other brands of weed trimmers instead.

Black Decker

This 14-Inch electric weed trimmer from Black Decker is exactly what you need (buy on Amazon). This company is known for its quality products and this is no exception.

It plugs in so you do not have to deal with gasoline or constant dead batteries. In addition, there are package options with additional spools, so you do not even need to worry about finding the right brand later.

Makita

The Makita XRU15PT1 trimmer kit. on the other hand, ensures you will never need more weapons against weeds again.

It comes with four batteries and an all-out charging station so you will never have a battery die on you again. No more dragging the extension around the yard and accidentally cutting it.

The Final Breakdown

The most important thing you need to remember about weed trimmers, and lawn equipment in general, is that it is all about quality.

Buy the good trimmer line and you will not have to keep buying the cheap stuff, which will cost you more money in the long run.

Similarly, if you buy a really high-quality trimmer like the Black Decker or Makita, they will work smoother. The smoother the operation, the better luck you will have with keeping your line intact.

Hi! I’m Peter, the owner of BackyardGadget. Working around the house has always been a big part of my life. I’ve created this site to share my experience, and to help people choose the right tools for the job. Thank you for stopping by!

Recent Posts

Have you ever pulled on the starter cord to get your mower started, but the rope snaps? Or perhaps it pulls all the way out and doesn’t rewind by itself. Either way, it’s clear the pull cord is.

One of the most common features of most gas-powered push mowers is the cord or rope that you use to get it started. But why do they have pull cords rather than some other starting mechanism? The.

About Us

Hi! I’m Peter, the owner of BackyardGadget. Working around the house has always been a big part of my life. I’ve created this site to share my experience, and to help people choose the right tools for the job. Thank you for stopping by!

Legal information

BackyardGadget.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. BackyardGadget.com also participates in affiliate programs with Clickbank, Commission Junction, and other sites. BackyardGadget.com is compensated for referring traffic and business to these companies.

Problem: Trimmer Line Feeds Too Fast [Solved]

Bewildered by weed eaters? Here‘s the difference between automatic and bump feed trimmers

Why the way in which a trimmer feeds the string is important when choosing the best type of weed eater for your needs.

Choosing between the best electric weed eaters is not an easy task. As long as they succeed in cutting those pesky weeds down to size, it’s job done, right? Well, almost, but there are still some important differences to consider that could make your weed wacking even more pleasurable than it probably already is.

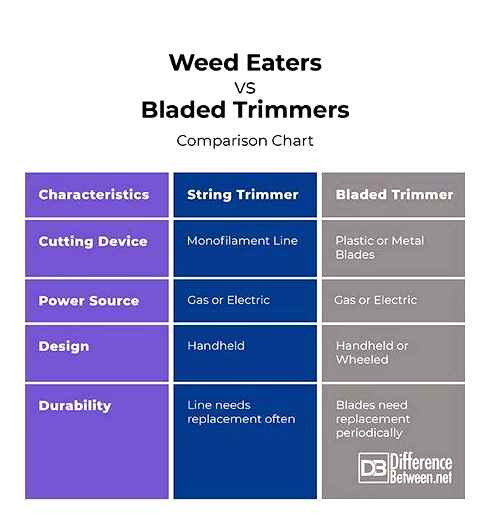

One of the biggest factors in selecting an electric weed eater is how it feeds the string. In this respect, there are two types of electric string trimmer to consider: automatic feed and bump feed trimmers.

The first automatically advances the string and the second requires you to tap the head on the ground to move the string along. To save you the time of worrying about which is the best weed eater for you, we’ve laid bare the advantages and disadvantages of both types of trimmer feed.

Automatic feed electric weed eaters

The automatic advancing mechanism works by sending out more line when the string gets too short. Importantly, if you have an automatic feed electric string trimmer, the last thing you’re going to want to do is tap the head on the sidewalk because it will break it and negate your warranty.

The advantages of automatic feed

The great thing with an automatic feed weed eater is that instead of focusing on the length of the string, you can pay attention to where the grass ends and the prize daffodils begin. Since you don’t have to pause to tap the head on the ground, you can finish trimming faster, leaving more time to dig out the lawn edger and fire up the lawn mower to give your garden the complete works. Automatic feed string trimmers are more prevalent in stores than bump feed trimmers, so shopping for one will be a breeze as well.

The drawbacks of automatic feed

As with any machine with moving pieces, the motor on an automatic feed electric weed eater is bound to break or malfunction at some point. If the motor still works but it doesn’t feed the string properly, you may spend a lot of time trying to fix the line feed jam. Fixing the motor on the automatic feed may be more difficult and expensive than it would be to replace the whole unit.

Bump feed electric weed eaters

With a bump feed weed eater, when you press the head of your trimmer against a flat surface, it squeezes a spring in the head of the string trimmer. This action releases string from the spool so you have a line with which you can cut down debris. The bump feed electric trimmer uses centrifugal force to pull the string from the spool.

The advantages of bump feed

When you have a bump feed string trimmer, you manually advance the string by gently bumping it on the ground. This gives you control over how much line you use. The bump feed is also a more simplified system for advancing string, so if it stops working, it’s more likely you can make repairs quickly and easily. Keep in mind that most electric string trimmers also come with a warranty.

The drawbacks of bump feed

With a bump feed electric weed eater, you’ll need to pay a little more attention and take action when it’s time to advance the string. it’s your responsibility to keep things moving. Another potential problem comes if you push down on the head of your trimmer too hard, as it can crack the spool or damage the spring. Even if you’re gentle with your string trimmer, over time the spring in the head will wear out and you’ll need to replace it.

Pre-wound spools vs. wind your own spools

If you experience feed problems, they are likely to originate with imperfections in the way the line is wound on the spool. If the line isn’t just right, the feed can jam.

How To Replace Weed Eater Line | STIHL String Trimmer

Today I’m out in the yard doing some work trimming things up and I’ve run into a little snag: I’ve run out of line in my weed eater.

Replacing the line in a weed eater is a common maintenance item when it comes to lawn and garden. I have a few tips to share that can make the job easier.

My trimmer is a STIHL FS 55 R with a C 25-2 auto-cut trimmer head. Even if you have a standard trimmer head, keep reading! I’ll be going over two methods to replace the line in a weed eater that covers both models.

Reloading a STIHL String Trimmer: Step-by-Step Guide

The object of this tutorial is a STIHL string trimmer, which we more commonly refer to as a weed eater, weed whacker, or weed whip.

You can see that on my auto-cut C 25-2 trimmer head we still have some line on one side and the other is completely out.

STIHL is a popular brand of string trimmer. They have a good reputation when it comes to lawn care equipment because their products are durable and easy to use.

In this step-by-step guide, I’m going to show you two different ways to replace the trimmer string in a STIHL FS 55 R weed eater. Both of these methods work for the C 25-2 auto-cut head. The second method works for the more common (standard) 25-2 trimmer head.

Rather watch than read? Check out this 11-minute video.

Alternatively, you could use a flathead screwdriver; there’s a little slot on the side of the casing to open the trimmer head that way.

Now that the cover’s off, I’ll grab the center section, which will pull right out.

This center section of the head is a spring-loaded spool that holds the trimmer string.

You can see that one channel has a little bit of line left in it and the other is empty.

Thickness and Length of Weed Eater Line

The string I’m using is.105 thickness. It’s a 24-foot length, which will give me 12 feet of string in each channel.

If you use a thinner line, you’ll be able to fit more linear feet in each channel. For example, with a thickness of.95, you can get about 16 linear feet in each channel.

How to Replace Weed Eater Line: Method One

For our first method of reloading line into our STIHL weed eater, we’ll use a convenient feature of the C 25-2 trimmer head. This feature enables us to replace the weed eater line from the outside of the head.

Note: Method One works for the STIHL C 25-2 trimmer head. It won’t work if you have a standard flat cylinder trimmer head that you bump on the ground to feed out the line.

Before loading in the new line, we want to remove any remaining line. To do this, I’ll just pull on it until it detaches from the spool.

Now I’ll put the center section (spool) back into the trimmer head housing and put the cover back on, matching up the two little tabs.

Before loading the string, I want to make sure that the line above the word “LINE” on the cover of the trimmer housing is lined up with the circle on the central disk of the spool. Just rotate the central disc to align these things.

Turning the trimmer head sideways, I’ll insert some of the string into the hole. Note that I won’t precut the string when using Method One.

You might have to work the line a bit as you feed it in. You should feel a little resistance as it enters.

Now insert the other end of the length of string into the other hole of the trimmer head. (Remember that I didn’t cut the string beforehand.)

Next, manually rotate the central disc of the spool clockwise. This will start feeding the line into the channels.

Keep turning until only about 5 inches of string remain exposed (it will take a little while), then cut the string.

Don’t worry if the two ends of the string aren’t exactly even lengths. When you start up your weed eater, the steel cutter on the guard will cut the string to the correct length.

Super easy. Also the preferred method for the STIHL C 25-2 trimmer head.

How to Replace Weed Eater Line: Method Two

Method Two is the more common method for replacing weed eater line. This is the method to use for the regular 25-C STIHL trimmer head. You can also use it to reload the C 25-2 but isn’t as fast or convenient.

With the cover and central section (spool) of the trimmer head removed, you’ll want to detach any remaining string. (Refer back to the “Opening the Trimmer Head” section for notes on how to remove the cover.)

IMPORTANT: Keep the cover within easy reach.

Loading the First Chamber

I’m going to load the new line into the top chamber of the spool first. For Method Two, I cut my line ahead of time into two equal pieces.

First, I’ll feed the line into one of the holes.

Note: The line needs to be wound in a certain direction. This is indicated by an arrow on the spool.

You’re going to wind the string by hand around the cylinder in the direction indicated by the arrow. You’ll want to work with some care to get the line nice and tight. I also try not to overlap the line so that I can fit in the maximum amount. You should be able to easily fit 12 feet of.105-thickness string inside this chamber.

When you’ve got about 5 inches of line left, click it into place in the notch on the side of the spool.

This is an important step. If you don’t do this, the string will unravel and all your hard winding work will be lost.

Loading the Second Chamber

To load the other chamber, I usually start with a hole on the opposite side of the spool.

Again, I’ll seat the string in the hole and start winding it by hand in the direction indicated by the arrow for that chamber, taking care to wind tightly and without overlapping. As before, when about 5 inches are left, I’ll secure the string by pressing it into the notch, this time on the opposite side of the string I already loaded.

Reinserting the Spool into the Trimmer Head Casing

To reinsert the spool now loaded with string into the trimmer head casing, we need to line up the notch where the string is emerging with the slot in the casing.

Holding the spool securely in place (recall that it’s spring-loaded, so I’m pushing down pretty hard), I’ll pull the string out of the notch and lead it through the slot.

Then I’ll do the same with the other side.

Remounting the Cover of the Trimmer Head Casing

To remount the cover, I’ll keep the pressure on the spool inside the casing with one hand and grab the cover with the other. Keep in mind this part of the process can be a little tricky because the spool is spring-loaded.

Bringing the cover up to the casing, I’ll put the thumb of the hand holding the cover through the hole to keep the spool in place so I can free my other hand.

Now I’ve got both hands available to manipulate the cover and line it up, but I’m always keeping pressure on the spool with one thumb.

Once the tabs of the cover are lined up, snap it into place and make sure it’s locked in.

How to Replace Weed Eater Line: Final Check

As a final step, you might want to tug a bit on the strings. There should be resistance.

If the line pulls out easily, something’s wrong. In that case, you’ll want to disassemble and recheck everything. It likely means the line is wound in the wrong direction.

How to Replace Weed Eater Line: Conclusion

In this tutorial, we covered two different methods for replacing the line in a STIHL FS 55 R weed eater.

Both methods are pretty easy but the C 25-2 trimmer head is a lot easier to load using Method One, where we installed new line through the exterior holes. That’s the major difference between the two trimmer heads, and really what the C-model is designed to do.

Related Article: How to Get Great Deals on Seasonal Items

For tips on how to get great deals on seasonal items like weed eater line, have a look at our article on Home Depot Clearance Price Tag Secrets.

Got other home repair projects to tackle?

For other home repair projects, please check out our YouTube channel.

The Secret To Restring A Weedeater Trimmer In Seconds! With Video Included

So just how do you restring a weedeater / string trimmer without losing all of your patience?

Quite simply, a weedeater (or weed whacker, string trimmer or line trimmer as it is often called), is a must-have tool for keeping the lawn and landscape looking neat and tidy.

But it can also be an absolute nightmare when it runs out of string!

I am not afraid to admit that the entire process has frustrated me for well over 35 years.

And I mean, really, really frustrated me!

I actually love to use the weedeater. Until it runs out of string of course. And then the nightmare comes alive.

Sometimes, I get lucky and have it re-strung in just a few minutes. And I might even pat myself on the back and think I finally have it all figured out.

But then, the very next time it runs out of string, I might fight for 20 to 30 minutes trying to rewind the spool. Only to of course finally fire it back up and watch the entire spool discharge in seconds!

I am ashamed to admit at that point, the inner child in me most likely threw the spool across the lawn in disgust.

But one day, it all changed – and I have my wife to thank for it 100%!

All it took was me being out of town on a business trip to make it all happen!

Learning To Restring A Weedeater With Ease

Mary and I have a pretty set mowing and trimming routine. She mows most of the 3 acres, while I trim with the weedeater.

She can get poison ivy by looking at it, and the covering of weeds and grass that results from using the weedeater has never been a good combination for her.

But it just so happened last summer that I was stuck out of town for two straight weeks, and the trimming was getting bad.

And Mary decided poison ivy or not, she was going to tackle the chore.

So she put on jeans and long sleeves, and fired up our old trusty Echo string trimmer.

I have owned my Echo for going on 6 years now. And beyond never knowing how to easily restring it, it has been an incredible power tool for me.

And as soon as Mary went off to trim with the weedeater, it happened. She ran out string.

Now, you have to understand, Mary to this point had a long history of watching me in total frustration when it came time to restring a weedeater.

So she did what any Smart, intelligent person would do.

She decided to “read the directions”, or in this case, look up a few “how-to” videos on line to see how it should really be done.

Why You Should Read Directions – How To Restring A Weedeater

You can imagine my surprise when she called me that night to tell me everything was mowed and trimmed.

I asked, “Were you able to start the weedeater?” When she responded back with a quick yes, I have to admit I was totally impressed. I mean, that can be a whole other frustrating thing with weedeaters.

But then she went on: “And, I learned how to restring it too – in seconds!”

I remember laughing and said, “you mean you got lucky.” Obviously, thinking to all of the times in the past I actually got lucky and had it work.

She finished by saying, “And I wound it back up with it all together.”

That was simply too much for me to believe. So much so, when I got home I went out and asked her to show me.

And about two minutes later, I stood there with my jaw on the floor.

Learning The Secret

How easy was it? Apparently, my Echo trimmer, and many others as well, have a “Speed-Feed Head” that can be wound with the entire string head together.

As you can see in the video below, it should be a simple process. One that I was making way too hard for 35 plus years.

VIDEO : IF you are unable to see the video above – you can also see it on our YouTube channel here : How To Restring A Weedeater

To restring a weedeater, you simply run the wire through the head, and then put it through the eyelets. And then, put it back together, with all of the wire still out.

Simply by holding the top side of the head, and twisting the lower side of the head in the opposite direction, it winds it up perfectly. Every single time.

I was both elated and ashamed all at the same time! Elated that it would never be a pain again.

And ashamed that I hadn’t taken the time to learn this over the last 35 years LOL!

Another lesson learned from my wife to read the directions first.

Happy Gardening and Weedeating – Jim and Mary

As always, feel free to email us at thefarm@owgarden.com with Комментарии и мнения владельцев, questions, or to simply say hello! You can sign up for our free email list in the subscribe now box in the middle of this article. Follow us on here : OWG This article may contain affiliate links.