Can I Cut a Neon Ribbon

Two important points

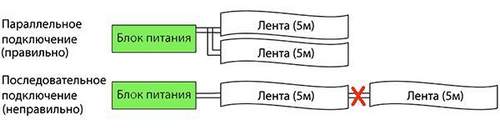

- Most manufacturers do not recommend connecting more than 5 meters of LED strip in series (which is especially important when connecting a powerful strip).

If you decide to break this rule, then firstly, get significant loss of brightness at the end of the connected tape, and secondly, due to overload on the conductive paths, LED strip to servesignificantly shorter, than I could.

- All sellers of LED strip give a guarantee. BUT in practice, most of them in the event of a marriage will NOT take the tape back under warranty, citing the fact that the integrity of the product is violated. Therefore, before cutting the tape into pieces, soldering and gluing, carefully unwind the tape reel and connect it to the power supply (more on this below). Let her work 8. 24 hours. Thus, you will be convinced that the LED strip and the power supply are working as they should, and in case of marriage you will be exchanged.

General Connection Rules

- LED strip can not be subjected to mechanical stress (bending, wrinkling and all that). Otherwise, there may be problems with the contacts and the tape will burn in parts (if at all).

- When connecting pieces of tape, do not damage the conductive tracks on the board. Otherwise, the result will be the same as in the previous paragraph.

- Connectors for connecting and connecting LED strip are on sale. BUT with a current load on a tape segment of more than 4 A, manufacturers do not recommend using them. Use solder. She is much more reliable.

- Make sure that the power supplies correspond to the full load of the product and have a power reserve of 20. 30% (how to choose a power supply for the LED strip). If you decide to save money and put a power supply of less power than necessary, say goodbye to it in advance. Most likely, it will burn out during the first year of service. And maybe with the tape.

- The power of the RGB controller or dimer to control color or brightness should NOT be less than the total power of the connected tape. No power reserve required. If the power of the RGB controller or dimmer is not enough. additionally use signal amplifiers of the missing power and the required number of channels (single-color tape. 1 channel, RGB. 3 channels, RGBW. 4 channels).

- When placing the LED strip on a metal or other conductive surface between the strip and the supporting surface, it is imperative to install an insulating material. Otherwise, someone may be pulled by an electric shock.

- The degree of dust and moisture protection of the tape (IP) must comply with the operating conditions of the tape (more about the degrees of IP)

- Static electricity can damage your tape, be careful.

- For powering the tape, it is better to contract qualified specialists. If there are none, then you can connect it yourself, without interfering in places the input of the 220V power supply and the output. 12 / 24V. If you do not want to be jerked with electric current. It is not advisable to work under voltage.

Видео: Can I Cut a Neon Ribbon

You can re-read the instructions again and pack your spirits;).

LED strip connection

We assume that you have already purchased an LED strip, dimmer or RGB controller and a power supply unit of suitable power.

- First of all, it is necessary to prepare the surface for installation. It is better to mount a powerful LED strip (power more than 10 W / meter) on a metal profile or some kind of aluminum substrate. The mounting surface should be solid, clean and fat free (alcohol and a clean cloth can help you with this). When mounting the tape on metal and other conductive surfaces, it is necessary to isolate the tape from the surface.

- You can cut, solder and solder wires to the LED strip only in specially designated places. Usually these are strips every 2.5. 10 cm tape. To connect two pieces of tape or tape with wires, solder them to both

- Before sticking the tape, we recommend soldering it, connecting it to the controller or dimmer (if necessary) and the power supply and socket. Then make sure your entire structure works perfectly. And only after that stick the tape with a 3M adhesive layer or glue / sealant.

- Solder pieces of tape between each other only at designated areas. The temperature of the soldering iron should be no more than 260 ° C. In this case, the soldering time should not exceed 10 seconds.