Can I Cut Hollow Core Slabs

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Reinforced concrete slabs are one of the most common types of floors. They provide high strength and allow you to mount a rigid structure in the shortest possible time. Installation of floor slabs is a responsible task that requires certain knowledge in the field of construction. First things first.

Types of floor slabs

Before you begin to mount a horizontal structure, you must select a type. Reinforced concrete prefabricated structures are available in the form of:

- multihollow;

- flat (PT);

- tent panels with ribs located around the perimeter;

- with longitudinal ribs.

Most often, the use of reinforced concrete multi-hollow. They are available in two types, depending on the manufacturing method:

- hollow hollow (PC);

- continuous molding (PB).

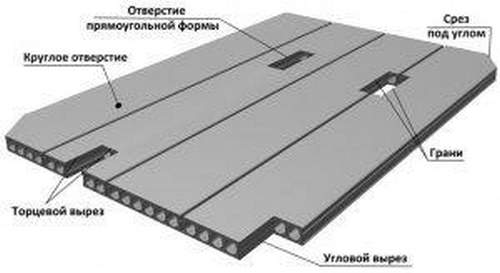

Layout of a hollow core slab with holes

Hollow core slabs are time-tested products that have been used in construction for several decades. A lot of regulatory documents and installation rules have been developed for them. Thickness. 220 mm. Products are installed in serial sizes, which creates inconvenience in individual construction.

The manufacturing technology of these plates involves the use of reusable molds for filling, and before manufacturing non-standard products, you will first need to prepare the formwork. Therefore, the cost of the right size can increase significantly. Typical PC boards have a length of 2.7 to 9 meters in increments of 0.3 m.

The scheme of reinforced concrete products with dimensions

The width of reinforced concrete products may be:

Structures with a width of 1.8 m are acquired extremely rarely, since the installation process in the design position is greatly complicated due to the large weight.

PBs are used in almost the same way as the previous type. But the technology of their manufacture allows you to give the product any length. Thickness. 220 mm. Width as a PC series. The disadvantage is the small experience of use and the rawness of the regulatory documentation.

As additional elements for hollow-core slabs, flat PTs are often acquired. They are available in a thickness of 80 or 120 mm and have smaller dimensions, allowing you to block narrow corridors, pantries, and bathrooms.

Plate support

Laying of floor slabs is carried out after the preparation of the project or the scheme on which the layout of the products is carried out. The overlapping elements must be selected so that they are sufficiently supported by a brick wall or expanded clay concrete blocks and laid without breaks in width.

The minimum bearing for the PB and PC series depends on their length:

- products up to 4 m long. 70 mm;

- products longer than 4 m. 90 mm.

Visual diagram of how to correctly and incorrectly support floor slabs

Most often, designers and constructors accept the optimum value of bearing on the wall of 120 mm. This value guarantees reliability with small deviations during installation.

It will be correct to pre-position the load-bearing walls of the house at such a distance that it is easy to lay the slabs. The distance between the walls is calculated as follows: the length of standard plates minus 240 mm. The PC and PB series must be placed with support on two short sides without intermediate supports. For example, PK 45.15 has a size of 4.48 m, 24 cm are subtracted from it. It turns out that the distance between the walls should be 4.24 m. In this case, the products will lie with the optimal support.

The minimum bearing on the wall of products of the PT series is 80 cm. Installation of such reinforced concrete slabs is possible with the arrangement of support points on all sides.

Video: Can I Cut Hollow Core Slabs

Bearing should not interfere with the passage of ventilation ducts. The optimal thickness of the supporting internal wall of brick is 380 mm. 120 mm on each side goes under the reinforced concrete floor, and 140 mm remains in the middle. the standard width of the ventilation duct. In this case, it is necessary to lay it as correctly as possible. Displacement of the product towards the ventilation hole will lead to a decrease in its cross section and insufficient ventilation of the premises.

- PC and PB series up to 4 m are supported on both sides by at least 7 cm;

- PC and PB series over 4 m. at least 9 cm;

- PT series. on two, three or four sides at least 8 cm.

Plate Storage

Storage schemes for different types of products

After the scheme has been developed and the products purchased, they need to be located on the construction site for convenient installation in the design position. There are rules for the storage of materials:

- you need to lay elements under a canopy;

- the storage location should be located in the access area of the crane;

- under support points provide linings.

Failure to comply with the last rule will lead to a break in half. PC, PB and PT products work so that the appearance of intermediate supports or a solid base leads to the appearance of cracks. Stacking is performed in the following order:

- wooden blocks or boards are laid on the ground under the edges of the plate;

- on the boards with a crane from the machine I shift the floor element;

- boards or bars are again placed on the stacked plate;

- unload the second plate from the machine;

- points 3 and 4 are repeated, the maximum storage height is 2.5 m.

Masonry requirements

The scheme of calculation of floor slabs

In order to correctly install the floor slabs, it is necessary to ensure that the special requirements for the brick wall are met:

- evenness of masonry in the place of laying floors;

- laying in three rows to overlap reinforcing mesh with a cell of 5 by 5 cm from a wire with a diameter of 3-4 mm;

- the top row of the masonry on the inside should be a bump.

If the slabs are mounted on expanded clay concrete blocks, a monolithic belt is additionally arranged for the floors. This design will help to evenly distribute the load from heavy ceilings on expanded clay blocks with less strength. Construction technology involves pouring on blocks of a monolithic concrete tape with a thickness of 15-20 cm.

Flooring

At least three people will be required to carry out the work: one performs a sling, and two install them in the design position. If the installers and the crane operator do not see each other, when installing the plate, you will need another worker who will give commands to the crane.

Reinforced Concrete Product Layout

Fastening to the crane hook is carried out by a four-branch line, the branches of which are fixed at the corners of the plate. Two people stand on both sides of the support and control its evenness.

When installing a PC, pinched into the wall is carried out in a rigid way, that is, bricks or blocks are laid on top and bottom of the plate. When using ceilings according to the PB series, it is recommended to perform articulation. To do this, do not pinch the plates on top. Many builders mount a series of PBs just like PCs and buildings are worth it, but it’s not worth the risk, because human life and health depend on the quality of the installation of load-bearing structures.

Another important feature of the use of products from the PB series is that it is forbidden to make technological holes in them.

These piercing is needed for heating pipes, water supply and sewage. Again, many builders even when erecting multi-story buildings neglect this. The difficulty is that the behavior of this type of flooring under load over time has not been fully studied, since there are no objects built long ago. The ban on punching holes has reasons, but it is rather preventive.

Plate cutting

Sometimes, to install the slab, it is necessary to cut it. The technology provides for the work of an angle grinder with a disc on concrete. It is impossible to cut PC and PT slabs along the length, since reinforced reinforcement is located in the supporting zones. If you support such a trimmed plate, then one edge will be weakened, serious cracks will go along it. It is possible to cut PB plates along the length, this is due to the features of the manufacturing method. A beam or board is laid under the cut site, which will facilitate the work.

The separation along the length is performed according to the weakened part of the section — the hole. this method is suitable for PC, but not recommended for PB, since the width of the walls between the holes is too small.

After installation, the holes in the abutment areas on the walls are poured with lightweight concrete or clogged with mineral wool. This is necessary to provide additional strength in places of crushing in the walls.

What to do if you could not evenly spread the products in width

Sometimes the dimensions of the room do not correspond to the width of the products, in this case, all the gaps are driven into one. This space is blocked by a monolithic section. Reinforcement occurs with curved nets. In length, they rest on the top of the floor and seem to sag in the middle of the monolithic section. for floors use concrete not lower than B 25.

The technology of prefabricated floors for bricks or blocks is quite simple, but requires attention to detail.