Can You Cut Brick With A Dremel. Cut brick circular saw

Can You Cut Brick With A Dremel?

Knowing the right tool for the job is the first step in getting something done. When it comes to cutting brick, it can be difficult to get it right, so how well does a Dremel do for cutting brick?

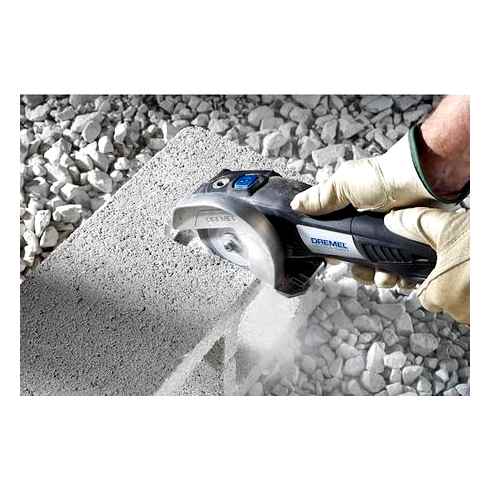

A Dremel tool is one of the easiest ways to cut a brick. A circular saw of this kind when used with a diamond wheel is designed to cut through tough material such as brick extremely well. The diamond wheel can cut through most harder materials with ease which is why it is key when using a Dremel tool to cut bricks.

Without a doubt, a Dremel is a great choice for cutting brick. So, why exactly is this? Read on to find out.

Why is a Dremel best for cutting brick?

The important thing to stress first of all is that a Dremel is only as good for cutting brick as the bit or wheel that’s attached to it. You need to have the right bit to effectively cut through brick.

That said, the main reason Dremel tools are good for cutting brick is the diamond wheels they offer. Diamond, as you might know, is one of the hardest materials we know of. That means that it can cut through basically anything if we put it to correct use.

Brick is not only tough but porous, so cutting it precisely without it cracking can be a challenge. This, again, is where the Dremel comes in. As I mentioned, the best kind of tool to cut brick is a circular saw. The Dremel is the best option, but you can also use things like angle grinders.

A small, but tough circular saw can pass through the brick without completely cracking it, which is the hardest part of cutting brick. Keeping cuts through brick clean is very tricky for many people. But the small circular saw made of the toughest materials like a Dynamo Bricksaw Diamond Blade increases the quality of your cuts.

Is a Dremel the best tool for cutting brick?

There are many advantages to cutting a brick with a Dremel. For one thing, it has a cutting blade as opposed to a grinding wheel. A cutting wheel will allow you to cut both brick and mortar with clean lines, but you can produce lots of debris. It will definitely do the job. You will need to be a bit more precise with your cutting though.

A diamond rotary saw is considered the best tool for cutting brick. The strength gives you the ability to cut through it cleanly with less debris. But this does change depending on if you are cutting through a brick wall or cutting loose bricks. When it comes to cutting loose bricks, a circular saw is the best tool.

There are advantages to using an angle grinder too, though. An angle grinder with a masonry wheel will, again, cut through both brick and mortar and allow for tighter angles. This is a lot more important if you’re cutting through a brick wall, rather than cutting up a loose brick.

So, while it can depend a little bit on the nature of the exact job, as a rule of thumb, a diamond blade Dremel or rotary saw is the best tool for cutting brick.

Is there a technique to cutting brick with a Dremel?

There isn’t a great deal of technique to cutting brick with a Dremel. Safety is first and the main FOCUS. One thing about using these rotary saws is that they are likely to produce a lot of debris. So, PPE is important when cutting brick. Make sure you grab goggles and a mask. Gloves are also a good idea to wear when cutting any materials.

Beyond that, just be careful to make clean, clear cuts, and do it very slowly. The faster you go, the more likely you are to crack or break the brick. Take it slow, and make sure you have a firm grip on the Dremel. It’s also a good idea to mark where you want to cut, so you have a clear view of where you need to cut. You can use engineers chalk pencil to mark bricks for cutting.

If you’ve never cut bricks with any power tool before, it might take one or two tries to get it right. But with a bit of practice, you will be fine cutting bricks.

As long as you stick to slow and steady, you’ll get the hang of cutting brick with a Dremel in no time.

Can you carve brick with a Dremel?

Dremel will cut through brick well, and it can also actually carve brick too! This can be useful to precisely fit brick around a corner or for engraving special designs in the brick. It adds a bit extra to the exterior appearance and personalises houses. It’s handy that not only can you cut brick, but also carve brick with a Dremel! It means one less tool that you need to invest in considering this one has multiple functions.

You will need a level of precision in your hands to carve brick. As always, safety when carving with a Dremel is the most important part. But it could definitely be a fun experiment!

What can a Dremel cut through?

It’s probably worth clarifying exactly what we mean by the term ‘Dremel.’ Dremel is a brand name but has become a generic term for rotary and circular saws. What a Dremel can cut through will depend on what bit you have attached to the end.

We’ve been talking about the diamond wheels so far, which is certainly best for cutting hard materials like brick, concrete and even marble. As we said, diamond is one of the hardest materials we know of, so as you can expect, there isn’t much it can’t cut through.

A Dremel can also cut through all kinds of metal, from aluminium to steel.

It can cut hardwood and softwood, drywall, vinyl, laminate, plastics, fibreglass—pretty much anything you can think of! Nothing is too tough for diamonds.

For extra help though, we have compiled a list of the best diamond blades for your project. We also have a guide to help install perfect brick tiles. There is lots more top renovation advice on our Paragon Tools resources page, so be sure to check it out! For quality bricklaying, grinding and cutting tools, check out our shop, or contact us with any questions!

EXTREME Performance Ceramic Brick Cutting Blades

Austsaw manufacture Ceramic Brick Cutting Blades designed for use with Angle Grinders, Brick Saws, Circular Saws, Concrete Saws, Portable Saws and Radial Arm Saws.

Ceramic Brick Circular Saw Cutting Blade Products in the Austsaw range of saw blade technology products includes Diamond Saw Blades (Super Turbo and Super Turbo Boxer) and Segmented Diamond Saw Blades (General Purpose and Trade White).

A brick is a block of ceramic material used in masonry construction, usually laid using various kinds of mortar. “Bricks” for buildings and other construction can be made from clay, shale, soft slate (Soft Slate / Brick Cutting Blades), calcium silicate, concrete (Concrete Block/Brick Cutting Blades), or shaped from quarried stone (Rock/Stone Cutting Blades). However, true bricks are ceramic, and therefore created by the action of heat and cooling.

Ceramic Bricks are generally used for building and pavement. Clay is the most common material, with modern clay bricks formed in one of three processes. soft mud, dry press, or extruded. Mud Bricks, Dry Pressed Bricks and Extruded Bricks are all manufactured using the action of heat (fired or burned) and subsequent cooling.

The Australian Saw Company range of Austsaw Ceramic Brick Cutting Blades are specially designed to cut ceramic bricks.

For EXTREME ceramic brick cutting performance, purchase from one of our Ceramic Brick Cutting Blade stockists today. Circular Saw Ceramic Brick Cutting Blades are available in a range of diameter, bore and teeth sizes. You’re sure to find the perfect Ceramic Brick Cutting Blade for your application.

Australian Saw Company Pty Ltd. Manufacturer and Supplier of Austsaw Ceramic Brick Circular Saw Cutting Blade Products.

Super Turbo Diamond Blades

For use with Angle Grinders, Circular Saws and Portable Saws. Designed for CUTTING Wet and Dry: Ceramic (Bricks, Pipes, Terracotta), Clay and Mud Products, Concrete (Blocks / Bricks, Pavers, Pipes, Reo. Rebar, Reinforced), Drywall (Cement Sheet / Board) and Rock/Stone (Basalt / Bluestone. Hard, Granite, Marble, Slate / Bluestone. Soft).

Super Turbo Boxer Diamond Blades

For use with Angle Grinders, Circular Saws and Portable Saws. Designed for CUTTING Wet and Dry: Ceramic (Bricks, Pipes, Terracotta), Concrete (Blocks / Bricks, Pavers, Pipes, Reo. Rebar, Reinforced), Drywall (Cement Sheet / Board) and Rock/Stone (Basalt / Bluestone. Hard, Granite, Marble, Slate / Bluestone. Soft).

General Purpose. GP Segmented Diamond Blades

For use with Angle Grinders, Brick Saws, Circular Saws, Concrete Saws and Radial Arm Saws. Designed for CUTTING Wet and Dry: Ceramic (Bricks, Pipes, Floor Wall Tiles, Terracotta, Roof Tiles), Clay and Mud Products, Concrete (Blocks / Bricks, Pavement, Pavers, Pipes), Drywall. (Cement Sheet / Board. Super Turbo Diamond Blades are better for this application) and Rock/Stone (Basalt / Bluestone. Hard, Granite, Limestone, Marble, Slate / Bluestone. Soft, Sandstone).

Boxer Segmented Blades

For use with Brick Saws, Demo Saws / Concrete Saws and Quick Cut Saws. Designed for CUTTING Wet and Dry: Ceramic (Bricks, Pipes, Terracotta), Concrete (Pipes), Rock/Stone (Marble, Slate / Bluestone. Soft).

Trade. Segmented Diamond White Blades

For use with Concrete Saws, Brick Saws and Radial Arm Saws. Designed for CUTTING Wet and Dry: Especially Hard Bricks, Ceramic (Hard Bricks, Firebricks / Refractory Bricks), Concrete (Blocks / Bricks) and Rock/Stone (Basalt / Bluestone. Hard, Granite and Marble).

Trade. Crack Chaser Segmented Blades

For use with Angle Grinders. Designed for CUTTING Wet and Dry: Ceramic (Bricks), Concrete (Mortar, Blocks, Bricks, Green Concrete / New).

How to Use a Circular Saw Safely and Correctly

Your circular saw is probably one of the most impressive power tools in your workshop, so it’s worth knowing how to use it to its full potential. An electric circular saw is the perfect tool for making quick cuts in wooden boards for professional and DIY projects, however incorrectly using your saw can be dangerous. If you need to know how to safely cut with a circular saw, you’re in the right place.

This SGS how-to guide is designed to help you make simple cuts through timber in a quick, safe and accurate way. If you want to learn how to use a circular saw, this guide is a great place to start for the essentials. We’ve also included a couple of top tips and trade secrets so you can be a cut above the rest.

Looking to upgrade your tired, old circular saw? Check out our circular saw buying guide or view the entire range of circular saws here.

Staying Safe When Working with a Circular Saw

- If you’re using a corded saw, keep all cables and leads away from the cutting path.

- Never take your eye off where you’re cutting. that’s how you lose fingers.

- If you cut between two points of pressure, you’re likely to squeeze the blade during the cut (called binding), possibly causing kick back.

- Make sure your workpiece is supported properly when you’re cutting. Use a work bench and clamps for smaller pieces, and an extension table or roller supports for larger pieces.

- Make sure the excess wood (waste side) is free to fall away after a cut, while your “keep side” stays firmly in place.

- Wear safety glasses and a dust mask.

- Your saw blade should be in good working condition and sharp before you attempt to cut anything.

- Most saws are designed for right handed people and therefore if you’re a leftie, you need to be extra vigilant against chips and saw dust. Waste material will normally be ejected to the left of the saw.

- Circular saws have a pretty impressive kickback when they first begin to cut. Watch the position of your body and stay slightly to one side of the tool.

- Don’t set your blade depth too deep. The saw blade should come 5-10mm past the depth of the wood you’re cutting. The more exposed blade you have, the bigger the risk of your saw binding or kicking back.

- Make sure the retracting guard blade is working correctly. With your saw unplugged (or with the battery out), test the guard can freely move back and forth (most blade guards will automatically spring back into the safety position when a cut is complete).

- Double check for nails or any other metals your saw might come into contact with. Nothing will damage your saw more, or create a stronger kickback, than a circular saw hitting something metal.

Get to Know Your Circular Saw

Before we get started with any cutting, it’s worth taking a good look at your circular saw and familiarising yourself with all the functions and feature. Not every circular saw is set out the same, but the diagram below should give you an idea where the various parts of a saw are. If in any doubt, check through your instruction manual.

Depth adjustment. This is normally a knob or a lever that can be used to move the base-plate / shoe. Always remember to tighten the depth adjustment lever or knob after you’ve set the depth of your cut.

Base-plate/ shoe. Allows you to set the depth of cut by exposing more or less of the blade.

Trigger. Unlike other power tools, a circular saw has only two speeds; on and off. As soon as the trigger clicks the motor is trying to bring the cutting blade to full speed. Always give the saw a few moments to reach top speed before you begin your cut.

Retracting blade guard. When not in use, the blade guard will cover the saw, keeping it safe. Typically, when you push a saw onto a piece of timber the blade guard will retract automatically. When you’ve finished a cut the blade guard should spring back into place. The blade guard is the most important safety feature of the tool because a circular saw takes time for the blade to come to a complete stop after a cut has been made. Check the blade guard is working correctly before even plugging it in.

Choosing a Circular Saw Blade

The first thing you need to do when purchasing a blade is make sure it’s suitable for your saw. There’s 3 basic things to check:

- The blade diameter your saw can handle. Handheld circular saws will normally take a blade anywhere between 110mm and 185mm in diameter.

- The arbour hole (centre hole) size you saw can take. Most arbour holes tend to me around 10-30mm, but can vary from brand to brand.

- Only purchase a saw blade that has a higher RPM rating than your circular saw can produce, so take note of your tool’s RPM before starting to shop for a blade.

Now that you’ve noted down this information about your saw, you’re ready to choose a blade.

Types of blade:

There’s a plethora of different circular saw blades available, and all of them are useful for slightly different applications. We’ve put together a list of the most common blade types and their uses to help you shop with confidence.Blades with fewer teeth cut faster, however blades with more teeth give a finer finish. The saw’s “T” (or teeth) will indicate how many teeth the saw blade has. Just remember, the higher the “T”, the finer the finish, and the slower the cut.

Cross-cut blades

CUse with wood or wood composites. Specifically for cutting against the grain of the wood (down the width of a board). These blades will have between 40 and 80 teeth and are designed to give you a nice, clean finish. You only need small gullets as less stock is removed.

Dremel 31.8mm Rip/Cross-Cut Blade 2pk (For Mini Saw Att 670)

Combination Blades

These are more generic wood cutting blades available with a huge array of teeth and can be used for either cross-cutting or rip-cutting. For every one tooth for ripping, there’ll be four for cross-cutting, giving the blade a distinctive look.

Framing Blades

These blades have 24 teeth and are effective for rough carpentry. Choose one of these blades when speed is more important than a clean cut.

Plywood Blades

These blades have 100 or more very fine teeth and are designed for cutting without splintering the work piece.

Thin-kerf Blades

These blades have a narrow profile for faster cutting, less material wastage and lower power drain.

Hollow-ground Blades

These blades have a thinner body and fatter teeth, meaning wood is less likely to “pinch” or bind around the blade.

Continuous-rim Blades

These specialist blades are diamond-edged and are also known as diamond blades. They’re used for tiles and slate, rather than wood, and have an ultra-fine finish. These blades are normally specifically for wet or dry cutting (check the packaging).

Turbo-rim Blades

Another style of diamond rimmed blade, these specialist saw blades have a serrated rim for cutting materials such as brick and concrete. They’re more aggressive than continuous blades, but won’t leave you with a fine finish. Normally, dry cutting only.

Segmented blades

Another type of diamond blade, but with a rim divided into gullets. These are the most aggressive style of diamond blades and will cut quicker than other types. They leave a rough finish when cutting brick or concrete. Available in wet and dry cutting varieties.

Abrasive blades

These blades cut brick and concrete like a diamond blade, however they’re made of aluminium oxide or silicon carbide. They don’t have any teeth and will give a medium fine finish but will typically be a lot slower than a diamond alternative.

Rip-cut blades

Use with wood or wood composites. Specifically for cutting with the grain of the wood (the length of a board). Typically these blades have 16. 40 teeth and are designed to cut aggressively while removing waste stock with larger gullets.

To get the most out of your saw, you’ll need a couple of pieces of equipment. For a start, we recommend a good work table or bench for supporting your material. There’s other ways of brace wood for cutting, but a workbench is by far the simplest and most straight forward method.

What you’ll need

If you’re working with a corded circular saw, make sure you get yourself a good size extension cord that gives you enough room to move, and not so long that you’re tripping over it.

Basic safety equipment like a pair of safety glasses, dust mask and maybe even some ear defenders will all minimise the risk of injury while you work. And of course you’ll need some basic marking and measuring tools like a pencil, tape measure and a tri-square.

How to Safely Make a Cut With Your Circular Saw

The two main types of cuts you can do with a circular saw are called a cross-cut and a rip-cut. A cross-cut is a simple cut across the length of a piece of timber, against the grain. A rip-cut follows the length of the timber and goes with the grain. Rip-cuts are trickier and can take a little practice to get right.

The following method is ideal for both types of cut, however we suggest you try a few cross-cuts before moving on to a rip cut:

How to cut bricks with a Circular Saw / Skil Saw Dry Cut Pavers

TOP TIP: For longer work pieces use a guide fence. This can be as simple as second piece of wood clamped to your workpiece. The aim of a saw fence is to give you a straight edge to keep at one side of the baseplate of the saw. Once you’ve done your measuring up, simply clamp your “fence” so it’s flush against the circular saw’s baseplate. Now when you make your cut you can use the fence as a guide (see picture below).

Top Circular Saw Tips and Tricks

So now you’ve seen how to make a simple cut, here’s a couple of extra trade secrets, tips and tricks to get you working like a pro in no time at all.

Your blade has a width

HSS blades are thinner than TCT blades, so if you’re ripping thinner pieces out of a wide board, you’ll make less waste with the thinner HSS blade. Remember if you cut a 100mm piece of timber in half, you won’t end up with two 50mm pieces. there’s always going to be a few millimetres of waste.

Do a kiss test

When accuracy really counts, do a quick kiss test to make sure you’re all lined up. Line up as best as you can, start your saw and make a slight cut (or kiss) in the timber to see where the saw will actually cut. The idea is to make the shallowest possible cut to test how your actual cut is going to perform.

Making a mistake

Cutting straight lines every single time, takes a little practice. If you do make a mistake, don’t try and force the blade back on track. Let the saw stop spinning and then start again from the markings.

Cutting wet wood

If you’re cutting wet wood set the depth so that the entire gap between the teeth is clear of the board you’re cutting. This will stop your saw and cut line from getting clogged with wet saw dust.

Aim ahead

Once you’ve set up your circular saw against your markings, follow the line slightly ahead of the saw. You’ll naturally “follow-through” the cut and end up with a straighter line.

still need help?

Our in house experts are always on hand for buying advice and to provide bespoke care, regardless of the application.

Masonry saws

Compact design, easy for moving Removable water tub, easy for cleaning Electric water pump with quick coupling, easy for changing the pump Removable blade guard for easy blade change Special water nozzle for optimized water cooling Transportation.

sliding table saw MS400AL

Circular saw blade diameter: 400 mm

Professional universal aluminium masonry saw with 45° tilting head! _ Cutting table ball beared for exact cutting Removable water tub, easy for cleaning Foldable legs Electric water pump with.

circular saw TS series

Circular saw blade diameter: 300, 350, 400 mm

TS 400 F is an efficient universal masonry saw with high cutting capacity for all kinds of bricks and building blocks. With this table saw you get a maximum cutting depth of 125 mm in.

sliding table saw CM 501

Circular saw blade diameter: 500 mm

robust masonry saw with a modern design. Conveyor cart with anti-slipping surface. Easy access to water pump. Double lifting rails. Building Construction Armed Concrete

circular saw C350 IPOWER

Circular saw blade diameter: 350 mm

Water-cooled saw with sliding cutting head. High power saw for cutting marble, bricks and stone. It is designed both for building sites and for the installer. Standard Equipment Single-phase 230V/50Hz.

circular saw Manta LX TB series

Circular saw blade diameter: 1,000, 750, 800 mm

Heavy-duty, versatile and inexpensive machine with an extremely accurate cutting. Mainly suitable to cut masonry blocks. The head slides on two chrome-plated ground bars by means of linear ball-bearings. The cutting head.

Band saw MBS 510

quick-coupling, the saw table can be opened with one hand movement Automatic saw cut-off – no unnecessary saw Band stress, as the saw belt only runs when actually sawing The.

circular saw MP1H

Round piece diameter: 356 mm

The Mason Pro MP1 Series combines portability and performance in one compact package. This saw is designed for vigorous masonry cutting operations. Reinforced, jig-welded steel frame construction provides.

sabre saw EDB 480.1

counter-saw blades. blow-back proof sawing. Blower function. dust protection for gearbox and user. Ergonomic handle. mountable on two sides. Compact and slim design. easy to handle.

circular saw Ambassador MS 500 series

Circular saw blade diameter: 500 mm

The Ambassador MS 500 system, manufactured by Belle Group, is a circular saw for stane that is suitable for precise cutting of any masonry products. It offers precise cutting of any materials up to 195.

sliding table saw STS/N series

Circular saw blade diameter: 550 mm

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left

reach your clients in one place, all year round

Filters: find the right products faster. Terminology: use the most common industry terms. Brands: a wider selection. Products: to improve the relevance of the collection. Other

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.