Carburetor Spring Calm 180

Home »Dismantling Chainsaw Carburetor Calm 180

Related posts

Do-it-yourself calm 180 chainsaw repair. video

The Stihl 180 chainsaw is a universal garden tool that is widely used in the garden. So, it is used for cutting firewood, pruning trees and other greenish plants.

The Shtil 180 chainsaw enjoys the least popularity both in construction and in farming. She is very comfortable and ordinary in operation. It also has a low price, which makes it more affordable for the population.

Unfortunately, no matter how high-quality the instrument is, sooner or later it breaks. A prerequisite for this may be wear or destruction of parts as a result of frequent use.

Some malfunctions can be removed in the home. The price of a repair kit for a carburetor calm 180 chainsaw? Adjust ms181 ms211 ms 211 c-be. But, in order to repair the chainsaw with your own hands, you should know the structure of the tool, as well as more frequent breakdowns and methods for eliminating them.

Oil Supply Repair

Often in the chainsaw calm 180 oil system is damaged. You can find such a malfunction by the dryness of the working circuit or the presence of leakage.

The solution to this difficulty must begin with a painstaking inspection of the hose through which oil is supplied. Also inspected by the connection of the hose with fittings.

During inspection and repair of the oil system, it is also necessary to clean the filter. Often, its contamination leads to poor oil passage.

If there is an oil leak, this means that the system is leaky. This primarily concerns the hose and oil channels. Most often, such malfunctions occur as a result of mechanical damage to system elements.

Read the same

The process of removing and cleaning the air filter

If as a result of the inspection a violation of the integrity of the hose was determined, then it is replaced. If the damage is minor, then they can be hidden with sealant. Carburetor repair stihl ms-180 disassembling the chainsaw from my chainsaw calm 180. This radical way will reduce the cost of repairs.

Carburetor Troubleshooting

If, as a result of pressure on the gas, the chainsaw starts to stall, then the problem is in the carburetor. Adjustment of the carburetor of the chainsaw calm 180, a video tip to which you can see. Also, a prolonged start of the chainsaw and the inability to set speed may become a symptom of a carburetor malfunction.

Carburetor repair stihl 180

repair cleaning carburetor stihl 180.

Stihl ms 180 carburetor repair

How to repair carburetor on a chainsaw Calm ms 180.

Most often, such a malfunction occurs as a result of wear of the rubber cuff, which is placed on the piston of the fuel accelerator. As a result of this, when the tool is started, air leaks. Basically, such a breakdown occurs after several years of operation of the chainsaw.

The elimination of this malfunction is carried out in the following sequence:

- Remove the carburetor. Remove the screw that holds the membrane cover. Turn the carburetor so that the pin is visible. From it it is necessary to remove a lock ring and to disconnect an air damper spring. After that throttle. To do this, unscrew the screw that holds it. The next step is to remove the valve axis.

- Pull out accelerator with spring. It has a cuff on it. Depreciation of this particular element leads to air leakage and engine shutdown after a recent start. Carburetor adjustment stihl calm ms 180. Piston with cuff needs to be replaced.

- Reassemble the carburetor in the reverse order and install on the chainsaw.

Carburetor Dismantling

Now it’s known how to eliminate a common carburetor malfunction. Dismantling the carburetor chainsaw Chinese calm 660 not carb adjustment on. Observing all the rules, you can easily do these jobs with your own hands.

Our partner article tells how to repair the Partner 350 chainsaw.

Chainsaw Calm 180 (aka Stihl MS 180) is the most popular and recognizable model of the German brand. This chainsaw is simple and reliable. The only unit that requires close attention is a carburetor. This article will discuss the carburetor adjustment, its repair and maintenance.

What carburetor is used on a chainsaw Calm 180

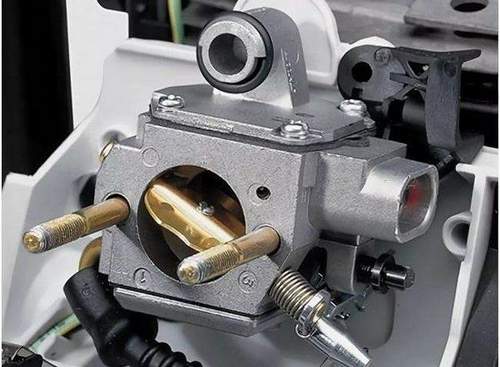

The Calm 180 chainsaw has a Japanese Zama carburetor of membrane type. Some users are confused by the inscription China on the carburetor. Yes, indeed they are going to China. But the plant is owned by Stihl, and quality remains high. However, the chainsaw also has Chinese counterparts with corresponding carburetors. But such saws are usually cheaper than the original.

How the carburetor Calm 180 works: device, principle of operation

The main components of the Shtil 180 chainsaw carburetor are the following components:

- fuel pump (with internal diaphragm);

- main (membrane) chamber;

- diffuser;

- throttle and air flaps;

- needle valve;

- fuel jets;

- nozzle with valve;

- idle speed screw.

The principle of operation is as follows. The chainsaw crankcase is connected to the fuel pump in the carburetor by a special channel. Due to the alternating stroke of the piston, a vacuum is created in the engine crankcase. As a result, the diaphragm rises in the fuel pump and the valve for supplying fuel to the carburetor opens.

Further, the fuel passes through a filter element (mesh) and through a special channel enters the main chamber. A control membrane is installed in this chamber, which regulates the fuel supply by pressing the rocker arm, which in turn lowers the needle valve.

For raising the control membrane is responsible for the vacuum that occurs in the diffuser of the carburetor due to the rotation of the air, throttle valves. Once the engine has started, the mixture needs to be leaner. We lower the air damper, the vacuum in the diffuser is minimal, the membrane falls into place.

From the main chamber, fuel enters the diffuser using a nozzle with a check valve, or through idle nozzles (when the gas throttle is closed). There it mixes with the intake air and the finished mixture enters the engine cylinder. The non-return valve prevents air from the diffuser from entering the main chamber.

Chainsaw carburetor adjustment Calm 180

Usually, special screws are responsible for the quantity and quality of fuel entering the diffuser, by adjusting which we change the cross section of the fuel channel. But on the Shtil 180 chainsaw carburetor used, to facilitate the operation of the saw, these two screws are missing.

The channels are designed so that the optimal amount of fuel gets into the diffuser at all engine speeds. And for the adjustment here, the LD screw is responsible, the rotation of which regulates the air supply to the idle jet. Due to which there is a change in engine speed.

So, to adjust the carburetor of the Calm 180 chainsaw, you will need an ordinary flat screwdriver and an electronic tachometer (not necessary). The adjustment algorithm is as follows:

- Check air filter. If necessary, replace the filter element.

- Tighten the LD screw counterclockwise to the end and then unscrew by 2 turns. Attention, the left thread! To access the screw, a hole for a screwdriver is provided on the saw body. Start the engine and warm up for 5-7 minutes.

- Turning the LD screw slowly clockwise, arbitrarily adjust the idle speed. There are 2 possible situations:

- The engine idle speed is very small. The engine does not hold idle. Turn the LD screw until the saw starts to rotate, and then turn the screw 1/2 back (the chain should stop).

- The saw spins idling. In this case, slowly turn the screw counterclockwise until the chain stops, then turn the screw another 1/2 turn in the same direction.

If after all the manipulations with the carburetor settings, the chain continues to spin at idle, you need to give the saw to the dealer at the service center.

The video below provides a detailed adjustment of the carburetor of the Shtil 180 chainsaw using an electronic tachometer.

Chainsaw carburetor repair Calm 180

The main malfunctions of the carburetor of the Shtil 180 chainsaw include the following.

- Gas does not enter the carburetor. The commonplace reason is a fuel pump failure. The diaphragm has lost elasticity or has lost weight. This happens due to material fatigue during prolonged use. As a result, with a vacuum in the engine, the diaphragm does not rise and does not open the fuel channel with the valve. It can be replaced by a spare from the repair kit by dismantling the carburetor.

- Gasoline may also not flow due to a clogged filter element (net) in the channel between the fuel pump and the needle valve. It is also treated with a replacement from the repair kit.

- Carburetor overflows. It’s not hard to guess that the problem lies in the main camera. Dirt particles enter the cavity between the needle and the channel, i.e. the valve does not completely close the channel when necessary and fills the chamber. Very often, the membrane ceases to fulfill its functions due to stretching (natural wear). As a result, when lowering the membrane does not fully raise the needle, and fuel continues to flow. The main membrane is also part of the repair kit. Replace it is not difficult.

- Very often, after winter downtime, the owners of the Calm 180 chainsaws are faced with a difficult start. In this case, the valve sticks in the nozzle. The manufacturer recommends that you burn the remaining gasoline in the carburetor before putting the chainsaw in storage. Gasoline is prone to evaporation and during long-term storage, engine oil remains in the carburetor, upon contact with which the nozzle valve begins to stick to the body. As a result, fuel does not enter the diffuser. Since the nozzle is not part of the repair kit, you have to knock it out and rinse thoroughly. This must be done very carefully.

- If an idle nozzle or nozzle is clogged, it is enough to blow them with compressed air. Or rinse with gasoline, in 90% of cases it helps. But you cannot use needles or wires, as there is a risk of changing the flow area, thereby changing the throughput of the nozzles.

A common problem due to which Calm 180 is unstable is the loss of the retaining ring on the axis of the throttle, as a result, it begins to hang and play, which in turn leads to interruptions in work.

So, you decided to remove the carburetor and carry out diagnostics. The removal procedure is as follows:

- Pull the trigger and lower the choke lever down. We turn the latch and remove the chainsaw cover.

- We unscrew both fastening nuts with a socket wrench for 8 and remove the air filter with the housing.

- Remove the thrust of the gas (throttle) carburetor.

- Disconnect the cable from the control lever

- We take out the engine control lever from its place. At the same time, we disconnect the draft of the air damper.

- Pulling the carburetor towards you, remove it from the studs. Do not forget to disconnect the fuel supply hose.

A more detailed and intuitive algorithm for removing the carburetor from a chainsaw is presented in the video.

As for the disassembly of the carburetor chainsaw Calm 180, then everything is simple. 1 bolt is unscrewed on the cover of the fuel pump and 4 bolts on the cover of the main chamber. This is enough to change all the necessary components from the repair kit.

After disassembling, the carburetor must be washed in gasoline, and the channels and jets must be blown with compressed air. In no case should you blow out the carburetor under high pressure and in the assembled state. Otherwise, you may stretch the membrane or diaphragm. The carburetor will stop working properly.

In order to assess the state of the filter mesh and membrane, you need to perform the following sequence of actions:

- Unscrew the screw.

- We evaluate the condition of the membranes, remove dust and dirt, if necessary, change the membrane to a new one. Everything should be clean under the membrane There should be no dirt on the membrane.

Video: Carburetor Spring Calm 180

As for the Shtil 180 carburetor repair kit, it includes a set of gaskets for covers, a diaphragm and a membrane, a needle valve, a rocker with an axle and a spring. The price of such a kit is from 100 to 400 rubles.

Advantages and disadvantages

Zama carburetors are very reliable and easy to operate. Specifically, a Shtil 180 chainsaw has a carburetor on which there are no screws to adjust the quality and quantity of the mixture, as we are used to. One screw greatly simplifies the adjustment.

The membrane carburetor has no significant drawbacks. With such a carburetor, the chainsaw works in any position. With side cut, vertical, etc.

Despite the above advantages, the carburetor is sensitive to fuel quality. In addition to clean air from the air filter, it is required to supply purified fuel from the gas tank to the carburetor. But this is not always possible, therefore, at least once every six months it must be cleaned and purged.

How much is a new carburetor

Stih 180 chainsaws are in great demand, primarily due to their reliability. The carburetor was no exception and also quite reliable and unpretentious. Adjustment or repair of the carburetor is required only after prolonged use, not less than 5-7 years (with an average load). The tuning process itself is maximally simplified by Calm engineers, this is the first chainsaw in which only one screw is provided for adjustment.

The consumer can repair the chainsaw calmly on its own due to the simplicity of the design. The tool recommended in the construction segment has a capacity of 1400 watts, an engine capacity of 31 cubic meters. cm.

The tool has excellent recommendations, popularity among users. This is due to a reasonable price and quality characteristics. However, the operation of the chainsaw is periodically accompanied by breakdowns.

The cost of repair work in the service is quite high. In many cases, their own technical knowledge allows consumers to repair the Calm 180 chainsaw with their own hands.

The most common types of chainsaw malfunctions

Operation of the chainsaw calm 180 is carried out in accordance with the instructions attached to the tool. The user starts the start-up system after he is convinced of the presence of oil, gasoline, and makes sure that the chain is correctly tensioned.

Work with the tool begins after it is securely fixed in the hands. If a tool failure is detected, it is necessary to determine the cause of the malfunction of the chainsaw calm.

The causes of a malfunction of the tool may be:

- leakage in the oil system;

- clippings formed in the crankcase cord;

- carburetor malfunctions;

- air entering the crankcase through oil seals;

- worn gear in the oil pump;

- no spark appears on the ignition section;

- worn drive sprocket;

- violation of the integrity of the eye under the control lever.

To carry out self-repair, a failed calm chainsaw, tools that are in stock at each consumer are used.

It can be:

- screwdrivers;

- Socket and wrench keys;

- hexagons;

- vacuum gauge used to determine defects in oil seals, carburetor, crankcase;

- air compressor used in the purge and cleaning of components and assemblies;

- T-key STIHL Torx 27;

- stopper restricting crankshaft travel;

- bearing puller.

Actions in case of malfunction detection in various parts of the unit

Unpleasant phenomena such as loss of power, lack of connection, and idle support are common.

The reasons for this behavior of the tool are the malfunctions of the chainsaw carburetor. This is expressed in pollution by dust particles, sawdust. Such a breakdown can be fixed on its own without problems.

Carburetor cleaning is carried out using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

The sequence of steps when performing repairs:

- To begin repairing the carburetor, they begin by cleaning them of dirt and dusty particles, fine wood. To do this, use a brush. When the surface is completely free of debris, the repairman removes the cover, and then the filter.

- The air collector is released after unscrewing the mountings of the air filter. Now the user gets access to the accelerator and rods. The accelerator lever is removed immediately, as the shutter is lowered by pressing the finger down.

- From the seat, the carburetor moves back after the suction lever has been removed and closed. Then the wire is removed and stretched out to stop the engine. A plastic lever is being shot, which is the place where the wire is attached.

- He is raised on the left. As a result, the carburetor is released, which makes it possible to pull it out and clean it. For these purposes, the use of a compressor is convenient. In its absence, the parts are washed in clean gasoline.

Stihl chainsaw disassembly. video

The assembly process of the saw carburetor is carried out in reverse order. If after this process there is the appearance of smoke from the muffler and the saw engine does not start well, then you need to make sure that there is a spring located under the lever needle.

A spring shuts off the fuel supply. In its absence, spontaneous "overflow" of fuel into the candle occurs. It is important to ensure that the spring is installed in its place, and make sure that the candle is working.

If the candle is poured with gasoline, then it should be dried. To do this, the part is twisted, merged, the excess fuel that has got inside, through the existing hole. The candle dries for more than half an hour. Then it is put into place, and the chainsaw is brought into working condition.

Insufficient contact between the high-voltage wire and the end of the plug can also be one of the causes of tool breakage. Stihl chainsaw parts can be repaired by replacing problem parts.

For example, when a candle fails, it is replaced by a reliable one. Chains, sprocket, tires are subject to fast wear. They solve anti-vibration tasks in the device of the chainsaw, so their replacement is carried out urgently. Such spare parts are recommended to be kept in stock.

Particular attention to the oil pump

The oil supply can be interrupted for various reasons. The most common malfunction of the oil pump. You can verify this by the condition of the chain lubrication.

If the oil supply to the circuit is interrupted, it becomes dry or excessively wet. these are signs of poor operation of the oil pump.

To eliminate the problem, an inspection of the oil supply hose is performed. The connection between the hose and the oil pump and tank is examined for leaks.

Serving a chainsaw oil pump. video

Problems arise such as the result of mechanical damage to parts of the oil system. To get to the problem area, this unit is disassembled.

If the repairman has ascertained that the hose is damaged, replace it. However, depending on the degree of damage, it is possible to carry out sealing with special compounds.

Before sealing begins, the surface is washed and degreased. By repairing the stihl ms 180 on its own, the consumer has the opportunity to radically save.

Identify problems in starting up the unit

A problem may arise in which the calm 180 does not start. It is usually associated with a breakdown of the starter. Actually, the unit does not start after tensioning the cord.

The reasons for the failure to start the starter can be:

- Failure of the spring.

- Cracked or broken pulley.

- A rush of rope to run.

Before you find out the cause of the breakdown, and begin repairing the starter of the chainsaw, the body of the chainsaw is removed. To do this, unscrew the screws that hold the cover with the starter.

In this case, screwdrivers or a special tool are used. A visual inspection of the starter reveals the reasons why the tool did not start.

Damage to the pulley with cracks and tears is reflected in the performance of the tool. Detection of mechanical malfunctions or defects at the attachment point of the soft spring.

The attachment point, as well as the tip of the spring inserted into it, is vulnerable. If faults or damage to individual parts of the starter are detected, they are replaced with new ones.

Dismantling and maintenance of the piston system of the Stihl 180 chainsaw. video

The unit can be repaired qualitatively with full compliance of the details with the brand of the chainsaw. The same scheme for replacing spare parts applies to do-it-yourself saws.

Stihl MS 180. a reliable and unpretentious tool, but sometimes requiring repair, like any equipment. In this article, we will consider how the dismantling of a calm ms 180 chainsaw, which is necessary in the case of an overhaul of the engine, takes place.

Preparatory stage

Repair of any equipment should begin with the stage of preparatory work, and drank calm 180, no exception. At the preparatory stage, before dismantling the chainsaw calm 180, it is necessary to remove the side cover, chain and tire from the chainsaw. Next, with the help of a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil drips and other things.

Particular attention when cleaning the saw should be given to the place where the chain sprocket of the chainsaw is located, because this is the most polluted area.

In places of large accumulation of oil, you can rinse with clean gasoline.

Handle removal

Direct disassembly of the calm 180, begins with the removal of the handle, which is attached to the body of the chainsaw using three rubber shock absorbers. To remove, it is necessary to remove the plastic plugs from the inner cavity of the shock absorbers, and then, using a powerful screwdriver, squeeze the upper shock absorber first, then the one that is closer to the rear handle.

A gas trigger is installed in the rear of the handle, which is connected to the carburetor through a wire rod, in order to disconnect the rod from the gas trigger, two screws must be loosened and the handle disassembled.

When the handle remains on one shock absorber, it is necessary to unscrew the chainsaw body from the inside of the handle and breaking it to the side, remove the body from the last rubber band.

Starter Removal

At the next stage, the upper housing cover is removed and 4 starter mounting screws are untwisted, after which it is necessary to remove the oil tank and fuel barrel covers. The starter is removed quite simply and no problems should arise.

After removing the starter, the opened internal cavity of the chainsaw needs to be cleaned, because usually on the body under the starter there is a large number of pressed small sawdust.

Flywheel removal

The chainsaw flywheel Calm 180 is twisted with great effort, so to remove it you will need a head with a metal handle. The nut holding the flywheel is unscrewed by 13.

To block the crankshaft from turning, you need to unscrew the candle and install the piston stopper through the spark plug hole, if it is not there, you can use the old string from the starter, with knots imposed on it and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to keep the flywheel from turning by installing a power screwdriver and other tools between its ribs and the body, with this method of locking from turning, the flywheel blades are not able to withstand loads and break off.

After the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the nut is normal, so you need to twist to the left side. After loosening the nut, it is not necessary to completely remove it, it is enough to unscrew it until its upper edge is equal to the tip of the shaft, after which a soft metal drift is installed on the nut and a sharp blow is made to it. Thus, the flywheel jumps off the shaft from a sharp impact and can be easily removed without the need for additional tools.

Dismantling the clutch and drive the oil pump

Before disassembling the clutch, it is necessary to dismantle the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

High head 19, unscrew the clutch. The thread on it is left, so it is unscrewed towards the tire, and not the rear of the Calm 180 saw.

Having untwisted and removed the clutch, you need to immediately remove the reflecting plate and the pump oil drive, this is easy to do, because they are put on the shaft without any attachment.

Carburetor, silencer and ignition coil

To remove the carburetor, it is necessary to have a head for 8 and an extension cord, with which it is convenient to unscrew the nuts of the carburetor and air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and the choke rod from the engine control lever and remove the lever, only then the air filter and carburetor are removed.

The silencer Calm 180 is fastened with two nuts, unscrewing which you need to pull it towards yourself, it can easily be removed.

The coil is mounted on two screws, for removal you just need to unscrew them.

Removing and disassembling the engine

The engine is held by 4 screws installed on the bottom of the Calm 180 chainsaw. To remove, you need to untwist them, and then carefully remove the engine from the seat and the rubber pipe of the carburetor.

To disassemble the engine, 4 crankcase screws are untwisted, and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat, using a thin screwdriver, then the piston pin is extruded from the opposite side, after which the piston is removed to the side.

Chainsaw assembly Calm 180

To assemble the stihl ms 180 saw back is quite simple, the main thing is to adhere to the following algorithm:

- Install the piston on the connecting rod, the arrow on the piston should look in the direction of the Calm 180 chainsaw, and on the left hand side of the piston should be the side of the crankshaft, which is used to install the flywheel;

- Carefully insert the piston back into the cylinder, the place for mounting the coil should be on the side where the flywheel is mounted on the crankshaft;

- Install bearings, seals, circlip on the shaft and lower everything in the assembly into the seat in the cylinder;

- Then degrease the crankcase installation location and the crankcase itself, then grease with sealant and install in place and tighten the 4 fastening screws;

To assemble the Calm 180 saw after the moment the engine is assembled, it is necessary to observe the reverse disassembly sequence. It is important to take the process carefully and remember to install traction on the carburetor, and connect the ignition wire.

Below you can see the disassembly of calm 180 in the video, it is made for inexperienced users, it shows in detail the whole process.

Dismantling the chainsaw calm 180 and its assembly, with some experience, is quite simple, the main thing is to thoroughly clean the saw before work and not rush. In order for small parts not to get lost, you need to use containers in which, in the process, it is worthwhile to lay out spare parts.

With the advent of summer, many owners of household plots are concerned about the issue for the purpose of how to put knife on trimmer. relevant are the questions of why and when purposefully replacing the scaffold on the scythe with a stronger cutting element. In our article, we will try to disassemble the complete set and give useful tips to summer residents.

Trimmer with a knife installed at this address, it is most convenient to use it for more comfortable mowing of the highest and coarser grass in the country. The fishing line on the Lawn Mower in this version does not control. Narrow torn in a short time. The introduction of a thick 5.3 mm cord or homemade rods with cables forces the vegetation to wind up on the spool. This increases the load on the engine. As a result, the piston group and the remaining moving units of the unit wear out in a short time.

If the mowing of the weeds is done with an electronic trimmer without a knife, only fishing line, even if it is thick with a curly section, the problem cannot be solved. There is always a risk of overheating the motor and damage the flexible shaft. And the thing is what remains to be done by our client in the large torque of the electronic motor. The spindle-wound grass makes a strong resistance to the shaft, resembling a speedometer cable, which does not withstand and twists.

To protect the equipment from early wear, domestic manufacturers have provided the ability to install special knives on trimmers. The design and shape of the existing cutting parts makes it easy to manage not only with coarse and overgrown grass, but also successfully fight against young shrubbery.

Before you take and put a knife on the brushcutter, we will find out what they are and where they are used. Now domestic manufacturers offer the consumer many types of these consumables. As a result, the entire cutting tool created for mowing grass can be systematized:

HOW to assemble a trimmer starter?

- In the manner of the material from which it is made;

- In the shape of its cutting blades.

Related posts

The main material for the production of trimmer knives you will like plastic on another metal. The introduction of such consumables in almost everything depends on 2 characteristics:

For safety reasons, the Russian automotive industry is not advised to put iron knives on electronic trimmers. All motor-scythes powered by electronic network and battery are equipped with plastic blades. Proceeding from the manufacturer, they are usually of an integral design of a disk shape, with several blades or in the form of a special mowing head providing for the installation of removable plastic blades.

Smooth bar at the gas trimmer and curved at the electronic

To put iron knife on electronic trimmer do not allow its design features.

- The curved rod of the unit reduces the distance from its working part to the legs of the mower. For which the design of the collision of blades with a stone or other rigid object is intended, the braid is thrown to the feet.

- The highest torque that we mentioned above, for which the construction of a collision of an iron knife with a rigid object is intended, transfers a huge load to the flexible shaft of the trimmer and its engine. What causes their early breakdown.

- The handle of the electric braid in most cases does not have a restrictive bar acting as a stop. Which does not exclude injury to the legs.

These features use only plastic knives on trimmers with electronic engines. In a collision with an obstacle, the blades are destroyed, thereby protecting the legs of the mower from receiving possible injuries.

Plastic knives work well with overgrown and dry weed. It is possible for them to mow nettles and burdock trunks.

How to wind a spring or assemble a starter calm 180

The use of iron knives only on gas trimmers is also justified by design features.

- The smooth design of the bar increases the distance to the legs, which ensures complete safety for the scythe.

- Comfortable U-shaped and J-shaped handles allow to hold the tool firmly. D-shaped handles of a Lawn Mower are equipped with the limiter resting against the leg of the pigtail that does not allow to let the head to legs having met the cutting disk with a hard obstacle.

- The clutch of the internal combustion engine allows you to smoothly gain momentum to a rational level. And when the blade collides with a hard surface, it can absorb part of the impact.