Cart for a motor-block Neva with their own hands

Making a power tiller with your own hands

A cart for a power tiller is an indispensable thing for owners of both large plots of land and modest gardens. Of course, it can be purchased at almost any specialized store, but you can try to make your own hands.

How to make a cart for a power tiller with your own hands

High-quality processing of the soil is not an easy matter, it will require not only incredible labor, but also certain skills. Even relatively recently, labor was completely manual, today it is possible to automate a number of processes to achieve even more impressive work efficiency. Below we suggest considering how to make a quality and reliable cart for your power tiller with your own hands, equip it with all the necessary.

Necessary tools

Depending on the chosen materials can be useful different set, including a welder, “angle grinder”, drills, lathe, power saw, electric screwdriver, etc.д. Do not do without wrenches, file, ruler and tape measure, hammer and sledgehammer, pliers, sandpaper.

All the necessary “helpers” it is better to prepare in advance, in order to avoid long delays in assembly.

How to make a shelf for shoes with their own hands. simple and complex options. Step by step instructions with photos and descriptions

How to make a fence with their own hands: detailed instructions, diagrams, drawings. Description of the process from A to Z!

How to make a barbecue with their own hands from metal. the best options for making with drawings and step by step instructions (100 photo ideas)

Amazing Cardboard Crafts Remote Control Car Own Hands

The variations of carts depend directly on the ability to transport a particular load.

- Simple single-axle cart. The maximum lifting weight of up to 70 kg. Its design will be simple and inexpensive.

- Cart for a power tiller with lifting capacity up to 110-120 kg. The most universal version for use in a farm.

- A trailer for transportation of weights over 120 kg. The design becomes more complicated, the cost of the frame material and facing increases. This option is more expensive, but the possibilities of the cart increase significantly.

Briefly about trailers for the motor-block Neva

Among a number of well-known brands and firms, the single-axle tractor Neva with a trailer requires special attention. Imported and domestic manufacturers have taken care of engine durability, quality of performance of different kinds of work, comfortable ride. Completion of Neva transport is simple: body, cultivator, plow, cart for power tiller and, optionally, a lot of other equipment.

Trailer devices for the Neva power tiller are made of durable metal. Their load capacity depends on the size, ideally it is 250-500 kg. When transporting a load of more than 350 kilograms, the cart for the Neva motoblock is equipped with a mechanical brake drive, so that it is easier to drive the transport.

in demand in gardening works, the trailer, proven by more than one farmer, for the Neva MB-2 power tiller. Thanks to the folding sides it is possible to transport not only bulky things, but also loose items. It is equipped with a brake drive and will not have a large load on the single-axle tractor itself, which undoubtedly acts as a plus in its favor.

Cart for a power tiller with my own hands

The simplest cart for power tiller can easily carry loads weighing up to 400 kg.

The structural parts of the cart

In any cart we can conditionally distinguish the following component parts: the driver’s seat, which is mounted on a welded frame, the central frame, the cart itself with the body and the wheels.

What material should be used for the wheel axle??

The easiest way to weld it is to use channel and angle bars, which can be purchased at any hardware store. The frame is welded as carefully as possible, as it must be able to withstand the bumps and ruts of broken country roads.

Components for the wheel axle

For it you can take a steel round of minimum diameter 30 mm. The axle is connected by welding to the longitudinal joint and to the angular supports. Select the length of the axle so that the wheels are under the body.

How to make a body for a cart

The body is assembled from boards up to 20 mm thick with steel brackets in the corners. The boards are bolted to the frame. It is better to make the sides hinged: it will be more convenient to unload large loads.

Wheels

You can use them from any agricultural machinery. The wheels of an ordinary motorcycle sidecar will do just fine. The axle will need to be turned to the diameter of the bearings in the wheel hubs.

hitch for the trailer

Made from any suitable piece of metal by boring a hole through which the coupling can easily pass. it is desirable to make the swivel knot from a bearing with a suitable diameter, fixing it by welding as firmly as possible.

bottom of a cart

You can of course make it from cut wood. But the more durable bottom is better to do from sheet metal with a preferred thickness of two or three millimeters. Such a cart for power tillers, which itself can be done in two or three days, can serve for several years and almost without repair.

Homemade cart for power tiller

No suspension, no problem!You could at least put the springs.What are the hubs from??

hubs on a lathe made, and not hard at all go

It makes sense! You should think about hydraulics for dump truck.

They make a U-shaped stand and a winch with a rope on pulleys.

Again, you can transport someone standing in the body, hold on the crossbar, put a tent on it I go fishing 5-7 km away. On the road, you can’t carry everything on you.

No blueprints left? I’ve got a similar single-axle tractor in the garage, I think it’s a Cascade.

I can write the basics here, and the rest is improvisation

The body flip axle, if not to carry sawdust and hay, should be placed near the center, otherwise you will rip the navel to unload it.You can make such a mess on a loaded one, injure yourself and others, you can’t brake with a half-ton of cargo with your foot.The stiffening ribs inside will leave all the debris on themselves.Rubber damper is needed at the junction with the tiller, so that the roughness of the frame with the track would not bend.The attachment point of the wheel axes should be strengthened with a profile or angle in the form of a triangle.There are still a lot of flaws, but for the hands out of the shoulders respect.

Brakes will still be, not a fool, and overturn will be fine, that to place the center of the whole design should be redone and I do not want to, so reliable and lightweight design, at the expense of the damper is nothing all is reliable and will not lead, the axis and so strengthened, the plate thick as necessary

I did not call you a fool. You may listen to me if you want to. Forum a lot of nproda reads. If you put your creation on review, there will be not only applause and praise, but also criticism. Why take it so violently? ? I did not write anything bad, and shared their operating experience.You will remember me when you push a loaded load back in a forest, against a stump with its reinforced plate fixing the wheel axle, after you have bent or broken it. I see that you have a new single-axle tractor, I think you don’t know its character, but it has a great burdensome temper, I’ve been using this kind of tractor with a trailer for 15 years. a single-axle tractor is a high-risk vehicle and if you run away without brakes into a ditch, you will be easily injured on a pin that in the photo holds the trailer and rises up on the move.

A cart for a power tiller can carry a load of 400-450 kg plus the weight of the driver. It can easily carry six or seven bags of potatoes without overloading.

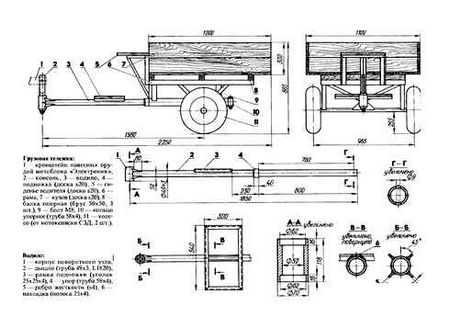

Drawing of the cart for power tiller

- 1. bracket for power tiller attachments;

- 2. arm;

- 3. driver;

- 4. footplate made of planks20;

- 5. driver’s seat made of s20 board;

- 6. frame;

- 7. body from board s20;

- 8. 50×50 bar support beam, 3 pcs.;

- 9. M8 bolt;

- 10. chock ring made of steel pipe.58×4;

- 11. wheel from sidecar, 2 pcs.

The cart driver structurally contains only a few parts that are fastened together by welding. The most overloaded part will be the junction of the drawbar with the swivel part. Therefore, in this place we need to install additional stiffeners.

Bogie frame

Made of steel angle and pipe scrap with round and rectangular cross-section. The whole structure looks a little bit intricate and has overstrength. It is designed for use on rough terrain and hence the heavy conditions for the cart.

Bogie frame for power tillers

- 1. Angle strut St.L21×3;

- 2. seat frame from angle piece st.L21×3;

- 3. riser made of steel pipe st.50×25×4;

- 4. seat supports from steels st.L40×4;

- 5,14. front struts of st.50×25;

- 6, 15. longitudinal side members from ST angle tube.L40×4;

- 7, 8. Wheel axle stands from steels steel angle.L32×4;

- 9,16. rear struts of st tube.50×25;

- 10.reinforcing crossbar from angle bars st. L40×4;

- 11. longitudinal hinge body from st.58×4;

- 12.wheel axle of steel circle.30 mm;

- 13,17. transverse side members from angle steel steels.L40×4;

- 18. braces (s4).

Who does not expect such high loads could take a simpler version.

Bogie carriage

- 1. body of the swivel unit;

- 2. drawbar made of tube st. 49×3, L1820;

- 3. Footstep frame st.L25×4;

- 4. stop made of steel tube st.58×4;

- 5. stiffener of sheet steel st.s4;

- 6. stripes on the drawbar.25×4.

Steel round 30 mm diameter is used as a preform for wheel axle. Wheels are under the body when the axle is about one meter long. A wheel axle with angle supports and a drift brace is connected by welding with longitudinal spars and joint body.

Body

It is made of 20mm boards, on the corners of which the steel corners are fastened. Bogie body is fixed to the frame through three strong supporting beams of 50×50 bars.

Wheels

They are taken from the sidecar together with the hub assembly. Both ends of the axle are turned to the diameter of the hub bearings.

Coupling with a power tiller

Linking the bogie to the power tiller is made possible by the linkage. The upper part of it follows the contour of the headstock, as it is fixed in the standard linkage bracket of the power tiller. Around the lower part in the form of an axle in two RUP-bearings is fixed a swivel steering assembly. The space between the arms is filled with grease and covered from the outside with dust caps. For heavy-duty applications, the linkage between the bogie and the driver should be a swivel joint.

Drawbar is inserted into the tubular body of the longitudinal joint and fixed with a thrust ring. Such design leads to independence of bogie wheels from the wheels of power tiller, that significantly simplifies steering of power tiller when riding over bumps.

Swivel head unit

console, 2. dust covers, 3,6. bearings 36206, 4. body, 5. expansion sleeve, 7. spacer sleeve, 8. washer, 9. nut M20×2,5, 10. oil can, 11. drawbar. The driver sits on a semi-rigid wooden seat in front of the body. The driver has his hands on the tiller arms and rests his feet on the wooden step in the frame of the drawbar.

Power tiller: Types, Selection and Mounting

The single-axle tractor is one of the machines in high demand in agriculture. It can help you do almost anything on the farm or homestead. One of the most necessary functions is the transportation of all kinds of goods and materials. You can do these things on a power tiller only if you have trailed equipment in the form of a small cart.