Ceiling foam skirting boards how to cut corners

Features of cutting different materials

The following materials are used for the manufacture of ceiling plinths:

- Styrofoam;

- Wood;

- Expanded polystyrene;

- Polyurethane.

Each option has a number of characteristics, so they need to be considered separately.

How to properly cut the ceiling plinth in the corners. options and methods for plinths made of different materials

Ceiling skirting boards are special parts designed to visually separate walls from the ceiling, as well as to mask the joint between them. Such skirting boards are used almost everywhere and well complement the interior of the room. Installation of skirting boards is quite simple, but it has a number of nuances. for example, to connect individual parts, you need to cut them off correctly. How to properly cut the ceiling plinth will be discussed in this article.

Expanded polystyrene

By and large, expanded polystyrene is a type of polystyrene that has an increased margin of safety. The cost of products made of extruded polystyrene foam is slightly higher compared to foam, but the reliability of such skirting boards is much higher. It is already problematic to break such a detail.

Cutting styrofoam skirting boards requires any sharp tool, such as a construction knife or a hacksaw. Due to their high strength, it is much easier to work with such products. they practically do not break or deform during operation. There will be less waste in the end.

Styrofoam

Styrofoam fillets are one of the cheapest options. However, the advantage in the form of low cost is offset by a large number of disadvantages. In particular, the foam itself is a rather brittle and soft material that is very easy to break. Even if you just squeeze such a product in your hand, it can deform.

Due to the low strength, it is very difficult to handle foam skirting boards. If there is little experience in cutting such parts, then most of them in the process of work will become unusable, so all the benefits from the cheapness of the skirting boards will be leveled. A hacksaw or a well-sharpened knife is usually used to cut foam fillets.

Polyurethane

Polyurethane skirting boards are the most expensive products. The high cost is due to a large number of advantages, among which are excellent resistance to moisture, high mechanical strength, reliability and elasticity. For most situations, this option will be optimal.

However, there are exceptions. polyurethane does not withstand temperature extremes. If you place such skirting boards in the kitchen near the stove, then over time, the polyurethane will deform and crack. Cutting of such fillets is carried out with a special knife, and no complications arise during work.

Inner corner cutting

The inner corner cutting technology is as follows:

- The first step is to attach the plinth to the ceiling. The required length is deposited on the plinth.

- The skirting board is inserted into the miter box in the same way as it will subsequently be located on the ceiling. The part is pressed against the far wall of the miter box and held in a stationary position.

- The hacksaw is positioned in the slots that mark the 45-degree angle. The workpiece laid in the miter box can be cut, and the effort required for this is minimal. you should not press too hard on the hacksaw.

- Now you need to cut off the opposite plank. The operation itself will be carried out in the same way, only the plinth must be placed not at the near wall of the miter box, but at the far one, so that the corners can be joined in the future.

- The cut skirting boards need to be joined together to make sure the cut is correct. When cutting internal corners, it is recommended to start working from the outside of the product. After work, it is advisable to slightly adjust the cuts with a file in order to improve the quality of the joint.

Pruning with a miter box

To give the plinth the required angle, a special tool is used. a miter box. Structurally, this tool is a tray made of wood, metal or plastic. In certain areas of the miter box, there are vertical slots that allow you to cut various parts at an angle of 45 or 90 degrees.

complex devices can be found on sale, in which, in addition to the angles already described, there is a possibility of a 60-degree cut. There is also a professional miter box equipped with a swivel mechanism. This tool differs from the simplified one in that it has the ability to fix the cutting blade at any angle. You need to know how to properly glue the ceiling plinth in the corners so that everything looks beautiful.

Cutting the skirting board in the corners without special tools

The question of how to properly cut off a 45-degree angle on a plinth can be solved without a special device. To do this, perform the following actions:

- Take a sheet of paper and apply a baseboard to it.

- Draw two parallel mowing lines to mark the sides.

- Then they take a regular protractor and measure 45 0.

- The line of the future cut is drawn along the mark made.

- Before trimming the ceiling plinth, it is laid on a sheet of paper, while controlling the coincidence of the lines and sides.

- The markings from the sheet are transferred to the plinth and a cut is made in the right place.

The disadvantage of this method is the need to keep the saw on weight during the cutting process.

How to cut a ceiling plinth in the corners. options and methods

Ceiling skirting boards are an integral part of the finishing of the ceiling space. With their help, cracks and wall defects are masked, they can be used to cover the irregularities of the suspended ceiling structure or wallpaper. In addition, skirting boards complete the interior of the room. One of the problems in the assembly process of these elements is the perfect joining in the corners. The question of how to cut a plinth to the ceiling in the corners is solved in several ways.

Skirting board cutting tool set

Working tools when solving the problem of how to properly cut the ceiling plinth in the corners are selected depending on the material from which the plinth is made, since each of them has its own processing characteristics:

- The PVC skirting board has no resistance to mechanical stress at all. Even light pressure results in irreparable damage. Therefore, no great effort is required during the cutting process. The question of how to cut a PVC skirting board is solved using a blade, a sharpened construction knife or a hacksaw for metal.

- The skirting board made of polystyrene also does not differ in particular strength, but in comparison with polyvinyl chloride it has a higher quality, moreover, it crumbles easily. Cutting foam ceiling plinths is done with sharp tools, just like PVC.

- Wooden skirting boards have higher strength characteristics and aesthetically pleasing appearance. However, the cost of such products is quite high. For cutting skirting boards made of wood, it is recommended to use a wood hacksaw with frequent teeth, since the teeth of a hacksaw for metal are easily clogged with sawdust.

Working with outside corners

As a rule, there may be external corners in the rooms, which also need to be pasted over with skirting boards. The question of how to cut the skirting boards at the corners of the ceiling in this case can be solved in the following ways:

- Using a miter box. Almost the same actions are performed as for internal corners. The only difference is that the glued side of the plinth is pressed against the surface of the device.

- The markup is in place. Similar to the inner corners, a mowing line is drawn on the ceiling and the same technology is used. With a rounded external corner joint, the joint is finalized with a knife.

How to cut a plinth for a ceiling

First, a miter box is used to properly cut the skirting board. This device is a special tray that allows you to cut wood, plastic or other materials at the desired angle. The miter box can be purchased in a retail network or made by hand; in the first case, a saw may be included in the kit. However, a tool available from a home craftsman for cutting materials may well be used.

The device has a recess into which skirting boards or boards are inserted. There is also a saw slot with an inclination of 45 and 90 degrees. For example, you can consider how to cut corners on a ceiling plinth at an angle of 45 0 using a miter box.

Such a process involves the following actions:

How To Install The Inner Corner of Cornice Mouldings. Orac Decor Installation Video

- The plinth must be attached to the attachment point.

- Make a mark for cutting.

- Install the plinth into the recess of the miter box, pressing it against the surface of the device with its underside. In this case, the side intended for applying the adhesive must look up.

- A saw is inserted into the hole for a 45 degree cut and the plinth is sawed off.

- Using the same saw or knife, the cut can be corrected by removing irregularities.

- The plinth is glued in place. The task of how to cut the ceiling plinth in the corners is considered solved.

How to cut a skirting board for an angle other than 90 degrees

Many rooms boast angles that do not correspond to 90 degrees. Such situations arise as a result of shrinkage of the soil and the structure itself, as well as in violation of the technology of wall construction.

In this case, the correct marking using a miter box or drawing will not work, all actions are performed directly on the spot:

- Before trimming the corner of the ceiling plinth, it is applied to one of the walls and an emphasis is made with the end to the other wall.

- A line is drawn along the plinth.

- Perform similar actions on another wall.

DIY Coving Cornice Cutting Tips for Beginners

- At the intersection of the two lines, a mark is made on one of the skirting boards, which is connected to the corner of the workpiece. An incision is made along this mowing line.

- Repeat the steps on the other plinth and try on both blanks. Make the necessary adjustments.

- The skirting boards are glued in place, the joint in this case must be tight enough.

Self-made miter box

The miter box can be made by hand using wood or metal. The width of the workpiece can be different, the main thing is that it does not exceed the size of the hacksaw, in this case, such a task as cutting off the corner of the ceiling plinth will be easier to complete.

The manufacturing process is as follows:

- A transverse line is drawn in the center of the workpiece.

- From it, in both directions, measure half the width of the workpiece and make marks.

- Labels connect crosswise.

- Now you need to mark the side walls of the device.

- The walls are alternately applied to the base and marks are made in accordance with the markings on it.

- At these marks, straight transverse mowing lines are drawn along the walls.

- Next, they start assembling the miter box. The side walls are attached to the base with self-tapping screws or bolts, depending on the material used.

- Saw slots are made after hollow assembly of the fixture.

With the help of a factory-made or self-made miter box, you can speed up the process of cutting skirting boards up to 10 times. This is especially important for craftsmen who regularly carry out repair work and are faced with the task of how to cut a ceiling plinth.

Outside corner

- Measure the length of the plinth from the nearest wall to the outer corner, leave the fishing line on the wrong side with a pencil, indicating the desired length. It should be noted that the edge (its upper part) should protrude slightly outward.

- The plinth is moved to the miter box and cut off.

- The adjacent bar also needs to be measured with a margin and cut off in a mirror image to the first part.

Trying on the ceiling plinth: the joining of the parts should be perfectly even. If the result is not achieved and there are irregularities at the joints, you can trim the edges with an ordinary knife to a perfect fit.

How to cut the corner of a skirting board evenly

A beautiful and neat edging of the ceiling hides the joints between the coverings and is an additional element of the room’s decor. But in order for the ceiling plinth to look really beautiful, you need to be able to qualitatively join its corner joints. How to cut the corners of the ceiling plinth evenly can be found in our article. Related article: how to properly glue the ceiling plinth with glue and putty.

Inner corner

- Making the right measurements.

- We install the plinth strip in the miter box so that this position exactly coincides with the placement on the ceiling.

- The plinth should be firmly pressed against the opposite wall of the miter box. Hold and press with your free hand.

- We put a hacksaw at an angle of 45 ° in a special hole and cut off the part.

- The adjacent part must be cut in the same way, only in a mirror image, as shown in the photo.

When cutting soft materials (PVC, expanded polystyrene), use a metal hacksaw or an ordinary construction knife. Then the work will be neat and with smooth edges.

The first way is with a miter box

Professional miter box with rotary hacksaw

The miter box usually looks like a tray with vertical holes for a hacksaw. It can be made of wood, metal or plastic. This tool is the oldest and simplest carpenter’s tool for cutting wood pieces at 90 ° and 45 ° angles. There are types of such a device for professional work, with a rotary mechanism, in which the cutting tool can be rotated and fixed in any position.

How to cut a ceiling plinth correctly

Ceiling corners are divided into internal and external, the method of joining on them is slightly different.

If necessary, you can make a miter box with your own hands. To do this, you need three trims from plywood or boards of the same size. First, they are applied in the form of an inverted letter “P” and the corners are marked. Then, according to the marking, slots are cut out for a hacksaw almost to the very bottom, and the boards are twisted.

Method two. no additional tools

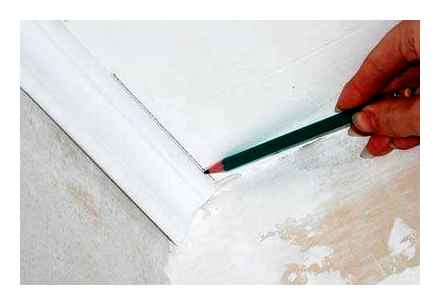

For the inner corner, you can use the simplest way of perfect joining. by marking on the ceiling. Another example of how to cut a corner nice and even.

- Apply a fillet to the ceiling, firmly pressing its even edge into a corner.

- Draw a line along the long side of the plinth on the ceiling.

- The same action is done with the adjacent part on the other side.

- Mark the point of intersection of lines.

The end result is an even 45 ° angle when you draw the line from the point of intersection to the edge of the part. Note that the above marking method works only for perfectly flat corners.

other methods

With a good eye and accuracy of hand action, you can use a homemade template that resembles an imitation of a miter box. To do this, take a thin board or thick plywood and draw a layout in the form of a horizontal rectangle. Using a protractor, mark 45 ° on the right and left sides of the rectangle. Draw mowing lines connecting opposite edges. You can now cut off the ceiling plinth using this layout. The actions are simple and similar to the description above in the first option. Only the ceiling parts should not be inserted, but placed on the drawing and the hacksaw should be combined with the layout of the layout.

Special accessories for docking