Chainsaw Doesn't Work At Idle

Chainsaw stalls when you press the gas: causes and elimination

Hello, dear subscribers and readers of my blog! In touch Andrey Noak. We continue the topic of chainsaws. So, I have already said before about what should be checked in a chainsaw in order to know the cause of its malfunction. Today I’ll move on to more valuable directions so that you don’t look for the cause of the problem for a long time and know approximately how to solve it. A chainsaw is not the most difficult tool, but you need to properly care for it. There are different cases, sometimes the chainsaw stalls when you press the gas, sometimes in the load, and sometimes it does not work at idle. Let’s look at different situations together and try to find the right solution.

If you find that the tool does not start and stalls at all, then you do not need to rush to the service center right away, you can try to solve the problem yourself.

Checking the main chainsaw system

We consistently check each system:

- Fuel tank. Perhaps there is not enough fuel there or it is of poor quality.

- The next one to be tested is the spark plug and high-voltage wire. Please note that the clearance of the candle normally does not exceed half a millimeter.

- If the above items are checked and work correctly, go to the carburetor and fuel filter. If a carburetor breaks down, contact a specialist.

Stalls at idle

Sometimes the saw dies at idle, and a muffler clog is a common cause of breakage. It can be easily cleaned independently; for this, a high specialist is not needed.

In addition to cleaning, there is another option, but we treat it very carefully so as not to harm the internal parts of the device.

To adjust the carburetor, you need to find two bolts with the letters L and H. The latter needs to be turned, a little, only half a turn. He is responsible for the revolutions of the tool and, if necessary, will raise the idle speed.

Turns off when loaded

Often powerful chainsaws stall from the load. Most likely your fuel filter is clogged and needs to be replaced. If this does not help, then you need to check the quality of the fuel mixture and prepare a new one.

The saw stops working when increasing speed

Localization of problem areas:

Filters are often clogged, especially when the chainsaw runs almost daily. The air filter can be disconnected and washed under a stream of warm water. Before inserting into place. dry thoroughly.

If, after disconnecting the fuel hose from the carburetor, no fluid flows out of it, it means it is clogged. It can be cleaned, or replaced with a new one.

With frequent use of the tool, a gasoline pump may fail. After all, every detail has its own expiration date. It should be replaced or contact a service center.

The saw turns off when turning

In a horizontal position, the fuel tube is at the bottom of the tank, but if the tool is tilted, the fuel will not be able to completely cover it. This is the reason that the chainsaw stops working when tilted, since the tube levitates in the air and the right amount of mixture does not flow to it.

Hot issues

If you notice that the chainsaw starts without problems without warming up, and stalls after warming up. And do not start it until it cools down, here, there may be several problems.

Firstly, perhaps somewhere there is a suction of a hose, stuffing box or gasket. Secondly, inspect the muffler for carbon deposits. The third reason is the cylinder-piston group (CPG), for scoring or bumps.

Sometimes carburetor tuning is required. Another important cause of the malfunction is the ignition coil. In cases where it fails, the spark is lost or becomes very weak, which is not enough to ignite the fuel mixture.

There are cases when the master is trying hard the engine, then cold, then hot, thereby pumping fuel. Here you need to pull yourself together, transfer the flap to a “hot start” and gradually turn on the tool. At the same time, we reduce the speed to an almost idle level and for 40-45 seconds it warms up.

The saw stalls after releasing the "gas"

Here you need to adjust the carburetor and check if there is a powerful air leak.

The most common cases of chainsaw breakdowns we have already seen. It only remains to eat up that your saw will last without breakdowns. But even sturdy models like Stihl and Partner can sometimes fail.

Do not rush to immediately run to the service center, first use my tips, so you can avoid big cash costs.

If the article seemed interesting. share tips with your friends through social networks. And I say goodbye to you. Good luck and see you in the blog!

Chainsaw Loses Turnover Under Load AURAMM.RU

Chainsaw starts and stalls, cause

A chainsaw has long been not a luxury, but the right tool for at least someone who has at least some suburban area. Why does the chainsaw stall when the chainsaw is loaded, the machine stalls at idle. With its help, you can perform gardening, harvesting firewood, finalizing lumber and much more. There are a lot of chainsaw models on sale, differing both in power and in overall performance. You can verify this here. e-katalog.ru.

But no matter what technique can be moody, and chainsaws are no exception. Let’s consider more relevant tasks.

The tool stalls immediately after starting

One of the likely circumstances is a lack of fuel. Check the volume of fuel in the gas tank, and add as needed. For all this, the annotation tips should be strictly followed, especially regarding the properties of gasoline and oil. We often ignore such subtleties, refueling the saw as necessary, which causes accelerated wear of the motor and leads to failures.

Also, the saw may stall due to deterioration of the contact of the spark plug with the high-voltage wire. This can be caused by mechanical shear or carbon deposits. From time to time, it is recommended from time to time to replace the candle with a new one, even if the ancient one did not show any troubles in the work.

Read the same

Chainsaw stalls in load

stalls in load Free consultation is better by skype ork.vitek or by phone. 380979677418 than I can, the more.

Chainsaw stalls when pressing on gas. The chainsaw stalls when you press the gas.

The video addresses a fairly common malfunction chainsaws and 100% carb option method. How is this done.

A chainsaw can work normally, being in a straight horizontal position, but stalls with lateral inclinations. Even in the event of a breakdown, during operation, the chainsaw may lose power or under load. Usually this is also due to a lack of fuel: the fuel pipe rises when tilted, and if there is not much fuel, it rises above the fuel level.

Chainsaw idles

Firstly, it is recommended to check the muffler, because its pollution can lead to a deterioration in the exhaust gas output, which is why the engine stops.

Read the same

If cleaning the muffler did not help remove the problem, and the engine of your saw is carbureted, then you can try to configure it. Most engine models have coarse and clear adjustment bolts (H and L, respectively). By increasing their engine speed, the problem can be removed. Keep in mind that adjusting the carburetor is a fairly narrow process requiring the implementation of a tachometer.

The engine does not withstand loads

If the chainsaw stops just in the middle of a particularly thick log, then the problem can be caused by problems in the fuel supply system or problems with the air filter. Why does the chainsaw stall under load? Why does it stall when idling? The engine simply does not get a rather flammable consistency to work with a heavy load, and stops.

The commonplace solutions to these problems are replacing the fuel in serious agreement with the tips in the annotation (we already spoke about this) and cleaning (replacing) the air filter.

Chainsaw stalls with increasing speed

The prerequisites for this phenomenon are similar to the previous ones: either a problem in the fuel system or in the air filter. Try to disconnect the fuel hose from the carburetor. if gasoline does not flow well (but you know for sure that there is fuel in the tank), then the reason is in the gasoline filter. You can, at the same time, check the fuel pump. fuel should not leak through it. If this happens, then it is advisable to replace the pump.

Read the same

Chainsaw During Heating Stalls. NZIZN.RU

Why does the chainsaw stall when loaded

Chainsaw starts and stalls, cause

Chainsaw It has long been not luxury, but the right tool for at least some who have at least some suburban area. With its help, you can perform gardening, harvesting firewood, finalizing lumber and much more. There are a lot of chainsaw models on sale, differing both in power and in overall performance. You can verify this here. e-katalog.ru

But no matter what technique can be moody, and chainsaws are no exception. Let’s consider more appropriate obstacles.

The tool stalls immediately after starting

One of the likely circumstances is a lack of fuel. Check the volume of fuel in the gas tank, and add as needed. For all this, the annotation tips should be strictly followed, especially regarding the properties of gasoline and oil. We often ignore such subtleties, refueling the saw as necessary, which causes accelerated wear of the motor and leads to failures.

Also a saw can stall due to the deterioration of the contact of the spark plug with the high-voltage wire. This can be caused by mechanical shear or carbon deposits. From time to time, it is recommended from time to time to replace the candle with a new one, even if the ancient one did not show any troubles in the work.

A chainsaw can work normally, being in a straight horizontal position, but stalls with lateral inclinations. Usually this is also due to a lack of fuel: the fuel pipe rises when tilted, and if there is not much fuel, it rises above the fuel level.

Chainsaw idles

Firstly, it is recommended to check the muffler, because its pollution can lead to a deterioration in the exhaust gas output, which is why the engine stops.

If cleaning the muffler did not help remove the problem, and the engine of your saw is carbureted, then you can try to configure it. Most engine models have coarse and clear adjustment bolts (H and L, respectively). By increasing their engine speed, the problem can be removed. Keep in mind that adjusting the carburetor is a fairly narrow process requiring the implementation of a tachometer.

The engine does not withstand loads

If the chainsaw stops just in the middle of a particularly thick log, then the problem can be caused by problems in the fuel supply system or problems with the air filter. The engine simply does not get a rather flammable consistency to work with a heavy load, and stops.

The commonplace solutions to these problems are replacing the fuel in serious agreement with the tips in the annotation (we already spoke about this) and cleaning (replacing) the air filter.

Chainsaw stalls with increasing speed

The prerequisites for this phenomenon are similar to the previous ones: either a problem in the fuel system or in the air filter. Try to disconnect the fuel hose from the carburetor. if gasoline does not flow well (but you understand that there is fuel in the tank), then the reason is in the gasoline filter. You can, at the same time, check the fuel pump. fuel should not penetrate through it. If this happens, then purposefully change the pump.

Why does the chainsaw stall

There are several reasons why a chainsaw stalls. And, usually, practically all of them can be solved without the help of others, without going to the service center.

First, check the filters: fuel and air. If they are clogged, then this is probably the reason for the incorrect operation of the tool. In this case, the mud is not always visible to the naked eye. Therefore, even if it seems that everything is in order, it is better to carry out this function.

The second reason, maybe a candle. Remember when you last changed it? According to the rules for operating chainsaws, this should be done once a year.

If this did not help, then it is worth trying to adjust the carburetor. Maybe from vibration when working with a chainsaw, its factory options got lost.

If the saw stalls after long storage, for example, in an unheated garage, then it is worth looking at the fuel line. As a rule, this is a rubber tube, which, due to dampness and temperature difference, can crack and become a cause of a chainsaw malfunction.

If none of the above helped, then, most likely, the damage is more severe, and, unfortunately, you will have to go to the workshop.

What to do if a chainsaw stalls?

- The car stalls at idle: probable conditions

- Problems of fuel and air filters and their elimination

- Difficulties with a spark plug and methods for solving them

- Substandard carburetor operation

- Tasks related to malfunctioning fuel system

- Idle difficulties due to muffler malfunction

- Piston cylinder malfunctions

Builders, installers, rescuers and summer residents # 8211 they all at some point, completing their tasks, take on a chainsaw. And the final result of their activity depends on almost how much this tool will work.

A chainsaw is used to cut a tree.

It should be noted that the chainsaw belongs to relatively lightweight devices. Nevertheless, she, like other mechanisms, sometimes fails. When the chainsaw stalls while idling (this is one of the most common malfunctions), the biggest problem # 8211 is to determine the causes of this behavior of the device. If the source of the “disease” is correctly established, it will not be so difficult to return the apparatus to a working position.

Therefore, first you need to find out what kind of malfunctions a chainsaw is and what leads to engine idle stops.

The car stalls at idle: possible causes

In order to answer the question of why the saw, at times capricious, stalls at Idling, it must be understood that the basis of this tool is an ordinary two-stroke internal combustion engine.

From this it follows that various problems lead to malfunctions with the main components of any internal combustion engine: fuels and lubricants, ignition system, air-fuel consistency and compression inside the cylinder.

The main motor failures include the following:

- the engine does not start

- starts up, but, working unstably, rapidly stalls at idle

- The chainsaw is idling normally, but stalls under load.

The reasons for idle violations can be different. But all of them can be reduced to several common positions. So, difficulties such as:

Chainsaw engine of internal combustion.

likely clogging of the fuel and air filter

Chainsaw stalls when pressing on gas. The chainsaw stalls when you press the gas.

The video addresses a fairly common malfunction chainsaws and 100% carb option method. How is this done.

Chainsaw stalls at work

Chainsaw stalls in work. During work chainsaw Partner 370, optional stalls. The reasons for the malfunction.

Back to the table of contents

Malfunctions of the fuel and air filters and their elimination

Chainsaw drowned out on Idling, if the fuel or air filter is clogged. To find out the state of the first element of the fuel system, disconnect the gas line from the carburetor. If fuel is pumped in at doses that match the specified standards, then the cause of the malfunction should be sought elsewhere. If gasoline comes to the carburetor weakly or does not flow out of the hose at all, then most likely the filter is clogged with garbage.

For cleaning, it is removed from the tank (all fuel must be drained from the tank until this point). Extraction occurs through the filler neck of the tank using a wire hook. The filter is disconnected from the suction hose. If possible, clean the filter. If this is not possible or it is impractical to do this for several reasons, the used filter is replaced with a new one.

The chainsaw may muffle if the fuel filter is clogged.

The air filter may also become clogged with dirt or dust, causing malfunctions on idle. It should be remembered that clogging of this filter occurs quite often, as a result of which air intake into the system is difficult. In the fuel-air mixture, the proportion of gasoline increases, and it turns out to be excessively enriched. Normal operation of the engine in this case can not be expected.

For cleaning, the air filter is removed with special care so as not to dust off the carburetor. Then it is cleaned and washed thoroughly. Detergent is added to the wash water. After drying, the air filter returns to its place in the chainsaw.

For normal operation of the cutting tool, it is recommended to change the fuel and air filters every 3 months.

Back to the table of contents

Problems with a spark plug and methods for solving them

Usually, this key component of the ignition system is recommended to be changed at least once a year. But often the owners of the saws forget about this rule. And therefore one should not be surprised that the apparatus, whose maintenance is carried out fragmentarily, as a result, poorly "holds" idle speeds.

The chainsaw spark plug must be changed once a year.

Therefore, you should pay attention to the following malfunctions associated with the operation of this system:

- Filling candles with gas at the time of start. To eliminate the problem, turn out the candle and, without calcining, dry it. Excess gasoline is drained from the engine through a hole-socket into which the candle is screwed. After a break of 30 minutes, the candle is put in place, the mechanism starts.

- No spark due to poor contact between the tip of the plug and the high voltage wire. The connection is checked, in case of violation, the defect is eliminated.

- There is no spark due to a malfunction of the electronic ignition unit. If there is confidence in the reliability of the connection of the tip with the high-voltage wire, but there is still no spark when the starter is switched on, then the cause of the breakdown may be a malfunction of the ignition unit. This component is not restored, it is only replaced with a new one.

- Incorrect clearance between spark plug electrodes. In different types of candles, this indicator ranges from 0.2 to 0.5 mm. The correct clearance is set using a feeler gauge of the appropriate thickness. Greater or lesser clearance for a given type of candles is not allowed.

Meanwhile, during the initial inspection of the spark plug, it may turn out that the reason the chainsaw refuses to work is not at all caused by defects in the spark plug or other elements of the ignition system.

Spark plugs can tell about malfunction of a saw.

So, if the candle turns out to be completely dry, this may mean that the initial problem lies in the impossibility of fuel entering the combustion chamber. In this case, you should check the entire gas supply circuit from the carburetor itself.

At the same time, the presence on the candle body of a characteristic black soot # 8211 is a sign that the carburetor is probably poorly adjusted. Because of this, the fuel mixture is oversaturated with gasoline. Oil may have fallen into the fuel. In this case, clean the spark plug, replace the fuel and adjust the carburetor.

Back to the table of contents

Substandard carburetor operation

If it turns out experimentally: the filters are clean and the ignition system is not to blame for the fact that the chainsaw is not able to function at idle, it is recommended that the tool owner turn his attention to the carburetor.

It is necessary to disassemble and assemble the carburetor without haste, since there are many parts in it without which it will not be able to work.

Often unstable operation leads to deregulation of this unit, which is responsible for supplying a certain volume of air-fuel mixture to the engine cylinder. You can adjust it with three special screws located on the carburetor: maximum and minimum speed screws, as well as a screw that controls idle speed.

Some manufacturers, fearing unwanted interference from incompetent people, supply their products with just one idle screw. But in both cases, the carburetor can be adjusted only by precisely following all the manufacturer’s instructions.

However, after adjusting the carburetor, in accordance with the factory standards, this unit can junk. Then it is recommended to clean the fuel and air channels, jets, the mesh of the filter element. If the membrane is damaged, it must be replaced with a new and high-quality one.

When servicing and repairing a carburetor, you should always remember that it is usually crammed with a lot of very small parts, without which the device will simply not be able to work normally. Therefore, disassemble and assemble the carburetor should be without haste and with extreme caution.

Back to the table of contents

Problems Related to Fuel Malfunctioning

The chainsaw periodically stalls idling also due to a violation of the integrity of the fuel line or an incorrect ratio of the ingredients of the “fuel mixture” consisting of gasoline and oil.

Before each switching on of the cutting mechanism, it is necessary to visually inspect its blocks and units, paying attention to possible defects in the surface of the body, mechanical damage, and leaks of working fluids. This should be done with regard to the fuel line of the saw, which is usually a rubber tube.

If the device was (especially a long time) in a damp place and it had to withstand sharp fluctuations in air temperature, this tube could simply crack. Such a fuel line is not suitable for further use and should be replaced.

Another reason why the chainsaw at idle may stall is the non-compliance of the ratio of ingredients in the preparation of the “fuel mixture”. The proportions of the gasoline and oil included in it must exactly correspond to the proprietary instructions for a particular device. If they are not observed, the engine will not be lubricated sufficiently, and the entire mechanism will persistently stall.

Back to the table of contents

Idle problems due to muffler malfunction

In the event of a noticeable drop in the power of the internal combustion engine at idle, after which the car often stalls, it is necessary to remember to check the muffler. The fact is that this node can turn out to be heavily clogged with tarry particles and the products of the combustion of the spark extinguisher, falling on the walls of the silencer in the form of thick deposits.

As a result, the resulting impermeable layer interferes with the normal exhaust emissions. This situation must certainly be corrected. A simple repair of a clogged muffler is carried out as follows.

Cleaning the muffler with a dry cloth is not allowed, as carcinogenic soot particles can enter the respiratory tract.

The silencer is removed from the engine, disassembled (if this type of silencer can be disassembled). In this case, it is necessary to plug the remaining openings from under the muffler.

The entire assembly and its individual parts are thoroughly washed with a rag soaked in water with detergents. If the muffler is collapsible, they are waiting for all its parts to dry completely. The fixed unit is dried with an ordinary household hair dryer. Cleaning this appliance with a dry rag is not allowed, otherwise the carcinogenic particles that form carbon deposits can get into the respiratory tract.

As a preventive measure for the normal functioning of the silencer of a two-stroke ICE in a “fuel mixture” of chainsaws, it is recommended to use only high-quality oil and only that prescribed by the manufacturer of this unit.

Back to the table of contents

Piston cylinder malfunctions

It is possible that after the elimination of all the listed causes of malfunctions chainsaw will continue stall at idle or not at all. In this case, you will have to look into the very heart of the engine # 8211 its cylinder.

Sometimes even a visual inspection is enough to determine what is happening with the cylinder-piston group. Chips, seizures, obvious cylinder wear and other visible defects # 8211 are immediate obstacles to the normal operation of the device. Without a doubt, such parts must be replaced.

If there is no obvious damage, then you need to examine the piston rings. It is damage to these rings that lead to loss of engine power. Too freely running rings in the grooves of the cylinder suggests that it is time to change these spare parts for new ones.

Meanwhile, a complete picture of the technical condition of this group of parts can be made only after a complete analysis of the engine. Since this is a laborious, responsible business that requires a certain professional experience, it is better to entrust it to a specialist. This is the only way to extend the working age of the great helper person # 8211 chainsaws.

Chainsaw Stalls At High Speed AURAMM.RU

DIY chainsaw repair

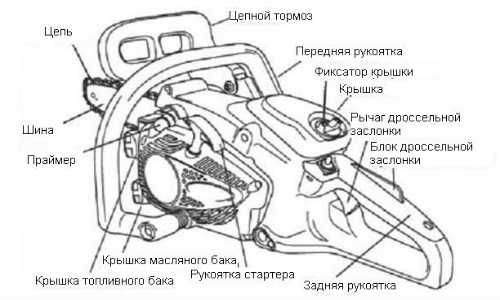

All malfunctions of chainsaws can be divided into two main groups: problems of the engine with all its components and systems (ignition, fuel supply system, cylinder-piston group, exhaust system) and malfunctions of other components (chain brake, lubrication system, clutch, tire, etc.).

Engine malfunctions

- the engine will not start;

- Starts up, but stalls;

- it is unstable;

- does not develop power, i.e. normally works at idle, but stalls under load.

When repairing a chainsaw with your own hands, it is necessary to act as an exception. alternately inspect all possible causes of the malfunction, starting with those that take the least time to check and eliminate (see here for the design and operation of a two-stroke motor).

Ignition system. Almost all types of engine malfunctions listed above can be caused by ignition system malfunctions. Therefore, when they occur, it makes sense to start troubleshooting with a candle. This is all the more justified because the state of the latter can provide useful information about the operation of the fuel system. So, if a problem occurs, you need to turn out the candle and inspect it.

The wire is disconnected, and the candle is twisted with a special key.

If the candle is dry, this means that the problem is most likely not in the ignition system, but in not entering the cylinder fuel mixture. You can wrap the candle back and take up the fuel system. If the candle is heavily sprayed with the fuel mixture, then there is an excess of it. This may occur due to misregistration of the carburetor or violation of the rules for starting. The candle is wiped and dried, the cylinder is drained, cutting off the fuel supply and working as a starter. to vent the combustion chamber and remove excess fuel. Then set the candle in place and repeat the launch.

The presence of a large amount of black soot also indicates a malfunction in the fuel system.

The ratio between oil and gasoline in the mixture may be violated, the carburetor is not adjusted, or poor-quality oil is used. The candle is washed in gasoline, cleaned with a needle or an awl of carbon deposits, clean the electrodes with a fine sandpaper and put in place.

In all these cases, it is not superfluous to check the gap between the electrodes of the candle. The chainsaw stalls; the chainsaw stalls at idle; the engine runs stably on. Depending on its brand, it should be in the range of 0.5-0.65 mm. It is necessary to check the sealing gasket of the candle. If it is worn or damaged, the tightness of the combustion chamber may not be ensured, which leads to a decrease in compression in the cylinder and problems in the engine.

Even if in the case of checking the spark plug there is good reason to believe that the fault is in the fuel system, you need to check the spark plug for a spark. At least in order to be sure that everything is in order with this. For this:

- put on the spark plug cable;

- using pliers with insulated handles, apply thread or nut to the cylinder;

- pull the starter handle and look. there is a spark or not.

If there is no spark, you just need to replace the candle. At high speeds stalls. Which does not stall at high. On the. If the new candle does not have a spark, it is necessary to check the condition of the high-voltage wire for an open and contact with the candle.

Read the same

The reason for the absence of a spark can also be a faulty ignition module or a violation of the gap between it and the flywheel magnetic circuit. It should be 0.2 mm. Violation of the gap becomes especially likely if before that the saw was disassembled with the flywheel and the ignition module removed. The clearance is set using a 0.2 mm thick gasket placed between the flywheel boss and the ignition module. Defective ignition module must be replaced.

Having checked the ignition system in this way and not having detected a malfunction, we can proceed to the fuel mixture supply system.

Fuel supply system. The chainsaw stalls, "when you press the gas, it works at high revs for 15-20 seconds then. If inspection of the spark plugs found that fuel does not enter the cylinder, you need to consider all the possible reasons for this. It could be:

- non-receipt of fuel from the tank due to a clogged hole in its cap (breather), while a vacuum is created in the tank that prevents fuel from flowing out;

- contamination of the fuel filter installed in the tank;

- not admission or insufficient admission fuel mixture from carburetor to cylinder.

To diagnose the first two reasons, it is enough to disconnect the fuel hose from the carburetor and see if fuel flows out of it or not. If it flows fully, the breather and filter can not be checked, if it does not or weakly flows, we can assume that the cause of the malfunction is found. The breather is cleaned with a needle. The fuel filter is removed through the filler hole of the empty fuel tank using a wire hook, together with a suction hose from which the filter is disconnected and cleaned or replaced with a new one. Chainsaw manufacturers recommend changing the fuel filter every 3 months.

Chainsaw Stalls when pressing on gas. stalls when pressing on gas. ADJUST THE CARBURETOR.

The video addresses a fairly common malfunction chainsaws and 100% carb setting method. lawn mowing stalls at high speeds. How is it done

Stalls chainsaw when you press the gas

Chainsaw stalls when you press the gas. Chainsaw Partner 370 start stall at the slightest pressure on the handle

Insufficient intake of the fuel mixture from the carburetor into the cylinder or a violation of the correct ratio between fuel and air mixed in the carburetor can occur for several reasons: due to clogging of the air filter, unregulated carburetor, clogging of its channels or mesh filter.

As a rule, repairing chainsaws is not complete without cleaning the air filter, since it gets dirty quite quickly. When this happens, air intake to the carburetor decreases, the fuel mixture at the outlet of it turns out to be too enriched, which disrupts the normal operation of the engine. Carefully remove the dirty filter for cleaning so that dirt does not get into the carburetor. The filter should be cleaned or washed in water with some detergent, dried and installed again.

Carburetor misregistration is eliminated by its adjustment. This is usually done with three screws. maximum and minimum idle speed and propeller. Adjustment must be carried out in strict accordance with the instructions, non-observance of which can lead to engine damage. Some saw manufacturers leave only one adjusting screw (idle). to exclude unwanted interference by inexperienced users in the carburetor. Adjustment example carburetor chainsaw See the article Working with a chainsaw.

If the carburetor adjustment did not help, you need to clean its channels and filter mesh, and at the same time check the integrity of the membrane. Carburetor. one of the most complex chainsaw devices, so proceed with disassembling and cleaning it with a full understanding of the responsibility of this operation. If the Stihl chainsaw does not maintain speed and stalls idling, the Stihl 180 saw. The chainsaw stalls at large if the tool stalls at high speeds. It consists of many small parts that have the peculiarity of quietly popping out of their seats and irretrievably lost, so that, having disassembled this capricious device, you can not assemble it.

Below is a diagram of another carburetor chainsaw.

If there is no experience and self-confidence, repair carburetor chainsaw it is better to entrust a specialist to a service center. Sometimes for high-quality cleaning of the carburetor it is necessary to apply ultrasonic cleaning.

Read the same

Muffler. Often the cause of engine malfunction, especially in the case when the engine is operating normally at low revs and stalls under load, becomes clogging of the silencer’s spark arrester, which prevents normal exhaust, from the combustion products. Repair in this case consists in removing the muffler, disassembling (if it is collapsible) and wet cleaning it from soot using detergents. The non-separable muffler is dried with a hairdryer after washing. Remember that soot contains substances that are carcinogens, and dry cleaning, which may cause inhalation, is unacceptable. When removing the muffler, the engine outlet is plugged with a clean rag.

Видео: Chainsaw Doesn’t Work At Idle

One of the reasons a muffler may clog. this use fuel mixture with an excess amount of oil (the amount of oil is more than recommended by the manufacturer), and the use of either unsuitable oil or low-quality oil.

Cylinder piston group. Malfunctions of the cylinder-piston group are the most serious. This is the deterioration of the cylinder and piston, scratches and seizures on their surface, wear or sinking in the grooves of the piston rings, wear of the crankshaft bearings. Most of these malfunctions lead to a drop in pressure in the cylinder and, as a consequence, to the inability to start the engine, or its inability to give full power. There are several ways to assess the status of a cylinder-piston group (CPG).

You can remove the muffler and look through the opened window, in which a part of the side surface of the cylinder is visible. Despite the limitations of the review, a general idea of the state of the CPG in this way can still be obtained.

It is useful to measure the compression in the engine, which is quite informative regarding the condition of the parts of the CPG. If you avoid damage and not at idle, the chainsaw stalls. The operation is carried out using a compressor installed in the candle hole.

The crankshaft is rotated using an electric motor (drill) with a flexible shaft or manually by a starter, while controlling the pressure on the pressure gauge. The last for a workable chainsaw should be at least 8-9 atm (0.8-0.9 MPa). With its decrease, engine power also drops. Do not forget the Stihl chainsaw stalls when the carburetor does not respond to the adjustment of the saw. At a pressure of 5 atm, the engine may perhaps work, but only at idle.

It is possible to accurately assess the state of the CPG only by completely disassembling the engine. disconnecting the crankcase from the cylinder and removing the piston. If the latter has scuffs, chips or deep scratches, it must be changed. In relation to the cylinder, when developing or damaging the surface, it is possible to squander it under the repair size. The cause of low compression may be wear and coking of the piston ring. The chainsaw stalls when you press the gas from the Stihl chainsaw stalls when the saw is working. The serviceable ring should be clean of carbon deposits, sit in the piston groove freely and firmly pressed against the inner surface of the cylinder.

Chain lubrication system

With a significant (small is considered normal) oil leakage, it is necessary to check the tightness of the connection of the tubes to the pump fittings. They may fall or crack. Violation of the tightness of the oil pipe, in addition to sagging, can lead to insufficient lubrication of the chain. The pump begins to suck in air, which affects its performance. The leak is eliminated by replacing the tubes or sealing them with sealant.

The most serious damage to the lubrication system are cracks in the oil pump housing. Information on what to do when the chainsaw stalls at high speeds. Two ways: troubleshooting yourself, trusting a professional. In this case, it will have to be replaced.

Chain brake

Replacing Wear Parts

If you do not replace the wearing parts in time, their excessive wear will adversely affect the other parts of the chainsaw. In particular, if you do not change the tire and the drive sprocket in time, increased vibration will adversely affect the crankshaft bearings. The maximum depth of the tooth teeth should be 0.5 mm. In practice, sprockets are often operated up to a wear depth of 1 mm or more. not suspecting that this leads to an increased load on the crankshaft bearings and their accelerated failure. When 3-4 chains are worn, it is necessary to change the tire itself, by this time its wear reaches its limit values.

The chainsaw tire wears out especially in the area most often cut, usually. this is the underside of the guide rail. Why the chainsaw is not gaining momentum and stalls. If the chainsaw, one minute after starting, is not able to gain momentum or stalls when the trigger is pulled, the carburetor is most likely or. For uniform wear, each time the chain is replaced, the tire must be turned 180 ° relative to the horizontal axis.

When installing a new chain, a new drive sprocket should be installed. Since under normal load the service life of the drive sprocket is twice as long as the service life of the chain, it is advisable to use one sprocket for alternating operation of two chains. Thanks to this, the sprocket and chains wear out almost simultaneously. If a new chain is placed on a worn sprocket, then the leading chain links wear out much faster. For cost-effective operation of the chainsaw, always spend together: one guide bar, two chain sprockets, four saw chains.

Read the same

The chainsaw stalls at high speeds: the engine is faulty

Even if there is a great desire, a chainsaw cannot be classified as a complex device. And note also: the simplicity of the design is its characteristic feature. However, despite this fact, even such a simple device breaks down, taking a considerable amount of time for repairs.

Chainsaw device diagram.

The difficulty is not the repair procedure itself, but the correct determination of the damage. One and the same failure can cause completely different flaws. Therefore, it is not worth rushing to disassemble the engine immediately or the carburetor before the signs of failure are investigated. The instruction manual for the operation and repair of the chainsaw can be of little use here, it will be necessary to connect your own mind more.

The existing failure options can be attributed to one of two categories: damage to the engine system with numerous groups and components in it (ignition, fuel supply, exhaust, cylinder-piston) and damage to other components (lubrication system, brake, tire, clutch, etc.). )

When the engine is faulty

Chainsaw electronic ignition circuit.

It often happens that chainsaws break the usual engine performance. It is the search and repair of damaged engine systems from users that take the lion’s share of the time. They can have manifestations such:

- cannot start;

- chainsaw stalls when it starts;

- job instability;

- normally runs at idle, but stalls at high speeds.

If you plan to repair the chainsaw yourself, it is advisable to use the exception method. consistently check the probable causes of damage. They begin to check those whose correction will take the least time.

Back to the table of contents

Malfunctions in the ignition system

Absolute all the indicated types of engine malfunctions can be caused by malfunctions in the ignition system. If a chainsaw malfunctions, it is necessary to start looking for a malfunction with a candle. What is there and some other meaning: the condition of the candle will give a hint about the work of the fuel group as a whole. If you find any malfunction, you need to analyze the candle, having turned it out first. Why disconnect the wire and use a special key to unscrew it.

The principle of operation of the carburetor chainsaw.

The dryness of the candle indicates that the source of the problem is not connected with the ignition system, but with the absence of fuel liquid in the cylinder. The candle in this situation is screwed back and taken for the analysis of the fuel group.

With a significant contamination of the candles with fuel, they imply an excess of the latter. This phenomenon is associated with deregulation of the carburetor or with non-compliance with the start requirements. The candle in this situation is cleaned and dried, the cylinder is released by shutting off the fluid supply and using a starter to vent the combustion chamber and get rid of excess fluid. Then the candle is returned back and start again.

The presence of abundant dark soot also only confirms the presence of malfunctions in the fuel system.

Violations can occur in the proportions between gasoline and oil, in poor adjustment of the carburetor or in the addition of poor quality oil. They wash the candles with gasoline, remove carbon deposits by means of a needle or an awl, clean the electrodes with an emery cloth and put them back.

Also in relation to all situations, it makes sense to control the gap between the candle electrodes. According to her vintage, he is obliged to correspond to a value from the range of 0.5-0.65 mm. Checks require a sealing candle gasket. If it is worn or damaged, it will provide insufficient tightness for the combustion chamber. And this will cause a decrease in compression in the cylinder and problematic functioning of the engine.

Scheme of a two-stroke engine of a chainsaw.

Even when the control of the spark plug gives reason to believe that the damage is related to the fuel system, the spark plug is tested. At least to exclude suspicions that there are problems with this issue. Perform:

- putting on a spark plug cable;

- using insulated pliers, the candle nut or thread is pressed against the cylinder;

- wring out the starter handle and watch if a spark arises or not.

When the spark does not occur, the candle is changed. If there is no spark when replacing the spark plug, then the high-voltage state is analyzed for breakage and contact with the spark plug.

A failure of the spark may be caused by a malfunction of the ignition module or non-observance of the gap between it and the flywheel magnetic wire. The latter should be equal to 0.2 mm. In particular, violation of the gap becomes quite possible if on the eve the analysis of the saw and the removal of the flywheel with the ignition module were performed. Defective ignition module is replaced.

Having completed all the steps to check the ignition system and not finding deviations, proceed to the analysis of the fuel supply system.

Back to the table of contents

Fuel supply system defective

If during the examination of the candles it was found that the liquid is not supplied to the cylinder, then the probable causes of this fact are clarified. They are:

- fuel is not supplied from the tank due to clogging of the cap opening (breather), and a vacuum appears inside the tank, which prevents the liquid from escaping;

- the fuel filter located in the tank is dirty;

- fuel fluid from the carburetor does not enter or enters in insufficient quantities into the cylinder.

Oil supply for chain lubrication.

In order to diagnose the first 2 reasons, remove the fuel hose from the carburetor and observe whether fuel is leaking or not. When it flows out with a full stream, the filter and breather do not look. If it flows weakly or does not flow at all, then it is believed that the source of damage has been found. The breather is cleaned with a needle.

Through the hole in the gulf of the empty fuel tank, remove the fuel filter, coupled with a suction hose, using a wire hook. From the last filter is removed and cleaned or changed to fresh. Chainsaw manufacturers recommend changing the fuel filter after each trimester.

A weak flow of fluid into the cylinder from the carburetor or a lack of proportions between the fluid and the air is caused by several reasons:

- clogging the air filter;

- unregulated carburetor, clogging its channels or mesh filter.

Typically, the procedure for repairing chainsaws is accompanied by cleaning the air filter, since its pollution is very fast. When this happens, the air intake to the carburetor decreases, the fuel fluid at the outlet becomes too enriched, which leads to interruptions in the normal functioning of the engine.

Removing a dirty filter for cleaning is done with great care, so as not to shake off dirt in the carburetor. The filter is cleaned or washed with water and a cleaning agent, dried and returned to its place.

Centrifugal clutch of a chainsaw: 1. friction linings, 2. springs, 3. drum.

Adjusting the carburetor eliminates its deregulation. As usual, this is carried out by means of 3 screws. maximum and minimum turns, idle speed. Adjustment is carried out strictly following the descriptions in the instructions. The engine otherwise just breaks down. Other manufacturers of chainsaws provide a single idle screw in order to eliminate unnecessary interference in the performance of the carburetor inexperienced users.

When the carburetor adjustment is ineffective, clean the channels with a filter grid and immediately check the integrity of the membrane. At a chainsaw, the carburetor is considered a moody device, so it should be disassembled and cleaned, understanding the full responsibility of the operation.

The peculiarity of working with it lies in the fact that many small elements of its components have the ability to quietly jump off their places and get lost forever. Having disassembled such a naughty mechanism once without hesitation, you can not assemble it back in the same form.

If there is little or no experience in repairing a carburetor, then it is better not to take it on your own, but entrust this important event to a specialist from the service center. Cleaning the carburetor there is sometimes done by means of ultrasound.

Back to the table of contents

The muffler is out of order

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-pump.

Often the cause of engine failure, especially when the engine is functioning fine at low revs, and when it is large, gets hot and the chainsaw stalls, is caused by the burning of spark arrester products in the muffler, creating obstacles to a full exhaust.

Repair in such a situation comes down to removing the muffler, disassembling it and wet cleaning carbon deposits with the participation of detergents. After washing a non-separable muffler, it is dried with a hairdryer. Since soot consists of carcinogenic particles, it is unacceptable to carry out dry cleansing, because toxins will enter the respiratory system of the master. After removing the muffler, the outlet opening is plugged with a cloth.

The reason for clogging is the one that uses fuel oil with an excessive amount of oil (more than recommended by the manufacturer), base oil or not suitable for 2-stroke engines.

Back to the table of contents

Damage to the cylinder piston group

Damage to the cylinder-piston group (CPG) is considered more thorough. These include: cylinder and piston wear, scratches on their walls, wear or retraction of the piston rings in the grooves, worn crankshaft bearings. Many of these problems cause a decrease in pressure in the cylinder and the inability to start the engine or to work at full efficiency when the chainsaw heats up and stalls.

Air purification system: 1. the cover closing the fine filter, 2. the fine filter, 3. the cover closing the coarse filter, 4. coarse filter.

The status of CPG is evaluated in one of several ways.

- Removing the muffler allows you to view part of the end surface of the cylinder in the opening opening. Although the foreseeable area is small, it still can shed light on the state of the CPG.

- Compression is measured, which is very informative regarding the state of CPG elements. The procedure is carried out by means of a compressor placed in the hole of the candle.

- Using a drill, use a manual starter or flexible shaft to crank the crankshaft, looking directly at the pressure gauge. For a saw with normal performance, it should be at least 8-9 atm (or 0.8-0.9 MPa). Lowering, it leads to a decrease in engine performance. A pressure of 5 atm still presupposes the operation of the engine, but already at idle.

The accuracy of assessing the condition of the CPG is possible only with a complete analysis of the engine: unlocking from the crankcase cylinder and removing the piston. If it is found on the last scoring, chips or deep scratches, it is replaced. As for the cylinder, in case of damage to the surface or its development, it is bored to the repair size. Slight compression may be caused by wear or coking of the piston ring. The serviceable ring does not contain carbon deposits, it freely holds in the piston groove, adjoining the cylinder surface from the inside quite tightly.

Back to the table of contents

Circuit Lubrication Malfunctions

Without exception, all chainsaw repair manuals contain references to damage to the chain lubrication system, which are quite common. It:

- missing or missing lubricant supply;

- oil leakage.

Coarse air cleaning system: 1. snow filter, 2. strainer.

When the chains are dry, they inspect and clean the channels supplying oil to the tire. Clogging them is not uncommon.

In case of significant (in small quantities, it is considered normal) oil leaks, the connection of the tubes to the pump fitting for leak tightness, which may fall or crack, is examined. Changing the integrity of the oil line (drips do not take into account) may cause insufficient lubrication of the chain. Air draws in the pump, which reduces its performance. Tightness problems are corrected by changing the tubes or by sealing them.

A significant problem of the lubricant group are cracks on the body of the oil pump. Then they change it.

Back to the table of contents

Chain brake failure

This malfunction is caused by contamination of the space under the cover and the brake bands by grease or sawdust. In the first situation, they clean the space under the cover, in the second. they replace the brake band.

Back to the table of contents

Replace parts with a short life

Chainsaw starter device: 1. drum, 2. cable, 3. handle, 4. frame.

Individual elements of chainsaws that wear naturally after the declared period of operation are to be replaced. Violation of their functions does not apply to damage. Elements with a short amortization period are the chain, the main sprocket, the tire, the components of the anti-vibration group, etc.

If you do not replace elements that have developed their expiration date in a timely manner, their increased wear will adversely affect other parts of the chainsaws. For example, untimely replacement of the tire and the main sprocket will lead to increased vibration, which, in turn, will harm the crankshaft bearings.

The sprocket has a depth limit of 0.5 mm for the production of teeth. In fact, they often allow wear and tear to a depth of 1 mm, without thinking that this will lead to an excessive load for the crankshaft bearings and an instant failure of the latter. The operation of 3-4 circuits should be the reason for changing the tire itself, because by this moment its deterioration exceeds the permissible values.

Especially severe is the wear of chainsaw tires in the part, cutting through which is carried out more often than others. In most cases, it is the bottom of the guide rail. For simultaneous wear of parts, changing the chain, the tire is rotated 180º according to the horizontal axis.

Oil pump adjustment: 1. adjusting screw.

When installing a new chain, install a new main sprocket. Since the period of operation of the sprocket exceeds this parameter for the circuit itself, then 1 sprocket is used for the sequential operation of 2 interchangeable circuits. So the sprocket and chain work out their term almost at the same time.

When a new chain is installed on an asterisk that is no longer suitable for operation, then the wear of the leading links of the chain occurs much faster. For the economical operation of chainsaws, you should always combine the consumption of one guide bar with two chain sprockets and with four saw chains.

If the chainsaw stalls when heated, you should immediately look for the cause of the malfunction.

But take this matter seriously. If there is not enough experience in the field of knowledge of the device of chainsaws, it is better to ask a professional to do this. Have a good repair!

The chainsaw only works on the choke, the saw stalls under load

Husqvarna 365 XP chainsaw. does not work without “suction”

Gray Poets 2012-06-16 18:07

“They made me happy” here with this craft of the Chinese chainsaw, well, and everything is clear from the name. Has anyone communicated with them? How to treat ? The nozzle seemed to be blown, the pump shakes, but at least the feathers. even on a hot one, just because of vibration the suction will open a little. it stalls.

And, is there still a ring between the “exit” of the carburetor and the rubber “elbow”, with a rim in the inner diameter. where should this rim be inserted into the carburetor or into the rubber band?

And another question. there are 2 shlings coming to the carba. one from the gas tank, the other from somewhere in the depths. this one from the depths is why there, what does it do?

Passerby 2012-06-18 11:03 a.m.

On the first.

In my opinion, the reasons may be the following:

1. Is the mixture of maslabenzine normal? Maslitsa not poured?

2. Stalls with open suction. poor mixture. Carb is misaligned. Turn the mixture quality screw to the left. And it’s better to give it to the servicemen.

In the second. the second hose. crankcase ventilation so that there is no pressure.

Father Michael 06/18/2012 11:24

Check the cleanliness of the air filter

three lines 06/18/2012 11:25

The second hose for the operation of the membrane of the gasoline pump.

Wash the crankshaft oil seals trend. See if they are raw.

carrier 06-18-2012 12: 41quote: Originally posted by Gray Poets:

Has anyone talked to them?

Once familiar to Gaster adjusted. quote: Originally posted by Gray Potz:

How to treat ?

It’s easier to throw it away. Not one normal service is taken for repair.

See the connection of the carba with the cylinder for air leaks and the connection with the air filter. You can try to enrich the mixture with a quality screw. If you saw it with a dozen cubes, then most likely the motor has died. The CPG is shitty there.Gray Poets 06/18/2012 16:18

V.G.life 2012-06-18 20:57

I somehow don’t want to disassemble my Chinese chainsaw. Has anyone taken apart? What kind of oil pump for chain lubrication stands? Aperture, gears? Why is he afraid of low-quality oil, such as from a sunflower?

Ursvamp 2012-06-18 21:26

if this is a model of a saw that is sold by gypsies near supermarkets such as “tipapilamizarplatuyd”, then it’s better to throw it away right away.

Pavel_a 06-18-2012 21: 31quote: Originally posted by Passer-by:

In the second. the second hose. crankcase ventilation so that there is no pressure.

Hardly on a two-stroke. The second hose is probably the choke button.

Most likely, air is sucking in somewhere. See the gasket between the carburettor and the cylinder, the crankshaft cuffs and the tightness of the engine housing connection. Start by laying the carburetor.

lelik76 2012-06-19 21:54

So to speak in continuation of the topic.

A neighbor in the country bought a sruk saw, as he was told "German Pro-va."

When filling gasoline, it flowed along the seam of the tank.

The saw started up, but the pressure on the throttle is zero.

One wants to say: “People, do not buy this shit from your hands!”

I attach a photo of a fake under Stihl.

carrier 2012-06-19 22:13

I recognize brother Kolya. (C))))

Pavel_a 2012-06-19 22:32

There is not enough money for a return ticket; buy a good saw.

Husqvarna used to be steamed, now Stihl has appeared.

Although some praise. They say their money is worth (2-3 thousand).

Ziminvlvl 2012-06-27 22:34

judging by the symptoms, air leaks. or between the carb and the cylinder, and (as noted here) through the crankshaft oil seals. or even from a leaky pad.

Gray Poets 2012-07-21 17:20

it’s a shitty decision to fill in 95th fresh gasoline (it was 92nd and old before), now it turns and doesn’t even stall at full throttle, but here’s a new misfortune. how can she put the idle off correctly?

Why the chainsaw stalls, the main reasons.

There are 2 screws at the bottom with springs that go into the carburetor and one slightly above that the throttle lever rests against. How much to twist and in what order?

Pavel_a 2012-07-21 17:57

2 screws with springs. one small gas screw, marked with the letter L, the second full gas screw, marked with the letter H. If there is no marking, then usually the screw that is closer to the engine is L. The third screw is the idle speed adjustment.

It is necessary to start and swallow the saw, to make sure that it does not stall (if possible). Using a small throttle screw, achieve maximum stability and high revolutions. Using the speed control screw, set the normal idle speed. Start sawing something thick, press the throttle lever to the end and use the throttle screw to reach maximum power.

Something like this.

A chainsaw has long been not a luxury, but a necessary tool for anyone who has at least some suburban area. With its help, you can carry out gardening, harvesting firewood, finalizing lumber and much more. There are a lot of chainsaw models on sale, differing in both power and overall quality of performance. You can verify this here. e-katalog.ru.

However, any technique can be moody, and chainsaws are no exception. Consider the most common problems.

The tool stalls immediately after starting

One possible reason is lack of fuel. Check the amount of fuel in the gas tank, and add if necessary. In this case, you should strictly follow the recommendations of the instructions, especially regarding the quality of gasoline and oil. We often ignore such subtleties, refueling the saw as necessary, which causes accelerated engine wear and leads to failures.

Also, the saw may stall due to deterioration of the contact of the spark plug with the high-voltage wire. This can be caused by mechanical shear or carbon deposits. Sometimes it is recommended to periodically replace the candle with a new one, even if the old one did not show any problems in operation.

A chainsaw can work normally, being in a straight horizontal position, but stalls with lateral inclinations. As a rule, this is also associated with a shortage of fuel: the fuel pipe rises when tilted, and if there is little fuel, it rises above the fuel level.

Chainsaw idles

Firstly, it is recommended to check the muffler, as its pollution can lead to deterioration of the exhaust gas output, because of which the engine stops.

If cleaning the muffler did not solve the problem, and the engine of your saw is carbureted, then you can try to configure it. Most engine models have coarse and fine adjustment bolts (H and L, respectively).

Chainsaw adjustment, do-it-yourself repair of common faults

By increasing their speed the engine can eliminate the problem. Keep in mind that adjusting the carburetor is a rather delicate process that requires the use of a tachometer.

Engine does not withstand loads

If the chainsaw stops just in the middle of a particularly thick log, then the problem can be caused by malfunctions in the fuel supply system or problems with the air filter. The engine simply does not receive enough combustible mixture to work with a heavy load, and stops.

The usual solutions to these problems are replacing the fuel in strict accordance with the recommendations in the instructions (we already talked about this) and cleaning (replacing) the air filter.

Chainsaw stalls with increasing speed

The reasons for this phenomenon are similar to the previous ones: either the problem is in the fuel system or in the air filter. Try to disconnect the fuel hose from the carburetor. if gasoline does not flow well (but you know for sure that there is fuel in the tank), then the reason is in the gasoline filter. You can, at the same time, check the fuel pump. fuel should not leak through it. If this happens, then it is advisable to replace the pump.

Tools, equipment and machinery

Recommendations for selection. Operation, repair and maintenance. Faults and solutions.

Stihl MC 250 chainsaw malfunctions

The problem is the following. saw Stihl MS 250 years six in operation. Oil is not supplied to lubricate the chain (it does not depend on air temperature), to be precise, it does not go towards the tire, but at the same time during operation it intensively flows into the hole under the muffler. He cleaned everything, wiped it, but everything remained the same. Tell me, what else can I do?

It happens sometimes. There, under the muffler, initially the plastic plug should stand. For some reason, it is sometimes squeezed out. You can do it, here’s what you need: Socket wrench “8”. remove the muffler. Long tap M6. lengths of about 100 mm, or standard with an extension cord. Screw M6, which is not a good-KO and a nut, respectively. Hacksaw for metal. Tisochki. Here is the technology: 1. Remove the silencer. 2. We remove oil streaks. 3. A small piece of cloth is lowered with a slight interference into the hole so that it can then be removed. Do not score tightly! 4. we cut a 5-6 thread thread in the hole with a M6 tap, clean the chips and remove the cloth from the hole with a hook. 5. cut a piece of thread length 5-6 (or 5-6 millimeters) from the M6 screw, cut a slot for a screwdriver on this piece. the cork is ready. (The aforementioned nut in order to tighten the screw through it and not damage the thread). 6. screw the plug into the hole. Here you need to carefully. it is impossible to screw deeply, otherwise it will block the outlet. You can insert a wire of millimeter 2 diameter into it from the side of the tire mounting and screw the cork up to

touching the wire. 7. put the muffler and check the oil supply.

I bought a Stihl MC 250 chainsaw. A week later I found smudges of black oil in the crankcase attachment, runs out from under the screw, it is on the right, closer to the handle. There are suspicions that the crankcase may not be sealed.

Husqvarna 365 XP chainsaw. does not work without “suction”

Do not worry. outwardly leaks do not occur. Neither streaks, nor similar manifestations. Only by indirect signs. at first a slight increase in power and an increase in maximum revolutions. Then, as leaks increase, problems with idle start, then. problems with starting.

The saw starts and stalls. How to fix?

You need to first remove the fuel filter from the hose in the tank and try to work a little without it. It doesn’t give anything. check the impulse hose. it is not visible well, but you can see it. Using a small flashlight, look into the gap between the top of the fuel tank and the bottom of the carburetor box. the hose should not hang loose. it should be worn on a nipple cast along with the carburetor body

boxes. Sometimes it happens. when the engine claps, it breaks it. If the hose is in place, then more difficult. Shake the right end of the crankshaft. if there is at least a slight backlash, you need to do the diagnosis. The pan fixing screws may be loosened, the oil seal (more often the right one) may be damaged. I can also advise you to rearrange the carburetor with a working saw and try to see if this is the case.

I have a Stihl MS 250 chainsaw, I bought 1.5 years ago, for harvesting firewood. The resource is clear, no more than 4 hours a day, and should you rest during the work? if so, how much? The saw works fall-winter, about 40 m / h per year.

The rest there is simple. you cannot refuel a hot saw, which means that after running out of the fuel tank, you need to take a break to cool down the chainsaw. The break time is not indicated anywhere.

The tool works fine, but it does not start when restarted (i.e. warm). Need to change the candle or wait for it to cool?

There are two options. either nothing to burn or nothing to set fire to. That is, if the filter is clean, then for some reason the suction is not removed in the carburetor during a warm start (and after a cold start it is removed) and the saw does not have enough air or the spark disappears when the candles are heated. Perhaps re-enrichment of the mixture. Try screw L not tighten much. There are 3 screws on the carburetor. T. idle, L. low speed, H. high speed. On the right side of the air filter cover there are holes marked opposite these screws. (screw H is better not to twist).

The Stihl MC 250 chainsaw, has been working for 2 years, but has recently begun to notice. if it has stood for a long time (more than 3 months), then it does not hold when idling or at other times the chain twists at high idle speeds. I’ll work out a tank of gas and everything returns to normal. Where is the problem?

If you do not produce gas from a carburetor, then perhaps this is the reason. Gasoline evaporates the oil remains, the membranes in the carburetor stick. In addition, the fuel mixture deteriorates over time, loses its properties. Even in a canister, the mixture is not recommended to be stored for longer than 2-3 weeks.

I bought this tool. He arrived at the country and started it, tried to cut it. everything is fine. Well, I move the universal lever to the stop position, but it does not stall! In general, he threw off the lid, closed the contact. Can you enlighten me on a device to stop the engine? I saw only one contact on the spring, and the second is stuck in the universal lever itself and there is nothing else! There seems to be some kind of record, but what kind of record?

At the end of the wire is a normal “mother” type contact. It is inserted into the corresponding socket on the lever and the contact spring should touch it when the lever is “off”. There are no intermediate parts. The spring should be on top. It has not so much a contact function as a fixing shaft in different positions.

I’m using a Stihl MS 250 chainsaw. I haven’t started the saw yet, I have no experience, so a few questions. 1. I was surprised by the operation of the brake, or rather, with what sound it turns on, such a sharp, unpleasant click, as much as the whole saw resonates, is this normal? 2. The leading asterisk is all black and red, it should be like all silver-metallic. What does it mean? 3. There was no tire in the box; it was given separately. Was this a reason to beware?

The brake is released with a rather loud click and a shock is felt. There is a powerful spring, there is something to click. The asterisk is not clear, you need to look. The tire and the chain. yes, separately. The main thing is that both of them should be Shtilevskoye.

After the saw warms up, idle disappears, does it stall? If the gas does not discharge, then you can work, as the gas released, it stalls. at the same time it starts up all the time normally, but on the hot one, you have to press the gas to start it, otherwise you can’t start it at idle, tell me what is the problem? I wanted to clarify about idle (spinning chain). I know that in the saw two screws can adjust idle speed. One LA, which the user can twist, the second L. it seems to be desirable to twist on the service, so as not to harm the saw. According to the instructions, the user is allowed to twist these two screws, and only if this does not help, you should contact the service. Should I go into carburetor settings to optimize idle speed? If so, what is the algorithm of actions?

There are three adjusting screws. “H” is not worth turning at all, and the main idle adjustment is better to do “LA”. it is just a throttle retaining screw. The screw “L” is connected with idling, but is more “responsible” for the acceleration of the engine and the transition mode, so it is better not to touch it, if possible. In general, the 250s were distinguished by a “buggy” idle speed. Depending on the year of manufacture and the carburetor model installed, of course, but sometimes it was not possible to achieve normal idle at all. Or too high and twists the chain, or stalls. And sometimes it “swam”. you adjust, it seems, normal and suddenly. once, it accelerates. Or vice versa. it falls. In general, it does not always succeed. So turn down the idle speed “LA”, what happens is what happens.

I work with a MS 250 saw, but after intensive use the saw set became unusable, i.e. both chains are stretched (although in principle they can still be cut if shortened), the bar (40) at the end has burrs outward, and the drive sprocket does not last long left to live. The question arose when, after stretching a chain with a hand on a tire, the chain seemed to stretch, then weaken, as if clinging to something. In general, after using 40, I decided to bet on 35 and the chain is not PM3 but PS (super). Is it worth it?

This is normal during heavy work. The chain stretched. the step increased. The asterisk has worn out. the step has decreased. One plus the other gives a big discrepancy between the steps of the tire and the sprocket, hence the run-up and jerking. I won’t say this to the bus, you have to watch. Cut the burrs, see how the new chain lies on the nose of the tire. If there is a gap between the sheet and the chain links, it is good and the tire will still work. If the chain “creeps along the sheets of the tire in the area of the nose, the tire conditionally developed a resource. In general, they (and not only Shtil) have the following norm: one bus should work with four chains, and two chains with one sprocket. But this is not completely applicable, but only for clean fresh wood. There, just a couple of chains are knocked off when the drive sprocket wears out. On construction works, it can work out 3 or even 4 chains on one sprocket (we blunt more often, we sharpen, respectively, too) And even on disassembling structures and even more so. 4-5 chains on one sprocket is quite real. And according to “Super” Chains. Yes, I recommend it for fresh wood. Saw faster noticeably.

There is a gap at the tip of the tire between the tire web and the chain. That is, as I understand it, you can shorten both chains. But in my opinion it is necessary to shorten a couple of links, and this, as I understand it, is also not good? Even with the replacement of the leading sprocket, I wanted to clarify. how does the crown behave?

I would advise you to shorten it by no more than one leading link. And if the shortened chain is no longer stretched, it is better to throw it away. The step will be too different and nothing good. The cup itself works out with about three to four asterisks. Sometimes more. Only the bearing must be smeared, otherwise on the second. third sprocket it will break the landing. And change the stars in time, and sometimes cups come across, almost cut in half in the center of the sleeve on which the asterisk sits.

About the brake, please tell me. Correctly turn it on before launch. in practice, how critical and necessary is this? And yet. at the beginning of the topic it was written about leaking saw oil during storage of the chainsaw. I also came across this and they told me that to avoid this, you just need to open and close the filler neck so that the air gets there. This is true?

The chain brake is larger for safety reasons, since when starting from the middle position of the lever, the chain immediately rotates. But if you be careful. there is no need for it at startup. I never use it, although the chainsaw is in my hands every day. And the oil on a working saw simply does not flow from anywhere, except from the tire and the recesses in the body and cover. Those few grams will not create problems. And the lid of the oil tank can be opened and closed. it will not be worse.

I have a chainsaw. In the third year of life, at the most unexpected moment, she refused to work. And it looked like this. in the presence of a normal fuel mixture, a working candle, the presence of a spark at first refuses to start, after some attempts it starts, it sharply picks up speed (as if the fuel in the tank is running out) and stalls, after which it does not start for a long time (normal. this is from the first, Well, from the second, well, in the winter from the third jerk of the starter with a suction).

After a long analysis, by repeatedly disassembling, inspecting and collecting found the reason. A “dog” rummaged in the fuel line. The reason is commonplace, storage in a raw unheated shed, so the rubber fuel line cracked. Outwardly, small cracks, the fuel does not flow, so it did not attach importance, but after removing and thoroughly feeling the excesses and blowing it found a hole. I didn’t take the photo, but I show the place on the diagram.

10 malfunctions of a chainsaw that you can fix yourself

Inside, I inserted a shank from a syringe with a volume of 5 cubes and increased it further with a plastic hose. A year of work showed that this was the place of the malfunction leading to setting, i.e. factory, a sharp set of revolutions and a sharp end to the work.

If your unit behaves in a similar way (starts, gains momentum and stalls), we are looking for a place for air leakage, it will not necessarily be the hose itself, it is also worth checking the joints of the hose and the carburetor fitting. If the carburetor is collapsible (in particular, the float chamber is separated from the rest), we pay attention to the gasket, when the air is sucked in, the picture is similar, i.e. it starts up more smoothly and picks up speed, after which it stops, and quite abruptly.

Dear visitor! You are in the archive of the old forum site mastergrad.com

Brakes a chainsaw

recently bought 180 Stihl. drank a couple of times (the day before the second time the fuel mixture was poured) and an unpleasant thing got out. periodically the chain began to slow down. as if the brake turns on, a couple of times the gas is rebuilt and again normal.

maybe someone had something like that?

The chain must be tensioned so that raising the saw by the chain, holding in the middle of the tire, when the saw body is torn off the surface, the tooth of the chain completely comes out of the groove of the tire and rises 1-2 mm above it.

If the chain is normal, lubricate the clutch.

Can the tape brake be deformed? Or the clutch is fooling. Look, the space around the asterisk cup with sawdust, etc. is not clogged. Maybe the chain is pulled?

I did not give a large load. I sawed 4 times in total.

When sawing 3 times after the saw factory, I remove the brake, give gas. and the chain barely spins. I feel that it is slowing down. several times gazanul. like the chain spun everything is normal.

Yesterday I sawed a couple of logs and at the time of sawing (3-4 cuts) the saw began to slow down, up to a stop. he pulled out a saw and played it for about 15. 20 seconds, it felt like the chain was slowing down something jerky. then it all went away.

nothing is clogged with sawdust.

Is it possible to see the clutch and the belt brake yourself / is it difficult?

1-2 mm is not enough, 4-5 mm is normal. It’s easy to look at the tape brake, remove the tire cover, look for what you are looking for around the sprocket cup. steel tape. When the safety lever is pressed, (saw off), the sprocket should rotate freely without touching anything. If sawdust and other forest products are removed between the brake and drum, remove. If the sprocket clearly touches something for some reason. remove it, there either the circlip (the half-washer inserted into the groove on the spindle is removed with a small screwdriver with a straight slot or awl) or the screw with the left thread (turns clockwise), look to see if clutch. The springs in this design are not a hindrance, and the need should not be removed. By the way, check the sprocket on the end of the tire, too, should spin without effort. Check if the chain moves easily along the bus, in the off state, pull the chain several times with your hand, there should be no difficulties either.

as I understand it, the mechanism of work is this:

the clutch has a rigid connection with the engine (the higher the engine speed, the faster it spins). the clutch cams move apart under the action of centrifugal force (the higher the speed, the stronger) and, at a certain speed, clamp the sprocket drum from the inside, and the chain is already spinning from the sprocket.

when the brake is pressed, the steel strip clamps and stops the sprocket drum from the outside. the chain stops, the engine continues to work (already under load), the clutch continues to spin and grinds the sprocket drum from the inside.

when the revolutions are reset, the clutch cams are pulled by the springs and the clutch spins into idle without touching the sprocket drum.

Everything is okay. not a lot of dirt. nothing prevents anything. everything is moving, spinning. the springs in place, the cams of the clutch mechanism with a screwdriver to move.

cleared everything, blew. what is all the same the problem did not understand.