Chainsaw Tension Screw Not Working? Here’s What You Need to Do. Chainsaw chain adjustment

How to Adjust Pole Saw Chain Tension

The pole saw is a great tool for pruning tree branches in your garden.

But to get the best performance and safety, you need to keep the chain tension well-adjusted as part of its maintenance.

The pole saw uses a chainsaw attached to its end. So the concept is the same whether you use a pole saw or a chainsaw.

You can read more about some good pole saw options available for your garden needs.

Why it’s important to adjust the chain tension?

The pole saw has a chainsaw attached to one end. The bar and chain need to have the right amount of tension.

If the chain is too loose, the performance of the pole saw will suffer. And you risk injuring yourself as well.

Kickback is a situation that can occur when using a chainsaw. This happens when the tip of the chainsaw touches the branch.

The saw flings towards your body and can result in a serious injury. A loose chain increases the chances of such kickback happening.

The loose chain may result in the chain flying off the guide bar. This is a serious issue as it may end up hitting someone and causing serious injury.

Chainsaw Chain Tension Adjustment

The loose chain also causes slanted cuts. You’ll need to put force when trying to cut the branches. And end up damaging the pole chainsaw.

Having the bar and chain too tight also has it’s set of problems.

A tight chain will prevent the guide bar from moving efficiently and impact the performance.

It will increase the risk of heating up the chain and causing sparks that result in a fire hazard.

All such issues reduce the life of the bar, chain, and other parts of your pole saw. This causes a lot of stress on the guide bar nose and drive sprocket. And damages the clutch and bearings of the chainsaw.

A tight chain causes the chainsaw to consume a lot more oil. And if there’s no oil while pruning branches, it compounds the problem causing even more heating issues.

Difference between good and bad tension

You need to make sure the tension is just right. It should not be too tight nor too loose.

The best way to know this is to pull the chain from the guide bar and see how much the drive links separate.

They should separate just a little bit from the bar. But not so much that the drive links dislodge out of the bar rails.

Safety precautions before adjusting the chain tension

Make sure that the pole saw is turned off before you try to adjust the tension. Otherwise, you risk serious injury if the saw turns on.

It’s good to let the chain cool down before you attempt to adjust the chain tension. A hot chain tends to expand and it will not adjust correctly.

You should wear safety gloves to protect your hands from getting cuts while handling the chain.

It’s good if you can clean the guide bar with a putty knife. This helps remove the gunk in the groove where the chain sits. It helps you get the best tension adjustment.

How to adjust the chain tension

There are different manufacturers selling a variety of pole saws. And each of them may have a difference in the design.

Some pole saws might come with an auto tension adjustment system as well.

You should read the manual provided with your chainsaw to know the exact steps. However, the basics of adjusting chain tension are the same.

Find the tension adjustment screw

The common location for the tension adjustment screw is on the side. This could be visible or just under the side cover.

You may need to take the side cover off by removing some screws. Or there might be an easy release knob in some models.

Loosen the guide bar

You may need to loosen the chain tensioning pin that connects the guide bar to the chainsaw. This gives you better positioning to adjust the tension.

You may need to loosen a few nuts on the side panel to do this.

Till you’ve adjusted the tension and tightened the nuts back, keep holding the bar tip.

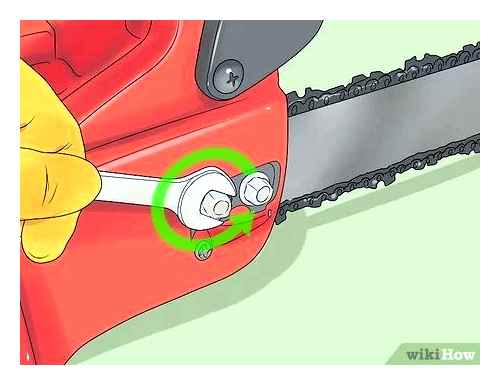

Turn the adjustment screw

To adjust the chainsaw chain tension, you’ll need to use a screwdriver. Many pole saws and chainsaws come with a screwdriver/wrench in the package.

Depending on your model, turning the tensioning screw clockwise will tighten the chain tension.

And turning the tensioning screw counterclockwise will loosen the chainsaw chain tension.

Keep turning the tensioning screw till you get the desired tension. You know this when the chain is not hanging down. It should sit into the guide bar.

Pull the chainsaw chain

To check the tension, you can pull the chain in the direction away from the chainsaw. It should move freely along the guide bar.

There should be no large gap between the drive links and the bar as you pull the chain. But it should be loose enough that you can pull the chain a little away from the bar.

You’ll know the proper chain tension by pulling the chain and testing it.

Just pull the chain at the underside of the guide bar till the links are away from the bar and then release.

They should fit right back into the bar without getting the chain loose.

Frequently Asked Questions

How much tension should be on a pole chainsaw chain?

A pole chainsaw should be tightened so that the drive links sit comfortably on the guide bar. But should be loose enough that you can pull the chain a little away from the bar.

Why does my pole chainsaw keep coming off?

The pole chainsaw chain may keep coming off because the tension is too loose. It may also come off if the chain is damaged.

Can a pole chainsaw chain be backward?

No. The chainsaw chain can only cut in the right direction. The chainsaw rotates in the clockwise direction. So the chain cutting edges should face away from the engine.

Why do pole chainsaw chains stretch?

The pole chainsaw chain may stretch if it becomes too hot. This could be due to insufficient chain oil in the reservoir. Or sufficient oil is not reaching the chain during cutting. If the chainsaw is new, the chain may stretch when used for the first few times.

Why won’t my chainsaw chain tighten?

You need to loosen the guide bar before you try to tighten the chainsaw. There are nuts on the side that hold the guide bar. And you need to use the wrench to loosen them. You will then be able to tighten the chainsaw chain with the tension adjustment screw.

About Me

Hi. I’m Kevin, gardener, author, and content creator. I’m certified in Home Horticulture and Organic Gardening.

Welcome to my website where I write about growing your own organic food in a limited space.

You’ll find useful information here whether you’re growing vegetables in an apartment, patio, or a raised bed.

Chainsaw Tension Screw Not Working? Here’s What You Need to Do

The tension screw on the chainsaw can sometimes malfunction and cause difficulty in loosening or tightening the chain tension as required.

The most common reasons behind your chainsaw tension screw not working like usual are:

- Faulty or damaged tension screw

- Incorrect set up of the tension screw

- When the chainsaw is frequently exposed to aggressive or abusive cutting jobs

- Overtime internal parts including tensioner screw can malfunction

Keep reading the following article to learn what to do when the chainsaw tension screw not working properly.

Why is My Chainsaw Tension Screw Not Working?

It is another common complaint against any modern chainsaw regardless of the brand.

You might occasionally notice that when you try to turn the tension screw on your chainsaw to adjust the bar or to tension the chain, the screw won’t work.

HAISHINE Pack of 2 Chain Adjuster Tensioner Screw for Husqvarna 42 44 50 51 55 Rancher 234 238 242 246 133 444 Chainsaw 501537101, 501 54 63 01

It might occur because the tension screw is faulty or damaged which mostly happens if your chainsaw has been exposed to aggressive cutting projects regularly for a long time.

How to Tension Your Chain on Your Stihl Chainsaw

Remember, internal elements or parts of the chainsaw, including tensioning screws, can turn bad due to overuse. Especially if you are a reckless user and do not perform regular maintenance of your chainsaw accordingly, such commotion will arise soon.

Another common scenario is where users sometimes notice tension screw clicking while rotating that screw. That is another sign that the screw is either damaged or stripped.

Over time the chainsaw and its major components turn older and rot. So, that will also result in the tension screw deteriorating.

A chainsaw can accidentally hit a stone, nail, rock, or other similar objects on the way, and these external objects can break some teeth on your chainsaw. It is another typical reason why chainsaw sometimes starts cutting in a curve.

Replace the Chainsaw Tension Screw with Just 7 Simple Steps:

If your chainsaw tension screw is not working, replacing it is the only effective solution to fix this trouble. Here are the 7 simple steps to replace the existing tension screw quickly.

So, read and follow the instructions thoroughly without skipping any details:

Tools Needed to Replace Your Chainsaw Tension Screw:

| Tools |

| New Tension Screw |

| A Bar Wrench |

| A Screwdriver |

| A Pair of Pliers |

| Pair of Protective googles Safety Gloves |

Step 1- Make sure your chainsaw has cooled off to Remove the top cover:

Before starting the procedures, ensure that the engine of your chainsaw has cooled down properly.

Next, release the top clips securely holding your chainsaw’s top cover to lift the top cover off.

Step 2- Detach the wire boot from the spark plug:

Now disconnect the wire and boot from the spark plug to prevent your chainsaw from accidentally starting during the replacement task.

Step 3- Remove the clutch cover tension bracket screw:

First, use a wrench or screwdriver to loosen the nuts that securely hold the clutch cover and remove them.

Carefully pull the clutch cover off and put it on a sturdy surface.

Step 4- Lift the Adjustment Assembly out of the way:

Now you can see the tension bracket screw there, so use a screwdriver to remove the bracket screw.

Next, carefully lift the adjustment assembly out.

Step 5- Remove the old tension screw install the new one:

Use a pair of pliers to lift out the old tension screw.

Then, bring the new Tension Screw and insert it into the cover.

Step 6- Reinstall the Assembly Clutch Cover Securely:

Ensure the bracket is in place before reinstalling the adjustment assembly in that clutch cover.

Now, secure that assembly with the screw and reinsert the clutch cover on your chainsaw.

While you are still on this, you can also replace the clutch cover if the Clutch Cover looks cracked, deteriorated, or damaged.

Step 7- Align the tensioner to put everything else back together:

Rotate the tension adjustment screw counterclockwise to align the tensioner with the clutch cover in place.

Then, reinsert the nuts and hand-tighten them first.

Now lift the bar and rotate the adjusting screw clockwise until there is no slack remaining in the chain.

When the adjustment is done the chain bar will look like this and use the wrench to tighten those nuts fully.

Then, attach the wire and boot to the spark plug. After that, realign the top cover and secure it with the top clips.

Why Causes the Chain on my Chainsaw Stretch so Fast?

Sometimes users notice that the chain on their chainsaws suddenly starts to stretch too fast, and there’s a reason behind this commotion.

Mainly chain stretching issue arises due to extremely generated friction during cutting the wood turns the chain on your chainsaw superheated. This additional heat gradually causes the chain to loosen up faster than usual.

This generated heat also expands the chain guide bar, and as it cools off, the chain turns stretched. The chain can also stretch when it eventually wears down due to aggressive use or overuse.

Frequently Asked Questions (FAQs)

Why the chain on my chainsaw fails to tighten?

Mostly you will encounter such a commotion due to excess built-up debris around the chain bar and worn or bent bar on your chainsaw.A similar problem will also arise if the chain oiler on your chainsaw is not in proper order or if there are some broken teeth on the chain.

What causing the chain on my chainsaw keep going loose?

This mostly happens when the axle or chain tensioning bolts have come loose and are not tight enough. Besides that, the chain can also keep coming loose due to worn teeth on either the front or rear sprocket (or on both sprockets).

How often should I tighten my chainsaw’s chain?

It will depend on how frequently you use the chainsaw. But if you use the chainsaw for a typical afternoon cutting session, tighten the chain at least 2 or 3 times.

Final Verdict

While using any modern chainsaw, users can sometimes witness a situation where they will notice that no matter whether they try to loosen or tighten the chain tension adjuster screw, the screw will not rotate or work.

Fortunately, there’s no need to get panic as soon you encounter such a situation because the easiest solution to fixing this problem is replacing the tension screw, and the replacement procedure is simpler too.

All you have to do is, follow the earlier discussed instructions thoroughly.

Oregon 3-Pack S56 AdvanceCut Chainsaw Chains for 16-Inch Bar.56 Drive Links – low-kickback chain fits Husqvarna, Echo, Poulan, Wen and more

ENGINERUN Chainsaw Chain Tensioner Adjuster Screw Assembly Compatible with STIHL MS271 MS291 MS311 MS391 029 039 Replaces OEM Parts 1127-007-1003, 1127-640-1900, 1123-664-1400, 1127-664-2200

How Tight Should A Chainsaw Chain Be: All You Need to Know

If you want the best performance from your chainsaw for cutting trees. you will need to keep it always sharp and properly maintained. That is why you should always i nspect its cutting chain tension. Correct tensioning protects you from getting injured while cutting.

It also enhances the cutting quality and improves the chain’s lifespan.

That said, the proper tension or tightness level is unknown to all users. If you want to know more about how tight a chainsaw chain should be, keep reading this post. We’ll help you understand everything related to cutting chains’ tightness.

The Importance of the Right Tension

It is always important to check the chain tightness before you operate the machine. Correct chainsaw chain tightness is a significant safety factor. Also, it is mandatory for the efficient operation of the machine.

Every time you operate your chainsaw, its chain is likely to stretch and become loose. Any cutting chain that becomes sagging or too slack should be replaced. Typically, a loose chain won’t cut. importantly, it can free itself from the bar and jeopardize your safety.

A too-tight cutting chain, on the other hand, will not provide efficient cutting. accurately, it won’t cut wood at all. It will eventually damage the bar. A too-tight chain will stress the bar and sprocket more, eventually causing them to wear out.

You can rely on the chain’s drive links to determine whether to readjust the tightness. You can perform this test whenever you want to ensure the correct tightness. Pull the links from the chainsaw guide bar

If they do not easily get pulled away from the bar, the chain is not tight enough. If you pull the chain and the links are unengaged, it is time for tensioning.

How to Measure Chain Tension

Chainsaws do not include gauges that can give a sign of correct tension. However, measuring the tightness is not a challenging task. Measuring the chain tension does not require any special tools. You can use a finger to pull the chain from the bar. If it sags, it is loose.

If the chain holds itself too tightly to the bar, it needs a bit of loosening. A general rule of thumb to measure the proper tension is that the chain should move only 1/4 inch away from the bar. Otherwise, you will need to manipulate the adjustment screw s.

Adjusting Chain Tension

As you already know, chainsaws come from manufacturers such as Husqvarna, STIHL, and Echo. They come with different power options. So, there are gas-powered, battery-powered, and electric chainsaws. However, all these different types and brands can be tightened similarly. Here are the steps for successful tension adjustment:

1. Find the Tensioning screw

In some models, tension screws are between their bars and felling dogs. However, this screw is found outside the bar’s cover in most models. accurately, you will find it positioned between the nuts on the cover of the guide bar.

2. Loosen the Guide Bar nuts

If you need to know which nuts to work on, you should aim for those securing the bar. In some models, there is only one bolt holding the bar. However, in other models, these screws can be two or three.

You should not remove these nuts. but make them slightly loose. This step gives the bar room to move while trying to reach the proper chain tension.

To loosen these bolts, you can use a scrench. It is an essential tool for maintaining any chainsaw. It is a combination of a flathead screwdriver and two wrench socket s. Make sure that you are using the socket end for this purpose.

Readjust the Tension level

Find the tensioning pin and manipulate it a bit. This chain tightener is, in fact, flat-headed, so you will need to use the screw end of the wrench. Before adjusting the tightness, it is mandatory to keep the tip of the guide bar nose up.

This helps reach the correct adjustment even when the bar moves up slightly. Otherwise, the chain will sag once the chainsaw starts cutting. So, do not release this tip until you finish the adjustment.

Then, turn the pin clockwise until the chain is adequately tight. You will know when the moment comes because you will find the chain holding itself against the chainsaw blade. Lastly, you will retighten the chain tension bolt and cover nuts.

If you follow these steps correctly, you will efficiently and quickly adjust the tension of any chainsaw. You will need to repeat this routine every three hours of operation.

Safety Precautions while Adjusting the Chain tension

As you might have guessed by now, adjusting the tension of your chain is manageable. However, it is risky, like dealing with any part of this heavy-duty machine. To avoid the risk of injury, you should keep these considerations in mind:

1. Wear your PPE

When you come into contact with your chainsaw, wear your protective equipment. However, it would be best to pay attention to wearing thick hand mitts when handling the chain. The chain is sharp, and the cutting risk is not underestimated.

2. Make sure the machine is Turned off

It is not safe to adjust the chain when the machine is running. Even if the chainsaw is idle, it is still dangerous. So, the engine should remain shut off. Also, corded chainsaws should not stay connected to their power sources.

3. Clean the Blade

The blade, during cutting, can get jammed with dirt or greasy deposits. In general, a lack of bar cleanliness will weaken the effect of bar chain oil. So, it is highly recommended to clean it before adjusting the tension. This step increases the chain’s safety, as it won’t sag easily. Also, it will help the chain settle in the correct position.

4. Do not operate on a Hot machine

While it is recommended to readjust the chain after each use, it is not right to do so when the machine is hot. A hot chainsaw will have a hot chain. The chain is made of metals and adheres to the heat expansion rule. So, give it a chance to cool down before making any adjustments.

Routine chain adjustment is relatively easy, but only some are comfortable or skilled enough. If you feel the same way about doing this routine, it is always better to seek the help of a professional service. At least for the first couple of times, until you are familiar with the process.

Conclusion

Tightening a chainsaw chain is not an extra activity. It is necessary for keeping the machine in shape. It is also required for maintaining the users safe. You will have to readjust the chain’s tension whenever it is too tight or loose.

It is too tight when the chain is stuck to the chain. When it is saggy and looks very loose. adequate tightening is necessary.

In general, you will have to check the condition of the chain after each session. However, shorter sessions won’t count. It is recommended to c heck the chain after three or four hours of operation. By doing so, you will make your chain cut sharply and powerfully. You will also reduce the chances of getting injured.

How to Tighten Chainsaw Chain in 4 Easy Steps? A 2023 Guide

Being one of the essential yet handy tools, chainsaw holds a vital position in every household. It not only helps in the fast cutting of trees and instant trimming of unwanted branches, but it also aids in cutting plastic pipes, shrubs, scrap wood, metal sheets and many more.

That said, this tool’s only downside is that its chain starts to lose a bit after a few hours of use, sagging away from the bar. This condition is hazardous as it can harm the user by jumping off the bar.

Thus, it is recommended to always double-check the chain every time you use the tool and tighten it whenever necessary. But wait, you don’t know how to do that? Well! If yes, then look no further as we have got your back.

This article will let you know the complete process on how to tighten chainsaw chain along with all of the other essential information.

So without any further due, let us dig into the article.

What Causes a Chainsaw Chain Tension to Lose?

Before we start discussing the tightening process, it’s better to understand the reasons that can cause your chainsaw to lose its chain. These reasons will also aid you in preventing the chainsaw chain from loose in the future as well. Have a look

The Chain Is Not Properly Set

The improper setting is the foremost reason that may cause a chain to lose after every few minutes. Thus get it examined by a nearby tool shop to ensure that it is correctly placed.

It Is Overtightened

Another common reason that may cause the chain to jump off the bar is that one may have overtightened it.

over, an overtightened chain impacts handlers negatively, which results in losing the chain. As a result, you get a more unsafe chainsaw user experience. And the situation is even worse if it is used at high speed.

Temperature Fluctuation

Surprisingly, temperature fluctuations also affect the chainsaw by losing or tightening its chain.

Steps About How to Tighten Chainsaw Chain?

Based on any of the above reasons, a gas chainsaw may result in an untightened chain. Thus here is the step-by-step guide to tension the chainsaw chain.

Step 1: Locate the tension points.

Firstly, mark the chain tension adjustment points on your chainsaw. Some common spots include the side cover and the front of the machine. Remember, adjustment points on some models are housed under the side cover release knob.

Step 2: Revolve the tension screws.

Rotate the adjustment screws clockwise to loosen them. It is one of the crucial steps of the whole process as it creates space for the chain and guide bar to ensure easy adjustment.

For some models, you may find the chainsaw brakes attached directly to the side panel. So, do not forget to unlock them prior to removing the side panel.

Step 3: Adjust the tensioning screws.

Now, this is the game-changing step. You will find some screws located on the side of chainsaw guide bars. These are called “Tension Adjustment Screws.” Tightening them will tighten the chain, and loosening them will loosen the chain.

Hence, adjust the tightness of the screws according to the need of your battery chainsaw machine. Also, double-check it before moving further to avoid any unease in the long run.

Step 4: Tighten the guide bar side panel nuts.

Last but not least, tighten up the nuts and secure the side panel along with the guide bar to reassemble the chainsaw.

Nevertheless, don’t forget to lift the nose of the chainsaw while tightening the nuts. And Voila! You have just completed the procedure of chain tightening.

Frequently Asked Questions

How Would I Know If My Chainsaw Chain Had Stretched?

You can know the case through a simple process. Switch off the chainsaw, place it on the table and let it cool completely. Now, check for a noticeable space between the chainsaw’s guide bar and the chain.

If you see any space, it means that your chainsaw chain has stretched and needs a little bit of repair.

Can I Prevent My Chainsaw chain From Stretching?

The simple answer to this question is “NO.” unfortunately, there is no way you can prevent your chainsaw chain from stretching. Yet, you can extend the period between each stretch by handling it with care and investing a little bit of time and amount on its regular maintenance.

How Much Slack Should A Chainsaw Chain Have?

An efficiently tensioned chainsaw must allow you to only move it up and down for half an inch. over, it should be a little bit lose on the chainsaw sidebar but extremely tight to the point that you can pull the drive links out of the bar nose.

In case you observe more slack in between, then the chainsaw chain has loosened, and you need to tighten it a bit. On the other hand, if there is no slack in between, it’s a sign that your chainsaw chain is unnecessarily tight and that you should loosen it.

A tightened chain does not tend to work with ease. Whereas an overtighten chain can break at any time. Thus always ensure to keep the chainsaw chain at the right adjustment.

Why Won’t My Chainsaw Chain Tighten?

If you cannot tighten your chainsaw’s chain, it means that you are not accurately implementing the procedure. Thus go back to the starting point, read out the procedure carefully and implement it again.

Final Takeaways: How to Tighten Chainsaw Chain?

In a nutshell, a chainsaw is a cardinal tool to own. It serves in simplifying one’s life up to a certain extent. However, chainsaw chains often tend to lose a bit. Thus you may need to tighten it after every few uses.

Tightening a chainsaw chain seems to be a complicated task. However, in all, it’s not. Instead, it is fairly a simple process which we have mentioned above for your ease. Thus, please read it and implement it to rest assure methodical functioning of chainsaw. Rest, we wish you a stroke of good luck.

Richard McMann

Richard lives out in the wild with his other half, Diana Richard. He tests chainsaws based on his personal experience and loves to share their nitty gritty details with his audience. Although Richard does FOCUS on other home improvement tools, his FOCUS remains on cutting fallen trees or maintaining his backyard via chainsaw tools. He pledges to come up with new knowledge about chainsaws every once in a while.