Checking Ignition Coil Chainsaw with a Multimeter

We continue the topic of chainsaw repairs and today we will study malfunctions of the ignition unit.

I want to remind readers of the blog that we are primarily concerned with issues related to instrument malfunctions that arose during work on the cutting area. How to be a lumberjack when his main tool stopped working when felling, bucking or pruning?

I must say right away that in the field it is impossible to repair the ignition module. only a replacement for a new part! The only solution to the problem is to have a spare ignition module with you. With a high degree of probability, I assume that you will respond to this statement negatively, to put it mildly, with a slight irony. "What nonsense, buy an ignition module and carry it with you!". But, once again I remind you that this article is for lumberjacks, many of whom work on a shift. First of all, this problem is relevant for "logger-kalymshchikov" who work with their own tool and negotiated with the employer the conditions, indicating the fact that the tool and repairs at their own expense. Such details of the contract may be included in the calculation of the piece rate for the work, therefore, in the case of force majeure, they can have a different effect on the result of such a “Partnership”.

Nevertheless, I propose to consider issues related to malfunction of ignition of a chainsaw in order to be able to at least diagnose this breakdown. As for the other parts of the ignition. magneto (I mean the flywheel), armored wire, candle, the malfunction can be eliminated directly by the lumberjack

A little about contact and electronic ignition

When I started working in the leshoz, in the late 90s, we fell down the old Urals, and mowed Huskvarna 262. The forest was solid, so the buckler only managed to divide the whips into ridges an endless stream of bundles. Ignition in the Urals was no longer fist (contact), but electronic. By the way, for beginner lumberjacks, who did not encounter contact ignition, but who are interested, I want to briefly clarify the old form of ignition.

The cam contact ignition on old models of chainsaws ("Friendship", "Ural") was simple, and most importantly, it had no electronics (various electronic circuit boards) in its design. The "cams" worked as a breaker, and a high-voltage coil supplied current. Any experienced person could fix the ignition problem at that time. lumberjack for short working hours. However, the ignition was too often “covered”. The disadvantage of cam ignition was the “open” spark, which negatively affected the metal contacts themselves. over time they were covered with soot, the layer of which grew and the spark worsened and disappeared. I had to clean the contacts, set the gap again. Another argument against cam ignition is a larger size and more weight than electronic (this comparison is relevant for modern gearless saws).

Electronic ignition, in turn, is a module, which includes not only the coil, but also the electronic board. On the first Urals with electronic ignition, as far as I remember, the electronic board was filled with mica (epoxy), which, in case of repair, was melted and the board was removed. Later they began to use sealant. Although it is difficult to call a board, since these are separate radio components. a triac, diodes, a capacitor, a resistor. There were two coils. high-voltage and low-voltage, which were located against each other. Under the low-voltage coil was still an additional coil (spark), which "carved a spark." Honestly, we never repaired electronic ignition in the Urals and handed over to the local wood processing complex to the electromechanical workshop, where we were resuscitated to it in a short time.

Modern chainsaw ignition

Ignition, on modern gearless chainsaws, is a module, which includes a coil, the electronic board is a transistor type. The ignition system (non-electronic part) includes a flywheel with magnets (magneto), a glow plug, an armored wire (high voltage wire).

What is inside the ignition module?

Perhaps someone watched videos on video hosting and watched the module in the context. I bring the frames for viewing from this video below.

This is how the ignition coil looks in a half-sawed module

On the other side of the coil there is an electronic board, intensively filled with sealant

Most likely, you can “ring” a board and a coil in a module. This requires a “manual." electrical diagram of a specific model of chainsaw. But this procedure will only help to find out the "diagnosis", confirm the functionality of the module or the lack thereof. It is impossible to repair such a module on your own, as you understand, both in field or field conditions, and in services.

Therefore, we, lumberjacks, must first of all be able to find a malfunction in the ignition. if it comes down to a breakdown of the module, then it should be replaced. If the malfunction is diagnosed in other parts of the ignition, we eliminate them. It is possible to check the malfunction of the ignition module without its “ringing”.

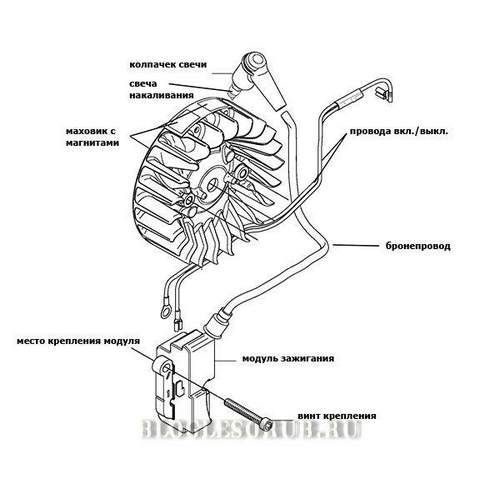

The main parts of the ignition of a chainsaw

We proceed directly to the main ignition units of a gearless chainsaw. I will list the parts of the ignition system:

- Flywheel with magnets (magneto)

- Ignition module

- Spark plug

- Armored wire (high voltage wire)

- Short circuit wires (on-off)

What is a flywheel? For beginner lumberjacks, I will explain that visually it resembles a huge (precisely in a chainsaw) gear-fan made of duralumin, the blades of which, during rotation, play, first of all, the role of engine cooling. A flywheel is installed on the left side of the chainsaw, right behind the starter cover. The flywheel is mounted by landing on the crankshaft with a key and on two studs. A thread is cut at the end of the shaft to fix the flywheel with a nut. This nut must be tightly tightened when installing the flywheel, otherwise it may cut off the key, which eliminates backlash. By the way, the key is located on the crankshaft so that when the magnets correspond to the core of the ignition module, the piston was at the appropriate level (top dead center) for cutting the spark and igniting the fuel.

From the end of the flywheel, among the blades, massive magnets with different north-south polarity are installed. As a rule, two magnets are installed, but on some models of chainsaws there may be more of them. Opposite them, on the other side of the flywheel, counterweights are installed for uniform rotation.

Massive magnets with different north-south polarity, which create a magnetic field when the flywheel rotates

A ignition module is installed near a magneto (flywheel) at a certain distance (gap) (a coil with an electronic board in a polymer or textolite “shirt” on a plate metal core, which also serves as a mount to the saw body). The ignition module can be installed from different sides. to the right of the magneto (flywheel), to the left or top. depends on the model of the chainsaw.

Video: Checking Ignition Coil Chainsaw with a Multimeter

Husqvarna ignition module with high voltage wire

On-off wires (breaker) and a cable (armored wire) are mounted from the module (coil), mounted in the cap, where the glow plug is inserted. The on-off wires have a small cross section, in contrast to the candle cable, along which high voltage moves. The candle has a lateral and central electrode, a housing and, accordingly, an insulator. A candle is screwed into the cylinder head and transmits a spark to ignite the fuel mixture in the internal combustion engine.

Work of ignition of a chainsaw

We will learn how electronic ignition works on a modern gearless chainsaw.

When the operator makes a jerk of the starter, the ratchet engages with the “dogs” on the flywheel, bringing it into rotation with the crankshaft. The magnets on the flywheel, passing the rotation, act on the iron plate core of the ignition module. This effect is a magnetic field. Due to the magnetic field, the low-voltage winding in the coil forms an electromotive force and transfers a high voltage to the cable through the high-voltage winding. The electronic board in the module is configured to generate a certain frequency of voltage, necessary for this particular model of chainsaw, or to be more precise, all the characteristics of the internal combustion engine.

The converted high voltage is supplied by the module through the cable to the glow plug, where a spark is cut out between the electrodes. The spark, as we know, ignites the fuel mixture and drives the piston, the internal combustion engine and, accordingly, the operation of the entire tool.

Ignition troubleshooting

It is very important for a lumberjack to make a correct diagnosis when his sawing tool begins to “mope” or “falls into a coma”. This, I repeat again, is extremely important, because the consequences of an incorrect diagnosis can lead to unreasonable expenses, wasted time and even nervous breakdowns.

The fact is that inexperienced lumberjacks are often associated with the failure of a chainsaw with a carburetor malfunction. Indeed, in wet or snowy weather with intensive work in the cutting area, some signs of a chainsaw failure with a carburetor malfunction can be correlated. If at the same time the “vagaries” of the carburetor were systematically observed, the prerequisites for a fault diagnosis error only increase. The operator begins to unsuccessfully adjust the carburetor, clean, blow and dry it. Even worse, if he is convinced of his innocence and decides to purchase a new carburetor. But by the way, a spare carburetor will not be superfluous)).

To immediately avoid such a mistake, you just need to check the spark on the candle. In general, in order to exclude any malfunction in the ignition system, it is necessary to start with checking the spark on the candle. Trite and simple! But for some reason, some lumberjacks began to ignore such a procedure and climb into the carburetor. Though…

How to check a candle

It is not worth eliminating a malfunction of the glow plug itself. Nowadays, there are a lot of falsified fuel for chainsaws. A low-quality mixture directly affects the "lifespan" of a glow plug.

We unscrew the glow plug from the engine and carefully examine it. if it is wet, then it is poured with the fuel mixture and, indeed, the carburetor may be the cause of the malfunction. If the candle is dry, then it is necessary to check for a spark. The defective candle should immediately be removed and replaced with a known-good candle.

Visually, a candle defect can be guessed by the following signs:

- layering or deposits (slag, varnish) on the electrodes;

- heterogeneous color and shape of the electrodes;

- carbon black plaque, oily plaque;

- molten central electrode;

First, make sure that the ignition key, when checking, is on. Exactly. It happens that the operator, drowning intermittently working saw, begins to check the spark plug on the ignition off.

The unscrewed (working) glow plug, without removing from the cap, must be threaded (with a "skirt") or with the side electrode directly to the cylinder. Contact must be reliable! Holding the candle by the cap with one hand, with the other hand we make a jerk of the starter and observe the presence of a spark on the candle between the electrodes.

High voltage wire

With proper ignition, there is either a spark or it does not exist at all. If the spark is weak, then the fault should be sought in the candle itself, or in the power cable (armored wire. high voltage wire). In rare cases, if a weak spark of a candle is observed with repeated replacements of serviceable candles, then a malfunction is still present in the ignition module. In this case, when the tool is operating, the faulty module heats up.

It is very rare, but it happens that a high-voltage wire is broken (from personal experience), in the case of mechanical stress and in case of overheating. A spark from a damaged cable breaks through to ground (per cylinder). a short circuit occurs and engine operation stops due to lack of ignition. In this case, it (armored wire) must be replaced. How to check the serviceability of the wire? Only a temporary replacement. an analogue from another working chainsaw. Or a barbaric way for your health. to hold the wire with your fingers when checking. I hope that the lumberjack has enough "intelligence", and he does not, therefore, begin to check the serviceability of the cable.

By the way, if the cap is broken (breaks through), then when checking the spark on the candle, when you hold the cap with your fingers, the malfunction will be revealed immediately)). Such a breakdown of the candle cap is usually detected in wet weather.

It also happens that the cap of the candle is not broken, but the malfunction is contained inside the cap. poor-quality (or lack thereof) connection of the cable with the landing spring, on which the glow plug is mounted. The cause of such a malfunction is the negligence of the user of the tool, which often pulls the cable from the candle, avoiding careful removal.

Ignition wires

Usually the wires for turning on / off the ignition are paired. one to ground, the other from the coil to the Stop-Start button. When they are closed, the ignition disappears and the chainsaw stalls. Although the wire may be one.

In my practice (experience) this wire was damaged.

How did this happen?

Because of his negligence and inexperience. When installing the starter, on Huskvarnaya, I did not lay the wire in the landing grooves on the deflector and it lay on the edges of the grooves. When I fixed the lid, the wire “crushed” these edges against the lid. The wire insulation was damaged, although the wire strands remained intact. What happened in the end?

The chainsaw actually worked properly. She will work. Even if the cores of the wires break completely, the tool (ignition) will work, however, the chainsaw will not turn off. But if the wires damaged in the insulation (the ends going to the module) are closed together (or a single wire about the “mass”), then the ignition will disappear and the tool will not work, it will not start.

Need for ignition adjustment

If it turns out that the fault is still in the module, then it is necessary to check the gap between the coil (core) and the flywheel (magnets). In the event that the gap does not meet the necessary parameters, then it is knocked down.

It should be understood that ignition alone, on imported direct-powered chainsaws, cannot go astray by itself. If this happened, then your tool is counterfeit, or you ran into a marriage!

The problem lies in the screw clamps, with which the ignition module is fixed. To be more precise. in their absence. What it is?

The ignition module is secured with screws. A chainsaw vibrates during operation, and vibration affects all parts of the structure, all components. The gap between the magneto must be constant and appropriate. The screws (seat) of the fastening of the ignition module must be “sealed” with a special clamp. a viscous substance of various consistencies. In the case of ignition of a chainsaw, the lock should be of a strong consistency. The latch, in fact, is a gasket, a seal, which eliminates the weakening of the fasteners. screws.

To troubleshoot, you must:

- to turn out screws of fastening of the module;

- to fix the fixing holes of the screws with the clamp;

- screw the screws back;

- set the gap;

- tighten the screws that secure the module.

Another case when it is necessary to set the ignition is to replace the faulty module with a new one. How the ignition is set, we will consider in the next chapter.

How to set the ignition

I myself have never replaced the ignition module or set the clearance. Although there was a malfunction in the module. at work it was covered at me more than once. The fault was fixed in the service.

However, as you know, there are a lot of videos and article notes on the network on how to replace and set the ignition on gearless chainsaws. Well, we will use these recommendations.

In our case, when a malfunction is detected in the cutting area, replacing the magneto and adjusting the ignition is relevant only when there is a working module in stock and a screw lock. With a high degree of probability, I can suspect that such an option is excluded, although among prudent "covens", "it may even be very possible."

If the repair “suffers”, the ignition was purchased after the “trouble” and not on the watch, then it is advisable to entrust the repair to a specialist in the service center. If you have the time and need for savings, then we make repairs on our own.

First of all, remove (disconnect the connectors) from the wire module. high-voltage cable, start wires. We unscrew the fastening screws (usually two of them) and remove the defective coil.

In its place, we install a new serviceable ignition module. We connect all the wires, use a screw clamp in the threaded mounting holes, bait fastening screws.

Now we need to set the necessary clearance. Turn the handwheel with magnets to the core fragments of the coil. Between the magnets and the ends of the core we install a probe 0.2-0.4 mm thick (check in the “manual” for your saw model). If the probe is missing, then it can be successfully replaced with a fragment from a plastic bottle from under the juice / beer. To do this, cut a rectangular strip, install between the coil and the flywheel, tighten the mounting screws of the module.

The gap is established, it is necessary to eliminate the strip of plastic bottle, which served as a probe. To do this, hold the edge of the strip with pliers and scroll the flywheel. The strip will be removed as the flywheel rotates.

What else do I want to say about the ignition. From my own observations from personal experience, I can say that ignition modules more often they “fly” to Khuskvarnykh (3 cases for all my work experience). On Calm, my ignition never “flew”, although I admit that I worked as a professional Calm for only 1.5 years. There is a “bytovuha” in the household (knot). Stihl 180, I have been operating it for 12 years, but such a misfortune did not happen. Worked at an early stage as a "Partner", but also no breakdowns with ignition did not occur. He didn’t work with other saws, he only “tasted” for a short time at sawing firewood.

Perhaps I’m wrong, so refute my speculation and allegations. I will be glad to discuss.