Chinese chainsaw carburetor factory settings

How to properly adjust the chainsaw carburetor

During the operation of the tool, situations arise when it is necessary to adjust the carburetor of the chainsaw. Within the framework of the article, we will figure out when to configure, how to do it correctly and whether it is worth adjusting it yourself, or is it better to give it to a specialized service. The carburetor is an important unit, the service life of the saw depends on how correctly it works.

- Situations in which adjustment is necessary

- Tools

- How the carburetor is adjusted?

- Process description

- Adjusting the carburetor of a Chinese chainsaw

- Video

- Summing up

Adjusting the carburetor of a Chinese chainsaw

Carburettors installed on Chinese-made saws are made similarly to European ones and have the same adjustment screws.

The carburetor of a Chinese chainsaw is adjusted according to the algorithm presented above, and differs in that when initially adjusting the screws (L) and (H), they must be turned out two turns. Further, the carburetors of the Chinese saw are adjusted in the same way as the European ones.

How to adjust the carburetor of a Chinese chainsaw in just 3 steps, read here (a very useful article). As an example, we recommend looking at the article about adjusting the carburetor on the Carver chainsaw.

The setting of the saw carburetor can be studied in the video below. In this video, the wizard shows how the step-by-step adjustment of the Champion chainsaw, made in China, is performed without the use of a tachometer. Carries out after adjustment check in various modes.

Situations in which adjustment is necessary

New chainsaws are supplied by the manufacturer with adjusted carburetors. This is called standard adjustment. But for the normal passage of the running process, it is required to lower the maximum engine speed, adjust the carburetor. After running in, the chainsaw needs fine tuning to achieve maximum engine efficiency.

Also, a signal for cleaning and adjustment is an increased fuel consumption, which negatively affects the operation of the exhaust system. Simply put, the chainsaw begins to smoke heavily and the muffler becomes clogged with carbon deposits, which in turn will lead to a decrease in power.

With an excess of fuel in the mixture, engine parts are poorly lubricated and premature wear occurs. Also, a poor-quality mixture can cause the engine to jam due to overheating (this is one of the reasons why the chainsaw will not start).

It looks like a jammed, overheated piston, from a disassembled chainsaw with an incorrectly tuned carburetor.

Adjustment is necessary when the engine does not idle, stalls, or does not develop full power. Carburetor tuning should be done with clean air and fuel filters. We also recommend reading an interesting article that tells in detail about the main reasons why the chainsaw starts up and immediately stalls.

How the carburetor is adjusted?

The algorithm for setting up the chainsaw is quite simple and consists of the following steps:

- Warming up the engine to operating temperature (the adjustment must be carried out only on a warm engine, this will allow you to get a more accurate adjustment).

- Adjusting the engine for smooth operation at low rpm.

- Setting the carburetor for the correct supply of the fuel mixture at maximum speed.

- Fine adjustment of the carburetor for idling.

- Chainsaw check in all modes.

Almost all carburetor models have three adjusting screws.

- The screw (T) is responsible for fine tuning in idle mode.

- Screw (H) setting for maximum speed.

- Screw (L) regulates the formation of a mixture at low rpm.

By tightening the screws (L) and (H), the fuel supply and the mixture becomes leaner, respectively, the speed increases.

Carburetor adjusting screws L. minimum rpm and H. maximum engine rpm.

Now let’s look at how the correct adjustment of the chainsaw carburetor goes in more detail.

Tools

To adjust, you will need the following tool: a tachometer, screwdrivers, in rare cases, special keys. We will analyze their purpose, the need for availability and cost.

| Tool | Appointment | Recommended | |

| Screwdriver set (slotted screwdriver) | Most chainsaws require a simple flat-blade screwdriver to turn the adjusting bolts. | 300. 700 rubles | Required |

| Special adjusting key | For example, to adjust the carburetor on Husqvarna chainsaws, a special key is required, it is available only in certified service centers authorized for repair by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who are engaged in repairs without official permission to do so. | Out of stock | Chainsaw dependent |

Chinese FAKE STIHL ms280 52 cube carburetor adjustment

Setting up the chainsaw, if possible, should be carried out in official service centers that have a manufacturer’s certificate and an appropriate permit for repair work.

Process description

- If the carburetor of the chainsaw is not adjusted and it is not possible to start the chainsaw, then the adjustment starts by setting the screws (L) and (H) to the standard setting. This is 1/5 of a turn of the screws until completely tightened.

- After that, you need to start the engine, let it run a little and warm up.

- The next step is to set up the low speed mode. Optimum low engine performance can be achieved by adjusting the screw (L) and idle speed (T). To do this, first the screw (L) is tightened until the maximum engine speed is obtained, then it is released by 1/4, and the idle speed is normalized with the screw (T).

- After adjusting the work on the “bottom”, the thrust and maximum engine speed are adjusted. To do this, slowly tighten the screw (H) and check the speed according to the readings of the electronic tachometer. It is unacceptable to allow exceeding the maximum engine speed declared by the manufacturer!

The location of the carburetor adjusting screws on the Husqvarna chainsaw.

An important step is to check the saw in all operating modes after adjustment, for this you need to let the chainsaw cool down, and then start it according to the cold tool start algorithm. If the saw starts up normally and idles smoothly, you need to check how it is sawing. If in the process of checking deficiencies in the power of the chainsaw are found, then it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the thrust in operation.

Loss of thrust at maximum RPM recommended by the manufacturer is an indicator of CPG wear or poor fuel quality. Speaking of fuel, 90% of faults are due to fuel. Which one to use? 92 or 95? How much is stored? We answered all these questions in the article on which gasoline to pour into the chainsaw.

We recommend watching a video on how to clean and adjust the carburetor of a chainsaw, the author of which also talks about the detrimental effect of fuel on the components of the carburetor. This example shows how to rebuild your carburetor using an inexpensive repair kit.

Chainsaw carburetor, speed control

Chainsaw RPM setting

For those who have a chainsaw, adjusting the carburetor with your own hands is not particularly difficult. To do this, you need to study the device of the carburetor and remember the sequence of actions performed to regulate the elements on which the correct operation of the parts of the carburetor itself and the elements located near it depends.

Before adjusting the chainsaw carburetor, you need to prepare the device. For this purpose, the following actions are performed:

- The motor is warmed up, for which it starts up about ten minutes before the start of repair work, and after they start it turns off.

- Air filter is being checked and rinsed.

- The chain is stopped by turning the screw T as far as it will go.

To ensure the safety of repair work, it is necessary to prepare a flat surface so that the tool can be placed neatly on it, and the chain can be turned in the opposite direction. A tachometer is required to determine abnormalities in the functioning of the carburetor.

Anyone who wants to know how to adjust the carburetor on a chainsaw should take into account that this procedure consists of two main stages. The first is carried out with the motor on, the second after the motor has warmed up.

For successful regulation of the carburetor, you should first study the instructions for using a specific model of a chainsaw to clarify additional nuances of adjusting this equipment.

At the first stage, the screws of low and high revolutions are turned clockwise until they stop, and then they are turned in the opposite direction by one and a half revolutions and kept in this position.

In the second stage, the motor is set to medium speed to warm up for ten minutes. The movement of the screw responsible for adjusting the idle speed should be done clockwise. It can only be released when the motor switches to stable operation. Ensure that the chain remains stationary during this process.

When the engine is idling, it can stall. In such a situation, immediately turn the screw clockwise until it stops. In some cases, chain displacement occurs. In such situations, turn the screw counterclockwise.

When deciding how to properly adjust the chainsaw. it is necessary to check the functioning of the motor during the execution of the maximum revolutions. With the correct functioning of the motor, after pressing the accelerator, the speed quickly increases to fifteen thousand revolutions per minute.

In the absence of such a reaction or an excessively slow increase in speed, it is necessary to turn counterclockwise the screw marked L. It is important to ensure moderate movement, since the turn should not be more than one-eighth of a revolution of 360 degrees.

The maximum number of revolutions is limited using the adjusting screw marked with the letter H. To decrease the number of revolutions, turn it counterclockwise, and to increase it. in the opposite direction. The maximum frequency should not be more than fifteen thousand revolutions per minute. When turning this screw, take into account the ignition processes. If even subtle failures occur, the maximum number of revolutions must be reduced.

How to tune the carburetor on a chainsaw to function properly at idle speed? To do this, the following conditions must be met:

- The chain remains stationary when idling.

- The sound emitted by the engine resembles the sound of a four-stroke unit.

- The motor increases revs at an accelerated pace, even with a slight push on the accelerator. With a smooth increase in pressure, the motor speed increases proportionally, reaching the maximum allowable level.

In case of non-compliance with these conditions, it is necessary to repeat the main stage of adjustment.

To correctly tune the carburetor of a Chinese chainsaw. you should remember its factory settings, and then turn on the motor. In order to accurately set your parameters, in the future you will have to keep it in working condition for several hours. In some cases, this problem can be solved immediately after ten minutes of engine operation, but many models of Chinese manufacturers need special treatment.

The setting is done in the following order:

- Regulation starts at idle speed. It is necessary to achieve a smooth increase in engine speed using the adjusting screws, so first leave it running for some time at low speeds. The movement of the chain on the tire represents an abnormality. In this case, the optimum position should be achieved by adjusting using the outermost screws so that the chain does not move.

- The transition to the average speed is made. In some cases, this is accompanied by smoke from the engine. This defect is eliminated by tightening the screw to bring in a less saturated fuel mixture. However, the engine speed will increase. It is necessary to change the settings until the motor starts to increase speed smoothly when pressing the throttle, without interruptions or sudden jerks.

- The chainsaw motor is being checked. The tool is transferred to the minimum speed, after which the lever is quickly pressed and held at the maximum pressure for three seconds. If a malfunction occurs in the functioning of the motor, the screw should be gradually loosened until the optimal position is reached.

- The saw should have been operating under real conditions for some time. To do this, you need to saw the wood, and then inspect all the parts involved in this process. If there are deviations, they must be corrected using adjusting devices. After eliminating all defects and setting the optimal settings for supplying the fuel mixture, the tuning procedure is completed.

Adjusting the chainsaw carburetor

Using a chainsaw greatly simplifies life even for amateurs, and in some professions it is almost irreplaceable. But, like any relatively complex equipment, the chainsaw needs regular maintenance. If it is performed out of time or poorly, then this leads to various malfunctions. One of the most common causes of problems is a wrong setting of the carburetor of the chain saw, knocking out due to movement of the adjusting screws due to vibration or as a result of unsuccessful attempts to adjust it.

Chainsaw adjustment is required in the following cases:

- the factory settings of the chain saw carburetor are knocked down;

- the engine starts with an effort and stalls almost instantly;

- the ingress of debris particles into the fuel distribution mechanism due to a malfunction of the air purification system;

- the exhaust is too thick, the fuel consumption is too high, the fuel is not completely burned in the cylinder;

- significant wear of the piston group (in this case, adjusting the carburetor of the chainsaw is a temporary measure).

The carburetor is designed to prepare the fuel mixture for feeding into the engine. Violations of the proportions in the fuel mixture lead to malfunctions in the operation of the engine.

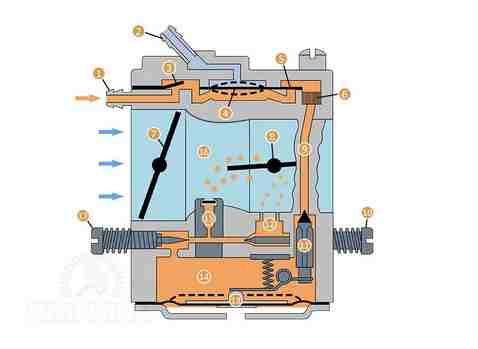

The design of carburetors varies from model to model, but they all operate on the same principle. The air flow moves quickly through the channel. The speed of its movement is regulated by means of a damper that closes the channel. The fuel supplied to the channel through the atomizer is mixed with air, after which the resulting air-fuel mixture enters the engine.

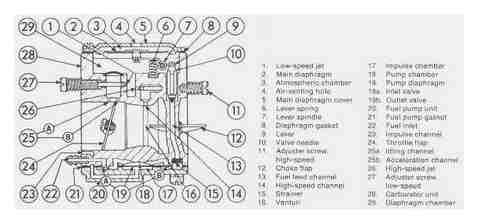

The carburetor always consists of the same set of parts, although it may vary slightly depending on the manufacturer. It includes the following parts:

- The foundation. It is a special tube that looks like an aerodynamic structure. A stream of air passes through it. In the middle of the tube in the transverse direction there is a flap, the position of which can be changed. The more it is pushed into the passage, the less air enters the motor.

- Diffuser. This is the constricted part of the pipe. With its help, an increase in the speed of movement of the air flow is ensured in the part from which the fuel is supplied.

- Float chamber. This element is similar in shape to a reservoir. It is used to continuously maintain the optimal fuel level in front of the entrance to the channel from which air is supplied.

- Fuel supply channels. The fuel mixture is in the float chamber, from where it enters the nozzle, and then is fed into the sprayer.

In order for the operation of the tool to be efficient and smooth, maximum output, and fuel consumption economical, timely adjustment of the chainsaw carburetor is required. Before performing it, you should check the cleanliness of the air and fuel filters. On most chainsaws, adjustments are made using three screws: high rpm, low rpm, idle.

Carburetor adjustment should be done with the utmost care, since errors are fraught with very significant consequences, up to engine failure.

Signs of a correct setting are as follows:

- the acceleration of the motor is carried out quickly and smoothly;

- the chain remains stationary at idle;

- the engine emits a smooth sound during operation, reminiscent of the sound of a four-stroke unit.

The carburetor of a Chinese chainsaw is adjusted in the same way as for models produced by European manufacturers, in fact, Chinese counterparts are copies of famous brand tools, but with some changes.

For this, the same screws H, L and T are used. The standard for the carburetors of Chinese chainsaws is the position of the screw L, at which it is loosened compared to the fully clamped state by one and a half turns. For screw H, the standard is one turn from the same position. Idle speed adjustment is performed on a warm engine.

On some models, only idle speed is regulated. However, owners of Chinese chainsaws and service employees talk about the increased complexity of adjusting the carburetor for tools manufactured by Chinese manufacturers. Even for experienced craftsmen, it takes a little more time to adjust a Chinese chainsaw, unlike original tools.

Add comment Cancel reply

To post a comment, you need to log in.

Idle speed adjustment

First of all, you need to find the position in which the idle speed will be highest by turning screw L. When you find this position using the tachometer, you need to turn the low speed screw (L) a quarter (1/4) counterclockwise. The chainsaw chain can rotate during this process. If this happens, loosen the idle screw (T) counterclockwise until the chain stops moving completely.

How to properly adjust the chainsaw carburetor

The vast majority of gasoline saw carburetor models have three adjustment screws:

- idle speed (T);

- low speed (L);

- high speed (N).

The required parameters are set by rotating these screws.

Use an electronic tachometer to fine tune the carburetor. It will make it easy to determine the engine speed of the chainsaw.

How to set the maximum speed of the chainsaw?

To change the maximum revolutions, you need to interact with screw H. If you tighten the screw, the revolutions will become higher, and if you unscrew. lower. As a rule, the highest permissible engine speed ranges from 11500-15000 per minute. If you try to work with an even higher number, the ignition problem will begin. In this case, the screw is slightly unscrewed.

In what cases is it necessary to adjust the carburetor of the chainsaw?

Here is a list of the most common cases in which you need to adjust the carburetor of a chainsaw:

- The engine starts, but the chainsaw stalls, or it cannot be started at all. Too much air in the fuel chamber may be the cause.

- Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to work well, the mixture must be of good quality.

- The bolts in the carburetor have lost their hold due to a damaged carburetor housing.

- Debris entering the carburetor. This can happen if the filter is damaged or poor quality fuel is used. You will need to completely disassemble the carburetor, flush it and re-adjust.

- Engine idling poorly or not delivering full power.

Important! If the engine is not performing well due to a worn piston, carburetor tuning will not work. In addition, along with the adjustment, it is advisable to clean the carburetor of debris. this will increase the efficiency of the procedure.

Acceleration check

If you press the gas button of the chainsaw, the engine should increase the number of revolutions. This should happen quickly enough. If the tool is slowly gaining speed, you need to loosen the screw L a little, no more than 1/8 of a turn.

When the adjustment is completed, you need to re-check the operation of the chainsaw at idle. the engine should work properly, and the chain should remain stationary. If the engine runs unstable or the chain moves, you need to repeat the adjustment, omitting the basic setting step.

Chainsaw carburetor adjustment

Chainsaws are a very popular gardening tool. They have gained great popularity among gardeners and those who care for the territory in the local area. Chainsaws are not complete without construction or repairs. Chainsaws are even more important in the lumberjack profession.

Any chainsaw requires proper care, maintenance and adjustment before operation. Overloading the tool can shorten its life and damage the tool.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare the fuel before it is fed into the engine cylinder. This function is performed by the chainsaw carburetor. It will depend on him how well the chainsaw works and how much fuel it spends during operation. If you see that the petrol chain saw is not working properly, the carburetor may need to be adjusted.

Basic carburetor adjustment

Screws H and L must be turned clockwise as far as they will go and then unscrewed 2 turns in the opposite direction. This is the standard procedure for setting up popular chainsaws for the first time. Other options are also possible.

How does a carburetor work?

- When the engine is started, the air damper is opened in the carburetor.

- The movement of the piston reduces the pressure in the air valve. This causes air to flow into the diffuser. The exact amount depends on the position of the air damper.

- Fuel enters the float chamber. The jets regulate the speed at which this happens.

- Gasoline and air mix with each other in the diffuser to form a fuel-air mixture. She goes to the cylinder. The mixture can be lean (a lot of air, little gasoline) or rich (little air, a lot of gasoline). The amount of the mixture entering the engine is directly proportional to its power and speed.

All processes occurring in the engine are not cyclical, but a constant basis.

Chainsaw carburetor adjustment

Chainsaws are a very popular gardening tool. They have gained great popularity among gardeners and those who care for the territory in the local area. Chainsaws are not complete without construction or repairs. Chainsaws are even more important in the lumberjack profession.

Any chainsaw requires proper care, maintenance and adjustment before operation. Overloading the tool can shorten its life and damage the tool.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare the fuel before it is fed into the engine cylinder. This function is performed by the chainsaw carburetor. It will depend on him how well the chainsaw works and how much fuel it spends during operation. If you see that the petrol chain saw is not working properly, the carburetor may need to be adjusted.

How does a carburetor work?

- When the engine is started, the choke is opened in the carburetor.

- The movement of the piston reduces the pressure in the air valve. This causes air to flow into the diffuser. The exact amount depends on the position of the air damper.

- Fuel enters the float chamber. The jets regulate the speed at which this happens.

- Gasoline and air mix with each other in the diffuser to form a fuel-air mixture. She goes to the cylinder. The mixture can be lean (a lot of air, little gasoline) or rich (little air, a lot of gasoline). The amount of the mixture entering the engine is directly proportional to its power and speed.

All processes occurring in the engine are not cyclical, but a constant basis.

Acceleration check

When the adjustment is completed, you need to re-check the operation of the chainsaw at idle. the engine should work properly, and the chain should remain stationary. If the engine runs unstable or the chain moves, you need to repeat the adjustment, omitting the basic setting step.

Idle speed adjustment

First of all, you need to find the position in which the idle speed will be highest by turning screw L. When you find this position using the tachometer, you need to turn the low speed screw (L) a quarter (1/4) counterclockwise. The chainsaw chain can rotate during this process. If this happens, loosen the idle screw (T) counterclockwise until the chain stops moving completely.

In what cases is it necessary to adjust the carburetor of the chainsaw?

Here is a list of the most common cases in which you need to adjust the carburetor of a chainsaw:

- The engine starts, but the chainsaw stalls, or it cannot be started at all. Too much air in the fuel chamber may be the cause.

- Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to work well, the mixture must be of good quality.

- The bolts in the carburetor have lost their hold due to a damaged carburetor housing.

- Debris entering the carburetor. This can happen if the filter is damaged or poor quality fuel is used. You will need to completely disassemble the carburetor, flush it and re-adjust.

- Engine idling poorly or not delivering full power.

Important! If the engine is not performing well due to a worn piston, carburetor tuning will not work. In addition, along with the adjustment, it is advisable to clean the carburetor of debris. this will increase the efficiency of the procedure.

Carburetor device

A carburetor is a mechanism that is responsible for preparing a mixture of fuel and air, which is then fed into the engine cylinder. Most chainsaws have very similar carburetors, so they are set up in the same way.

The main structural details of the chainsaw carburetor:

- Aluminium case. Aluminum is chosen as a material for its low weight. Chainsaws are a tool that must always be held in hand and carried, therefore, reducing the weight of the tool is a very important task facing the manufacturer.

- Diffuser and choke, which are located at the inlet of the carburetor.

- Jets. valves that provide the dosage of fuel that is supplied to the carburetor.

- Sprayer, which is responsible for injecting fuel into the chamber.

- Fuel chamber.

How to properly adjust the chainsaw carburetor

The vast majority of gasoline saw carburetor models have three adjustment screws:

- idle speed (T);

- low speed (L);

- high speed (N).

The required parameters are set by rotating these screws.

Use an electronic tachometer to fine tune the carburetor. It will make it easy to determine the engine speed of the chainsaw.