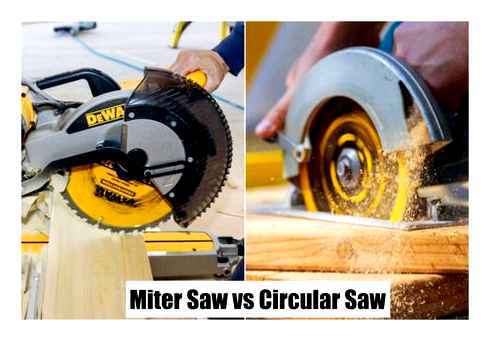

Circular Saw vs. Miter Saw – An In-depth Look at the Differences. Miter cut circular saw

Circular Saw vs. Miter Saw – An In-depth Look at the Differences

This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate, I earn from qualifying purchases. Please read my disclaimer for additional details.

As you’re building your tool collection, you’ll doubtlessly come to the conclusion that you need a saw. Just as certainly as you’ll need a hammer to nail things, you are sure to need a saw to cut things. Unfortunately, picking a saw isn’t as easy as that. Just as there are many types of hammers for different uses, there are different types of saws. Knowing the differences will help you pick the right saw.

What are the differences between a circular saw and a miter saw? A circular saw is a handheld, general use power saw that can be taken anywhere to make a lot of different types of cuts, from cross cuts to ripping plywood, though it usually produces rough cuts. A miter saw is a stationary, specialized power saw designed to efficiently and precisely cut trim or framing boards at an angle or bevel.

People often wonder which type of saw they should buy, or at least which they should buy first. As a general rule, because circular saws are less expensive and more versatile, they are typically most people’s first saw.

If you plan to do work that requires a lot of precise cuts, especially if they are angled or beveled, such as furniture or frame making, you should get a miter saw.

What is the Difference Between a Circular Saw and a Miter Saw?

In order to understand the difference between circular saws and miter saws, let’s first take a look at what each type of saw is.

Circular Saws

The circular saw is a handheld saw with a circular, spinning blade oriented vertically. Modern circular saws are electric powered either via a power cord or a battery pack. The blade is typically about 7 inches in diameter.

They are relatively small and lightweight, making them extremely portable. They are capable of doing a lot of different types of cuts, though they usually do so less precisely than specialized saws.

Pros

Circular saws are extremely portable. Their cases are essentially large briefcases, so it’s easy to bring them to the job site even if you only have a little bit of room in your trunk.

Even on-site, circular saws can be used just about anywhere. An extension cord or a battery pack is all you need to bring the saw to the thing that needs to be cut.

They are also extremely versatile. Simply by switching the blade, you can cut just about any type of material, from wood to metal.

Because it is handheld, the circular saw can be used to make just about any type of cut. This includes:

Circular saws are most beneficial for rip cuts. These are long cuts, often in the same direction as the grain of the wood.

If you need to split a 2 by 4 in half the long way, or to cut a piece of plywood in half, for example, you’ll need a circular saw to do so.

Circular saws are not very expensive, often costing less than 100. Because they are cheap and extremely useful, they are ubiquitous on job sites. If you need to make a cut, you can probably do it with a circular saw.

Cons

A lot of the pros of circular saws come with corresponding cons. Their extreme portability, for example, comes at the expense of accuracy. When you are making a cut with a circular saw, you are holding the saw in place by hand.

The cut’s accuracy depends on your ability to steadily move a 15-pound tool, which has a motor spinning a blade at high RPMs. It can also kick back while it is cutting if it hits knots or other tough parts of the wood.

You can steady the path of the saw by creating some sort of scaffolding. A metal speed square clamped in place as a guide, for example, is a great way to ensure a straight cross cut.

Angled cuts, however, require a lot more elaborate bracing. Even so, the circular saw blade’s wide teeth and relatively low RPM will always result in a rougher cut than a miter saw.

Not only does the portability of the circular saw result in a reduction of accuracy, it also results in a corresponding reduction in safety.

The saw must be held and moved independently, with the only safety feature being a shield that partially covers the blade when not in use but is pushed aside during cutting.

Miter Saws

The miter saw, developed in the 1970s, replaced the miter box. It is a stationary saw that is designed for miter (angled) cuts common in framing and other finishing work.

The miter saw is essentially a circular saw mounted on a pivoting arm. The circular blade is usually 10 to 12 inches in diameter and aligned vertically (unless the saw is set to cut at a bevel).

The saw consists of a rack to which a board is secured. The blade is engaged and pulled down through the board in order to cut it. This can be done at a 90-degree angle (cross cut) or some set angle (miter cut).

The miter saw can either cut straight down or cut through the board at a slant (bevel cut). A compound cut is one that is both mitered and beveled.

Pros

A miter saw is a specialty saw designed to cut miter and bevel cuts quickly and precisely. It is most useful when you need to miter cut many boards (usually at a 45-degree angle) precisely enough that they can be fit together with no gap. This is especially useful in trades that include:

Using a miter is relatively safe and easy. Because the blade only cuts in one spot, it is not as intimidating to beginners as a circular saw can be.

There can be some kickback when the blade bites into the wood, but because you only need to stabilize the wood and not the saw itself, it’s easier to manage.

Cons

Miter saws, unlike circular saws, are stationary. They need to be set up at a table or workstation and the boards that need to be cut need to be able to be brought to the saw.

Miter saws are also larger, so if you are transporting one, you’ll need a truck or van, or at least a completely empty trunk or backseat.

As a specialty saw, miter saws are only capable of the types or cuts they are designed for, such as:

Other types of cuts, such as ripping longboards or sheets of plywood, are not possible.

A miter saw also has a limited cutting width. Because the blade can only be pulled down through the board, the width a miter saw can cut is limited by the size of the blade.

Theoretically, a blade can cut the width of its diameter, which is typically 10 or 12 inches. In reality, however, the mechanisms that spin and move the blade inhibit this, and the actual cut capacity is close to the radius (half the diameter) of the blade.

Sliding miter saws increase the cutting width of miter saws by attaching the saw on an arm that not only pivots, but also extends. This can often double or triple the width a miter saw can cut. This is useful because when a cut is angled through a board instead of cross-cut, it requires a much longer cut.

How to Cut a 45 degree Angle with a Circular Saw

Versatility

If you are looking for a saw that can do just about anything; a circular saw is for you. It is a general-purpose saw, and, with a little practice or finagling, can be used to make just about any type of cut. A miter saw, on the other hand, is a specialty saw that only does a few types of cuts very well.

Circular Saws Can Make Most Types of Cuts

A circular saw is a portable circle of cutting power. The saw moves and the cutting material stays in place. This not only means that a circular saw can be taken anywhere, and brought to the thing that needs to be cut if the thing is too big to move, but it can also be moved along the cut. This allows the ripping of long pieces of wood.

Circular saws are also not limited to cutting wood. By simply switching out the blade you can easily cut:

If you can imagine it, there’s probably a way to cut it with a circular saw.

Circular saws are even capable of making miter and bevel cuts, though it requires more work and skill to pull them off.

A miter cut can be achieved with a circular saw if you measure and find a way to brace the path of the cut.

Bevel cuts are achieved by adjusting the slant of the circular saw’s “base” or “shoe,” though it is more likely to kickback in this setting.

Miter Saws Can Only Make 4 Types of Cuts

A miter saw, on the other hand, is a specialty saw. It is designed to make a few types of cuts quickly and easily. A miter cut, after which the miter saw is named, is a cut that is at an angle through the board being cut. This is useful in applications like framing and furniture making when two angled boards (usually at 45 degrees) are joined seamlessly.

Any other type of cut, however, is not possible. There is a fence that holds the board in place under the miter saw’s blade.

While this ensures clean cuts on the types of cuts a miter saw is designed for, it prevents passing boards under the blade for other types of cuts, such as ripping long boards or cutting plywood.

If you want to cut metal instead of wood, you need a different saw. Chop saws are like miter saws in design, except that they are built to cut metal at only 90 degrees and are reinforced with material that will not catch fire when showered by sparks during the cut.

Accuracy

When it comes to accuracy, the circular saw’s versatility results in low accuracy. While circular saws are general purpose, miter saws are a specialty saw designed to make a few cuts extremely accurately.

Circular Saw Cuts Are Always Rough and Inaccurate

A circular saw is a handheld power saw. Its accuracy is limited by how steady you are able to hold it, which is no easy task when it is spinning at a high RPM and kicking back against the wood it’s biting into.

The path the circular saw travels is likewise dependent on your fine motor skills unless you go to the trouble of setting up scaffolding or bracing to guide the saw’s path.

Because circular saws can be used anywhere, they are often used in situations in which the cutting material isn’t properly secured.

Often one end of the board is secured, either by being braced or clamped to a sawhorse or otherwise attached to a structure. The other end, however, is most often unsecured.

As the board is cut through, eventually there reaches a point at which the weight of the slag end of the board is more than the increasingly reduced amount of uncut wood can support.

At this point, instead of the saw being allowed to cut through the board cleanly, the board will break off at the weakened point, leaving a jagged edge instead of a smooth cut.

Even in the most controlled cuts, a circular saw will produce a rougher cut than a miter saw. This is because the blades of circulars are smaller, spin at lower RPMs, and have less teeth than miter saw blades.

Circular saw blades are typically about 7 inches in diameter as opposed to 10 or 12 inches for miter saws, and the larger teeth gaps result in rougher cuts.

Miter Saws Are Designed to Make Accurate Cuts

Because they are specialty saws, miter saws are designed to make the most accurate:

They achieve this by bracing the board in a fenced base. It can be clamped in place if desired, but even the fact that both sides of the cut are supported by the base is enough to ensure a clean cut.

Miter saws also have larger blades with higher teeth count that spin at higher RPMs than circular saws. This ensures a more accurate cut because the small amounts of wood the blade grabs is never stronger than the saw motor. This ensures that the wood is cleanly cut instead of torn or splintered.

Just as the board is secured, so is the blade. It can be adjusted and set at any angle or bevel. Because both the board and saw are secured, there is no chance that kickback when the blade bites into the wood can throw off the alignment and result in an uneven cut.

Safety

When it comes to safety, miter saws win hands down. Miter saws only cut one place and only where you tell them to, whereas circular saws can cut anywhere and anything if you aren’t careful.

Circular Saws are Dangerous Because They are Unsecured

The freedom of mobility of circular saws come at the cost of greater safety risk. Nothing is holding the saw back from cutting where you want it to go, but likewise nothing is holding it in place to keep it from cutting where you don’t want it to go.

Unless you set up extensive scaffolding or bracing, there is nothing preventing the saw from going where you don’t want it to go.

In most cases you will be guiding the saw manually. If you trip or slip or fall, or guide the saw somewhere it shouldn’t go, there is no structure in place to stop it.

The difficulty of this task is greatly amplified when the motor is spinning the blade at high RPMs and the saw experiences kickback as it bites into the wood.

The main safety feature of a circular saw is a hemicircular blade guard that uses a spring to partially cover the blade when not in use. When in use, however, the shield is pushed out of the way by the wood, and anything that is in the path of the blade is unprotected.

Miter Saws are Safe as Long as You Keep Your Hands Clear

Miter saws, on the other hand, are stationary and only cut in one spot. There Is no movement during the cut other than the blade moving down through the wood, so as long as you make sure your hand is not in the path of the saw before engaging the motor, you’ll be safe.

Why would you need one vs the other?

As discussed above, circular saws are a general saw and miter saws are a specialty saw. If you need a saw that is cheap, portable, and can make a lot of different types of cuts, you need a circular saw. If you need to make a lot of accurate cuts, especially cuts that are angled or beveled (or both), you need to get a miter saw.

Would you ever need both?

If you often need to make precise angled or beveled cuts, and also need to make other types of cuts in harder to reach locations, you’ll need both a miter and a circular saw.

Which to buy first?

If you know you will only be cutting boards to size (at an angle or bevel) you should invest in a miter saw first. If you are unsure what types of cuts you’ll need to make or know that you need to rip boards or cut things you cannot bring to the miter saw, you should buy a circular saw first.

How to Cut a Straight Line with a Circular Saw (4 Simple Ways!)

Over the years I’ve used circular saws for many different projects. It’s a great and affordable tool to have in your workshop! If you’re just starting to build up your tool set, a circular saw can be a great substitute for a more expensive table saw.

You can use your circular saw to get precise cuts and today I’m sharing 4 ways to cut a straight line with a circular s aw.

This post came about because I recently started a woodworking project that uses super heavy 2x8x8 boards. I needed to cut one of the 2x8s into 4 smaller pieces and instead of trying to balance the board on my miter saw cart I decided to cut them using my cordless circular saw – we just got a cordless one and I LOVE IT!

While setting up the board to cut with my circular saw I realized there was a time when I would have had no idea how to do this! (And it wasn’t that long ago.)

Power tools can be overwhelming, especially when you’re just starting out – they definitely were for me. In this post, I’ll explain how to cut straight with a circle saw and much more. Let’s get started!

Cut a straight line without a guide

For a recent project I used my circular saw to cut a straight line on a 2×8 without a guide. If the board you’re cutting is any wider than 8” I recommend cutting with a guide. I have instructions on how to set up a guide for your circular saw below.

Prop your board up

Set the board you want to cut on some sawhorses or, set it on some scrap wood. I stacked 2 scrap 2x4s underneath my board at a few spots to support it. If you are cutting on the ground you want to make sure that the board is high enough that your circular saw blade will not hit the ground when you are cutting. Two stacked 2×4’s is plenty of height.

Mark your Cut

Measure your board and mark a line where you want to cut. Take the measurement at 3-4 points and mark a few dashes. Then, use a straight edge to draw a line connecting the dashes.

Make the Cut

Line your circular saw up with the line you drew. When you turn your circular saw on, make sure that the blade is not touching the board. You don’t want the blade touching anything when you start it. Follow the line with the guide on your circular saw to make your cut. Keep the saw level on the board while you are cutting. Release the power button of the saw when you have cut through the entire board.

Using a guide to cut with your circular saw is a great way to ensure a straight cut and it’s quick to set up. I recommend using a guide for making longer cuts and for cutting thinner wood like plywood.

Make a DIY guide to cut a straight line

You can easily make your own cutting guide to use with your circular saw. To do this you will need a straight board that is at least as long as the piece of wood you are planning to cut. You can also use a long level as a guide – I often do this because I know my level is straight. You will also need a couple wood clamps.

First, measure the distance you want to cut. Mark your measurement in several places with a dash and then connect to the dashes to create a straight line to cut across the wood.

Next, measure the distance between the left edge of the bottom guard on your circular saw and the blade. Mine is 1 1/4”. Yours should be something similar. The measurement might be marked on the guard, but I recommended measuring yourself to get a more accurate distance.

Then, mark a dash on the edge of your board parallel to the line you already drew at the distance of the guard from the blade. Hold your circular saw up to the edge to confirm the blade and edge of the guard line up to the lines. If the measurement is correct, go ahead and mark another dash the same distance on the other end of your board.

Last, take your straight edge (a straight board or level) and clamp it to your board so that it lines up with the dashes. This board is your cutting guide.

This is the method I used for my Big X Wood Quilt and my DIY Geometric Wall Art.

When you’re ready to cut, hold your circular saw so that the edge of the guard is against your cutting guide as you’re cutting. Make sure that the board you’re cutting is well supported so that it doesn’t fall or fold in on itself while you are using the circular saw. If you can, clamp the board to your sawhorses to prevent it from moving while you cut.

Ultimately, it might be easier to use a track saw to make straight cuts. Check out my post on circular saws vs track saws for more info!

Cut Straight Lines with a Kreg Rip-Cut

I also own a Kreg Rip-Cut Circular Saw Guide that makes it super easy to cut straight lines with a circular saw without having to make a DIY guide. This has been the way for me to get the most precise cuts with my circular saw.

This tool is great if you’re going to making several cuts because you don’t have to measure out and mark your wood each time. Instead, you just set the guide to the measurement you need and line it up with the straight edge of your board. It’s much easier!

The Rip-Cut can cut up to 24” wide and is a great way to use your circular saw as a substitute for a table saw when you’re just starting to build up the tools in your workshop.

If you need to make a straight line, a table saw could be a better option. Check out my circle saw vs table saw comparison for more info!

Use a Speed Square

If you’re looking for an easy way to cut straight with a circular saw, using a speed square is a wonderful idea.

With this method, you’ll just need to use the square as a guide for your cut. You can mark the line ahead of time, or you can just maneuver the saw with the edge of the square to create a perfectly straight cut.

The chances are you already have a square laying around, making it a great option for anyone. You can also check out some of my favorite squares for woodworking.

Final Thoughts on Cutting a Straight Line with a Circular Saw

Circular saws can certainly be tricky, especially when making straight cuts – so hopefully you’ll be more confident than ever on your next cut.

There are four easy ways to make straight cuts with circle saws: making a cut without a guide, making a DIY guide, and using a Kreg Rip-Cut, or using a speed square.

I hope these quick circular saw tips are helpful to you! If you have any questions, leave them in the Комментарии и мнения владельцев below!

And, if you like articles with tool tips like this one, let me know! I’d love to create more content that will help you get started with woodworking.

Hi, I’m Emilee. I’m a woodworker, crafter and world class figure-outer. Mama Needs a Project is where I share all of my DIY adventures. I believe down to my core that working with your hands to physically create something will change your life!

I hope browsing Mama Needs a Project will leave you inspired and fired up to tackle your next DIY project. While Emilee is no longer actively blogging, her passion for woodworking can be found anywhere she goes.

Miter Saw vs Circular Saw

Circular saw or miter saw, which one should I get? What is the difference and do I need both?

Generally, if your project involves a lot of trimming then get a Miter saw. Conversely, if you are going to do rip-cuts or need to cut plywood, then a circular saw is what you need. However, the choice is not that easy.

Table Saw vs Track Saw vs Circular Saw! Which Should You Buy?

So, you notice it has been a while since you added a new power tool to your collection, and you decide now would be a perfect time to grab a new tool to use. But, you face the issue that all professionals face, what power tool should you get? In this article, we are going to look at two very different, and two very popular power tools, miter saw vs circular saw. You will learn what each does, what jobs each is best suited for, and finally, you will learn what person should buy each kind of saw.

What is a circular saw?

A circular saw is a power tool with a flat circular blade that rotates at high speed to cut wood, plywood, plastic, and even metal.

Circular saws are pretty straightforward as far as power tools go. They are handheld and come in both corded and cordless models. They are versatile and relatively cheap (especially when compared to other top of the line power tools) so you will find circular saws in almost every workshop and garage. Most of you out there, especially if you are interested in carpentry, woodworking, etc., have seen a circular saw before. They are round handheld saws that rotate at high speeds. They are generally capable of cutting through almost anything, including any kind of wood, plastics, and much more.

What is a miter saw?

Miter saw is a machine designed to do accurate crosscuts and miter cuts at the required angle. They can also cut bevel and a combination of both. For those who do not know, a “miter” essentially refers to cuts done at any angle other than 90 degrees (a crosscut). So, as you can probably guess, a miter saw is a kind of saw dedicated specifically to make those sorts of angled cuts.

Miter saws look somewhat similar to circular saws, as both have large circular saw blades that rotate at high speed and cut through the wood. However, there are considerable differences between the two power tools, which I will explain below.

Circular Saw Vs Miter Saw Comparison

Here is a quick comparison chart to help you decide betwen miter saw or circular saw.

| Features | Circular Saw | Miter Saw |

| Versatality | Excellent for wide range of cutting | Dedicated to crosscuts |

| Accuracy | Average | Highly accurate |

| Rip-cuts | Yes. Use straight-edge or guide rail | No |

| Crosscuts | Yes. But poor accuracy | Excellent for crosscuts |

| Cuts Plywood | Yes. | No |

| Rabbet Dado | Yes. Can be done. | Requires sliding miter saw |

| Ease of Use | Takes time to master | Relatively easy to use |

| Portability | Easy to store and carry around | Requires table or workbench |

| Price | Very affordable | Comparatively expensive |

| Recommended | Best Circular Saw |

Difference between a Miter Saw and Circular Saw

Let’s take a detailed look at both the power saws to figure out which is best for beginners and which tool is right for your job.

How do they work?

In case of a miter saw the cutting blade is dropped from above the work-piece to make the cut, whereas on a circular saw the blade is fed against the work along a straight path. Likewise, they have a bed that is used to hold the wood (or whatever else is being cut) in place.

Types of cuts

Looks aside, circular saws and miter saws are effectively two different tools. A circular saw is an all-around tool. It can make a variety of different cuts and it can be used on a variety of different jobs. It is effectively a mobile version of a table saw. With enough experience and technical knowledge, a circular saw can be used to make any kind of cuts that you can think of. It can even make miter and bevel cuts that you would normally have to use a miter saw for.

A miter saw, on the other hand, is a specialty tool. As I said earlier, it is explicitly meant to make angled cuts. Now, you may be wondering what the purpose of a miter saw is since circular saws can also make miter cuts. Well, miter saws allow you to make angled cuts easier, faster and accurately. The problem with using circular saws to make miter cuts is that it is difficult to get the cut straight and accurate and requires a lot of practice to get it right. The chance for error is also much higher when using a circular saw.

Storage and Portability

Circular saws are small and require very little storage space. On the other hand, Miter saw requires it’s own table or a miter saw stand.

In terms of portability, circular saws are much easier to move around; especially if you have a cordless model. Transporting a circular saw from job site to job site is as easy as throwing it in your car. Miter saws are not as difficult to move from place to place when compared to table saws, but they are definitely less mobile than circular saws.

Price

In terms of cost, there is a bit of difference, but not a major one. I generally notice that your average circular saw is cheaper than your average miter saw, but this is not a universal truth. For example, I have seen the top of the line circular saws that cost a bit more than a middle of the road miter saw. The price differences are not that major either way, at the most, you will be spending about 50-75 more dollars for a good miter saw. Still, if you are on a strict budget it is something worth considering.

When to go for a circular saw

So, when should you buy a circular saw? Well, if you have a job that requires you to make a large variety of cuts, then you absolutely must get a circular saw. The variety of cuts a circular saw can make far surpass the variety of cuts that a miter saw can make.

Almost any carpentry or woodworking job that you can think of can benefit from a quality circular saw. In order to make a perfectly straight rip-cut, first get straightedge cut from the edge of a sheet of hardboard and clamp it on your workpiece to use it as a jig. Alternatively, you can get expensive ready-made guide rails that can help you to make accurate straight cuts.

Most newer circular-saw models also come with the tiltable base, that you can set the desired angle to make bevel cuts.

Also, a good circular saw will be useful for the general house and/or property maintenance.

When to go for a miter saw

A miter saw is a specialty tool and thus you should get it if you plan on doing specialty jobs that require precise miter cuts in the future. There is no sense in buying a miter saw and just letting it sit in the garage or tool shed gathering dust.

Miter saw cannot be used for cutting plywood and can’t do long rip-cuts. You can’t make rabbets and dados unless you go for an expensive sliding miter saw.

If you plan on building something that requires a lot of trim work, like photo frames, build furniture, small tables, decks with 2×4 or 2x6s or anything else of that nature, then invest in a good miter saw as it will make those jobs both faster and easier. Learn how to use a miter saw before you build your next project.

However, if you just need a simple tool for cutting wood occasionally, then look for a different kind of saw. For woodworking, the table saw with miter gauge is a great alternative.

Who should buy what?

So, by now you have a good grasp on what each tool is and what jobs they are best suited for. The last thing I want to discuss who should buy each kind of saw.

Most beginners, especially women may find circular saw more intimidating. However, it is the most versatile tool that can perform nearly all the tasks that a Miter Saw can and more, but with less accuracy.

A miter saw is a specialized tool to miter, crosscut, and bevel cuts accurately. If the extent of your carpentry is around the house DIY work, then a miter saw is frankly just a waste of your money. You may get one or two uses out of it, but that does not really justify the cost of most miter saws. Unless you already have a circular saw at home, then I would definitely recommend buying one of those.

If, however, you know for certain that you are going to need to make miter cuts in the future. Say for example you are building some furniture and the local expert at the hardware store told you that you would need to make miter cuts, then you should definitely invest in a miter saw.

Conclusion:

Ideally, you should get both; miter saw for your work that requires accurate trimming and circular saw for all rip-cuts. However, if you must choose one over the other, I would recommend you to buy a circular saw first since it is the most versatile power saw you get.

Miter Saw Vs. Circular Saw: 6 Differences That Matter

Most people have the wrong impression that all powered saws are the same. A miter saw and a circular have similar-looking blades, but other than that, they do not look similar at all. It makes one wonder: what are the differences that matter between a miter saw and a circular saw? The differences that a circular saw and a miter saw have from each other are highlighted in the following areas: The way they look compared to each other, their size differences, what they can do concerning their intended purpose, how accurate their cuts are, their mobility factors, and their overall price. The differences that matter between a miter saw and a circular saw will be explored in this article using the information that I gathered from experts through research. The first section will go back into the history of these two saws. The remainder of the article will go into more detail about the differences between the saws, and then it ends with which is better.

Miter Saw Vs. Circular Saw- Difference In History

Miter saws and circular saws have been around for as long as most people can remember; we will use this section of the article to explore the history of a miter saw and a circular saw to find the differences. It is a known fact that both these saws are circular saws, but in 1922, something happened that would make these two saws different from each other.

The History Of The Circular saw

1762 is the year that it is said to believe that a gentleman by the name of Walter Taylor lived; he was an English engineer that supplied the Royal British Navy with various products. Walter Taylor had a workshop at the Southampton shipping dock where it is believed that he had various machines, including a spinning saw; this information was not verified, though. It was in 1777 that Samuel Miller invented the first spinning sawblade, and it was credited to him in this case, and that would eventually lead to people having the most popular handsaw in the world. They used these spinning blades in England in sawmills to cut huge pieces of lumber. It is from these saws that modern power saws were born. It is believed that a lady called Tabatha Babbit also had something to do with the invention of modern power saws in the 1800s, this time in America after she got inspiration from her spinning wheel. However, it was not verified because it was against her beliefs to have it patented. 1878 saw the invention of a foot-powered circular saw with a table. This invention was not portable yet, but it had a lot to do with the tools that are available today. The inventor of this type of saw was a gentleman by the name of John Barnes from Illinois, and the design was very similar to that of the sewing machines from that era. Finally, in 1929, we saw the birth of the first mobile circular saw from the Porter cable company. A gentleman called Art Emmons was the inventor that came up with the idea of a mobile circular saw.

The History Of The Miter Saw

The history of a miter saw is the same as a circular saw because it also uses a circular blade, but a difference occurred in 1922. It was in this year that a gentleman by the name of Raymond DeWALT launched a radial arm saw that works with a circular saw blade. It was the birth of what we know as a miter saw. This saw was not even close to being portable at this stage, but its design made work so much easier. It worked with a radial arm placed overhead, and then the rotating blade was lowered onto the workpiece. In 1923 Raymond DeWALT formed his own company to sell his invention. DeWALT still exists to this day, and it is one of the most sought-after brands of power tools in the world today. DeWALT grew substantially since 1923, and they do not manufacture only radial arm saws anymore. This brand is popular because of its high-quality power tools, including miter saws and circular saws.

Main Differences Between A Miter Saw And A Circular Saw

These differences, as mentioned earlier, will be discussed in more detail, each under its separate heading, starting with the difference in appearance between a miter saw and a circular saw.

Miter Saw Vs. Circular Saw- Difference In Appearance

After all our research, we think it’s safe to say that a miter saw and a circular saw can not be mistaken to be the same saw. The appearances of these two saws are very different except for the circular blade that they both have. Here are the differences in appearance that matter and stand out:

- A miter saw houses its blade on the arm above the main body, while the circular saw blade forms part of the main body. A miter saw stays stationary, and the material is brought to it while a circular saw is used on top of the material.

- A miter saw has a bulky appearance in its design, whereas a circular saw has a compact design. A miter saw needs to be placed on a table, counter, or workbench because of its design, whereas it is not needed for a circular saw.

- A miter saw has gauges on the foot end used for miter cuts, while a circular saw only has a base plate. It has to do with the types of cut that each of these saws can do.

The differences that matter are evident from looking at the points above. But it is not the only criteria that are different between a miter saw and a circular saw. The next section of the article will FOCUS on the size difference between the two power saws.

Miter Saw Vs. Circular Saw- The Difference In Size

The next difference between a miter saw and a circular saw is the size of the saw. Here are the size differences that matter:

- Miter saws are bigger and bulkier than circular saws in all directions. It means that more space is required for a miter saw than for a circular saw. The size of the saw also affects the size of the blade.

- Miter saws also require more headroom in height. The miter saw’s blade cuts into material from the top; a circular saw does not require that extra headspace because it cuts into the material from the side.

- The dimensions of a compact miter saw are 26 inches × 19.25 inches × 14.5 inches sporting a 7 ¼ inch blade. A compact circular will have dimensions of 15.1 inches x 4.2 inches x 5.8 inches sporting a 4 ½ inch blade.

- The dimensions of a sliding compound miter saw for professionals are 24 inches x 36 inches x 82 inches with a 12-inch blade. A professional circular saw will have dimensions of 21 inches x 8 inches x 9 inches with a 12-inch blade.

We can see from the information above the size of a miter saw, and a circular is different. It is because these saws were designed with specific tasks in mind. The next part will FOCUS on the differences between a miter saw, and a circular saw in terms of their capabilities.

Miter Saw Vs. Circular Saw- The Difference In Capabilities

A miter saw and a circular saw has different capabilities based on the manufacturer’s specifications. Here is more information about these saws to illustrate their different capabilities. For this section, they will be discussed separately.

Miter Saw Capabilities

A miter saw was designed primarily to make miter/cross-cuts to wood, plastic as well and soft metals like aluminum. It means that this saw cuts 45-degree and 90-degree angles with so much ease. The other term for a miter crosscut is an angled cut. A miter saw can also be used with the blade angled sideways at degrees that the manufacturers pre-set.

Cuts made when the blade is at that pre-set angle are called bevel cuts. Bevel cuts are difficult to do with most saws, but miters saws make it easy. Experts refer to a miter saw as being a specialty power saw. Seeing that a miter saw is very limited in its use, it is easy to understand why the experts feel that way. The one thing that can be said about this specialty power saw, though, is that it is very accurate.

Because the capabilities of a miter saw are limited, it does what it is supposed to at a superior level and better quality than most other saws. For people that only do miter or cross-cuts and occasionally do bevel cuts, this is the perfect saw regardless of the limitations that it has with its capabilities.

Circular Saw Capabilities

A circular saw is a very capable saw and can do a variety of cuts. In the hands of an experienced person, this saw can do most of the cutting that may be needed daily. Here is what a circular saw is capable of doing:

- A circular saw can do rip cuts; this means that it can cut big pieces or sheets of material into pieces or sections that are smaller and more manageable. Ripping is one thing that a circular saw does very well.

- When it comes to cross-cuts, a circular saw can do it as well, even though it is very easy to produce a skew cut with a circular saw when doing cross-cuts, which means that it may be necessary to use a self-identified guide to help with doing cross cuts with a circular saw.

- The same goes for miter cuts; you can make miter cuts with a circular saw. It does come with a few conditions, though. The circular saw can go off a line easily if the user is caught off guard. So it is better to guide the circular saw with a big square.

- A circular saw can do bevel cuts as well. A circular saw has an adjustable bevel function to set the blade at an angle to perform these cuts. Bevel cuts are angled cuts to material in length instead of across.

From this information, you can see that a circular saw is a very versatile and useful power saw. Many contractors and experts in the field prefer only to buy a circular saw, and it is easy to see why. However, some people prefer different saws for specific tasks, so as with most things, preferences also differ.

Miter Saw Vs. Circular Saw- Differences With Cutting Accuracy

The previous section outlined that a miter saw and a circular saw has different capabilities and that a miter saw is a bit limited in what it can do, so for this part of the article, the FOCUS will be on the cuts that both saws can perform. They are cross-cuts, angled cuts, and bevel cuts. Here are the differences in accuracy between the saws:

| Accuracy with cross-cuts | It is very accurate and produces perfect cross-cuts. | It is accurate with the aid of a guide. |

| Accuracy with miter cuts | It is very accurate and produces perfect cross-cuts. | It is accurate with the aid of a square. |

| Accuracy with bevel cuts | It is accurate, but the length is limited to the size of the saw. | It is accurate with the aid of a guide. |

A circular saw is more accurate with rip cuts, but only because a miter saw can not perform rip cuts. Other than that, the miter saw is more accurate because it is what it was designed for. Keep in mind that cuts made by a beginner using a circular saw will not be as accurate, but with some help, the accuracy greatly improves.

A circular saw can be more accurate with the help of guides and squares, and when a circular saw is in the hands of a capable professional, it can deliver cuts nearly as accurately as the cuts of a miter saw. Now that the differences in accuracy are out of the way, it is time to move on to the differences in mobility between a miter saw and a circular saw.

Miter Saw Vs. Circular Saw- Differences With Mobility

It is a known fact that a miter saw is bigger and bulkier than a circular saw; the basic dimensions of both these saws are shared in the size section of this article, which can be used for reference. It will also be included again in the table below. Here is a table to highlight the differences in mobility. Please note that the value is an average.

| Compact miter saw | 26 in × 19.25 in × 14.5 in | 30 pounds | No |

| Compact circular saw | 5.8 in x 15.1 in x 8.2 in | 6 pounds | Yes |

| Professional miter saw | 24 in x 36 in x 82 in | 37 pounds | No |

| Professional circular saw | 9 in x 8 in x 21 in | 17 pounds | Yes |

Studying the table makes it clear that a miter saw is bigger and heavier than a circular saw. The weight and dimensions, together with the fact that a table or bench is required for a miter saw, are reason enough to believe that a miter saw is not mobile at all. Circular saws, on the other hand, are mobile and lightweight.

A miter saw takes up space on a table or bench, while a circular saw can be stored in a closet or vehicle. Now it is known that a miter saw and a circular are different regarding how mobile the two saws are; the next and last difference that matters is the price difference between these two saws.

Miter Saw Vs. Circular Saw- Difference In Price

Pricing is the last difference between a miter saw and a circular saw. The price of an item is always a deciding factor in whether people will acquire a certain item. The in this section are based on what was found in one of the biggest online stores in the world.

The pricing is going to be listed as between amounts because fluctuate. Here is a table of some of the best miter saw and circular saw brands and their pricing.

| Makita | XSL06PT | Miter 18V battery | ||||

| Metabo | HPT sliding | Miter compound | ||||

| DeWALT | DWS779 | Miter compound | ||||

| JCB Tools | 7 ¼ inch | Miter 20V battery | ||||

| Skil | 3821-01 | Miter compound | ||||

| Wen | MM1214T | Miter compound | ||||

| Bosch | CM10GD | Miter Duel Bevel | ||||

| Wen | 36725 | 7 ¼ circular | ≤ 50 | |||

| Skil | 5180-01 | 7 ¼ circular | ||||

| Bosch | CS10 | 7 ¼ circular | ||||

| DeWALT | DWE575 | 7 ¼ circular | ||||

| Ryobi | 1231 | Circular 18V | ||||

| Makita | 5007F | 7 ¼ circular | ||||

| JCB Tools | 20CS-B | 6 ½ circular |

The information on pricing shows us that a miter saw and a circular saw are different. The majority of the circular saws fall in the 100 to 200 category, whereas the miter saws are more expensive, with only one brand falling in the same category. This pricing comparison stands out because one of the circular saws is well below 100 in price; this is a very cost-effective machine.

Which Saw Is Better, A Circular Saw Or A Miter Saw?

It is clear from the information we shared in this article that there is a clear winner between a circular saw and a miter saw, on which saw is better. Here is a table including all the differences that were discussed in this article to summarise it all.

| Appearance- both saws score a point here. They are different because of specific design needs. | ||

| Size | ||

| Capabilities | ||

| Accuracy | ||

| Mobility | ||

| Price |

The circular saw is the better saw because it is small and compact, making the saw easy to carry around and store. The design of a circular saw makes it mobile and capable of doing a variety of cuts. The pricing of a circular saw is also much better than that of a miter saw.

A miter saw is bigger than a circular saw, making it heavier and less mobile. A miter saw is limited in its capabilities but very accurate, and the pricing is steep for what it can do. A miter saw suits someone that needs a saw only for miter cuts. For any other tasks, the circular saw is much better, and with some practice, people get their miter cuts close to perfection as well.

Conclusion

The differences that matter when comparing a circular saw and a miter saw are their size differences, what they can do concerning their intended purpose (capabilities), how accurate their cuts are, their mobility factors, and their overall price. This article focused on each of these points individually, and the findings were surprising.

The conclusion is that a miter saw is a specialty saw with a bulky appearance; it has limits in what it can do, it is very accurate but not mobile, and the cost is higher than a circular saw. It turns out that a circular saw is better in size, in what it can do, how mobile it is, and in price. The only criterion that a miter saw has overhand is inaccuracy.