Circular saws with the possibility of stationary installation

Circular saws with the possibility of stationary installation Prorab

Category

The use of a guide bar in working with a circular saw allows you to get a more accurate and accurate longitudinal and cross cut than without using it, and when working with a plunge saw, this device is a must. A number of circular saws have a special groove on the base plate for fixing the guide, in other cases the guide is fixed using clamps or adapters.

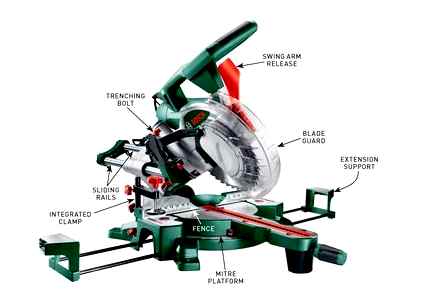

Miter Table Combination Saw BOSCH GTM 12 JL | Unboxing and Test

All saws are completed with various types of packaging: a simple box, a canvas bag (cover) or an ergonomic plastic case (suitcase). In the latter case, the durability of the tool significantly increases during its transportation and carrying from place to place due to the resistance of the suitcase to impacts. All accompanying consumables and accessories are conveniently placed in the case. This makes them easier to find and store.

The speed control on the circular saw allows you to adjust it for the most optimal work with different materials. By adjusting the rotational speed of the disk, you can work not only with wood and its derivatives, but also with plastic, non-ferrous metal sheets, composite materials.

Attempting to cut plastic parts at a standard high speed with a circular saw at an uncontrolled speed may melt the plastic due to excessive heat.

The maximum cutting depth at an angle of 90 ° varies with circular saws from 40 to 130 mm.

This indicator characterizes how deeply the cutting element of the tool can penetrate into the blade when the body is positioned perpendicular to the blade. This cutting method is the most common and intensive in terms of the degree of impact on the material.

Shallow cutters are suitable for thin products. Their use gives accurate and clean results. Devices with great depth belong to the professional class.

When sawing at right angles, the device can reach its maximum cutting depth, especially with a large saw blade diameter.

Power. from 710 to 2400 W. determines the speed of work, intensity, force of impact on the surface. Power consumption is a constant indicator, this should be taken into account when operating from a battery power source, for example, during repair work.

The correct ratio of density, structure of material and power of the device will avoid excessive loads on the device, eliminate the conditions for disabling it. For soft materials, low power is preferable along with the recommended diameter of the disc, while high power can lead to rejects in work and deformation of the material.

The most efficient tool is the one with less power and higher rotational speed.

The parameter of the weight of the hand tool is from 2.7 to 7.8 kg. determines how much force the user will have to apply to move the device. Ultimately, this means how tired the worker will be when using the saw.

The weight depends on the dimensions and power of the electric motor of the equipment. the higher the power, the heavier the material, the larger the dimensions of the engine and the weight of the entire body.

Heavy circular saws are recommended to be used only by specially trained people who have the skills to operate the tool safely. For the home workshop, lightweight devices are preferred. The low weight also determines the maneuverability, smoothness, natural holding by the user.

The maximum cutting depth at an angle of 45 ° varies with circular saws from 26 to 95 mm. This indicator characterizes how deeply the cutting element of the tool can penetrate into the blade when the body is tilted. Shallow cutters are suitable for thin products. Their use guarantees a neat, clean result. Devices with large cutting depths belong to the professional class.

The presence of a soft starter allows you to limit the starting current to a value of 16 A. This function is designed so that the saw can be connected to the household power supply without negative consequences for it. In addition, this system allows you to start the tool smoothly, without jerking.

Plunge saw is one of the types of circular saws. This saw has all the functions of a conventional “circular”: longitudinal and transverse cuts of various massive parts, workpieces or sheet material. In addition, thanks to a special plunge mechanism, it can quickly and accurately plunge into the material anywhere, not just from the edge. Using this saw, you can easily cut grooves, quarters and grooves on any surface. The plunge-cut saw makes it much easier to work with bulky workpieces when cutting from the edge is problematic.

For the stationary attachment of circular saws to a workbench or tabletop, a special mounting kit is used. Some of the circular saws shown on our website come with a fixed mount. In this case, you are guaranteed to receive a mounting kit that is ideal for your saw and additionally save time on finding and buying it.

Some saw models are equipped with an electronic constant speed control system under load. This function is designed to keep the number of revolutions of the motor shaft stable, regardless of the load level. Constant RPM protects the engine from overload, extending tool life.

All saws are completed with various types of packaging: a simple box, a canvas bag (cover) or an ergonomic plastic case (suitcase). In the latter case, the durability of the tool significantly increases during its transportation and carrying from place to place due to the resistance of the suitcase to impacts. All accompanying consumables and accessories are conveniently placed in the case. This makes them easier to find and store.

The presence of speed control on the circular saw allows you to adjust it for the most optimal work with different materials. By adjusting the rotational speed of the disk, you can work not only with wood and its derivatives, but also with plastic, non-ferrous metal sheets, composite materials.

Attempting to cut plastic parts at a standard high speed with a circular saw at an uncontrolled speed may melt the plastic due to excessive heat.

The maximum cutting depth at an angle of 90 ° varies with circular saws from 40 to 130 mm.

This indicator characterizes how deeply the cutting element of the tool can penetrate into the blade when the body is positioned perpendicular to the blade. This cutting method is the most common and intensive in terms of the degree of impact on the material.

Shallow cutters are suitable for thin products. Their use gives accurate and clean results. Devices with great depth belong to the professional class.

When sawing at right angles, the device can reach its maximum cutting depth, especially with a large saw blade diameter.

Power. from 710 to 2400 W. determines the speed of work, intensity, force of impact on the surface. Power consumption is a constant indicator, this should be taken into account when operating from a battery power source, for example, during repair work.

The correct ratio of density, material structure and power of the device will avoid excessive loads on the device, eliminate the conditions for disabling it. For soft materials, low power is preferable along with the recommended diameter of the disc, while high power can lead to rejects in work and deformation of the material.

The most efficient tool is the one with less power and higher rotational speed.

The parameter of the weight of the hand tool is from 2.7 to 7.8 kg. determines how much force the user will have to apply to move the device. Ultimately, this means how tired the worker will be when using the saw.

The weight depends on the dimensions and power of the electric motor of the equipment. the higher the power, the heavier the material, the larger the dimensions of the engine and the weight of the entire body.

Heavy circular saws are recommended to be used only by specially trained people who have the skills to operate the tool safely. For the home workshop, lightweight devices are preferred. The low weight also determines the maneuverability, smoothness, natural holding by the user.

The maximum cutting depth at an angle of 45 ° varies with circular saws from 26 to 95 mm. This indicator characterizes how deeply the cutting element of the tool can penetrate into the blade when the body is tilted. Shallow cutters are suitable for thin products. Their use guarantees a neat clean result. Devices with large cutting depths belong to the professional class.

The presence of a soft starter allows you to limit the starting current to a value of 16 A. This function is designed so that the saw can be connected to the household power supply without negative consequences for it. In addition, this system allows you to start the tool smoothly, without jerking.

Plunge saw is one of the types of circular saws. This saw has all the functions of a conventional “circular”: longitudinal and transverse cuts of various massive parts, workpieces or sheet material. In addition, thanks to a special plunge mechanism, it can quickly and accurately plunge into the material anywhere, not just from the edge. Using this saw, you can easily cut grooves, quarters and grooves on any surface. The plunge-cut saw makes it much easier to work with bulky workpieces when cutting from the edge is problematic.

For the stationary attachment of circular saws to a workbench or tabletop, a special mounting kit is used. Some of the circular saws shown on our website come with a fixed mount. In this case, you are guaranteed to receive a mounting kit that is ideal for your saw and additionally save time on finding and buying it.

Some saw models are equipped with an electronic constant speed control system under load. This function is designed to keep the number of revolutions of the motor shaft stable, regardless of the load level. Constant RPM protects the engine from overload, extending tool life. “,” sort “: 16,” additional “: false],” productCount “: 16,” queryString “:” “” data-category-ID = “25” data-category-name = “Circular saws (circular)” data-bowed-category-name = “in circular saws with the possibility of permanent installation” data-rname = “tsirkulyarnye-diskovye” data-tag-page-ID = “3956” data-make-ID = “0” data.search-string = “” data-reset-link = “/ instrument / pily / tsirkulyarnye-diskovye / statsionarnoj-ustanovki / # goods” data-ab-is-expanded-filters = “”

Saw types

- Household;

- Semi-professional;

- Professional.

Domestic hand saws have a power rating of up to 800 watts and are able to cope with sawing sheets of non-hard wood species. Semi-professional have a power of 800 W to 1.2 kW, and professional. over 1.2 kW, cutting almost any material.

Device advantages

A circular saw with the possibility of a stationary installation has a number of advantages:

- High revs provide high-quality sawing with an even edge;

- Compact size allows you to install the equipment even on small tables in a home workshop;

- Device mobility;

- Low weight;

- Low noise level;

- Stationary installation is provided by the sole;

- Safety of work is guaranteed by a protective cover.

All work of the same type can be carried out by attaching the reversible saw to the table. After completing the task, the device is dismantled and transported to another location.

Table-mounted circular saws

The hand-held circular saw with the possibility of stationary installation is especially popular, both in small home workshops and in large production halls. It can be used to cut virtually any material quickly and accurately. A special feature is the ability to cut both longitudinally and transversely at different angles. Thanks to the swivel mechanism, the handheld circular saw can be fixed at an angle of 45 and 90 degrees.

The inverted circular saw has a huge advantage over the ordinary circular saw. Some cuts require special precision, so the workpiece must be fed onto the blade. By flipping the saw over and attaching it to the table, we have a versatile cutting device that can handle any task. Accuracy of sawing can be achieved due to the fact that during work the sawing process itself is visible, and the master independently controls the supply of material.

How to make a choice?

Choosing a saw that can be attached to a table follows the same principle as conventional circular saws.

Parameters to pay attention to:

- Disc diameter. is determined by the tasks that will have to be performed using the device. You need to focus on the maximum cutting depth that is required.

- Engine power. the ability of the saw to perform sawing with the disc that will be installed depends on this parameter. The tool cannot be used at full capacity.

- Base plate. must be made of extra strong material so as not to bend during operation. This will prevent an emergency and jamming of the disc. It is considered ideal to make a plate of aluminum with a thickness of 4-5 mm. But the cost of such a saw is much higher, in contrast to a steel sole. It is imperative to ensure that stiffeners are installed on the sole.

Disk rotation speed

This parameter is directly influenced by power. Increasing the rotational speed allows for a more accurate cut. It should be borne in mind that when cutting plastic, it is advisable to choose a low cutting frequency, since otherwise you may encounter such an unpleasant phenomenon as the melting of materials caused by a high speed of rotation of the blade. The standard figure for this parameter for professional models is 5000 rpm.

Saw assembly

Each manufacturer offers many options for completing their products. The most important additions are:

- stopper. used to remove even edges of the material, turn an unedged board into an edged board, sawing off long strips of material from a piece;

- ruler. bolted to the platform and helps measure the width of the piece to be cut.

Most of the accessories are found in inexpensive Asian-made saws. Big-name brands are usually limited to a meager set of the device itself and the limiter. The rest will have to be bought.

Circular saws with the possibility of stationary installation

A hand-held circular saw is a must-have in the arsenal of anyone involved in construction or carpentry. The most convenient models are those that are installed on a workbench or table and are used stationary.

The first circular saws were developed by SKIL in the 1920s. Since then, the appearance of the instrument has undergone significant changes. Manufacturers are constantly working on improving the design, which to this day withstands fierce competition. What are the structural differences of the tool with a stationary mount and what models are on the market,

Power tool care tips

Remember that you have to deal with a dangerous tool. Due to this, you need to be very vigilant and careful. Only in this case you will be able not only to perform high-quality work, but also to protect yourself and the health of your family.

It is necessary to work with a circular saw only in protective clothing, gloves and goggles.

Before plugging in the saw, make sure it is off.

If you need to turn the saw on or off, it is advisable to do it at idle speed. Doing this under load conditions can result in reduced tool life.

Make sure that the load does not exceed the permissible level. To do this, it is recommended to take breaks after every 15-20 minutes of work. This will avoid overheating of the engine.

Make sure the workpiece is securely fastened before operation. It is unacceptable for it to dangle and bend. Otherwise, it can be fraught with serious consequences for you.

Keep the area free of moisture.

Power

This parameter has a value in the range of 400-2000 W. The exact figure is determined by the class and scope of the tool. As the power increases, so does the performance of the saw. This allows the user to spend less effort and time when sawing thick and dense material.

Power

Sawing wood requires a lot of effort, so powerful saws are more efficient. And the service life of the tool will be longer, because a powerful motor requires less effort, it does not overheat. However, the more powerful the device, the heavier it is. But the issue is partially solved by the presence of a table stand.

The smallest and weakest mechanisms have a power of 1200 W, the largest. 2500 W. The choice should be based on the mode of use of the tool.

Cutting depth

The value for this parameter ranges from 0 to 85 mm. The exact figure is determined by the class of the saw. Saws offered today can provide different cutting depths, which are determined by the power of the engine.

Installing the saw on a stationary mount

- We attach the legs: we take out the plug-bolts and instead of them we screw in the bolts to fix the legs.

- We attach the plate securing the protection. The guard must be pressed into the body and pressed down with a plate.

- Using clamps, we attach the tool to the workbench by inserting hooks into special holes.

Only specially designed models are installed “upside down”! Otherwise, overloading of the tool or a jamming of the disc is likely, resulting in costly repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. For information on this, see the operating instructions.

There are few models on the market with the possibility of stationary installation. These are mainly domestic products. Distinctive features. large circle diameter and powerful electric motor.

| Soyuz TsPS-50200 | Caliber EPD. 2100St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope DP-2000 | |

| Power, W | 2500 | 2100 | 220 | 15001800 | 2150 | 2000 |

| Idling speed, rpm | 6000 | 4800 | 5500 | 37004100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Inclination angle, degrees | up to 45 | up to 45 | – | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6.6 | – | 5.7 | 6,7 | 7.8 |

Saw assembly

Each manufacturer offers many options for completing their products. The most important additions are:

- stopper. used to remove even edges of the material, turn an unedged board into an edged board, sawing off long strips of material from a piece;

- ruler. bolted to the platform and helps measure the width of the piece to be cut.

Most of the accessories are found in inexpensive Asian-made saws. Big-name brands are usually limited to a meager set of the device itself and the limiter. The rest will have to be bought.

Installing the saw on a stationary mount

- We attach the legs: we take out the plug-bolts and instead of them we screw in the bolts to fix the legs.

- We attach the plate securing the protection. The guard must be pressed into the body and pressed down with a plate.

- Using clamps, we attach the tool to the workbench by inserting hooks into special holes.

Only specially designed models are installed “upside down”! Otherwise, overloading of the tool or a jamming of the disc is likely, resulting in costly repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. For information on this, see the operating instructions.

There are few models on the market with the possibility of stationary installation. These are mainly domestic products. Distinctive features. large circle diameter and powerful electric motor.

| Soyuz TsPS-50200 | Caliber EPD. 2100St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope DP-2000 | |

| Power, W | 2500 | 2100 | 220 | 1500 \ 1800 | 2150 | 2000 |

| Idling speed, rpm | 6000 | 4800 | 5500 | 3700 \ 4100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Inclination angle, degrees | up to 45 | up to 45 | – | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6.6 | – | 5.7 | 6,7 | 7.8 |

Selection Criteria for Fixed Mount Circular Saw

Although the choice of models with stationary fasteners is not rich, among them you need to choose the most suitable.

Fixed mount for circular

This simple device slightly increases the cost of the saw, but significantly expands its functionality. This is especially true for powerful heavy devices. The stationary mount is:

- a pair of clamps that fix the mechanism on the workbench;

- a pair of legs;

- plate fixing the protection;

- clip for the trigger button (the button is clamped in the “ON” position).

Стационарная циркулярка из ручной циркулярной пилы/Stationary circular

Holes are provided in the upper part of the tool body for fasteners. After installation, three points of support are formed, which securely and firmly hold the saw upward with the cutting teeth. It turns out a mini-circular machine with a working surface equal to the platform. Very convenient for cutting a large number of small parts.

Power

Sawing wood requires a lot of effort, so powerful saws are more efficient. And the service life of the tool will be longer, because a powerful motor requires less effort, it does not overheat. However, the more powerful the device, the heavier it is. But the issue is partially solved by the presence of a table stand.

The smallest and weakest mechanisms have a power of 1200 W, the largest. 2500 W. The choice should be based on the mode of use of the tool.

Circular device with stationary installation

The circular saw is designed for cross-cutting and longitudinal cutting of relatively soft materials: wood, wood-based panels, plastics, non-ferrous alloys. Hand tools work quickly and accurately, therefore they are widely used in various carpentry works, as well as in:

- roofing works;

- laying floor coverings;

- furniture making.

By replacing the blade on the hand circular, you can cut soft metals and profiles. And having installed it on a workbench using a special device. turn it into a machine.

- electric motor;

- gearbox in the housing;

- guide;

- platform;

- protective box;

- stationary mount.

The body of the tool is made of durable plastic and only a few models are made of metal. Since the work produces a lot of dust and chips, manufacturers provide a chip removal system. As a rule, this is an outlet for connecting an industrial vacuum cleaner. There are models with a built-in dust container. a convenient solution for one-off work.

On modern hand-held models, only 750. 2500 W collector motors are installed. This indicator determines the number of revolutions of the disc and the capabilities of the tool. The most powerful models have a speed of up to 5000. A powerful motor requires cooling, which is provided by the ventilation system of the case.

The platform is of great importance when choosing. She may be:

- stamped. cheaper, suitable for the amateur;

- cast aluminum. does not deform, strong and resistant.

Often, a graduated scale is applied to the platform to help cut workpieces more accurately.

Guide bar. serves to make a straight cut. Some manufacturers equip their tool with a guide rail. But this is not always the case.

When choosing a guide, you should consider the model and manufacturer of the manual circular. The tire is often quite expensive, so it is more advisable to purchase a tool already equipped with a guide.

Additional accessories

A laser pointer is a convenient option that allows you to cut a part with markings covered with sawdust. Increases the cost of equipment, but is welcomed by professionals.

Disc replacement. modern models are equipped with a spindle lock, which allows you to quickly and easily remove the disc for replacement. Otherwise, the disk is removed with two keys. a long and inconvenient procedure.

Cutting depth

This is also an important parameter, although it does not differ very much between large and small saws. Particular attention should be paid to the maximum cut at an angle. Modern models have the ability to cut by degrees. The value of the cut per degree is always much less than in a straight line, it is this indicator that you should pay attention to when looking for a small hand saw.

Hand-held circular saw with the possibility of stationary installation

If you have at least once been to a sawmill or in an ordinary carpentry workshop, then you probably paid attention to the presence of a machine there, with a disc with teeth peeking out in the center. This is what a stationary circular saw has. It is used to perform high-quality and accurate longitudinal sawing of wood of different densities.

Nowadays, many ordinary amateur builders are beginning to show interest in most special devices. They did not disregard the circular saw. At the same time, not only a stationary model is available for sale, but also a conventional hand-held circular saw. In this regard, it does not hurt to dwell in more detail on the features of the choice of a circular saw, its varieties and main characteristics.

This tool is used to solve the same problem for which the industrial version was created. We are talking about making longitudinal and cross cuts in wood, drywall, plastic and other materials. Of course, an ordinary jigsaw can also be used for such work, however, given the high intensity of work and the stringent requirements that the created cut must meet, it is much more logical to use a circular saw, which can perfectly cope with this task.

It is quite simple to use it, but for a start it will be useful to pay attention to its design. The role of the main unit in the device of this tool is performed by an electric motor, on the shaft of which the saw blade is located. To eliminate a minimum of discomfort when working with such a tool, it has two handles, one of which has a start button, and thanks to the second, the user has the opportunity to fix the tool with the other hand. The blade is equipped with a protective cover, the presence of which prevents injury to the operator. If necessary, the protective cover can be opened by gaining access to the saw blade by pressing the start button.

The action of this tool is as follows: to start the engine, you need to press the power button, after which the saw blade begins to spin, as a result, the main task is performed. the material is cut.

Adjusting the slope of the cut

Although this feature is mandatory for all modern circular saws, not all of them provide for the ability to tilt the tool to both sides. Tilt angle limited to 45 degrees.

Power

This parameter has a value in the range of 400-2000 W. The exact figure is determined by the class and scope of the tool. As the power increases, so does the performance of the saw. This allows the user to spend less effort and time when sawing thick and dense material.

Main characteristics

Considering various models of circular saws for a stationary installation, first of all, it is necessary to pay attention to their performance characteristics, which determine the effectiveness of their use in solving a particular problem.

Selection Tips

Considering the various models of circular saws, it should be remembered that this tool poses a health hazard. For this reason, it is important to select this tool with particular care, taking into account the following points.

Particular attention should be paid to the economic component. When choosing a saw, you should take it in hand, try to understand if it is comfortable enough for you to hold it.

Do not think that the same model can be suitable for two people, since each of us has a different body structure, skills and habits. over, it does not even play a big role here, whether a circular saw of a trusted manufacturer is considered or not.

You should also take into account the material from which the protective casing is made. It must be characterized by high strength, the ability to withstand deformation in the event of a tool fall.

Test in operation the regulators located on the model body. Set up a few different angles. Find out if they just twist and twist just enough.

Make sure you can easily get to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, as neglecting these points can lead to serious injury in the future.

Cutting depth

The value for this parameter ranges from 0 to 85 mm. The exact figure is determined by the class of the saw. Saws offered today can provide different cutting depths, which are determined by the power of the engine.

Disk rotation speed

This parameter is directly influenced by power. Increasing the rotational speed allows for a more accurate cut. It should be borne in mind that when cutting plastic, it is advisable to choose a low cutting frequency, since otherwise you may encounter such an unpleasant phenomenon as the melting of materials caused by a high speed of rotation of the blade. The standard figure for this parameter for professional models is 5000 rpm.