Containing Mint. Cut saw mint

Harness its vigor in the garden, enjoy its bracing flavor in the kitchen

Sometimes in the summer, I steal away to a secret spot on our farm. This is The Herbfarm’s dump, a collecting ground of cast-off potting soil and homeless plants. Here, amid motley patches of other herbs, the robust mints have made a home. And how they thrive! By July, I can stroll chest-deep through huge, healthy patches of peppermint, spearmint, and Apple mint.

No kitchen garden should be without at least a few mint plants. For drinks or desserts, or to pair with savory foods, mint’s clean and bracing flavor has earned it a place in many recipes.

But mint is never content to stay put, and can be one of the most invasive plants in the garden. So to avoid starting an herbal jungle, you’ll want to keep mint in check.

Start with two mints

Mint wants to cover the earth. Left to its own devices, mint multiplies by sending out fast-spreading underground runners.

Though there are names for 600 mints or more, there are only 25 or so truly distinct forms. Because mints cross and hybridize easily, it is best to propagate them by taking cuttings, dividing roots, or buying plants rather than starting them from seed.

Before you begin planting exotic mints, start with the two cornerstones of any kitchen mint collection—peppermint and spearmint. Peppermint (Mentha piperita), with its head-clearing aroma and expansive, menthol-cool flavor, gets the decided nod for tea, for dessert, and for taming spicy fare. Peppermint is popular in Middle Eastern, African, and Southeast-Asian cuisines because its cooling effect offsets the fiery ingredients.

Peppermint leaves are dark green, smooth, and have tiny serrations along the edges, as the photo at right shows. The stem is touched with a deep violet, almost chocolate, color. Peppermint loves partial shade, good rich soil, and moisture.

In our restaurant, we choose spearmint (Mentha spicata) to go with savory fare. Because its flavor isn’t as overpowering as peppermint’s, spearmint accentuates the subtle, natural sweetness of meats and vegetables. It also blends well in sorbets and dessert sauces.

Spearmint leaves are thinner, more pointed, and more coarsely serrated along the edges than peppermint leaves. They’re a medium-green color and have an overall pebbled texture, clearly evident in the top photo. Spearmint tolerates more sun and a somewhat drier soil than does peppermint.

Once you’ve got a basic patch growing, try experimenting with other mints. Chocolate peppermint is a good choice for desserts and confections. True mint and curly mint can substitute for spearmint. Exotic mints, such as pineapple mint, lemon mint, Apple mint, and ginger mint, are often more aromatic than our two mainstays, but are usually less flavorful.

Growing mint

Growing mint Start with cuttings or plants, not seeds. Plant in containers to keep mint from spreading. Water the soil deeply. Pinch back for bushier plants. Cut plants to the ground as winter approaches. Divide and repot root-bound plants.

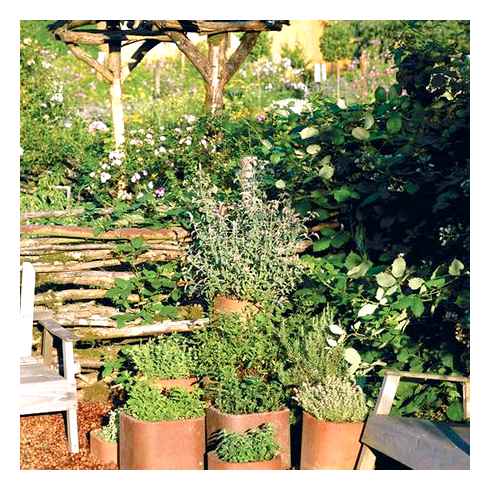

Potted mint can’t stray

Creative gardeners have tried almost everything to keep mint from invading neighboring beds and walkways. At our farm, we curtail its habit by planting it in terra-cotta chimney-flue liners. These can be set directly on the ground or partially buried, and because they have no bottoms, drainage isn’t a problem. By playing around with their placement, you can add architectural interest and charm to your garden.

Flue liners are available from building or masonry suppliers. They are 1 ft. square and 2 ft. long, but they can be shortened using a circular saw with a masonry blade. Like most terra-cotta, the flue liners can spall—that is, they flake off in pieces with repeated exposure to rain, snow, and freezing. Our liners usually last five to eight years before their antique charm seems excessive.

To plant your mint containers, you will need one to three mint plants per liner. Fill the liner to within 1 in. of the top with rich potting soil. Make a hole in the soil a little larger than the mint’s root ball, place a plant in the hole, and pack the soil firmly around it. Sprinkle the soil with a little time-release fertilizer if you wish. Water in the plants well. Finally, positioning your fingers like mine in the photo at left, pinch off the top two to four leaves on each plant. This will make the mint branch out and become bushy.

Keeping mint healthy

Water mint deeply and heavily once in a while, rather than watering it lightly more often. To help prevent the spread of leaf diseases, such as rust, water the soil and not the foliage. Pinch off any leaves that have small brown spots on them—these could be rust. If your plants become heavily infested with rust, pull them up and throw them out. If this seems too drastic, try cutting the plants back to the ground and sprinkling the surface of the soil with a liquid sulfur compound.

Mint plants stay healthy and produce better if you pick them regularly and often. If you need just a little mint or want an attractive garnish, pinch off the top two sets of leaves. If you need a lot of mint, cut the stems near the ground, leaving just a couple of leaves, as I’m doing in the top right photo on the facing page. Don’t worry—your mint pots will soon be full of lush new growth.

Mints are perennial, but in most American climates they go dormant or die back in the winter. Plants left above ground risk rotting or becoming woody. So when winter approaches, cut your mints right to the ground. Plants that have been cut back to their roots will be more prolific the following year. In cold climates, protect the roots by piling mulch around the pots or by bringing the pots into the garage until spring.

In about three years, your mint will probably outgrow its container. A sure sign that the plant is root-bound is when the center of the plant dies. Then it’s time to pry your mint from the container and cut the root mass into thirds, as I’m doing in the photo above. Then replant each third in new soil in a separate container.

Did you like this article? Our new Web site, vegetablegardener.com. is your place to go to learn everything about raising edibles, from starting seeds to preparing tasty dishes.

From Kings and Queens to blanks and banks

Producing coins is a very complex process. They might be familiar objects, but the range of processes and skills involved will surprise many people.

Every one of the millions of coins struck every year must meet very strict standards relating to composition, weight, thickness and design. The Royal Mint prides itself on mass-produced accuracy.

Artwork for the 2011 £2 coin marking the 500th anniversary of the maiden voyage of the Mary Rose

Making a coin involves three distinct steps: creating the designs, preparing the blank disc of metal and striking the coin.

Coin design

often than not, a coin design begins with a drawing. A design brief outlines the subject, but artists are given as much freedom as possible in interpreting the brief.

INTAGLIO MINT OCTOPUS #CASHCREW#GLIZZYGANG��

Artwork for the 2011 £1 coin depicting the official badges of the capital cities of the United Kingdom, with the badge of Cardiff being the principal FOCUS

Usually, both freelance artists and Royal Mint designers are approached, although sometimes the process is also open to the general public as with the latest £1 coin design, based on the artwork of 15-year-old David Pearce from Walsall.

The designs submitted by artists are then presented to The Royal Mint Advisory Committee, an independent panel of specialists in areas such as art, heraldry, lettering, sculpture, history and numismatics.

Artwork for the 2016 £2 coin marking the 400th anniversary of the death of William Shakespeare

After careful consideration the Committee picks a winning design for recommendation to the Chancellor of the Exchequer, who also holds the title of Master of the Mint. Once endorsed by the Chancellor, the design is passed to The Queen for final approval. Only after Her Majesty has approved a design can The Royal Mint begin production. It is an approval process that can take several months to complete and the same procedure occurs for each and every coin design found in your change.

Christopher Ironside

When Britain changed from the old system of pounds, shillings and pence to the current system of pounds and pence, new designs were needed for the coins.

Christopher Ironside

Christopher Ironside was one of the leading coin designers of his generation, so it was natural that in the early 1960s he was one of those approached to produce ideas for these decimal coins. He worked tirelessly on the designs in total secrecy for a number of years before learning in 1966 that the Chancellor of the Exchequer, James Callaghan, had decided it would be better to start again with an open and anonymous competition.

Ironside decided he would enter the public competition and eventually, his years of work paid off. His designs were chosen for the reverse or ‘tails’ side of all six new denominations, from the halfpenny to the 50p.

Definitive reverses designed by Christopher Ironside for the first United Kingdom decimal coins

Design and die-making

From the winning design, a large-scale plaster model is prepared with the details cut into the plaster by hand. Working at a large scale allows tiny details to be included that would be nearly impossible to do if working at the actual size of a coin. The plaster is placed on a scanning machine where a digital camera photographs the details from all angles. As a digital image, changes can now be made on screen, and when complete the digital file is turned into a cutting programme, instructing a computer-controlled engraving machine to cut the design into a soft piece of steel at coin size.

From left to right: Computer-controlled engraving machine; Hand engraving

The resulting tool, known as a reduction punch, is the first in a series of tools which, after a number of stages, result in the finished dies which are used to strike the coins.

The tools used to strike the coins are often worked on by hand to ensure the resulting coins are of the highest quality.

The exact composition of each coin is agreed between The Royal Mint and HM Treasury and is a closely guarded secret.

Metal ingots for melting

The different metals required for each coin are melted together in a furnace which can reach temperatures of up to 1450°C. A sample of this molten metal is then analysed to confirm the composition is correct.

Furnaces in the melting, rolling and blanking facility

The melt is then poured into a holding furnace where it is cooled before being rolled out into a continuous strip which is wound into large coils.

Each coil can weigh approximately 2.5 tonnes.

Coils of metal in the factory

Casting impurities are removed from the surface of the strip by a scalping machine, where rotating blades shear off half a millimetre from the upper and lower faces. This transforms the dull and grubby appearance of the strip into one that is clean and shiny.

The strip, usually cast about 16mm thick, has to be rolled down to the correct thickness. A heavy roller initially reduces the strip to around 3mm before the process is completed on a finishing mill where the strip is reduced further to the correct thickness.

Around 480,000 blanks for 1p pieces can be punched from a single coil.

Coil strip metal

Blank discs of metal of the correct size are punched from the strip in a blanking press; a single blanking machine is capable of producing some 8,000 blanks a minute. Next, the blanks are placed in a rimming machine. This gives them a slightly raised rim which serves a number of purposes including making the coins easier to stack and protecting the surface of the coin.

Blank discs punched from the strip in a blanking press

With the rise in costs of raw materials The Royal Mint is also able to offer plated coins, and a number of United Kingdom coins are today made from plated steel.

A thin layer, of copper, nickel or brass is electroplated directly onto a steel blank. The resulting coins typically have a lifetime of 25-30 years in circulation and, as a result, plated blanks and are becoming an increasingly popular option with many countries around the world.

Having become work-hardened, the blanks must be annealed, or heated, in order to soften them ready for striking. To achieve this, they are passed along a conveyor belt through an annealing furnace, where they are heated at temperatures of up to 950°C.

Blank discs being fed into the annealing furnace

The blanks are then pickled, or cleaned, in an acid solution to remove any blemishes from the surface. Ball bearings are added to the drums containing the blanks and, together, they are swirled around in a cleaning solution, the abrasive action of the ball bearings and the solution cleaning the surface of the blanks. After a final diluted wash and dry, the blanks are ready for striking.

Large stillages of clean and shining blanks are then tipped into a container, known as a hopper, above a coin press. Each blank is fed into perfectly sized recesses in a circular plate. As the plate rotates, the blank is held by a collar as it sits between a pair of dies. With one strike, the heads and tails are added and the blank disc becomes a coin.

Coining presses can strike around 750 coins a minute.

Newly struck £1 coins

Since at least 1282 coins produced by The Royal Mint have been independently checked in a procedure known as the Trial of the Pyx. It is thought to be the oldest independent control process in the world.

It takes its name from the pyx or box that holds the sample coins set aside for testing. The Trial consists of an examination by a jury entirely independent of The Royal Mint, to check the coins are of the proper weight, diameter and composition. They are checked against official trial plates made of gold, silver, nickel, copper or zinc.

Trial of the Pyx ceremony

Today the Trial is conducted each year by the Goldsmiths’ Company of the City of London. A jury is sworn in by The Queen’s Remembrancer, the senior judge who presides over the ceremony. Throughout the year, in preparation, thousands of coins are set aside by The Royal Mint and a sample of these is selected by the jury for testing.

During the trial the jury first counts the sample coins to see that the correct number are present, and then the coins are weighed in bulk. Some are also weighed individually to confirm that they are within the tolerance allowed by law.

After an interval of two or three months the jury’s verdict is delivered to The Queen’s Remembrancer in the presence of the Master of the Mint or his deputy.

There can be no question that the most famous figure in the history of The Royal Mint is Sir Isaac Newton, appointed Warden in 1696 and then Master three years later.

Isaac Newton

Over a 30-year period he played a full and active part in running the Mint raising its status by his presence and scrupulous behaviour. Given his FOCUS on accuracy, it is no wonder that he reacted angrily in 1710 to the judgement of the jury at the Trial of the Pyx that his gold coins were below standard. The coins had been tested against the newly introduced gold trial plate of 1707 and the failure was of serious and personal concern to Newton. He simply would not accept that coins made under his direction could be sub-standard.

From left to right: 1707 gold trial plate

He was able to prove that it was the plate that was wrong, not the coins. The plate had mistakenly been made finer than the legal requirement.

Newton had cleared his name, as well as that of the Mint, and he saw to it that the previous plate of 1688 was returned to use.

NEW Silhouette Curio and Silhouette Mint

Wow! I go out of town for a few days and whole new line of Silhouette products is announced. That made for a pretty fun return home!

First, you’ve got the new die cut (and more) machine, the Silhouette Curio.

According to Silhouette, this machine will cut, emboss, sketch, stipple, and etch. It will emboss three ways: regular emboss, score and emboss, and print and emboss. The new Silhouette Curio has a dual carriage allowing it to do two things at once, like emboss and cut.

The Curio has a higher clearance than the Cameo allowing it to cut thicker material like woods, foils and thicker leathers.

There’s one drawback. The Curio only has an 8.5″ x 6″ cutting area. I assume that means a larger machine will come out later. You might remember that Silhouette got its start with the Silhouette SD, which had a small cutting area. They held onto that machine for years before coming out with the larger Cameo. I think it’s a strange choice to come out with less than a 12×12 cutting area for this new machine, but I’ll still be buying one.

It will be available in August at some places. Amazon is offering pre-orders of it now. Retail price 249.

Silhouette is also rolling out a Cloud that will sync your Design Store library which will make it accessible on other devices. With the Cloud, your design library is portable, so you can take your projects with you. You can learn more about the Cloud here.

The Cloud will be available August 2015.

This is super cool! You can make your own custom stamps with this little buddy. Choose from your Silhouette designs, create from your own fonts, import a photo, or design your own. You can learn more about the mint here. If you’re super eager to have one, it looks like it is a rebranded version of the Casio Pomrie, which is available now on Amazon.

It will be available in the Fall of 2015. Retail price 129.99.

Silhouette has a new deep cut blade, vinyl, scratch off sticker paper, pens and more coming out too. You can see those things here.

I love it when new stuff comes out, don’t you? The only hard part will be waiting for these new things to be released. I can’t wait! Which new product are you most excited about?

Similar Posts

Silhouette Cameo Party Banner – Glue Dots Design Team Post

Glass Etched Mirror Christmas Word Art

Комментарии и мнения владельцев

I’m excited about all of it, but I think the Curio mostly. I like the idea of a dual carriage and a wider clearance. My only problem… what to do with my current Silhouette when I buy a new one?!

curio 8.5 in. x 6 in. base 8.5 in. x 6 in. cutting mat 8.5 in. x 6 in. embossing mat Keep your Cameo, you will still need to use it on bigger projects

Thanks for the information! Does anyone know if the new blades are compatible with the Cameo and Portraits?

Thanks for the info Joy! Very interesting about the Casio Pomrie, I’ve been dying to know exactly how the Silhouette Mint works, but after watching YouTube videos on the Casio Pomrie, I don’t think I’m interested. The stamp material seems expensive, the stamps look a bit bulky to store and I’m not too fond of how you ink them up. I had my doubts when I saw their sample card with the washed out black ink (but I will admit I can be picky in that department).

I think it’s a strange choice to come out with less than a 12×12 cutting area for this new machine, but I’ll still be buying one. Counting down the days. It’s definitely on my to buy list

So many new toys, and so little time (and money!) I also agree about the smaller cutting space….seems an odd size.

I’m new to this and purchased a design in the store online….it came with 3 different designs, I only want to cut 1 design, how do I do it?

I am new to this and am about to purchase my first machine. I am torn between the Cameo and the Curio. Any suggestions or preferences?

Hi Shantelle, I would suggest you go with the Cameo for one main reason, the cutting area is bigger. That makes a huge difference in what you are able to create. (You can always cut/design smaller things with a bigger machine, but not the other way around.) Over the years, I’ve heard a lot of complaints from people who bought smaller sized machines and soon after wanted to upgrade to the bigger size. I should have remembered that recently when I bought a smaller sized embroidery machine and quickly wanted to upgrade to the larger one. Ack! So, that’s my 2 cents. I hope it helps!

Hello Joy and WOW! Fantastic blog, I’ve been reading so many of your posts (and re-reading!) trying to figure out what die-cut machine is the right choice for me… That is, when I’m not distracted by a “” that’s too cute to ignore! I’ve never purchased a die-cut machine before but I’m really interested in the opportunities it could open. The first issue I’m concerned with is the type of material I use. Many articles and Комментарии и мнения владельцев use being able to cut thicker materials as a selling point – what about thin materials? I FOCUS a lot on upcycling materials like old magazines, newspapers, and comic books that are printed on very thin delicate paper. From watching your videos I worry they would stick to the mat and tear, or even if the blades would cut the material properly! The other primary issues I’m concerned with is the software – I need a user friendly highly adaptable system where I can easily create my own designs. I am not particularly tech savvy but, for example, can use basic Apple software reasonably well – and I would prefer to not be dependant on an Internet connection all the time! Finally, I’m curious if you have had an opportunity to use the Silhouette Curio yet! If so, how does it compare? Wow, this is getting long now, but in case you’re interested… The initial reason I was inspired to investigate a cutting machine option was because of my new passion for making paper beads! Especially with an appropriate top coat, they’re surprisingly durable and you can create endless varieties – each hand rolled bead is lovely and unique, and I enjoy the process of rolling the beads, but measuring, marking, and cutting sheets of paper by hand is tiresome, time consuming, and not at all fun! Mostly, I need to be able to cut long thin triangles (as narrow as a half centimetre at the base tapering to a point the length of a magazine page!) – I really hope you are able to help me out and suggest a solution – either way, thank you for making such fantastic posts and being a glowing beacon of hope in a world that needs more crafts! xoxo KatS =^.^=

Sunshine Mint

Based out of the city of Coeur d’Alene, Idaho, Sunshine Minting is one of the most renowned private minting facilities in America. Not only does this mint process gold bullion, silver bullion, and other precious metals, but it also supplies silver planchets to the United States Mint. The US Mint then strikes silver coins using the some of the Sunshine Mint supplies silver planchets.

Of course as displayed here, the Sunshine Minting Inc. also has high quality, anti-counterfeit, low priced bullion products that are highly regarded in the bullion industry.

Sunshine Mint History

Sunshine Minting was founded in 1979. Over the past three decades, it has become the world’s largest silver supplier to the minting industry (Source).

Although Sunshine Minting is based out of Idaho today, it began its journey as a small business in Chino, CA. It started this journey with the name ‘TENTEX,’ which is an amalgam of the words Texas and Tennessee – the birthplaces of the husband and wife team who started this venture.

Is It Bad To Remove Original Mint Packaging (OMP) Part 2. Pressburg Mint!

The company’s primary FOCUS was set on making silver rounds and silver bars for bullion dealers and marketing agencies across the country. TENTEX quickly gained recognition for its quality and reliability.

Five years after its inception, Sunshine Mining, a mining enterprise based out of Kellogg, Idaho, acquired TENTEX in 1984. The company shifted its operations from Chino to Coeur d’Alene, Idaho that year, and took on the name – Sunshine Bullion Company.

The Sunshine Bullion Company expanded its client-base significantly and launched a line of exceptional silver bullion products – the famous Sunshine Silver Eagle Rounds. This series caught on quickly and attracted buyers from every section of the precious metals market, and it still does even to this day. However, these Silver Eagle rounds are not to be confused with the American Silver Eagle coins, which are coins struck by the US Mint, materializing over a year later in 1986.

After close to a decade, Sunshine Mines decided to sell the minting arm of its company. The founders bought back their business and formed another private limited company with the all-familiar name we know today – Sunshine Minting, Inc.

Although Sunshine Minting struggled for survival for over three years until 1997, it finally landed a contract to supply 1 oz pure silver planchets to the US mint, with a little help from a well-known precious metals refinery across the border in Canada.

Johnson Matthey Limited, Canada had been awarded the contracts for gold and silver blanks supply to the US Mint. However, the Canadian company decided to pivot their business strategy and needed to exit the silver and gold blank fabrication business to accomplish their goals. In 1997, a team from Johnson Matthey Limited flew to Idaho and assisted Sunshine Minting meet the stringent quantity and quality standards required by the United States Mint.

The rest, as they say, is history. Soon after landing the planchet contract, Sunshine Minting saw an inflow of capital that it reinvested into expanding its operations.

Current Sunshine Minting Operations

Sunshine Minting has evolved into a full-featured precious metals refinery and minting establishment. Steady, quality precious metals releases keep it on every buyer’s and collector’s radar.

Their in-house services now include – Art and Design, Tools and Die Casts, Assay Labs, Quality Assurance Services, Melting and Casting, Extruding, Precious Metals Alloying, Rolling, Annealing, Blanking, Gold Plating, and Edge Lettering and Serial Numbering.

With manufacturing facilities in Idaho, Nevada, and Shanghai, in addition to offices in Canada, Austria, and Argentina, Sunshine Minting, Inc. is considered a behemoth when it comes to top-notch privately-owned minting companies.

Sunshine Mint Technology

MintMark SI /h3>

This technology from Sunshine Minting, Inc. has protected the SMI brand for years. It is an exclusive scrambled indicia security method that aids the fight against counterfeiting. MintMark SI consists of a micro-engraving that is readable only when seen under a MintMark SI decoding lens.

Watch This Customer Produced Video To See How The Decoder Lens Works

COINWISE /h3>

COINWISE was one of the first technologies to leverage the use of smartphones running on Android and iOS. It allows companies to market to end-users directly. over, unlike QR codes and barcodes, this machine-readable technology is hidden within the gorgeous design of a coin, round, or bar – ensuring that these Sunshine Minting bullion product’s aesthetic appeal is not affected.

Popular Sunshine Minting Products

Sunshine Mint Silver Eagle

Probably the most renowned of all the silver rounds struck by Sunshine Minting, Inc., the Sunshine Mint Silver Eagle series precedes even some of the longest-running government silver coin programs.

Every silver round released in this series contains 1 troy ounce of 0.999 pure silver.

These silver rounds bear the image of an Eagle soaring across the sky with the sun in its backdrop. The famed MintMark SI mark grabs the center stage on the other side of this round. The mark is depicted as the sun – a Smart way of using elegant designs and creativity to mask the technology housed in it.

Sunshine Buffalo Silver Round

These silver rounds are modeled after the famous Indian Head Nickels. Not only does this series offer a more accessible and economical way of collecting renowned designs like Black Diamond the Bison and the Indian Chieftain, but it also helps build a cache of tangible pure silver assets that add value to your portfolio.

Every round contains 1 troy ounce of 0.999 pure silver.

The obverse features the famed Native American Chieftain complete with traditional headgear. On the other hand, the depiction of Black Diamond accompanies the MintMark SI mark on the reverses.

Sunshine Walking Liberty Silver Round

Replicating the famed Walking Liberty design created by Augustus Saint-Gaudens, this silver round from Sunshine Minting is nothing short of a tribute to American history, values, as well as the talented sculptor.

Every round in this series, much like other silver rounds from Sunshine Minting, contains 1 troy ounce of 0.999 pure silver.

The obverses bear the famed Walking Liberty design – featuring Lady Liberty walking across the landscape with the rising sun in the background. On the other hand, the reverses display John Mercanti’s rendition of the Heraldic Bald Eagle design, with the MintMark SI mark smack in the middle of the eagle’s portrayal.

Holiday Collection

Sunshine Minting, Inc. celebrates the festive season with holiday-themed releases. Melding colorized designs with elegant artwork and pure silver, these silver rounds successfully capture the holiday spirit for all to see and celebrate.

Each of the rounds released under the holiday collection contains 1 troy ounce of 0.999 pure silver.

Both sides of these rounds bear a festive message, depiction, or wish – making them thoughtful gifts to distribute throughout the holiday season.

Sunshine Mint Silver Bars

Available in various sizes, these silver bars from Sunshine Minting offer investors an opportunity to amass pure silver in the most cost-effective way possible.

Sunshine Minting releases 0.999 pure silver bars as heavy as 100 troy ounces – making storage relatively more convenient compared to smaller stores of silver like rounds and coins.

The mint’s steady stream of top-notch silver products over the past three decades in addition to technologies like MintMark SI give investors and collectors confidence in any product associated with the name Sunshine Minting, Inc.