Converting a screwdriver to lithium batteries

Conversion of a screwdriver to lithium batteries 18650 14 V

When converting screwdrivers of different power and flashlights from Ni-Cd to Li-ion, batteries of the form factor 18650 are more often used. They easily fit into a container or a nest, since instead of two or three relatives, one lithium is installed. Alteration of the screwdriver battery should be carried out taking into account the peculiarities of lithium 18650 batteries.

This type of energy source does not tolerate deep discharge and excessive charge. Hence, it is necessary to use voltage control boards. Since each battery has its own character, their charge is corrected by a balancer. The point of reworking a screwdriver with a voltage of 14.4 V lies in creating a device using lithium batteries to facilitate a hand tool and increase its performance. Lithium 18650 batteries are most suitable for these purposes.

When selecting components, it should be taken into account that the starting current of the screwdriver is high, you must select the appropriate BMS for the required number of cans and at least 30 A. To convert the charging of the screwdriver to a lithium battery, you must stock up on a good soldering iron, non-acidic flux and thick wires to make jumpers.

- Lithium-ion cans in the amount of 4 pcs.

- 4 cell li-ion battery controller, CF-4S30A-A works well. It has a built-in balancer that controls the charge of each element.

- Hot melt glue, flux for soldering TAGS, solder.

- Heat-resistant tape;

- Connecting jumpers or thick insulated wire with a cross section of at least 0.75 squares, cut for bridges.

The procedure for converting a screwdriver for 18650:

- Disassemble the case and remove a bundle of 12 Ni-Cd cells from the container.

- Remove the garland, leaving the connector with the “” and “-” pins. Instead of a temperature sensor, a thermocouple from the controller will be installed.

- Solder the assembly, considering that you cannot use acid, only neutral flux and pure solder. During the connection period, do not warm up the covers. Work pointwise.

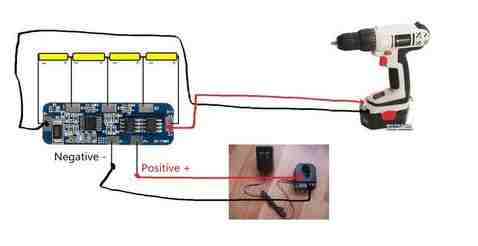

- Connect the balancing points to the controller according to the diagram. The board has connectors.

- Connect assembly with plus and minus pins.

- Check the functionality of the circuit. If everything works, assembled the battery, place the controller in the socket, secure with a sealant.

If the charger is not universal, additional alteration will be required. Screwdrivers for 12 V with a universal charger are assembled in the same way, but a protective circuit for connecting 3×18650 3.7 V for lithium batteries is used. In the same way, a screwdriver is reworked using a set of 18650 batteries in the amount of 2 elements.

Accumulators and batteries

Energy storage information website

Alteration of the “Hitachi” 12 V screwdriver for lithium batteries 18640

Features of reworking the 12 V Hitachi screwdriver for lithium batteries. The very compact battery compartment is designed for finger cells. Therefore, you should prepare a place for 18650 cells. It is necessary to cut one side of the partition in order to tightly place 1 element.

You need to get a gumboil, a flat metal connecting tape, hot glue. It is necessary to install lithium batteries in a screwdriver during rework through a protective controller. It should serve 3 18650 cells, 3.7V, and rated for 20-30 amps.

Remove the old battery from the socket, carefully disconnect the contacts in the assembly with the temperature sensor and the power indicator. Clean up and sign contacts. They should be brought out to one side, connected with solder to the leads from thick wires and filled with hot melt glue on the assembly.

Assemble a power source with one of the 3 cell controllers. Build a serial circuit of 3 Li-ion cells. Connect the controller. The conversion of the 12-volt lithium battery is completed when the structure is installed in the unit, secured, and the charging indicator lights up. After fully charging, the measurements show 12.17 volts in the external network. But this is enough for trouble-free long-term operation of the device.

Conversion of the Makita screwdriver to the lithium battery

There is a “Makita” screwdriver with a 1.3 A / h battery and a voltage of 9.6 V. To change the power source to a lithium-ion one, you will need 3 18650 components. The alteration will give the old tool new possibilities: it will increase the operating time on a single charge. will add power as the operating voltage rises to 10.8V.

The design will require the use of a BMS, a control controller that maintains the lithium cell operating mode within operating limits. With this breaker, each cell will be charged evenly without exceeding 4.2V, the lower voltage is 2.7V. The built-in balancer is used here.

The parameters of the controller should accompany the operation of the instrument when the operating current rises to 10-20 A. The Sony VTC4 30 A board, designed for a capacity of 2100 A / h, can ensure operation without shutdown. Of the 20 amperes, the Sanyo UR18650NSX accepting 2600A / h energies is suitable. The board is needed for 3 elements, which is marked in the 3S classification. In this case, the board must have 2 contacts, plus and minus. If the conclusions are designated with the letters “P-“, “P”, “C-“, they are intended for later models of screwdrivers.

Step-by-step instructions for converting a Makita screwdriver to lithium batteries looks like this.

- It is possible to disassemble the battery with glue if you tap the junction with a soft-headed hammer on the weight. Direction of impact downward, butt-joint along the lower part of the body.

- Take only the contact plates from the old assembly, carefully disconnecting them from the battery. The sensor and the breaker must be left.

- Solder 3 elements in series using TAGS flux and insulated jumpers. The wire cross-section must be greater than 0.75 mm2.

- Assemble the circuit with the controller, and connect the power supply to the contact connectors with 1.5 square wires.

- Check the functionality of the circuit and reassemble the case by placing it on the glue again.

Upgrading dead Black and Decker Screwdriver to Li-ion. 282

In a screwdriver with an old DC9710 charger, after charging the 18650 lithium battery, the red LED on the panel will turn off. The built-in controller monitors the charge level.

The Makita DC1414 T charger is used to charge 7.2-14.4 V power sources. While charging, the red light is on. But when charging a lithium battery, its voltage does not fit into the standards of salt products, and after 12 V the charger will flash red and green. But the necessary charging is already there. The screwdriver is ready to work.

The meaning and procedure for converting screwdrivers to lithium batteries

- Each Ni-Cd bank provides 1.2V and Li-ion 18650 3.6V.

- The capacity of a lithium battery is 2 times that of a nickel-cadmium battery, similar in size.

- An overheated li-ion battery threatens an explosion and fire, therefore, the installation of control of the uniformity of the charge in the banks is mandatory. BMS is not installed in nickel-cadmium batteries. the manufacturer is not interested.

- Lithium cells have no memory effect, unlike Ni-Cd, they can be charged at any time and within an hour.

- The screwdriver becomes much easier after converting the battery to li-ion, using 18650 cells.

There are only two obstacles to converting a screwdriver for lithium batteries. it is impossible to work with it at minus. The capacity of cans decreases, starting from a decrease already from 10 0 C. Lithium batteries are expensive.

Knowing what input voltage is required for the screwdriver, the charger is reworked, taking into account the placement of the lithium battery cans and control elements in the factory container. You can also do with a flashlight by upgrading the socket for a block of 18650 cells.

Let’s say you need to rework a 12 V screwdriver using Ni-Cd cans on li-ion. If you use 3 cans, the output voltage is not enough: 3.6 x 3 = 10.8 V. With 4 components, the power of the apparatus will be higher: 3.6 x 4 = 14.4 V. This will make the instrument 182 g lighter. its power will increase slightly, capacity. solid pluses. But when dismantling, it is necessary to leave the terminals and the native thermal sensor.

Converting a screwdriver to lithium batteries 18650

Every craftsman is faced with the problem of reduced tool performance, or complete failure due to the battery. Manufacturers use nickel-cadmium batteries in 12, 14, 18 volt screwdrivers. The sequential assembly of several elements creates the required voltage. Replacing nickel-cadmium batteries with lithium batteries extends battery life by making the design lighter. Mandatory BMS board installation adds reliability. Therefore, the conversion of a screwdriver to lithium batteries, mainly to the 18650 form factor, is justified.

Alteration of the Interskol screwdriver for lithium batteries 18650

Sooner or later, the nickel-cadmium assembly of 15 cans fails. One or two elements are lazy, and it is no longer possible to get the output voltage. Modern DSh “Interskol” on lithium batteries serve much better. Alteration of a screwdriver for 18 volt lithium batteries mastered by craftsmen.

It is necessary to purchase a protection board for 5S, 3.7 V and 40-50 A. You will need a balancing board and the energy sources themselves. 5 lithium 18650 batteries, you can leave them with factory thermistors by extending the wires. During installation, create a contact pad, insert the assembly, check the operability, secure. The assembly features of the wizard’s advice are given in detail in the video. See here for full details on reworking an 18-volt lithium screwdriver

What you need to estimate before starting work?

It is necessary to determine the number of cells in the battery, which ultimately decides the magnitude of the voltage. For three elements, the ceiling will be 12.6, and for four. 16.8 volts. We are talking about reworking widespread batteries with a nominal value of 14.4 volts. It is better to choose 4 elements, since during operation the voltage will drop pretty quickly to 14.8. A difference of several volts will not affect the operation of the screwdriver.

In addition, more lithium cells will give more capacity. This means longer operating time of the screwdriver.

Lithium battery cells 18650

The nominal voltage of lithium cells is 3.6-3.7 volts, and the capacity in most cases is 2000-3000 mAh. If the battery case allows, you can take not 4, but 8 cells. Connect them two by two into 4 parallel assemblies, and then connect them in series. As a result, you will be able to increase the capacity of the battery. But not every case will be able to pack 8 cans of 18650.

And the last preparatory step is choosing a controller. According to its characteristics, it must correspond to the rated voltage and discharge current. That is, if you decide to assemble a 14.4 volt battery, then choose a controller with this voltage. The working discharge current is usually chosen half of the maximum permissible current.

Charge-Discharge Controller Board

Above, we established that the maximum permissible short-term discharge current for lithium cells is 25-30 amperes. This means that the charge-discharge controller must be rated for 12-15 amperes. Then the protection will be triggered when the current increases to 25-30 amperes. Do not forget also about the dimensions of the protection board. It, together with the elements, will need to fit into the battery case of the screwdriver.

Converting a screwdriver battery to lithium cells

Many screwdriver owners want to convert their batteries to lithium battery cells. Many articles have been written on this topic and in this material I would like to summarize information on this issue. First of all, consider the arguments in favor of converting a screwdriver to lithium batteries and against it. And also we will consider some moments of the process of replacing batteries.

The cons

- Lithium battery cells cannot be charged above 4.2 volts and discharged below 2.7 volts. In real conditions, this interval is even narrower. If you go beyond these limits, the battery can be damaged. Therefore, in addition to the lithium cans themselves, you will need to connect and install a charge-discharge controller in the screwdriver;

- The voltage of one Li─Ion cell is 3.6─3.7 volts, and for Ni─Cd and Ni─MH this value is 1.2 volts. That is, there are problems with assembling a battery for screwdrivers with a voltage rating of 12 volts. From three lithium cans connected in series, you can assemble a battery with a nominal value of 11.1 volts. Out of four ─ 14.8, out of five ─ 18.5 volts, and so on. Naturally, the voltage limits during charge-discharge will also be different. That is, there may be problems with the compatibility of the converted battery with a screwdriver;

- In most cases, 18650 cans are used in the role of lithium cells for alteration. They differ in size from Ni─Cd and Ni─MH cans. In addition, you will need space for the charge-discharge controller and wires. All this will need to fit in a standard battery case of a screwdriver. Otherwise, it will be extremely inconvenient for them to work;

- A cadmium battery charger may not be suitable for recharging a battery after a redesign. You may need to revise the charger or use universal chargers;

- Lithium batteries lose their performance at low temperatures. This is critical for those who use a screwdriver outdoors;

- The price of lithium batteries is higher than cadmium.

Pros

Let’s start with the benefits:

- The energy density of lithium-ion cells is much higher than that of nickel-cadmium, which are used by default in screwdrivers. That is, the battery on lithium cans will have less weight than on cadmium with the same capacity and output voltage;

- Lithium battery cells are charged significantly faster than Ni-Cd. It will take about an hour to charge them safely;

- Lithium ion batteries have no memory effect. This means that they do not need to be fully discharged before charging.

Now about the disadvantages and complexities of lithium batteries.

Battery replacement

Well, then the assembly process itself follows. Disassemble the battery case first. If this is a 14.4 volt model, then there will be 12 nickel-cadmium batteries with a nominal value of 1.2 volts inside.

Assembling Nickel Cadmium Batteries

After that, you need to solder the purchased items into an assembly with a serial connection. Next, the controller is soldered to it in accordance with its circuit. In this case, balancing points are connected. The board has a special connector for them, and often wires with a connector are supplied in the kit.

Screwdriver battery housing

After assembling the battery, the terminals for plus and minus are soldered, and the whole structure is placed in the case. In principle, this is the end of the process. Problems can only arise with the charger. But in most cases, standard screwdriver chargers charge lithium cells without problems. In this case, the charge of the cans goes through the controller, so nothing terrible will happen to the elements themselves.

All pros and cons of converting a screwdriver battery to lithium cells

First, you should think about whether I need this alteration? After all, it will be a frank “self-propeller” and in some cases can lead to failure of both the battery and the screwdriver itself. Therefore, let’s consider all the pros and cons of this procedure. It is possible that after that, some of you will decide to abandon the conversion of the Ni─Cd battery for a screwdriver to lithium cells.

Replacing batteries in a screwdriver with lithium

Interview

I also reworked the 14.4V screwdriver for Li-ion

I also took a ready-made controller from the Chinese, but different. The indicator was made on TL431, on them (TL431), in principle, the balancer can be made.

You write it is better to use 4 batteries, since the voltage will quickly sink to 14.8v, here I agree, but the words that this will increase the volume are not correct, with a serial connection, the capacity does not change, and the capacity of one battery is equal, the capacity increases with parallel connection.

Dilyaver, and here you are only partly right. The fact is that the capacity in mAh will remain the same, this is a fact, but. the capacity in Watt hours will increase.

In this review, there is more crap than real advice (and the videos from YouTube have chosen the same dumb, empty ones). I remember such an example. The controller in China (according to their replicas) costs like a new lithium battery !? Yes, where and when it was. About ten minutes ago, a specialist looked at Aliexpress. it is overwhelmed, see the one I need, at 18 V. with delivery from 1.8 to 3-4-6 dollars, and this is with a temperature sensor and soldered wires!

Good afternoon! Please give advice on which BMS controller is needed for the 18v, 1.2 A screwdriver. Thank you in advance.

For an 18v screwdriver, you need to take a 21v controller!

ru.aliexpress.com/item/Aihasd-21-1005S-BMS-LMO-Ternary/32831689172.html

Hello! Please give a link to the 14v charging module for 4 batteries, as you describe in your video. Could not find.

Hello! I have a question: if the protection board to the batteries is not balanced, do I need to connect intermediate wires? I have 3S, I connected from the first battery minus to 0v, and from the last plus to 12.6v. Loading and charging on other terminals (.). But at 3.7v and 7.4v, I did not connect anything. Shurik twisted like that a couple of times, when the cartridge was clamped, he turned off, and more and more does not twist. It seems to have loaded everything, but with a multimeter on. Connectors shows 7.6v. and in the batteries themselves there are 12.6v. Tell me what is wrong there?

The controller believes that the banks are dead, you need to connect intermediate banks, and do not consider yourself smarter than the developers!

Converting a screwdriver to lithium batteries 18650

Energy storage information website

Every craftsman is faced with the problem of reduced tool performance, or complete failure due to the battery. Manufacturers use nickel-cadmium batteries in 12, 14, 18 volt screwdrivers. The sequential assembly of several elements creates the required voltage. Replacing nickel-cadmium batteries with lithium batteries extends battery life by making the design lighter. Mandatory BMS board installation adds reliability. Therefore, the conversion of a screwdriver to lithium batteries, mainly to the 18650 form factor, is justified.

Alteration of the “Hitachi” 12 V screwdriver for lithium batteries 18640

Features of reworking the 12 V Hitachi screwdriver for lithium batteries. The very compact battery compartment is designed for finger cells. Therefore, you should prepare a place for 18650 cells. It is necessary to cut one side of the partition in order to tightly place 1 element.

You need to get a gumboil, a flat metal connecting tape, hot glue. It is necessary to install lithium batteries in a screwdriver during rework through a protective controller. It should serve 3 18650 cells, 3.7V, and rated for 20-30 amps.

Remove the old battery from the socket, carefully disconnect the contacts in the assembly with the temperature sensor and the power indicator. Clean up and sign contacts. They should be brought out to one side, connected with solder to the leads from thick wires and filled with hot melt glue on the assembly.

Assemble a power source with one of the 3 cell controllers. Build a serial circuit of 3 Li-ion cells. Connect the controller. The conversion of the 12-volt lithium battery is completed when the structure is installed in the unit, secured, and the charging indicator lights up. After fully charging, the measurements show 12.17 volts in the external network. But this is enough for trouble-free long-term operation of the device.

Conversion of a screwdriver to lithium batteries 18650 14 V

When converting screwdrivers of different power and flashlights from Ni-Cd to Li-ion, batteries of the form factor 18650 are more often used. They easily fit into a container or a nest, since instead of two or three relatives, one lithium is installed. Alteration of the screwdriver battery should be carried out taking into account the peculiarities of lithium 18650 batteries.

This type of energy source does not tolerate deep discharge and excessive charge. Hence, it is necessary to use voltage control boards. Since each battery has its own character, their charge is corrected by a balancer. The point of reworking a screwdriver with a voltage of 14.4 V lies in creating a device using lithium batteries to facilitate a hand tool and increase its performance. Lithium 18650 batteries are most suitable for these purposes.

When selecting components, it should be taken into account that the starting current of the screwdriver is high, you must select the appropriate BMS for the required number of cans and at least 30 A. To convert the charging of the screwdriver to a lithium battery, you must stock up on a good soldering iron, non-acidic flux and thick wires to make jumpers.

- Lithium-ion cans in the amount of 4 pcs.

- 4 cell li-ion battery controller, CF-4S30A-A works well. It has a built-in balancer that controls the charge of each element.

- Hot melt glue, flux for soldering TAGS, solder.

- Heat-resistant tape;

- Connecting jumpers or thick insulated wire with a cross section of at least 0.75 squares, cut for bridges.

The procedure for converting a screwdriver for 18650:

- Disassemble the case and remove a bundle of 12 Ni-Cd cells from the container.

- Remove the garland, leaving the connector with the “” and “-” pins. Instead of a temperature sensor, a thermocouple from the controller will be installed.

- Solder the assembly, considering that you cannot use acid, only neutral flux and pure solder. During the connection period, do not warm up the covers. Work pointwise.

- Connect the balancing points to the controller according to the diagram. The board has connectors.

- Connect assembly with plus and minus pins.

- Check the functionality of the circuit. If everything works, assembled the battery, place the controller in the socket, secure with a sealant.

If the charger is not universal, additional alteration will be required. Screwdrivers for 12 V with a universal charger are assembled in the same way, but a protective circuit for connecting 3×18650 3.7 V for lithium batteries is used. In the same way, a screwdriver is reworked using a set of 18650 batteries in the amount of 2 elements.

Battery connection diagram

To get the cherished 12 or 18 V, the elements must be connected in series. That’s it, no tricks, just observe the polarity. The minus of each battery is connected to the plus of the next one, the outer two wires are connected to the terminal block.

If you double the capacity, not individual batteries are connected in series, but assemblies of 2 cells. In each assembly, the positive contact is connected to the positive neighbor, the same is the case with the negative.

So that in the end the jumpers between the batteries do not intertwine into an indistinct web, think over the connection scheme in advance. It is most convenient to solder the batteries when they are already wound in a tight bundle, choose the minimum length of the jumpers.

For soldering, the contacts of each battery should be well tinned. First, clean them with a file or fine sandpaper, removing the top nickel layer. Use phosphoric acid as a flux, the most common solder is POS-61 with rosin. The soldering iron must be powerful, 60 W, no less. Lithium batteries must not be overheated categorically, the contact time with the sting is no more than 2 seconds. Therefore, first we tinker, let it cool, then we solder.

Also, pre-tin the jumpers from a stranded conductor of 2.5 mm 2 and supplement them with balancing wires so that one wiring falls on each node between parallel-connected batteries or groups. The length of the wires. to reach the balancing connector in the case, the cross section is about 0.5 mm 2.

When soldering, the tinned core of the jumper is first heated, then it is brought to the contact of the battery until the solder melts on it. During cooling, you can press down the seam with a wooden chip. And do not spare the tin. the connection must be very reliable. Also, do not forget to wash off the remnants of the flux, otherwise after six months or a year of operation, all efforts will go to waste. Rinse the intricate positive contact with particular care; rubbing alcohol or acetone can be used to remove it.

If you try to solder the outermost wires of the battery to the nickel contacts of the shoe, you will most likely ruin it hopelessly by overheating the plastic. It is much better to drill two holes 3-4 mm in diameter and tighten the veins to the plates with a couple of small screws. Here it is convenient to use strips with double holes, which were massively plucked out of old Soviet forks.

Along with the outermost wires of the battery bundle, screw a couple more balancing wires. The resulting balancing cable must be soldered in a specific order. From the datasheet to the connector, determine its contact, numbered with one, and solder a wire from the positive terminal to it. Then follow the battery chain and solder the wires in series, one after the other, ending by connecting the last contact with a common negative core.

Disassembling the case

The first step is to disassemble the battery case into two halves. The easiest way to do this is if the battery pack is tightened with 4-5 screws: just unscrew them and pull out the top.

If the battery case is glued together (Makita, AEG), then the hassle will significantly increase. We lay the battery on its side and carefully tap the glue seam with a rubber mallet. The blows are accurate, not strong, and frequent. We beat off the joint evenly around the perimeter and try to stretch the halves every 50–100 strokes. Even the most stubborn corps surrender in 10-15 minutes of such “execution”.

Next, we throw away the unnecessary parts of the content. The terminal block must be carefully torn off the two upper cans so that two nickel tongues remain on it. Looking ahead, let’s say that usually, when reworking, a new package of batteries is welded together by contact welding in the manner of factory ones. This is a cool solution, but not everyone wants to build a welding machine. Therefore, leave the length of the strips so that the wires can be fixed to it with two small bolts, and the rest of the elements will be connected by soldering.

In any convenient part of the case, you also need to make a hole for the JST-XH balancing connector. On the outside with an awl we mark a rectangle 6 mm high and 15 mm wide for a battery voltage of 12 V or 20 mm for a voltage of 18 V. Insert the connector into the hole made and secure with hot glue or epoxy.

Alteration of the Interskol screwdriver for lithium batteries 18650

Sooner or later, the nickel-cadmium assembly of 15 cans fails. One or two elements are lazy, and it is no longer possible to get the output voltage. Modern DSh “Interskol” on lithium batteries serve much better. Alteration of a screwdriver for 18 volt lithium batteries mastered by craftsmen.

It is necessary to purchase a protection board for 5S, 3.7 V and 40-50 A. You will need a balancing board and the energy sources themselves. 5 lithium 18650 batteries, you can leave them with factory thermistors by extending the wires. During installation, create a contact pad, insert the assembly, check the operability, secure. The assembly features of the wizard’s advice are given in detail in the video. See here for full details on reworking an 18-volt lithium screwdriver

Many screwdriver owners want to convert their batteries to lithium battery cells. Many articles have been written on this topic and in this material I would like to summarize information on this issue. First of all, consider the arguments in favor of converting a screwdriver to lithium batteries and against it. And also we will consider some moments of the process of replacing batteries.

Replacing batteries in a screwdriver with lithium

Assembling a new battery (3pcs. 18650):

Alteration of a screwdriver for 12v lithium batteries

Alteration of the native charger (eerie collective farm):

We will remake with the calculation of the possibility of charging the old type of batteries.

We take our Chinese board, connect it to the laboratory power supply unit, set it to 19v, or disassemble the charging and cling to the diode outputs.

We turn the voltage trimmer resistor and set the output voltage to 15V. native Ni-Cd batteries have a full charge voltage of 1.4v-1.5v, and we have 10. For a new battery assembly, this parameter is indifferent, the main thing is more than 12.6v.

UPD: The protection board with the balancer automatically disconnects the batteries when the voltage on the batteries is 12.6V, so the 15V voltage is not important to us. It is important for us when charging old batteries. there is no protection board.

We switch the multimeter to the current measurement mode. We unscrew the current trimmer resistor counterclockwise (like in this direction) to the end, i.e. we set the minimum output current. We connect the ends of the multimeter to the output, close the circuit, set the current to 1A. The higher the current, the faster our battery will charge, but everything will also heat up more. Don’t put more than 1.5A out of harm’s way. This completes the setup of the board.

We disassemble our memory. To implement the new board, we will need to unsolder the native memory board, remove everything except two LEDs, a diode bridge, and a smoothing capacitor, as well as the battery connector itself. This is done because we will not be able to plug in the new board. the body kit interferes with the board. I decided to leave the original board intact and make a collective farm.

Berm a breadboard, diode bridge, capacitor, two LEDs, or we solder it all from the motherboard. We also solder the contact connectors.

Next, we need to collect on the layout, see fig. (as I could) what is circled in black line.

And solder our LEDs as shown. Brown is a minus for us, and orange is a plus (what wires were there). So that we do not break off the wires at the soldering point, we will fill them with hot melt glue. We solder everything according to the scheme. Do not mix up the polarity of the capacitor and all connections. We attach the LEDs in the case with hot melt glue.

As a result, we have such a collective farm.

Now we check everything, assemble and use it. For me, the protection with this board does not work when pressed, but by hand, perhaps, to make it work. The charge lamp turns off when the charge current is less than 10% of the set, i.e. less than 0.1A

This article discusses:

What we have: the old Interskol Da-12ER-02 screwdriver working quite vigorously, but with dead batteries.

Our goal: to replace old Ni-Cd batteries with new li-ion

For alteration according to my version, we need:

- – screwdriver Interskol Da-12ER-02)))

- – soldering iron from 60W because less powerful you cannot dissolve

- – multimeter (tester)

- – “Soldering acid”. there are many variations of them, we take with a brush

Precautions:

- – when working with batteries, you must be extremely careful not to short circuit them, at the moment of short circuit at the point of contact, huge currents arise, which can lead to burns, damage to the eyes, explosions and fires. As well as the exit from the standing of all components.

- – when working with acid, you must be extremely careful because it can get in the eyes, skin, etc. the consequences can be very sad.

- – perform work only on disconnected equipment from the 220V power supply. It should also be borne in mind that capacitors are used in power circuits, which accumulate charge and when you disconnect the device from the network, this does not mean that the board is de-energized.

Assembly:

We use batteries with ponytails already welded on. First of all, we remove the protection from the tails, then we need to tin the ends. Tinning without the use of acid (carefully) you will not succeed in such a way that we take acid, a soldering iron and solder and tinker. We trick from both ends. We apply the acid in a thin layer, this is quite enough, otherwise you will get splashes in different directions.

If you bought acid without a brush, then you can pour it into a tube of nail polish, or you can use a disposable syringe, where you squeeze out a drop and immediately pull it back, leaving a thin film. We also need to tin the pluses of the first two batteries, in these places we will connect the batteries to each other.

After you have tinned everything, we solder the batteries in sequence, see fig. On one of the batteries, the tab is turned in the opposite direction. We also make soldering with a powerful soldering iron, simply by attaching the tongue and pressing the tip of the soldering iron. This is what we should get.

Now we fix everything with electrical tape or it can be done in advance before soldering. Glue double-sided tape to fix the board.

Let’s start soldering the batteries to the board.

Result:

We disassemble the native battery. We take out the old batteries (Caution).

We bite off the black piece and solder it. We need thick wires. we will have currents up to 25A in periods or more. that with thin wires can lead to their fire, as well as we will have a loss in power. Carefully put the batteries aside.

Now we need to find a thick, wide, relatively soft pad of 1.5-2cm. I tore it from the packaging of a certain gadget. Cut to the size of the case and put it on the bottom, glue the double-sided tape and glue the batteries. We fix that black thing, the protruding end should be of such length that it rested against our batteries and allowed the case to be closed with a certain interference. Do not reverse polarity!

In this case, the brown wire is minus, and the black wire is plus. Brown is an order of magnitude thicker than black.

We cut the wires, making them as short as possible, so as not to lose current through losses, but we must take into account that we still need to be soldered to the board. We solder and assemble the case, the battery is ready.

About the native charger.

At idle, the charger gives us 19-20V and the short-circuit current. did not measure. The manufacturer claims the operating current is 1.8A.

Diagram of SD-C804S memory found on the Internet.

The scheme has, in my opinion, a number of incorrect designations, but not the essence. There are no nodes in the circuit that would monitor and limit the charge current. But there is a circuit for monitoring the execution voltage on the U1 microcircuit (not a fact, it was not possible to confirm the operability of this node), as well as a charge time limiting node performed on the U2 microcircuit.

What is stopping us: the charging time limitation circuit interferes with us, but it can simply be turned off, otherwise everything seems to be fine. But, I could not get the charger to show the end of the charge. Turning on the native battery for charge, the charge indicator lit up, but breaking the circuit on the battery i.e. we received the supply voltage at the output, the indicator did not go out, but it should have been, if the end of the charge is regulated by the voltage on the batteries (I am not an expert in electronics and I cannot understand how it completely works). And for us this is a critical moment because the protection board of our molded batteries at the end of the charge simply breaks the circuit.

There were many thoughts on how to do exercises. from the modernization of the current circuit, with automatic selection of which battery is inserted old or new on simple elements, to the front end of everything on Arduino with control of everything and everyone. But all this takes a lot of time and effort…. It was decided not to reinvent the wheel and go like everyone else.

As a charge control, a DC-DC converter with charge current control on the XL4015 microcircuit was chosen read

How long does it take to replace batteries?

Converting the screwdriver to lithium batteries will take approximately 2 hours. If all parameters are checked, then it will take 4 hours.

Everything can be done on your own, without the help of another person. But contact welding and selection of batteries cannot be carried out without specialized equipment.

Disassembly and assembly

Converting a screwdriver to lithium batteries includes the following steps:

- Open the old battery by unscrewing five screws.

- Remove the Ni-Mh battery from the housing. It will be noticeable that the contact pad engaging with the contact group of the screwdriver is welded to the negative contact of one of the Ni-Mh cells. The welding points should be cut using a tool with a DREMEL 4000 cut-off stone installed in it.

- Wires are soldered to the contacts, the cross-section of which is at least 2 mm 2 for the power leads and 0.2 mm 2 for the thermistor. The contact pad is glued to the battery case with hot melt glue.

- According to the indicator of internal resistance, four cells are selected on the meter. The value must be the same for all four fixtures.

- Lithium cells are glued with hot melt glue so that they are compactly located in the housing.

- Welding of cells is carried out on a resistance welding machine by means of a welding tape made of nickel (its cross-sectional index should be equal to 2X10 mm).

What lithium batteries look like?

Most lithium devices are housed in a prismatic body, but some are cylindrical in shape. These batteries use roll electrodes and separators. The body is made of aluminum or steel. The positive pole goes out to the housing cover.

In prismatic configurations, the electrodes are rectangular plates. To ensure safety, a device is provided in the battery that acts as a regulator of all processes and opens the electrical circuit in critical situations. Increased sealing of the case does not allow electrolyte to leak out and oxygen and moisture penetrate inside.

How to Determine the Choice of Lithium Cells?

In order to make the selection of lithium-based cells, the limiting factors should be outlined. Currently, lithium devices are produced with a permissible load current of 20-25 A.

Pulse current values (short, up to 1-2 seconds) reach 30-35 A. Battery configuration will not be violated.

Advantages of the second option

The second option is more suitable, because the voltage in the battery drops quite quickly from the maximum to the minimum (from 16.8 to 14.8 V). For an electric motor, which, in fact, is a screwdriver, an excess of 2.8 V is not a critical mark.

The lowest voltage indicator is for the 3S-Li-Ion modification. It is 7.5 V, which is insufficient for the normal functioning of the electrical device. By installing four configurations, we will increase the electrical capacity of the battery.

Choosing the rated voltage

First of all, you should decide on the choice of the voltage rating indicator for a lithium-based device. The choice should be made between the 3S-model (its voltage range is from 12.6 to 7.5 V) and the 4S-Li-Ion battery (voltage range is from 16.8 to 10 V).

Connecting to a screwdriver

- A sharp pull on the trigger provokes the activation of the protective current mechanism. But in fact, such a protective mode is unlikely to be needed when using the tool. If you do not specifically provoke protection, then the work of the screwdriver will be stable.

- The tip should be clamped in a vice. The battery power freely triggers the ratchet, which limits the increase in the number of torsion revolutions.

- The screwdriver’s lithium battery is discharged electronically. The discharge current should be 5 A.

- The battery is inserted into the standard charger. The charge current indicator when measured is 3 A, which is acceptable for lithium cells. For the LG INR18650HG2 configuration, the maximum charge current will be 4 A, which is indicated in the technical specification.

What else can you test the state of charge besides the controller?

The screwdriver was converted to lithium batteries. The built-in charger is ideal. But the cost of the controller is quite high. The device will cost 30. which is equivalent to the cost of the battery itself.

To test the charge level of a lithium battery on the go without using a charger, you can use the special RC helicopter lipo battery AKKU portable voltage meter tester alarm 2-6S AOK. The cost of the device is very low. It has a balance and charge connector similar to the iMax6. The device is connected to the battery via an adapter. This voltage level monitor is very convenient. It can measure from two to six lithium cells connected in series, and also give the total indicator or voltage of each element separately with extreme accuracy.