Correct Sharpening Of The Chainsaw Chain With A File

3 ways to sharpen a chainsaw chain with your own hands Learn how to properly sharpen a chainsaw chain at home using a file, grinder and machine. Detailed do-it-yourself sharpening process. We will show you how to work correctly with tools and devices.

File types and tips for choosing

Following the rules, before choosing files for sharpening the chainsaw chain, the exact chain pitch is determined by the chain marking. Further, they adhere to the recommendations:

| Step size | File diameter, mm |

|---|---|

| 0.25 | 2×2 |

| 0.325 | 2×2.4 |

| 0.375 | 2×2.6 |

| 0.404 | 2×2.75 |

There are saw chains where it is appropriate to use round files with a cross-sectional diameter of 2×1.6 millimeters.

Signs of a dull chain and the consequences of further operation

The difficulty of working with a dull chainsaw should not be confused with the difficulty of sawing hardwood or heavily dry logs. In all these cases, the speed of the operation decreases, but a blunt instrument has a certain character of behavior, signs by which one can judge the need for sharpening:

- The chainsaw does not immediately bite into the tree trunk, as if grinding, moving from the point of contact;

- During cutting of soft breeds, the tool sluggishly enters the thickness of the wood, you have to press on the tire;

- Shavings from large with characteristic oblong particles turn into small thyrsa, which very rarely crumbles;

- The chain heats up quickly and there is an unpleasant smell of burning oil to lubricate the guide bar.

In addition to these alarms, always after hitting a chain on metal nails, wire or burying a chainsaw in the ground, you can be one hundred percent sure of the need for subsequent sharpening of cutting edges.

What can happen to the tool later if you ignore the problem? The most harmless chainsaw will be impossible to work, in the end it will get bored and will force you to service the unit. But adherents of the saying Strength is mind is not necessary can come to the following conclusion:

- An extra load on the body, because, frankly, you have to put pressure on the tool so that it saws;

- Overconsumption of fuel up to 30%, which is explained by the need to go through a longer cycle of revolutions to achieve the same result;

- Accelerated wear of the tire and other parts of the chainsaw.

In addition to all these negative consequences of a blunt saw, there is a high probability of the chain jamming in the trunk and injury to the operator performing the work.

Than manual sharpening is inferior to machine

- Difficulty keeping the required angle. There is no need to think that only one round file can be used to sharpen the chainsaw chain; for this operation you will need at least a special guide and a second flat file.

- Low speed of the operation. It is necessary to fix the guide on the tooth, manipulate with a round file, check the gap between the limiter, if you need to correct it with a flat file, and only then proceed to the next tooth.

- The need for experience. Despite the various helpers for sharpening a chainsaw by hand, first of all you need to feel the process, and this requires some experience.

3 ways to sharpen your chainsaw chain with your own hands

Learn how to properly sharpen a chainsaw chain at home using a file, a grinder and a machine. Detailed do-it-yourself sharpening process. We will show you how to work correctly with tools and devices.

It is very convenient to work with a chainsaw. Despite the fact that the unit weighs 57 kilograms, or even more, cutting a tree trunk into logs, you simply wonder how quickly this happens, and there is practically no fatigue. But then the moment comes when it is harder and harder for the tool blade to enter the wood. Diagnosis one saw is dull, so it is required to sharpen the chainsaw chain.

Whoever comes across this for the first time is a little upset, because it is not clear whether to do it yourself or give the instrument to specialists in the workshop. And what is the general sharpening method? But in fact, there is nothing terrible here, and with the knowledge you can easily sharpen chainsaw chains with your own hands. The correct strategy for solving the issue in this case directly depends on the load of the unit.

If a chainsaw is used from time to time, several times a year, then it may not make sense to buy a special sharpening machine or accessories, it is easier to solve the problem by using the services of a service center. But if a chainsaw is a means of earning or there is a desire to master the sharpening process yourself, then you should definitely purchase a sharpener or a machine and manually carry out this simple manipulation of the chain. Let’s see below what the correct sharpening of the chainsaw chain is based on.

Sharpening the chain with a grinder

For the operation you will need:

- Bulgarian, preferably slightly powerful and large;

- Cutting wheel for metal of the corresponding diameter and 23 mm thick;

- A vise or clamp to firmly secure the grinder to the table.

The grinder is clamped in a vice so that the disk is located strictly vertically, without a protective casing, in the direction of the operator. Sparks must fly towards the operator, therefore protective clothing and goggles must be worn to operate. The grinder is turned on and, observing the angle, each link of the chainsaw chain is sharpened by eye.

Sharpening angles and configuration of the chainsaw tooth

- The base is the lower part of the tooth, which has holes for connection with the rest of the chain elements and during operation is hidden in the guide channel of the bar. It is this part that is lubricated.

- A special stop is an element of the tooth structure that allows the cutter to remove only a certain thickness of wood chips in one pass. Thanks to him, the chain does not get stuck in the fibers, and the chainsaw does not wedge.

- The so-called blade of a tooth is a cutter consisting of vertical and horizontal working surfaces that form cutting edges.

Tooth blades, or cutting edges, need to be sharpened at a specific angle, otherwise it will be difficult to achieve optimal sawing characteristics of the chain. The upper blade (horizontal) has the function of cutting the tooth into the wood and forming a groove. The side or end blade (vertical) helps to trim the fibers from the side.

The productivity of operations when sawing wood in the transverse direction increases if you increase the angle of sharpening of the chainsaw chain to the maximum possible and vice versa. Chains designed for longitudinal cutting of the tree trunk should be sharpened at an angle of approximately 10 degrees.

Under no circumstances should the depth gauge be touched once again: improper grinding can lead to vibration during tool operation. Its finishing is done according to a special template.

DIY chainsaw sharpening

The chain tooth planes the wood like a plane, and the chip thickness is adjusted by the height of the stop.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. The shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. The service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by an increased feed force, then the teeth are dull. A dull chain can also be recognized if only small chips fly out of the cut instead of coarse, thick chips.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. The consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means reduced productivity, high fuel consumption and increased wear on all parts of the chainsaw.

Chain sharpeners

The round file holder has a mowing line that can be correctly positioned in relation to the chain. The holder fits onto the sharpened tooth in accordance with the line orientation. In this case, the insert itself rests on the upper edge of the tooth and the depth gauge, and the file is located under the cutting edge.

The use of a holder ensures that the file will fit to the tooth at the correct height. There are different holders for different pitches of the saw chain. The correct choice of holder, combined with the correct file diameter, ensures that the file protrudes over the back of the tooth by 1/5 of its diameter. Use only special saw chain files.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, keeping the position of the holder and pressing the file to the sharpened edge, to make several (2-3) turning movements away from you. Do not try to press too hard on the file, the movements should be smooth and measured. Rotate the file regularly to avoid one-sided wear. All other teeth are sharpened in the same way. It is more convenient to first sharpen the teeth in one direction, then change the position and do the same with the teeth in the other direction.

When sharpening all teeth, file the same number of strokes at the same pressure. This will result in the same tooth length. All cutting teeth must be of the same length. Different tooth lengths cause uneven chain running and cracking. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. To do this, a template is superimposed on it so that the limiter falls into the slot, and the tip protruding from the slot is grinded with a flat file.

The principle of using a different set for sharpening chainsaws is no different from the first, although its design is different.

A round file is also used to sharpen the cutting tooth, and the depth gauge is used to sharpen the depth gauge. Flat. A special template provides parameters for sharpening both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. The direction of movement of the file must be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the slot, near which it says SOFT (for soft wood) or HARD (for hard wood). As in the case of the first tool, the file is seamed with smooth, even movements of the flat file away from you.

General rules for sharpening chainsaw chains. Chain teeth parameters

To achieve optimal cutting properties, the tooth blades are angled. The back of the tooth falling back at an angle forms the posterior angle of the upper blade. This angle is needed to cut the upper blade into the wood.

The backward tapering blade of the tooth forms the back angle of the end blade. This angle is needed for side cutting of the chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. The rake angles for different types of chains range from 60 to 85.

The back angle of the top blade refers to the backward tilt of the top blade.

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 to 60. The upper blade is the main blade and the rear angle of the upper blade. This is the most important corner. The clearance angle of the upper blade is difficult to measure, and the correct value is obtained by observing other prescribed values.

The sharpening angle or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. Rule of thumb: the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the angle of sharpening when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 and less than 25 should be avoided (except for rip chains, where this angle is 10).

The rake angle, sharpening angle and upper blade angle change during sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

A depth gauge is located on each cutting link in front of the tooth blade. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus the productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and type of execution. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will lead to an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. After 5-10 chain sharpenings.

Chainsaw chain sharpening machines

Stihl produces two versions of hand-held machine tools. Stationary FG 2 and mobile FG 1 mounted directly on the tire. There are analogues of lesser-known companies, comparable in price with the simpler devices described above.

The working part of these devices structurally resembles a bow saw, into which a round long file is inserted instead of a saw blade. FG 1 and FG 2 not only sharpen chains, but also straighten them, adjusting the length of the top edge of all teeth to the same size. On the smallest tooth, which is taken as the control one. A rather complex configuration mechanism allows you to set all the necessary parameters. Sharpening is done with 2-3 movements, after which they proceed to the next tooth, keeping for it all the settings that were made for the control tooth. This ensures the same sharpening parameters for all teeth. When sewing the stopper, the round file changes to a flat file.

Simple and convenient to use electric chain sharpener for chainsaws. It has an adjustment system that allows you to set the chain at the desired angle and bring the disc exactly to the sharpened edge. There are machines that automatically clamp the vice when the disc is lowered onto the chain.

General rules for sharpening chainsaw chains. Chain sharpeners

The round file holder has a mowing line that can be correctly positioned in relation to the chain. The holder fits onto the sharpened tooth in accordance with the line orientation. In this case, the insert itself rests on the upper edge of the tooth and the depth gauge, and the file is located under the cutting edge.

The use of a holder ensures that the file will fit to the tooth at the correct height. There are different holders for different pitches of the saw chain. The correct choice of holder, combined with the correct file diameter, ensures that the file protrudes over the back of the tooth by 1/5 of its diameter. Use only special saw chain files.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, keeping the position of the holder and pressing the file to the sharpened edge, to make several (2-3) turning movements away from you. Do not try to press too hard on the file, the movements should be smooth and measured. Rotate the file regularly to avoid one-sided wear. All other teeth are sharpened in the same way. It is more convenient to first sharpen the teeth in one direction, then change the position and do the same with the teeth in the other direction.

When sharpening all teeth, file the same number of strokes at the same pressure. This will result in the same tooth length. All cutting teeth must be of the same length. Different tooth lengths cause uneven chain running and cracking. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. To do this, a template is superimposed on it so that the limiter falls into the slot, and the tip protruding from the slot is grinded with a flat file.

The principle of using a different set for sharpening chainsaws is no different from the first, although its design is different.

A round file is also used to sharpen the cutting tooth, and the depth gauge is used to sharpen the depth gauge. Flat. A special template provides parameters for sharpening both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. The direction of movement of the file must be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the slot, near which it says SOFT (for soft wood) or HARD (for hard wood). As in the case of the first tool, the file is seamed with smooth, even movements of the flat file away from you.

Chain teeth parameters

To achieve optimal cutting properties, the tooth blades are angled. The back of the tooth falling back at an angle forms the posterior angle of the upper blade. This angle is needed to cut the upper blade into the wood.

The backward tapering blade of the tooth forms the back angle of the end blade. This angle is needed for side cutting of the chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. The rake angles for different types of chains range from 60 to 85.

The back angle of the top blade refers to the backward tilt of the top blade.

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 to 60. The upper blade is the main blade and the rear angle of the upper blade. This is the most important corner. The clearance angle of the upper blade is difficult to measure, and the correct value is obtained by observing other prescribed values.

The sharpening angle or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. Rule of thumb: the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the angle of sharpening when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 and less than 25 should be avoided (except for rip chains, where this angle is 10).

The rake angle, sharpening angle and upper blade angle change during sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

A depth gauge is located on each cutting link in front of the tooth blade. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus the productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and type of execution. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will lead to an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. After 5-10 chain sharpenings.

DIY chainsaw sharpening

The chain tooth planes the wood like a plane, and the chip thickness is adjusted by the height of the stop.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. The shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. The service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by an increased feed force, then the teeth are dull. A dull chain can also be recognized if only small chips fly out of the cut instead of coarse, thick chips.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. The consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means reduced productivity, high fuel consumption and increased wear on all parts of the chainsaw.

Chainsaw chain sharpening machines

Stihl produces two versions of hand-held machine tools. Stationary FG 2 and mobile FG 1 mounted directly on the tire. There are analogues of lesser-known companies, comparable in price with the simpler devices described above.

The working part of these devices structurally resembles a bow saw, into which a round long file is inserted instead of a saw blade. FG 1 and FG 2 not only sharpen chains, but also straighten them, adjusting the length of the top edge of all teeth to the same size. On the smallest tooth, which is taken as the control one. A rather complex configuration mechanism allows you to set all the necessary parameters. Sharpening is done with 2-3 movements, after which they proceed to the next tooth, keeping for it all the settings that were made for the control tooth. This ensures the same sharpening parameters for all teeth. When sewing the stopper, the round file changes to a flat file.

Simple and convenient to use electric chain sharpener for chainsaws. It has an adjustment system that allows you to set the chain at the desired angle and bring the disc exactly to the sharpened edge. There are machines that automatically clamp the vice when the disc is lowered onto the chain.

Stihl chainsaw sharpening files Stihl

There are different files for sharpening Stihl Stihl chainsaws on the market. Despite the external differences, they are all proprietary. Some of them are accessories for sharpening machines and are sold in packs of several pieces. They have no handles and are therefore inconvenient to use without a base. Files sold individually can be packaged or sold individually. There are 2 options with and without a sharpening template.

In addition to files, Stihl also produces a range of accessories:

filing gauges;

sharpening mandrels;

templates (holders) of different types;

clamps.

The filing gauges are designed to check the depth of sharpening, clean grooves and check corners by hand.

The mandrel is a plate with guides applied on it, indicating the angle of sharpening of the link. By moving in accordance with the guides, it is easier to maintain the correct degree of the angle. It is attached with magnets to a metal rail.

The clamp works on the principle of a holder and allows you to sharpen the cutting and limiting teeth of the link in one step.

Stihl chainsaw files

Chainsaw chain file diameter

The diameter of the chain saw file is very important in the selection process. An incorrectly selected file will damage the chain and cause problems during the sawing process. The saw can get stuck inside a tree, break off, and damage expensive tools.

The diameter directly depends on the chain pitch. When sharpening, 4 main sizes of diameters are used, corresponding to their step:

Step ¼ diameter 4.0 mm;

Pitch 0.325 ″ 4.8 mm;

Pitch 3/8 ″ 5.2 mm;

Pitch 0.404 ″ 5.5 mm.

For some types of chains, files with a diameter of 3.2 mm are also used.

Different diameters of files for sharpening chainsaw chains

Chainsaw chain file

- How to choose a file for sharpening a chainsaw chain

- Chainsaw chain file diameter

- Stihl chainsaw sharpening files Stihl

- Correct sharpening of the chainsaw chain with a file

The cheapest way to sharpen your saw is to get chainsaw file and do it yourself without any help. However, this scenario implies a lot of nuances. You need to know how to choose a file, what characteristics are worth focusing on, learn the cutting technique, and, in the end, have patience, sharp eyesight and firm hands. The last three factors are indispensable, because without them it is impossible to sharpen the correct file with a file.

Chainsaw chain sharpening files

How to choose a file for sharpening a chainsaw chain

Most users are wondering: how to choose a file for sharpening a chainsaw chain. The answer to it is complex, since implies a lot of options. But the most correct way to pay attention to the chain pitch. The size (diameter) of the cylindrical file depends on it. But besides it, a second flat one is also required.

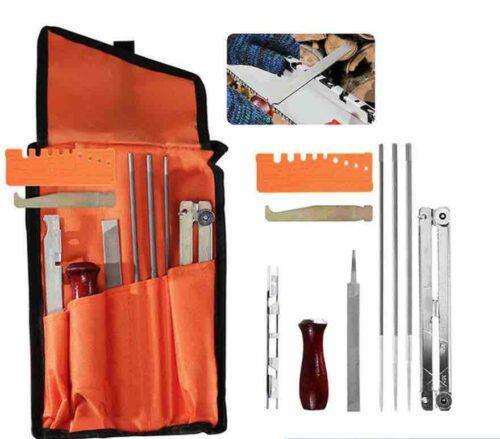

Two files are used to sharpen different parts of the same link. If we consider the process in more detail, the saw tooth of the link, namely the end and upper blades, is sharpened with a cylindrical file. Use a flat file to cut the depth gauge. It is important that both files can be purchased as a set with a set of templates and a hook for cleaning the saw and bar from the saw set. Some manufacturers of chainsaws and their electric chain analogues even produce similar kits themselves.

Different types of saw chain files

Correct sharpening of the chainsaw chain with a file

It is easiest to start sharpening directly on the bar, but some manufacturers oppose this, citing various arguments, and recommend removing the chain from the device and securing it in a vice. But this is extremely inconvenient, because After sharpening each link, the chain must be dismantled and reinstalled.

If, nevertheless, the sharpening of the chain takes place directly on the saw, the tire can move on the weight under the pressure of the hand with the file, therefore it is necessary to install a stop for the tire from the opposite edge, for example, a block of wood. It is important to clean the chain from sawdust, grease and debris before sharpening. This will make the job easier.

Sharpening the saw chain correctly with a file

Begin sharpening from the sharpened tooth itself. It is on it that all the others will be aligned. If the tooth is broken, it must be replaced by riveting the chain with a special machine and installing a new element of the appropriate size and type. After the element is selected, start sharpening. The file is moved straight away from you along the semicircular edge of the saw tooth, resting with the template against the edge of the adjacent chain link. In this case, it is necessary to observe the parallelism between the file and the plane of the surface on which the saw or vise is installed, as well as the angle of the guide indicated on the plate template.

Thus, all chain links are processed in turn through one, i.E. Only those that are on one side of it. At the end, they go to the other half of the links and do the same operation, but at the opposite angle, also indicated on the guide in the template. After completion, the file for sharpening the chainsaw chain is set aside, and the chain is swept with a brush, eliminating metal shavings.