Disassembly of the Makita 2450 Hammer Video

The assembly of any mechanism should begin after careful preparation. It is necessary to prepare not only parts, but also tools, a place, a lubricant.

Of the tools can not do without pliers, screwdrivers, a hammer, a brush for applying lubricant.

But what is the assembly scheme of the Makita 2450 and 2470 rotary hammer?

Do-it-yourself assembly of a Makita rotary hammer can only be carried out subject to the attached instructions.

The task of the assembly process is to replace the parts that have gone out of order with fit parts and to ensure interchangeability and operability of the tool.

Assembly order for Makita 2450 rotary hammer

Shock assembly

How to assemble the hammer mechanism of a Makita punch?

The impact mechanism is assembled from two nodes: the shaft shaft with a spur gear and the intermediate shaft with a rolling bearing.

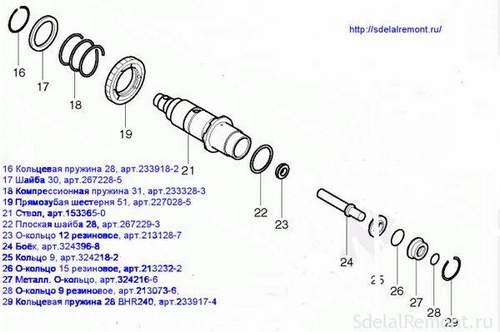

A). A spur gear pos. 19 is put on the barrel pos. 21 and pressed by a compression spring pos. 18.

For fixing, the spring is pressed by the washer 30 pos.17 and secured by the circlip 28 pos.16.B) To assemble the striker, put on the ring 9 pos. 25 on the striker shaft, tighten the rubber ring pos. 26, press down with the metal ring pos. 27.

Now go to the opposite side of the barrel pos.21. On the other hand, the inner surface of the barrel must be greased and inserted into the assembled drummer pos.24.

Assembling the intermediate shaft and piston

Assembly of the intermediate shaft assembly

To assemble the intermediate shaft, it is necessary to put the rolling bearing pos. 41 on the shaft pos. 40 with teeth to the splines of the shaft, put the coupling pos. 39 on the splines of the shaft.

Translational motion

On the opposite side of the shaft, a helical gear 26 pos. 42., A flat washer 8 pos. 45, a bearing 608zz pos. 46 and a snap ring 8 pos. 47 are put on.

The intermediate shaft is assembled.

Gearbox Assembly

The gear unit is mounted on the inner housing, item 49.

Inner casing

By the way, there are cases when the axles pop out of the inner aluminum case. Both axles are pressed into the housing.

The assembled intermediate shaft is inserted into the housing, pos. 49, the rolling bearing arm of which must fall into the hole of the cylinder hinge.In this case, the lever of the rolling bearing pos. 41 of the intermediate shaft must fall into the hinge of the cylinder pos. 32, and the lower bearing of the intermediate shaft in the socket in the housing. This procedure is usually carried out by rocking the structure until the parts completely get into the indicated places.

Setting the mode lever

The mode switch is designed to translate the clutch pos.39 in various positions and transmit translational motion to the shaft of the shock mechanism through the rolling bearing pos.41 to the cylinder pos.32.

Assembly of the lever of the switch of the regimes of the puncher of Makita 2450

On the axis of the inner case, put on the lever of the mode switch pos. 82, pressurizing spring pos. 88 on top, and press down with a flat washer pos. 87. Install the snap ring pos. 86. and fix.

The snap ring must be carefully fixed. Turning the intermediate shaft, it is necessary to carefully check the correct operation and free movement of the cylinder in the housing. This must be done now so that it does not become clear at the end of the assembly that the assembly was not assembled correctly.

Assembly of the shaft of the percussion mechanism

First, lubricate the inside of the cylinder, pos. 32, and insert the drummer, pos. 30, into it.

It remains to put the oiled barrel assembly in pos. 49 into the inner case pos. 21 in place, putting it on the oiled cylinder pos. 32.

As lubricants, it is recommended to use a special grease developed for Makita rotary hammers.

Lubricants are available in several types: Makita P-08361 and Makita 183477-5 SDS-PLUS.

Makita 183477-5 SDS-PLUS grease is recommended for the gearbox. For drill shanks, Makita 196804-7 brand grease is used.

Lubricants vary in color, but have exactly the same characteristics.

What lubricants are used in the Makita 2450 and 2470 rotary hammer?

And here is the assembled mechanical block.

Video of the general disassembly and assembly of the Makita 2450 rotary hammer

Check its performance by rotating the countershaft and controlling the movement of the piston in the percussion mechanism. Everything!

Now lubricate all parts of the mechanical unit with the recommended lubricant. Here is an example of proper lubrication on rotating surfaces.Here is another example of a generous lubrication of a mechanical unit.

Do not spoil the porridge with oil

So it is also allowed to apply grease. Do not spoil the porridge with butter!

A lubricated mechanical unit must always be closed with a plastic case, item 14, in black.

Having placed the housing on top of the assembly, press the housing down until the assembly is completely fixed in it.

Backwardness, insert the four screws, pos. 10, into the housing and tighten.Now it’s the turn of joining the mechanical part of the rotor of the electric motor.

Rotor installation

The helical gear of the rotor is firmly inserted into the body of the mechanical unit and pressed.

It remains to insert four self-tapping screws m4 × 60 pos. 57. and screw them into the body of the electrical unit.

Installation of electric brushes

Remove dirt from the grooves of the brush holder and put the brushes in place, fixing them with latches.

Now is the time to check the performance of the punch. Connect the punch plug to the outlet, turn on the punch for a while in the "drilling" mode. After making sure that the tool is working, turn it off. Set the mode switch to the “punch” position. Do not insert the tool.

Check the performance of the rotary hammer in this position. At the same time, you checked the operation of the mode switch.

It remains to check the installation of the speed control knob, make sure the contact connections are reliable and you can proceed with the installation of the cover plate.

Cover installation

The cover is fastened with three self-tapping screws M × 4 of different lengths.

Connect the rotary hammer to the 220Β network and check in all modes.

The Makita 2450 or 2470 rotary hammer is assembled and working properly!

Makita 2450 rotary hammer diagram

DIY Makita 2450 punch repair manual

Hammers are called percussion drilling devices designed for drilling and chiselling holes in particularly strong materials. Two ideas are implemented in the puncher: the working tool rotates and immediately moves longitudinally, creating a shock impulse.

Hammers always work in extreme conditions. The duration of the drill depends not only on the correct operating criteria, but also on the reliability of the parts included in the product.

But no matter how hard you try, over time, punchers begin to fail.

To properly repair the hammer, you need to study its device. Repair of the Makita 2470 and 2450 rotary hammer can be performed independently by a person who owns the capabilities of a locksmith and understands the basics of electrical engineering.

Remember! Compliance with safety regulations and disconnect hammer drill from the network during parsing.

Makita 2450 and 2470 rotary hammers are assembled practically according to a similar scheme and from among the same parts. Repairing them is no different. For ease of repair, the assembly diagram and catalog of parts for Makita rotary hammers are given below.

The Makita 2450 and 2470 rotary hammer circuit consists of a mechanical and electronic part.

The mechanical part provides the transmission of torque to the drill bit, creating immediately translational movement, creating a shock. The mechanical part consists of a rotation drive and a percussion mechanism.

The electronic circuit of the Makita rotary hammer provides the conversion of electronic energy into kinetic through the rotation of the rotor. The electronic part includes an electric motor, a power button with a speed controller, a reverse switch, connecting wires. The main makita rotary hammer malfunctions The malfunctions of the rotary hammers are divided into electronic and mechanical.

Next, we will examine our client remains the faults of the electronic part of the Makita 2470 and 2450 rotary hammers and methods for their elimination:

Electronic malfunctions of the Makita 2450 and Makita 2470 punchers Electronic malfunctions appear in such that when the punch is connected to the mains voltage, the tool does not cut. The connection scheme of the Makita rotary hammer to the network is ordinary.

The electronic circuit of the Makita 2450 rotary hammer is essentially a serial connection of the electric motor, start button and wires. The layout of the Makita 2470 rotary hammer is similar.

Through the connecting cord, pos. 72, the 220 V supply voltage is supplied through the switch pos. 68 and electronic brushes through the brush holder pos. 66 to the lamellas of the electric motor rotor pos. 54, and through the contacts of the reverse switch pos. 60 to the stator winding pos. 59. The most common malfunction is the lack of contacts in the connections.

The procedure for determining electrical faults

Video: Disease Makita HR 2470 Finished cutting into the puncher 2470 Burned contacts maintenance tool

Determination of the integrity of the electronic part of the Makita rotary hammer. If you set a goal to repair a Makita 2450 rotary hammer or a Makita 2470, you yourself need to arm yourself with devices and equipment. Any tester, a set of screwdrivers, wrenches, a hammer, a wooden extension will work. It is great to have a screwdriver with an integrated phase indicator.

You need to take the tester, connect to the ends of the punch plug and press the punch switch. If the tester indicates some resistance, then the power supply circuit of the punch is intact.

If the tester indicates infinity, then the integrity of the circuit is broken and it is necessary to remove the back cover to control the connecting cable and electric brushes of the punch.

The back cover (usually dark) of the punch is easy to remove, you just need to unscrew the three screws with a screwdriver or screwdriver.

Remove the cover and use a screwdriver to disconnect the ends of the wires from the electric brushes. Using a tester or a home-made device, also called an “arch”, determine the integrity of the lead wires and the correct operation of the switch.

A few words about the ordinary control device, the name of which is "arcade". The device consists of an LED or a bulb from a flashlight, a finger-type battery and 2 pieces of wire. The entire electronic circuit of the control device is alternately connected parts. Connect the battery with one end of the LED, in other words light bulbs, connect wires to the free ends of the LED and the battery. You will get a universal device for checking the integrity of electronic circuits.

Relevant malfunctions of the Makita 2450 and 2470 rotary hammer Common faults in the electronic part of the Makita 2450 and Makita 2470 rotary hammer:

- fracture of the supply cable at the entrance to the perforator;

- breakdown of the TG813TLB-1 switch button, art.650508-0, pos. 68.;

- wear of electronic carbon brushes SV-419, art.191962-4, pos.65;

- wear of reverse switch contacts;

- wear of rotor bearings: bearing 609LLU, art.210060-6, item 51; bearing 607LLU, art.211021-9, item 56;

- short rotor closure 220-240 V, art. 515668-8, item 54;

- breakdown of the stator winding 220-240 V for HR2450, art.633488-5, pos. 59.

For the start button, the switch TG813TLB-1, art.650508-0; pos. 68.

Substitution of the brushes is done with their complete abrasion or bad contact. This malfunction is found by strong heating of the points where the electric brushes are installed.

Video: Disassembly of the Makita 2450 Hammer Video

The failure to turn on the punch you like more is caused by the abrasion of the contacts on the reverse switch. This malfunction is eliminated to pain simply.

Makita rotary hammer reverser repair

When repairing the reverse switch, the back cover must be disconnected. Carefully disconnect the wires from the button. Look closely at the switch.

The upcoming disassembly consists in removing the brush holder, after having previously released the brushes themselves. Removing the brush holder, you will get to the contacts of the reverse switch.

Determine its condition, if necessary, change the contacts.

Additional, often encountered electronic malfunction, bad contact between the stator and the lower contacts of the reverse switch.

Repair contact between stator and reverse switch

To remove the stator, you need to disconnect the gear housing (dark color) from the stator housing (greenish color).

Remember! In the mechanical part of the rotor, the bearing is pressed by a special ring. When disassembling, do not lose it.

The stator is located in the greenish case. Having visited the middle, you will see two self-tapping screws 4 × 60, art. 266334-3, pos. 57, securing the stator to the housing. Unscrew them, remove the plastic protection of the stator for HR2450, art. 419201-3, pos. 58., Release the stator. When you get the stator, you will see the contacts on the stator and the reverse switch panel.

Carefully clean the contacts with sandpaper, treat with solvent or alcohol.

Before assembly, bend the contacts so that they fit tightly into each other. Lubricate the contacts with a technical Vaseline in a thin layer.

The assembly of the electronic part of the punch is done in reverse order.

Makita 2450 rotary hammer disassembly instruction

A hammer drill is a percussion drilling tool that immediately performs the function of percussion and drilling equipment while working with particularly strong materials.

The device used two ideas at once: the tool spins and moves longitudinally, transmitting the impulse of impact to a solid surface.

Hammers always operate in extreme environments with the highest degree of dust.

The uptime is affected not so much by the operating conditions, but by the quality of the components included in the tool.

Makita 2450, 2470 rotary hammers are reliable tools of high-quality work. Even the most reliable tool requires proper care and timely maintenance.

To perform maintenance on Makita 2450, 2470 rotary hammers, you must certainly become familiar with the internal contents of the tools that make up the components. A real annotation will help you find out the weak spots of a Makita punch.

To carry out repairs of the Makita 2450, 2470 rotary hammer in artisanal conditions, a person with locksmithing capabilities and knowledge of electrical engineering is allowed.

Remember! Carrying out repair of the puncher it is necessary to observe safety measures during the work with electric devices.

Makita 2450 and 2470 rotary hammers are assembled practically according to a similar scheme and, in fact, from similar, interchangeable parts. Repairing them is no different.

Type of punch Makita 2450

For ease of repair, the assembly diagram and catalog of parts for Makita rotary hammers are given below.

Makita 2450 rotary hammer assembly diagram

The device of Makita 2450 and 2470 punchers

The Makita punch conditionally consists of electronic and mechanical parts. At the same time, the mechanical assembly of the punch is located in a dark plastic case, and the electronic part of the punch is hidden under a greenish plastic case.

The procedure for disassembling the mechanical part of the punch

The mechanical assembly is designed to transmit the rotational moment of the shaft to the tool, creating not so much torque and translational shock impulse.

The task of the mechanical assembly is to transmit rotation from the rotor to the tool, while simultaneously providing the tool with longitudinal movement.

Disassembly of the punch begins with the removal of the quick-detachable cartridge.

Even very reliable Makita rotary hammers break down over time.

Any breakdown is eliminated, you only need to have straight arms and perseverance.

In addition to electrical malfunctions, rotary hammers are also subject to mechanical breakdowns.

Content:

The work of rock drills with solid materials in a dusty environment shortens the life of the machine and requires user intervention for repair.

Repair of the mechanical part of the Makita 2450 and 2470 puncher

Any repair of the tool begins with the determination of the nature of the malfunction and disassembly.

A Makita 2450 and 2470 rotary hammer can be repaired by a user with basic locksmithing skills and knowledge of electrical safety requirements.

This article discusses the mechanical part of the Makita puncher, the main malfunctions and how to solve them.

Dismantling the mechanical part of the Makita 2470 rotary hammer

To get to the mechanical part of the punch, you need to remove or disassemble the cartridge.

Dismantling the quick release chuck

Place the hammer drill on the back of the cabinet on the surface of a table covered with a clean cloth or paper.

Using tweezers or a screwdriver, remove the rubber tip 35, item 1.

Carefully loosen the annular spring, pos. 2, the clutch cover, pos. 3, the steel ring, pos. 4. You will reach a steel ball with a diameter of 7 mm, pos.20.

Now you can remove the case of the mechanical part

It is black.

Using a screwdriver, unscrew the four screws at the end of the case.

Holding the black case with your right hand, press the end of the shaft from which the cartridge was disassembled with your thumb. The plastic case is easy to remove.

Next, remove the gearbox shaft.

To disconnect the mechanical part from the electric, you must first remove the electric brushes.

Remember! In the lower part of the body, the rotor is held by electric brushes, which must be removed.

After checking that the electric brushes are disconnected from the lamellas of the rotor, use a screwdriver to pry the metal case of the perforator at the border of the green plastic case.

Now we proceed to disconnect the rotor from the mechanical part of the punch

pa The rotor is held in the mechanical part due to helical gears of the gearbox.

If you take the rotor case in one hand, and the mechanical part in the other case and pull it in different directions, swinging, you will separate these two nodes.

You get such a knot in the old grease.

Next, unscrew the two M4 × 12 bolts, pos. 43, using the hexagon, item 2666273-7 with the internal hexagon head.

Pull out the shaft with the intermediate spur gear 10 pos. 80, art.226399-7.

from the inner case pos. 49, art. 153687-8.

How to repair a Makita hammer drill

Clean parts from old grease.

You get such a mountain of clean details.

Now carefully review the details, immediately discard the rubber rings, picking up new ones.

Replace defective parts with new ones.

Mechanical makita 2450 and makita 2470 rock drill

Common mechanical problems with Makita rotary hammers include:

- destruction of the quick-release cartridge;

- bearing failure;

- breakdown of the shock mechanism;

- punch barrel wear;

- wear of rubber strikers and striker;

- gear breakage.

Repair of the perforator cartridge is done to replace the anther and rubber ring, as well as the conical spring and the steel ball, which provides clamping of the working tool (drill). What does the working tool indicate? namely, the drill is poorly held in the cartridge.

The main reason is the wear of a steel ball 7.0 pos.20, art. 216022-2. Ball wear occurs from contamination of the barrel of the cartridge due to ingress of dust and dirt.

The general view and arrangement of the Makita rotary hammer cartridge is shown in the photo below.

Do-it-yourself makita 2450 rotary hammer cartridge repair is easy to do. The cartridge must be disassembled, freed from old grease, discard rubber parts, replace defective ones.

complex failures require knowledge of the mechanical design of the Makita 2450 rotary hammer.

Having determined the nature of the malfunction of the Makita rotary hammer, proceed to disassemble the mechanical part called the gearbox.

Disassemble the mechanical part according to the attached video.

Release it from the old grease.

Carefully inspect all parts, their integrity, level of wear. All rubber products during any disassembly require replacement.

Consider repairing a perforator barrel. We will analyze the mechanism completely.

Video disassembly, lubrication and assembly of the Makita rotary hammer

Video: Makita 2450 rotary hammer bulkhead

Repair of parts of a shaft of the Makita 2450 puncher

Remember! In the lower part of the body, the rotor is held by electric brushes, which must be removed.

At the next stage, the rotor must be disconnected from the removed mechanism. The rotor is disconnected from the mechanism simply by pulling out, because it is held by the friction of two helical gears.

It turned out such a dirty knot.

Now you need to separate the shaft of the percussion mechanism.

Most often, rubber rings, striker poses wear out. 24, compressor spring pos. 18. and cylinder parts.

Here’s how barrel parts wear out and collapse during improper use of the tool.

Consider the most difficult malfunction. failure of the shock mechanism.

The characteristic signs of failure of the impact mechanism is the absence of impact and the unpleasant noise of a working punch in the “Impact” mode.

Video: A moment of vandalism) (21) Makita HR 2450 rotary hammer Strong impact in impact mode

Such a malfunction is typical for those perforators that during operation were pressed strongly against the work surface.

Having disassembled the gearbox, we remove debris and pieces of foreign objects. We find the defective part and clean everything from the old grease.

Very often the striker pos. 24 is destroyed, art. 324396-8, which is part of the trunk.

metal ring pos. 27. art. 324216-6.

Discard damaged parts, replace with new ones, cover with a thin layer of grease. Parts are ready for assembly. But more on that in the next article.

How to repair a Makita HR 2450 hammer drill if the shock mode is lost

Makita power tools have long established themselves as professional, reliable and easy to maintain. In addition, it has good maintainability and a relatively low price.

Of all the ruler ranges, I would like to dwell on the Makita HR 2450 model. The tool is very convenient in operation, has three operating modes and withstands very long loads. For the author of these lines, the puncher worked faithfully for more than six years without damage. over, it was used in intensive loads.

But as you know, nothing eternal happens. And reliable technology breaks down. Once, in the midst of work, he stopped pecking. In the rotation mode, the machine worked, and the blow suddenly disappeared.

The gearbox was disassembled and the cause of the breakdown was identified. A sleeve was broken in the barrel body, in which the striker (striker) directly performs shock work.

How to repair a Makita HR 2450 hammer drill if the shock mode is lost

As a result, the drummer stuck in the fragments of a collapsed sleeve.

The service center advised to replace the barrel completely. It turned out that the sleeve is pressed into the barrel at the factory and is not supplied separately. I had to buy a whole new barrel.

In this article, the author will tell you how to bring the puncher into working condition after this, in general, simple breakdown. If you have the skills to repair a power tool and the desire not to pay someone your hard earned money, then we take the tool and begin disassembling the car.

Instruments

It will take two ordinary flat head screwdrivers and one Phillips screwdriver. One of the flat screwdrivers should be thin and narrow, not more than 4 mm wide. You will also need a wire hook to remove the snap ring. It can be made from a bicycle spoke, the main thing is that the wire is rigid and does not easily bend. A rubber mallet or wooden mallet will also be needed.

Work process

Disassembly of the punch should begin with the removal of the protective rubber cap. anther. It is easily removed, just take it with your fingers and pull it off the barrel.

Then, having pressed on a plastic cover and having squeezed a spring of a lock of the SDS mechanism, we remove a lock ring with a screwdriver.

Using a screwdriver, remove the stopper

The lid is removed from the barrel, and after it, again compressing the spring, we pull out the retainer ball along with the spring and figured washer.

SDS disassembly

Then the mode switch is disassembled. Under the cover holding the red button-lock, there is a special groove for the screwdriver. After inserting a screwdriver into this groove and prying off the lid slightly first from one edge and then from the second, carefully remove it. No significant efforts should be made here, the cover is still plastic and may break. The red button along with the spring is removed from the switch housing and it is moved to the left until it stops, a little further than the drilling mode. It is from this position that he is removed from the gearbox. For this operation, the switch should be slightly picked up with thin screwdrivers on both sides and removed together with the rubber O-ring.

Remove the punch mode switch

Now the gearbox is removed. Using a Phillips screwdriver, unscrew the four bolts connecting the box to the stator housing. Then, holding it with your hand, you need to lightly tap with a mallet on the end of the barrel so that the box comes off the gearbox.

Remove the gearbox

Having removed the box, we take out the barrel from the gearbox. It is removed easily.

We take the barrel out of the gearbox

It is necessary to remove old grease with a rag, and rinse the barrel with gasoline or kerosene and wipe it dry.

So, as mentioned above, it was necessary to completely change the entire trunk. However, this item purchased at a service center was “a goal like a falcon”. That is, there was absolutely nothing on it and I had to rearrange all the details from the old barrel to a new "blank".

The most difficult operation was extracting the drummer from the barrel. There are special holes in the barrel body through which the snap ring is visible. This ring holds the striker in the saddle with rings and rubber dampers. Insert a thin screwdriver into the hole, slightly bend the ring. We do this first on the one hand, and then on the other. The stop must come out of the groove.

Using two screwdrivers, squeeze the stopper

Then, from the inside, we pull out the stopper from the wire with a homemade hook into the light of God.

Using a wire hook, pull out the stopper from the inside

Next, we remove the striker with washers and rubber rings. It is necessary for assembly to remember or sketch the location of all rings and washers. If something goes wrong, photos and drawings from the article will help.

Now you need to remove the gear from the shaft. Having pressed on a washer and having squeezed a spring, with a thin screwdriver it is necessary to remove a lock ring from a flute. After removing it, remove the washer, spring and gear from the barrel.

Remove the gear

The gear wheel is put on a new barrel and engages with splines. Following it, a spring with a washer and a stopper are installed. Insert the circlip and lock the mechanism in the working position.

To do this, take the barrel in both hands and, resting it in the palm of your hand, use your fingers to compress the spring with force, while shifting the washer and stopper down. It is necessary to compress until the stopper engages in the groove.

Then, a striker with washers and rubber rings is installed inside the barrel in the order in which he understood. But first you need to pay attention to the condition of the drummer, his appearance.

If the striker has potholes and sinks after long work or because it has been scratched on a broken sleeve, then it should be sanded a little.

To do this, it is clamped into the drill chuck and processed with a fine-grained emery cloth. But if the bumps are too big, then the drummer will be easier to replace.

Assemble shock mechanism

It is necessary to lubricate the striker with special grease before installation and to continue to use lubricant during operation. When inserting a drill into the hammer, it is necessary to apply a little grease to its shank. This extends the life of the machine.

Having installed the striker mechanism in the barrel, we fix it with the circlip. We try using a screwdriver to move the drummer from both sides inside the barrel. He should walk easily in the canal and not jam.

Putting a new barrel

The assembled barrel is installed in the gear housing. Putting it on the cylinder with a piston, we engage it with the pinion gear and insert it into the housing. All parts should be well lubricated during assembly.

Install the barrel in the gearbox

Then we install the gearbox, after lubricating the needle bearing. With four bolts we draw the box to the stator housing and set the operating mode switch in place. To do this, set it to a position slightly to the left of the drilling mode.

We insert the red latch button with the spring and move the switch to the drilling mode. We click on the plastic cover and check the operation of the switch.

Set the mode switch in place

We snap the cover of the punch mode switch

Then, in a final chord, the SDS mechanism is assembled. Having installed the mechanism spring, we put on a figured washer and insert the ball. Then we squeeze the mechanism spring with a plastic cover and insert the snap ring. Putting on a rubber boot is no longer difficult.

Having pressed a spring with a washer, we establish a ball a clamp

Install the SDS engine

We try a hammer drill under load. When the machine is operating, there should be no extraneous noise in the gearbox; the operating mode switch should easily move without jamming. In general, everything should work, as before the breakdown.

The author of this article hopes that it will help dear readers understand the repair of a hammer drill. Any breakdown can be simple if you find its cause. And then it all depends on your skill and diligence.

2 comments on How to repair a Makita HR 2450 hammer drill if the shock mode is lost

In the construction industry, the use of Makita rotary hammers is a must. The value of this technique is difficult to overestimate; it is indispensable when working with concrete, stone or brick. All extremely durable materials lend themselves to the onslaught of this versatile tool. In everyday life, Makita punchers are used for drilling holes in concrete and stone, for the manufacture of openings, recesses, cable channels in walls and in the floor.

Device

The Makita rotary hammer has dual motor protective insulation. Among the required structural elements is a trip clutch that prevents jerking when the drill is jammed, and electronic speed control. Corporate identity indicator. the instrument is equipped with a convenient suitcase for storing the instrument.

Most models are equipped with a dust extraction system and come with a soft rubber pad on the handle. The assortment includes Makita rotary hammers, both with a direct and vertical arrangement of the engine.

Principle of operation

It can perform 3 functions: drilling, drilling with impact, chiselling.

Makita hr2450 punch disassembly video

Depending on the number of functions performed, they are divided into three groups:

- single-mode. perform drilling with impact, for example, Makita HR 2010.

- dual-mode. drilling and drilling with impact, or drilling with impact and chiselling. The most popular hammer drill is. Makita HR 5001 C can drill with a blow or hammer.

- three-mode. switch to any operating mode. For example, Makita HR 2450.

- With SDS Plus, single, dual and tri-mode rotary hammers weighing up to 5 kg are available.

Characteristic: power up to 850 W, impact force up to 5, 3 J, drilling diameter in concrete 18-30 mm. - With the SDS max cartridge two- and three-mode models in weight from 5, 9 kg are offered.

Characteristic: power 1100-1500W, impact force 8, 3-17, 5J, maximum drill diameter 40-50mm, crowns 105-160mm.

Advantages: high power and low vibration.

Shop "Makita. "Is the official dealer of the Japanese company and offers a wide range of Makita punchers with a manufacturer’s warranty and delivery. Professional managers who have completed training courses will help you choose the best model!

We offer Makita rotary hammers throughout Russia: Moscow, St. Petersburg, Yekaterinburg, Chelyabinsk, Nizhny Novgorod and many other cities with delivery and warranty, call! You can find out detailed information about the conditions and cost of delivery from our managers.