Disassembly of the tiller neva mb 2 gearbox

Disassembly of the tiller neva mb 2 gearbox

Dismantling and assembly of the reducer of the tillers Oka, Neva, Kaskad (MB-2)

Disassembly and assembly of the MB-2 reducer

I disassemble the gearbox, remove it from the tiller, for which it is necessary:

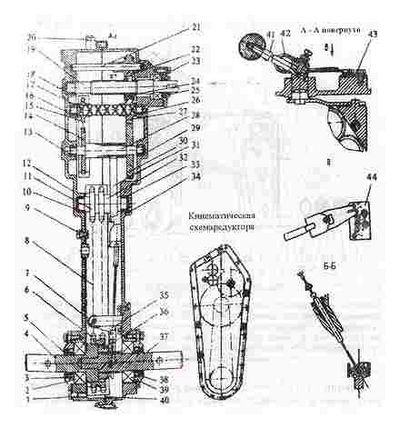

Remove the lever 41 (Fig. 32) gear shifting, spring 42 and plate 44.

Unscrew the bolts securing the covers 14 and 21 (Fig. 33) and take them out together with the cuffs.

Unscrew the nuts of the tightening bolts of the gearbox housing halves, place the gearbox on the left half of the housing, using a thin screwdriver or knife, carefully so as not to damage the gasket, separate the gearbox housing halves, remove the right half.

Lift the intermediate shaft 10 (Fig. 34), remove the sprocket 8 from it and disengage it from the chain.

Remove the fork 15 from the shift shaft 12 together with the gears 15 and 14, the sprocket block 3 together with the chain.

Remove block shaft 1 together with chain 37 and right side axle 38.

Disengage the cable for controlling the axle shaft clutch 33, unscrew the bracket 25, remove the fork 24, the clutch 34, remove the left axle shaft.

Wash the removed parts and the gear housing, inspect the parts, paying attention to their integrity and the degree of wear of the working surfaces. Wear of the inner surface of the shift fork 15 should not exceed 0.5 mm.

The sealing gasket of the body halves must not have breaks.

Replace defective parts, reassemble the gearbox in reverse order.

During assembly, periodically check the free rotation of the engaging parts.

Apply a thin layer of sealant to the mating surfaces of the body halves. Start installation and tightening of the bolts for fastening the body halves from the middle part of the gearbox with a successive transition of tightening the bolts to the edges. Recheck the smooth running of the moving parts of the gearbox before final tightening.

The detailed design of the MB-2 reducer is shown in Fig. 33 and 34.

The halves 23 and 25 (Fig. 33) of the gearbox housing are cast from an aluminum alloy and are bolted together through a gasket 24. They have flanges for fastening caps 14 and 21 of bearings with cuffs.

Note. In gearboxes of tillers of early release, instead of bushings pos. 2, 7, 35 bearings were installed: pos. 2. Bearing 300, pos. 7. Bearing 202, pos. 35.Bearing 304 GOST 833-75.

Dismantling the tiller neva mb 2 gearbox

Dismantling and assembly of the gearbox of the tillers Oka, Neva, Kaskad (MB-1)

Disassembly and assembly of the MB-1 reducer

The tiller MB-1 reducer is the basis on which other units and assemblies of the tiller are mounted. Therefore, to repair the gearbox with disassembly, it is necessary to disassemble the tiller, for which dismantle the engine, steering column, pallet, brackets with forward and reverse belt pulleys, gear pulley, wheels.

Before disassembling the gearbox, clean it from dirt, drain the oil.

Remove the rotating head from the shift knob by knocking out the retaining pin with a thin drift.

Unscrew the locking screw 11 (Fig. 36) and remove the bushing 9 and the spring 10 of the retainer from the shift shaft 7.

Remove the bolts 17 (Fig. 35) securing the body halves, then the tie bolts 7 (2 pcs.) And 10.

Place the gearbox on the left half of the housing, using a thin screwdriver or knife, carefully so as not to damage the gasket, separate the halves of the gearbox housing and remove the right half. Leave the tie bolt washers on the sprockets.

Note. It is recommended to remove only defective parts from the gearbox without disassembling the gearbox completely.

To disassemble the gear change mechanism, remove the retaining ring b from the shift shaft 7 (Fig. 36), ensuring free play of the sprockets 31. 32 (Fig. 35). Remove the cotter pin 3 (Fig. 36) from the threaded part of the shift knob 1, unscrew it (counterclockwise) from the cracker 8 and remove the knob and cracker from the shaft.

Rinse removed parts, replace defective parts. Replace the shift shaft seals after removing it from the gearbox.

Assemble the gearbox in reverse order. Apply a thin layer of sealant to the mating surfaces of the body halves.

How to disassemble a version 2 gearbox

Start the connection of the body halves with the central tightening bolts 7 and 10 (Fig. 35), then the bolts of the halves, starting from the middle part of the gearbox with a sequential transition of tightening the bolts to the edges.

Before final tightening of the bolts, check the smooth movement of the moving parts of the gearbox.

The internal structure of the gearbox is shown in Fig. 36-40.

Application nuances

In order for the user to have to deal with a breakdown of the tiller as rarely as possible, it is necessary to monitor the operation of not only the engine, but also the gearbox. Experts give their advice on what basic requirements must be observed during operation.

Features of the

A gear-chain unit is installed in the tiller’s design, the main task of which is to transmit rotational movement, and therefore, to change the rotational speed of the cutters. It is thanks to the gearbox from the driven pulley that the mechanical action is transmitted to the wheels of the equipment, whereby the speed and direction change.

There is oil inside the housing, which is necessary to ensure the operation of the gearbox. The element is enclosed in a robust sealed housing. Its kinematic diagram consists of a chain and two stars located in opposite directions. The lower one is called the slave, since it stands on the shaft and drives the entire tiller system.

Composition

The tiller gearbox includes the following important parts:

- screws;

- bearings;

- axles;

- asterisks;

- body;

- bushings;

- shift levers;

- gear wheels;

- shaft;

- clutch;

- half shafts;

- pay;

- spring.

These are far from all the elements that are involved in the design of the gearbox, but they are the main ones. Failure of one of them leads to loss of performance and subsequent repair.

Compared to a worm gear, the gear-chain is more reliable. It is convenient and easy to operate, and can support the reverse function. As a rule, this is a collapsible design, where all the elements are connected to each other by bolts, thanks to which you can inspect the condition of the chains and gears if necessary. Such gearboxes are installed on large tillers, which need a strong and reliable unit to transmit power to the wheels and cutters.

The simplest and most common cause of breakage is a chain break or stretching, but any user can fix the problem without contacting a service center.

тиллер нева мб2 Редуктор: устройство, разборка, ремонт

Tiller gearbox “Neva MB-2”: diagram and device, purpose and operating rules

- Features of the

- Composition

- Application nuances

- Possible breakdowns

The gearbox is an indispensable component of any technique where an engine is used, since without it, the transmission of rotary motion is impossible. Structurally, this element in the Neva-MB-2 tillers is similar to the parts used in other equipment, but to learn more about it, you need to study the issue in more detail.

Possible breakdowns

It should be said that the gearbox from the Neva-MB-2 tiller is repaired quickly and easily. This is possible due to the fact that you can always find spare parts for it on the market. Such a need arises when the following symptoms appear:

- oil starts to appear on the output shaft;

- the chain is jammed;

- no kinematic connection;

- no gear shifting.

In all these cases, it is required to disassemble and inspect the gearbox. If oil leaks, the problem can be eliminated by simply replacing the cuff, which can lose its original qualities over time. Jamming is always associated with a broken chain, so this problem can only be eliminated by a complete replacement. If this element is intact, but there is no kinematic connection, you should pay attention to the sprockets present in the design. One of them could break off.

In the absence of a gear change, a cracker is inspected, which can be destroyed. Sometimes the threaded part of the handle is cut off. If the user begins to notice that oil leakage is observed on the shift shaft, then this is not always an indicator of a breakdown. Sometimes the permissible oil level in the gearbox is simply exceeded. Excess just needs to be drained.

It is worth remembering that improper start-up and adjustment can also lead to malfunctions during the operation of the gearbox, therefore the manufacturer advises to carefully study the instructions before using the equipment.

complex breakdowns should be eliminated only by specialists, since improper disassembly of the unit by an inexperienced user often leads to an even greater problem and the need for expensive repairs.

The following video is about the disassembly and repair of the gearbox.

tiller neva MB2 Reducer: device, disassembly. assembly, repair

Adjustment of valves

The valves on the Neva tiller are adjusted as follows:

- Install the unit on a flat surface.

- Start the engine and then let it cool down.

- Remove the cover.

- Remove the cover from the valves to provide access to the parts underneath.

- Unscrew the lock nut.

- Carry out the adjustment. You need to loosen the nuts, insert the dipstick, adjust the valves.

- Screw the valve nut back into place.

- A razor blade (no more than 0.2 mm thick) is inserted into the gap formed. It must pass freely between the piston part and the tiller valves.

- Screw all the parts back.

The size of the gap formed can be checked with a feeler gauge, which should pass under the valve, if the cut is made correctly.

Operation and maintenance Neva-MB-2

So that there are no failures in the operation of the MB-1 and MB-2K mini tractors, you should follow all the recommendations for the operation and maintenance of equipment prescribed in the instructions:

- It is necessary to tune the engine. To do this, you will need to study the device of this part, choose the right oil liquid for servicing the engine, spark plugs and fuel.

- Tune and adjust the gearbox and transmission. The serviceability of these parts must be checked every day before starting work.

- Install optional equipment only in accordance with the user manual.

How to set the ignition

Before carrying out the procedure, it is recommended to make sure that the structure can cause a spark that will ignite the fuel in the internal combustion chamber.

The procedure for adjusting the ignition of the tiller:

- Turn the crankshaft so that the marks made on the pulley and the gas equipment of the unit match.

- The slider, which is responsible for the distribution of gas flows, must be directed to the high-voltage wire of the cylindrical part.

- Loosen the nut and remove the high-voltage wire from the cover of this system.

- Place contacts at a distance of 0.5 cm from the equipment.

- Turn ignition.

- Rotate the mechanical structure in the opposite direction.

- After a spark appears, quickly tighten the screw.

Gearbox repair

If the engine is running, but the gearbox does not rotate, check the keys and the cutter stopper.

The situation is complicated when the gears are turned off spontaneously, noises appear or the gearbox does not rotate, the engine stalls. Then the repair of the Neva-MB-2 tiller is required in the workshop.

Tiller Neva MB-2 reducer. internal structure.

DIY repair of the tiller Neva MB-2

No doubt, contacting the service center is the right decision. But when time is running out, it is worth asking which problems occur more often. You can compare the manifestations according to the description, roll up your sleeves and repair the Neva MB-2 tiller with your own hands.

The unit, in addition to agricultural operations for plowing, cultivation, cutting furrows, digging root crops, hilling, watering, copes with mowing, snow removal, sweeping with a brush, transportation.

Advantages of the Neva MB-2 tiller:

- On the domestic market. more than 30 years.

- Subaru EX21 engine. 5.5 kW.

- Tillage depth. 0.3 m.

- Frontal coverage. 0.85-1.2 m.

Practice shows that half of the cases of failures and breakdowns are not associated with natural wear and tear, but with improper tuning, adjustment, running and maintenance of the engine and gearbox.

Tiller device “Neva MB-2”

Changing the engine oil

The procedure for changing the oil in the engine:

Appointment

The possibilities of regulating the speed of rotation of the shaft of an internal combustion engine are limited by the available operating modes, therefore, in motor equipment (from chillers to cars), devices are traditionally used that make it possible to change the speed of rotation transmitted from the engine to certain structural elements.

If a gearbox is used in cars for this purpose, then gearboxes are traditionally installed on Neva tillers, which make it possible to control the rotation speed, torque and direction of movement. It is to this element that the wheels of the device are connected, and various attachments that require connection to the engine (for example, cultivator cutters, mower blades, brooms, and so on).

Typical breakdowns and their repair

The most frequent breakdowns of the device are as follows.

- Oil flow through the output shaft. To eliminate this problem, it is necessary to change the oil seals installed in the gearbox. To replace them, you need to purchase new ones, dismantle the ones installed in the gearbox with a screwdriver, and then install new oil seals in their place. This will help strengthen the tiller, the power of which is reduced due to constant oil leaks from the gearbox.

- If there is a shift shaft leakage, you may have added too much grease to the gearbox. Therefore, it will be enough to drain the excess oil and check if this helped in fixing the problem. If leaks continue, replacing the oil seals will help.

- Open circuit, which leads either to jamming, or to the impossibility of operating the device in individual gears. For repair, you need to replace the broken chain with a new one.

- If the gearbox does not transmit torque in any of the installed gears, it is most likely that one of the gears has broken. After disassembly, you need to find a broken sprocket and replace it with a new one.

- If the gears do not shift, you need to check the condition of the fork, bushing and threads of the gear knob, and then replace the damaged element.

To expand the capabilities of the tiller, its modernization will help by installing a full-fledged gearbox, for example, from a VAZ car, instead of a gearbox.

Tiller gearboxes “Neva”: design and maintenance

- Appointment

- How does it work?

- Basic rules for performing work

- Typical breakdowns and their repair

- How to choose spare parts?

Tillers of various sizes and firms (including those from TM “Neva”) have become an indispensable assistant for farmers and owners of large summer cottages. The reliability and efficiency of this device depends on its technical condition and proper care. Therefore, it is worth considering the basic principles of servicing Tiller “Neva” gearboxes.

How it works?

Despite the fact that the St. Petersburg plant “Krasny Oktyabr” produces a wide range of Neva tillers, differing in power and configuration, the gearbox in all these devices is arranged according to a single general scheme. According to the principle of operation, the used gearbox belongs to the type of gear-chain, where the change in rotation speed is carried out due to the interaction of a system of gears of different diameters and with a different number of teeth, which are either in direct contact with each other or are connected by a chain drive.

This design combines the device used on the tillers with the gearshift mechanism of the bicycle. slowing down the rotation is achieved by transferring the transmitting chain to a gear with a large diameter. The only difference is that, in addition to the gears located on the same axis, in the gearbox, separate gear links are also used, which make it possible to vary the speed and direction of rotation over a wider range, as well as transmit rotation simultaneously to the wheels of the tiller and to the equipment used on it.

The entire system of chains, shafts and gears of the Neva tillers’ reducers is housed inside a robust sealed case made of aluminum. Lubrication of rotating parts is carried out by filling the product with oil (this principle of structure is called “oil bath”).

An important design feature of the gearboxes used on the “Neva” tillers is the presence of a mechanism for decoupling the wheel axle shafts, which allows, if desired, to transfer torque to only one of the 2 wheels of the device. This makes maneuvering much easier.

The gear shift lever, as well as other elements for controlling the gearbox, are brought out, which greatly facilitates its adjustment. There are 5 positions in total. When the lever is pressed, the fork connected to it disengages the rotation transmitting clutch from the gears. When shifting the lever, the fork moves the clutch to the desired position. When you release the lever, the clutch engages with the desired gear system and the fork returns to the home position. In standard operation, rotation is transmitted through a gear located near the input shaft of the device.

Connecting the drive to the right axle will decelerate the tiller. “Drowning” of the shift knob causes the clutch to shift to the left, larger gear, which results in a downshift. This is useful when you need to develop more torque at a lower travel speed.

Finally, extending the lever all the way to the end results in an overdrive, allowing for higher travel speeds.

The dimensions of the gearboxes used on the products of the Krasny Oktyabr plant are 23 × 30 × 61 cm, and their weight without oil does not exceed 18 kg. The volume of the oil sump used to fill the device with oil is 2.2 liters.

The diameter of the shaft transmitting rotation from the device to the wheels is 30 mm.

A significant drawback of the design used in the gearboxes of the Neva tillers is the fact that to change gears it is necessary to turn off the engine and wait until the rotation of the pulley of the device is completely stopped. Shifting gears “hot” can lead to seizure, chain breakage or breakage of gears.

Basic rules for performing work

Any work on disassembly and assembly of the gearbox, as well as on its maintenance must be carried out at a pre-prepared workplace with all the necessary tools. It is imperative to ensure the cleanliness of the workplace, which will eliminate the ingress of dust, dirt and debris into the mechanism. It is advisable to carry out all work in clean work gloves, which will provide both protection of hands from injury and dirt, and protection of gearbox components from unwanted debris and dust.

Carefully monitor the condition of the tool used. there should be no visible damage, especially cracks. Failure to do so will result in dangerous injury.

Drain the oil from the gearbox before disassembling it. After that, you need to thoroughly clean all parts of the device from possible contamination.

After repairing and assembling the gearbox, be sure to fill it with fresh oil before operating it.

Редуктор тиллера НЕВА, ремонт

How to choose spare parts?

Pay particular attention to the type of oil you intend to add to the gearbox.

The following brands of transmission oil are best suited for devices used on Neva tillers:

- TEP-15;

- TM-5;

- SAE90 API GI-2;

- SAE90 API GI-5.

To learn how to change the Tiller “Neva” reducer chain, see the video below.

Checking and adjusting the clutch tiller Neva MB-2

The main function of the clutch is to connect the gearbox to the engine, disconnect it, as well as connect other working devices to the engine. If an overload occurs during operation, the clutch begins to slip. this is how other parts of the tiller are protected from breakage.

Checking the operation of the clutch can be carried out according to the scheme below.

If the clutch lever is in the OFF position, the clutch cable is loose. Consequently, the idler pulley goes down and comes into contact with the drive belt. Then the drive belt and the small roller move to the lowered position. this is how the power supply from the engine to the transmission stops.

When the clutch lever is in the on position, the clutch cable tightens the tension roller, so the lower part of the belt is tightly pressed, the small pulley drives the large pulley and power is transferred.

Adjustment or adjustment of the Neva MB-2 tiller clutch is performed as follows:

- if the clutch lever is engaged, it will raise the idler pulley, driving the tiller. Correct position. parallel V-belts on either side of the engine pulley.

- if the clutch lever is loose, the idler roller will lower and disengage the clutch. To avoid disengaging the clutch, and hence slipping the tiller, you need to monitor the position of the V-belts, bringing them to a parallel position.

Replacing the gearbox oil seals

Replacement of oil seals in the Neva MB-2 tiller is carried out in case of oil leakage.

Such a condition is dangerous because the tiller gearbox may remain without oil, and this will lead to rapid wear of the unit.

The sequence for replacing the oil seals is as follows:

- Remove the cutters from the shaft, cleaning the shaft and covers from dirt and oil residues.

- Unscrew the cover bolts, knock oil and debris off it, remove the cover from the gearbox.

- The old oil seal is replaced with a new one, wiped dry.

- The cover is returned to its place (if necessary, it is placed on the sealant) and fixed with bolts.

Candle malfunctions

First of all, check if the spark plug is working.

To do this, unscrew the candle, wipe the electrodes and remove carbon deposits. Then follow the steps described above in the ignition adjustment. The candles are working. if there is a spark. If there is no spark, the spark plug may need to be replaced.

In the instruction manual for the Neva MB-2 tiller, the manufacturer indicates the size of the gaps between the spark plug electrodes and the recommended plug models:

- spark plug А11Р (made in Russia). gap 0.5 ÷ 0.6 mm. Turnkey dimensions 20.8 mm;

- spark plug NR17С (BRISK). gap 0.5 ÷ 0.6 mm. Turnkey dimensions 20.8 mm;

- candle WR8AC (BOSCH). gap 0.5 ÷ 0.6 mm. Wrench dimensions 20.8 mm.

Before starting work on the tiller, it is necessary to check whether the sealing washer is installed on the spark plug and whether the sealing washer from the previous spark plug remains in the cylinder head hole.

Remove and install the spark plug only after the cylinder head has completely cooled down to ambient temperature. If, when removing the spark plug from the engine, the tightening torque was exceeded by more than 50%, further use of such a spark plug is NOT ALLOWED.

First start-up and running-in of Tiller Neva MB-2

The first start-up must be carried out adhering to the following scheme:

- make sure that the tiller is complete (the height of the steering rod and handles must correspond to the height of the user);

- the engine can only be started if the chiller is located on a flat surface;

- check the oil and fuel level in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- idle time (without load and movement) should be about 10 minutes, then you can move from a place and operate the tiller.

The break-in period is the first 20 hours of tiller operation, after which the oil must be changed. During this period, the most important:

- do not run at full throttle;

- work only on previously prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that is included in the kit;

- tiller “Neva” MB-2 during the running-in period can be loaded only at ¾ of the power;

- shifting gears in the gearbox can only be done when the rotation of the drive pulley is completely stopped;

after the first 20 hours of operation after the first start, change the oil in the engine.

Belt adjustment and dimensions

The A-1180 drive belt is used for the Neva MB-2 tiller. This model uses one belt for forward travel.

In other modifications of the Neva MB-2 model, two drive belts are used. Reverse is done in the gearbox itself.

Replacing the belt for MB-2 tillers is carried out in the following sequence:

- The shield is removed, and then the protective pulley casing.

- The spring is removed from the tiller rod to loosen the belt.

- The screws that secure the bracket are rotated.

- The bracket pivots to such a position that the stop pins do not interfere with the removal of the part from the pulley.

- Adjust the pulleys, and then install a new belt.

- Pull the belt over the gear shaft pulley, and then onto the motor pulley.

- In reverse order, place the rest of the parts in their places.

Changing the engine oil

The manufacturer recommends using such well-known brands of engine oil for the tiller as LUKOIL. SAE 10W30 API SF / CC standard, as well as RAVENOL SAE 30 API CD / SF.

At temperatures above 4 degrees Celsius, using thickened oils (for example, grade 10W30) will lead to increased consumption of this type of fuel, therefore, in the cold season, it is recommended to check the oil level in the engine more often, not allowing its mark to drop below normal.

The oil change is carried out after the tiller has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is completely drained from the tank, and then a new one is added until the oil level reaches a special mark. The drain plug is then screwed on tightly and wiped dry.

Major malfunctions

Adjustment and tuning of the carburetor Neva MB-2

The functionality and durability of the tiller engine depend on the stable operation of the carburetor. This is why adjusting and tuning it is so important. In addition, if the carburetor is incorrectly adjusted, the gasoline tiller may experience increased fuel consumption.

The carburetor of the Tiller Neva MB-2 is adjusted as follows:

- The screw for full throttle and idle throttle is unscrewed to the limit.

- Both screws are unscrewed 1-1.5 turns.

- Next is starting and warming up the motor.

- The throttle control lever is set to the position at which the engine will operate at minimum speed.

- Set the minimum idle speed until stable operation of the unit.

- Idling speed is set to maximum.

- The minimum idle speed is being adjusted.

- Steps 6 and 7 are performed until the engine runs smoothly (smoother by ear) at idle speed.

For long-term and trouble-free operation of the tiller, it is necessary to regularly carry out diagnostics of the engine operation, monitor the frequency of oil changes, as well as observe the operating conditions and time intervals of scheduled maintenance.

Do-it-yourself repair of the Tiller Neva MB 2 gearbox

Auto mechanic specializing in agricultural machinery

over, the price of agricultural machinery is quite affordable. Reliable and multifunctional assistants appeared. tillers, who quickly and efficiently process a plot of land: plowing, hilling, planting, mowing, as well as removing garbage and snow in the local area. All these and other operations are performed by means of attachments driven by the MB 2 Tiller gearbox.

The gearbox can be repaired by hand

If the device fails, the process of repairing the breakdown is identical to other tiller designs. The most common violations in the operation of mini tractors, which are worth paying attention to:

- when the rotation of the crankshaft stops, it is necessary to unscrew the gearbox and carefully inspect the internal elements for destruction;

- if white smoke poured out of the muffler. the reason is in the carburetor;

- the engine slows down and stalls. you must wait for the engine to cool, then check the oil level and clean the cylinder head and block surface from dirt.

Basic rules for using the mechanism will help to avoid expensive unit repairs.

Device by assembly type

Depending on the ability to disassemble and repair the device, converters are divided into two types:

- A budget option that installs inexpensive disposable parts. If the spare part fails, it is better to replace the gearbox with a new.

- A collapsible design that allows you to easily replace a failed spare part. Can serve reliably for several years without breakdowns.

By the type of design of the gearbox, the following are:

- Corner.

- Downward.

- Gear.

- Worm.

This type of mechanism is equipped with a reverse tiller.

Gearbox device

The purpose of the device is to transfer rotary motion from the engine to additional attachments. The design of the gearbox consists of a gear shift system, a clutch and a shift lever. When you press the lever, a low gear is included in the work. If the handle is moved all the way, an overdrive will be engaged.

In this video, you will learn about the pros and cons of this tiller:

Oil change

The level of the lubricant indicates the need to change it. If the time has come, then the procedure is performed as follows:

- To begin with, choose a horizontal platform and put the Neva MB 2 tiller on it.

- They find a plug for filling the engine oil on the engine and clean it and the surface next to all kinds of contaminants. The cork, it is also a probe, should be at the bottom of the side.

- New oil is poured through the hole and the liquid level is checked with a dipstick.

Important! All work is performed with the engine cold, otherwise the oil level will be too high. The maximum mark must not be exceeded. This will increase the consumption of the lubricant, and the oil will begin to leak from the excess.

Gearbox repair and malfunction

If there are moving parts in the device of a motor-cultivator, it means that machine oil must be used. For high-quality operation of the mechanism, only a high-quality product is used and the oil level is monitored. If it is necessary to carry out repair work, all stages can be conditionally divided into:

- Drain the oil and clean the surface of the gearbox from contamination.

- The case is disassembled and each element of the device is examined.

- The necessary details are changing.

- Reassembly with new lubricant refilled.

Disassembly of the Tiller Neva MB 2 gearbox is presented in detail in the video on our website.

The main reasons that can lead to failure of the gearbox:

- oil leaks through a worn cuff;

- poor quality lubricant;

- drips on the output shaft due to wear on the lip of the cuff;

- block sprocket break;

- open circuit;

- gear lever thread wear.

Advice. If you check the oil level in time and use only high-quality materials when replacing, then you can forget about repair work in the Neva MB 2 gearbox for many years. Otherwise, there will be nothing left but to disassemble the tiller gearbox.

Oil seal replacement

If there are oil leaks, this means that it is time to change the oil seal. The work should be done as soon as possible, otherwise you can be left without a tiller, because the movement of metal elements inside the device will lead to its destruction.

The sequence of operations is as follows:

- Dismantle the attachment mounted on the output shaft.

- Clean the shaft and gearbox from dirt and debris.

- Having unscrewed the fastening bolts, remove the cover.

- The old one is being replaced with a new oil seal.

- The cover is put in place and fixed with bolts.