Disc harrow for power tiller with your own hands

Harrow for power tiller with your own hands and proper harrowing with power tiller

In order to increase the harvest in the field, always plowed and harrowed the soil. Our ancestors did so, and modern agrarians do the same. But in order to do this work, in the old days they harnessed horses, and today the harrow is attached to a power harrow (for small farm plots, private cottages) or to a tractor (this is for large farms on large territories). Based on the above, the harrow for the power harrow with their own hands is an important tool for any dacha farmer, below we will consider in more detail the manufacturing process and how to do the correct harrowing with a power harrow.

Types of harrows

Such devices are divided into three such types:

It is worth considering each of the types separately.

Tooth harrow

The toothed harrow, which is popular today, consists of several rows of tines, thanks to which the soil is cultivated along with loosening it, as well as leveling. The difference in these models lies in the different numbers of tines. Wide versions with 4 or more rows of teeth are commonly used.

Widespread their use with power harrows belonging to the category of traction. These include most models of the Neva brand, as well as MTZ. These types have a high traction, due to which there is a significant longitudinal force. Harrow is often used after working a piece of land with a tractor. At the same time you can install special springs instead of cogs, which are less likely to break.

Disc harrow

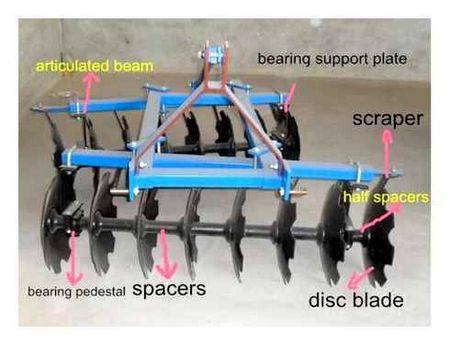

Active harrows. They are often used in combination with tillage tractors. For traction applications, a special shaft designed for power take-off must be constructed. The disc harrow allows you to cultivate the ground by cutting through it with rotating discs. These products come in a variety of forms, from the usual rectangular to the cup-shaped.

The latter are more labor-intensive in design, but allow you to bypass the bed, due to which the partial plowing is carried out. Due to that they are used for shallow early tillage of topsoil before weeds rise and before planting potatoes or grains. To improve the cutting of the soil, as well as to reduce the level of resistance during the rotation of the layer, the edges of such discs have an uneven shape.

Rotary harrow

Such products are somewhat similar to the cultivator and disc models. This is due to the rotating toothed elements, which plunge into the ground and overturn a certain part of it.

Rotary harrow has a distinctive feature, which is a shallow cultivation depth, as well as the presence of many working teeth. The discs are at right angles to the axis of rotation. In addition, the tines have a slight bend. Its radius depends on the coefficient of traction that the wheels have with the ground. So, as the sliding action increases, the camber of the tines needs to be stepped up.

In the process of work, it will allow to pierce the soil at an almost right angle. This provides good aeration. When such tines go out, they slightly undermine the soil, due to which there is an uprooting of small weeds that have not yet taken serious roots. The rotary harrow is used to cultivate the soil, even if the plants have risen. In this way, large plants are not traumatized. Such models allow you to reduce the amount of fertilizer used, due to the fact that the substances in the process of aeration are well assimilated from the air, and also improves root growth.

Design features of the homemade harrow

The optimal and easiest option for making your own hands is considered a tooth harrow. To create it, you will need to carefully study the drawings, which should specify the sequence of operations in the assembly of equipment. It is also very important that the diagrams show the dimensions of all the parts used in the harrow.

The harrow itself resembles a cage made from a frame, to which the tines are bolted. The front part of the construction should be equipped with a hitch, which is in most cases in the form of a hitch with holes. If mounted on a single axle tractor you must insert the drawbar hitch into the tow bar pipe and secure both elements with a pin. It is extremely important to weld a special chain between the towbar and the hitch to make it easier to work with the equipment.

The cage of the tooth harrow should be as strong as possible, so square or plumbing pipes should be used for its manufacture, as well as corners to reinforce the joints of the structure. Each part should be made of steel, at least 5 mm thick, otherwise the soil will tear out the teeth together with pieces of metal.

The design of the grid to be made must consist of transverse and longitudinal parts. At the same time, the best option would be a cage with bars welded together at a 45 ⁰ angle in relation to the direction of movement of the power tiller. Such a homemade harrow will be much less exposed to bending stress.

To determine the cell size you must first decide on how the tines of the harrow will be set up. To do this, you need to draw the tines on the drawing, and on top of them you need to finish drawing the grid on which they should be attached. The frame itself should have such dimensions, so that it does not interfere with the work with the power tiller afterwards. It is also very important to take into account the dimensions of the hitch in time. Remember that a harrow more than 1 m wide is too big for many tillers.

For making tines it is better to use ribbed reinforcing steel. Its diameter should be at least 18 mm, and the length of each manufactured tooth is about 15 cm. The height of the teeth does not depend on the height of the hitch, as the homemade harrow will be attached to the tiller through the chain. The latter must be thicker if the harrow has thick tines.

The structure of the harrow is as follows. A grid that is either welded or connected with hardware to the prongs. On the front compartment there is a drawbar with a gap, into which a metal tube of a small tractor towbar is placed and secured with a pin. A chain is welded between the harrow and the tractor to ease the plowman’s work.

LEMKEN. Compact disc harrow Rubin

The frame is made stable. The material for it can be square corners or water pipes. Metal with thickness of 0,3 or 0,4 cm is ideal. If the thickness is less, the tines will break off.

The structure must have a longitudinal, transverse mowing line. The design of the harrow can be in the form of a cage, consisting of longitudinal and transverse elements, and welded at a specific angle. The specific angle is 45 degrees, when the manufactured structure is not so much exposed to bending moments. But a grate with “iron mowing lines” welded at a 45 degree angle to the direction of travel of the motoblock is better. such a grate will be less exposed to force factors.

The size of the honeycomb relates to the tine location. A mock-up is made with the arrangement of all the tines in place and the grid attached. The frame size should not interfere with the tiller’s steering and free movement.

The frame of the harrow should be within.The dimensions of the coupling are taken into account. If the width of the grid is larger. than 1 meter, a single axle tractor will not be able to pull it.

The best material for the tines is corrugated reinforcing steel. the diameter should be 10 18 mm. Each bar has a different length. Length size varies between 10 and 20 cm. Height of trailed implement has no influence on tine height.

Chain has to be used to secure harrow. Tooth length affects thickness. It is recommended to sharpen and harden the tines at the beginning of the mounting process. Unhardened tines will bend. Light soils are designed for unsharpened tines.

Keep a spacing of 10 cm between tines. Rare placement will result in ineffective plowing. It is advisable to find tines with slight offsets in every second row. This recommendation is given for welding the tines, which improves the quality of ploughing.

It is necessary to control the direction of resistance to the symmetry of the traction axes, because “wiggling” and inability to control the power tiller may occur. At the same time it must be understood that their resistance is directed symmetrically to the traction axis, otherwise the single axle tractor will vibrate and will not be able to work with it.

Specifications by model

All frame disc harrows, mounted

| Model | Number of circular saw blades | Width | Tractor power | Weight | Area |

| БДМ. 1.8×2 H | 12 pcs | 1.62 м | 50¸ 60 l/s | 750 kg | 2.19 ha/h |

| PM. 2.0×2 H | 14 pcs | 1.88 м | 60/70 hp | 850 kg | 2.54 ha/hour |

| PM. 2.2×2 H | 16 pcs | 2.04 м | 70/80 hp | 940 kg | 2.75 ha/hour |

| PM. 2.4×2 H | 18 pcs | 2.30 м | 70/90 l/s | 1,093 kg | 3.11 ha/h |

| PM. 3×2 H | 22 pcs | 3.00 м | 90/120 hp | 1,265 kg | 4.05 hectare/hour |

| PM. 4×2 H | 30 pcs | 3.76 м | 120/150 hp | 1680 kg | 5.08 ha/h |

Modular and rigid semi-trailers

| Model | Number of disks | Width | Tractor power | Weight | Area |

| БДМ. 3х2 П | 22 pcs | 2.82 м | 90/120 l/s | 2400 kg | 3.78 ha/h |

| PM. 4×2 P | 30 pcs | 3.86 м | 120/160 hpf | 2910 kg | 5.21 ha/h |

| PM. 5×2 P | 38 pcs | 4.90 м | 150/190 hp | 3,650 kg | 6.62 ha/h |

| PM. 6×2 P | 46 pcs | 5.94 м | 180/230 hp | 4160 kg | 8.02 ha/h |

Semi-trailed, sectional

| Model | Number of disks | Width | Tractor power | Weight | Area |

| PM. 6×2 PC | 46 pcs | 5.94 м | 180/230 hp | 4640 kg | 8.02 ha/hour |

| PM. 7×2 PC | 54 pc | 6.98 м | 220/270 hp | 5100 kg | 9.42 hectare/hour |

| PM. 8×2 PC | 62 pc | 8.02 м | 250/310 hp | 5655 kg | 10.83 ha/h |

| PM. 9×2 PC | 66 pcs | 8.55 м | 300/330 hp | 5900 kg | 11.54 ha/h |

Butterfly” type semi-trailed discs

| Model | Number of disks | Width | Tractor power | Weight | Square |

| BDM. 4×2 B PC | 30 pcs | 3.86 м | 120/160 hp | 3433 kg | 5.21 ga/h |

| PM. 5×2 B PC | 38 pcs | 4.90 м | 150/190 hp | 3950 kg | 6.62 ha/h |

| BFM. 6×2 B PC | 46 pcs | 5.94 м | 180/230 hp | 4390 kg | 8.02 hectare/hour |

PLEASE NOTE: When selecting a discator for MTZ or UMZ tractor, check the tractor’s power against the specifications in the table below

The disc harrow with his own hands

The disc tool is a more advanced model that performs more functions to till the ground. The construction is more complicated, so it’s better to buy a ready-made device on the industrial market. But for those who are not afraid of work, you can make a disc harrow yourself.

The fabrication work comes down to the following:

- You need the discs and 2 pipes, which must be firmly attached to the shaft of the power tiller. The total length of the tubes should not exceed 1 m. The discs have a diameter of up to 20 cm.

- On the discs angle grinder make cuts at a distance of 10 cm from each other on the circumference, in the center. slots for further installation on the shaft.

- The finished discs are fitted on the rollers every 5-8 cm, inclined to the shaft axis: left side to one side, right side to the other.

To make a harrow for a power tiller with your own hands is not difficult, but it requires correctly constructed according to the size drawings, diagrams, tools and materials. The choice of device depends on the capabilities of the handyman and the intended use of the machine.

How to make a harrow for power tiller with your own hands according to the drawing

The impact on the ground is made by tools attached to a common frame, such as:

Harrowing with a power harrow is an important agro-technical process of cultivation of the ground for increasing productivity, quality of grain and technical products.

Device Features

Special attention should be paid to the pre-sowing processing of the fields. After plowing the land with the plow, the soil must be leveled. That’s why the harrow is needed, it helps to rid the area from unwanted weeds, which the plough couldn’t cope with.

Harrow protects the land from drying out, also removes soil crust, so that the seeds can be accurately put in the future rows.

This harrow can be attached to a tractor or used together with other implements, like a seeder or cultivator. The combined use saves time, especially when there are tight deadlines. The main thing here is that the equipment allows such manipulations.

Types of harrows

Agricultural harrows are divided into types:

Tooth harrow. a simple mechanism, which is a frame made of metal with teeth attached to it of the required length. The power of a power harrow affects their number and frame size. Tines are zigzag or rectangular in shape and attached to the frame either rigidly, articulated or on a spring stand.

Depending on how the tines are set, the depth of harrowing. When they are mounted with the sharp edge facing forward in the course of travel, the opening depth increases, when mounted backward, it decreases.

The disc harrow is different from the tine harrow by its working tool. Instead of tines, spherical-shaped discs with a smooth or notched cutting edge are attached to the frame and placed at an angle called the angle of attack. It varies and is 10-25°. During tillage each disc cuts surface layer of soil, breaks roots of weeds intensively, mixes them with soil and compacts the soil. Carrying out harrowing, agronomists recommend using a needle harrow. Needles dig into the ground and loosen it.

Disc-type mounts are attached to the power tiller via the front or rear linkage.

The rotary harrow is best suited for initial cultivation. Working depth is 7 cm, but this factor does not prevent its application for loosening of virgin soil. It is similar in appearance to the cultivator and disc unit.

The rotary tool for the power tiller consists of 6 edges, a disc and a hub. Its working elements are sharpened plates that are positioned at different angles.

The active rotary harrow is mounted on shafts instead of wheels or a soil tiller, which greatly increases its performance, especially on virgin and heavy soils. For quality work it is better to attach to high power tillers with gearboxes.