Disc Sharpening

WS126A Machine for sharpening teeth of saw blades Sharpening of circular saws using a machine for sharpening discs WS126A Buy woodworking machine, lathe, drilling, cut-off, inverter, pump, sawmill, parquet grinder, concrete mixer, pump

WS126A Saw Blade Sharpening Machine

| Abrasive materials ABRAFLEX (Germany) |

| Welding, transformers, accessories |

| Pipe cutting kits, taps, dies |

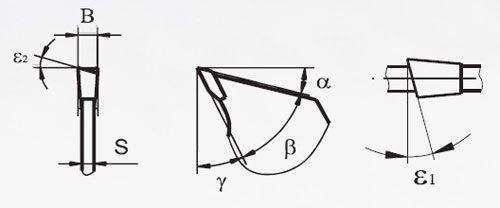

Carbide tooth geometry

The following types of teeth are distinguished by shape.

Straight tooth. Typically used in rip saws where quality is not critical.

Oblique (beveled) toothwith left and right angles of inclination of the rear plane. Teeth with different angles of inclination alternate with each other, which is why they are called alternately cut. This is the most common tooth shape. Depending on the size of the sharpening angles, saws with alternating cut teeth are used for sawing a wide variety of materials (wood, chipboard, plastics). Both in the longitudinal and transverse directions. Saws with a large backplane tilt angle are used as scoring saws when cutting double-sided lamination boards. Their use allows you to avoid coating chips at the edges of the cut. Increasing the bevel angle reduces the cutting force and reduces the risk of chipping, but at the same time reduces the tool life and strength of the tooth.

The teeth can have an inclination not only of the rear, but also of the front plane.

Trapezoidal tooth. A feature of these teeth is the relatively slow speed of blunting of the cutting edges in comparison with alternating beveled teeth. They are usually used in combination with a straight tooth.

Alternating with the latter and slightly rising above it, the trapezoidal tooth performs rough sawing, and the straight one following it. Fine. Saws with alternating straight and trapezoidal teeth are used for cutting boards with double-sided lamination (chipboard, MDF, etc.), as well as for sawing plastics.

Conical tooth. Tapered saws are auxiliary and are used to cut the bottom layer of the laminate, preventing it from chipping as the main saw passes.

In the vast majority of cases, the front face of the teeth is flat, but there are saws with a concave front face. They are used for fine cross-cutting.

Equipment and materials for sharpening saw blades

When using abrasive wheels (especially diamond), it is desirable to cool them with coolant.

As the temperature rises, the microhardness of abrasive materials decreases. An increase in temperature to 1000C reduces the microhardness by almost 2-2.5 times compared to the microhardness at room temperature. An increase in temperature to 1300C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on the parts and assemblies of the machine. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.) are added to the water, which form protective films. For normal sanding, soap and soda solutions are most often used, and for fine sanding. Low-concentration emulsions.

However, when sharpening saw blades at home with low intensity of grinding work, they do not resort to cooling the wheel so often. Not wanting to waste time on it.

To increase the productivity of grinding with abrasive wheels and reduce specific wear, you should choose the largest grain size, which provides the required surface cleanliness of the sharpened tooth.

To select the grain size of the abrasive, in accordance with the stage of sharpening, you can use the table in the article about sharpening bars. For example, in the case of using diamond wheels, wheels with a grain size of 160/125 or 125/100 for finishing can be used for rough sharpening. 63/50 or 50/40. Wheels with a grain size of 40/28 to 14/10 are used to remove chipping.

The peripheral speed of the wheel when sharpening carbide teeth should be about 10-18 m / s. This means that when using a 125 mm diameter wheel, the engine speed should be around 1500-2700 rpm. Sharpening of more brittle alloys is performed at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation of increased stresses and cracks, and sometimes to chipping of the cutting edges, while the wear of the wheel increases.

When using machines for sharpening circular saws, changing the relative position of the saw and the grinding wheel can be realized in different ways. Moving one saw (the motor with the wheel is stationary), the simultaneous movement of the saw and the motor, only moving the motor with the wheel (the saw blade is stationary).

A large number of sharpening machines of various functionality are produced. The most complex and expensive programmable complexes are capable of providing a fully automatic sharpening mode, in which all operations are performed without the participation of a worker.

In the simplest and cheapest models, after installing and fixing the saw in a position that provides the required sharpening angle, all further operations. Turning the saw around its axis (turning per tooth), feeding for grinding (bringing it into contact with the wheel) and controlling the thickness of the metal removed from the tooth. Produced by the worker manually. It is advisable to use such simple models at home, when the sharpening of circular saws is episodic.

An example of the simplest machine for sharpening circular saws is the system shown below. It consists of two main units. Motor with circle (1) and support (2) on which the sharpened saw is mounted. The turning mechanism (3) is used to change the angle of inclination of the blade (when sharpening teeth with a beveled front plane). The screw (4) moves the saw along the axis of the abrasive wheel. This ensures that the required rake angle is set. The screw (5) is used to set in the desired position the limiter, which prevents the wheel from excessively entering the interdental cavity.

Material and properties of carbide teeth

In domestic saws, sintered tungsten-cobalt alloys of grades (6, 15, etc., the number means the percentage of cobalt) are used as material for cutting inserts. At 6, the hardness is 88.5 HRA, at 15.86 HRA. Foreign manufacturers use their own alloys. Cemented carbide is mainly composed of cobalt cemented tungsten carbide. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Attach the carbide plates to the disc by high-temperature brazing. As a material for soldering, at best, silver solders (PSr-40, PSr-45) are used, at worst. Copper-zinc solders (L-63, MNMTs-68-4-2).

Basic principles of sharpening

When cutting massive workpieces, the side edges are also subject to rapid wear.

The saw should not be excessively blunt. The radius of rounding of the cutting edge should not exceed 0.1-0.2 mm. In addition to the fact that when working with a very blunt saw, productivity drops sharply, it takes several times more time to sharpen it than to sharpen a saw with a normal bluntness. The degree of bluntness can be determined both by the teeth themselves and by the type of cut they leave.

Correct sharpening of circular saws consists in ensuring the maximum number of sharpenings, which in the optimal case can reach 25-30 times, while ensuring the proper sharpness of the cutting edge. For this purpose, it is recommended to sharpen the carbide tooth on the front and rear planes. In fact, the teeth can be sharpened along one front plane, but the number of possible sharpenings is almost two times less than when sharpening along two planes. The figure below illustrates why this is happening.

The last pass when sharpening saw blades is recommended to be done along the back plane of the tooth. Standard metal removal rate. 0.05-0.15 mm.

Before sharpening, the saw must be free of dirt such as resin and the values of the sharpening angles must be checked. On some saws, they are written on the disc.

Ways to sharpen circular saws

Any sharpening machine can be used to form a new cutting edge. It is important to initially choose the right emery wheel and sharpen the edge with it. For this it is necessary to use corundum or diamond models.

The best option is to use special equipment designed to do this job. But due to its high cost, in many cases, its acquisition is impractical. An alternative way is to use a grinding machine with the ability to change the angle of the corundum disc.

In no case should you do the sharpening by hand yourself. First, it will take a very long time. Secondly, the result obtained will not meet the standards. If it is not possible to sharpen the saw blade on wood yourself, it is recommended to use the services of specialized companies.

Do-it-yourself professional sharpening of circular saws is performed according to the following rules:

- The main deformation occurs at the upper edge of the tooth. The edges are rounded from 0.1 to 0.3 mm. It is from this place that you need to start processing;

- Sharpening is carried out along the leading and trailing edges. This will provide the ability to repeat the procedure up to 25 times;

- Removal rate should not exceed 0.05-0.15 mm;

- The level of machining of the leading and trailing edges must be the same.

After the sharpening of the discs on the wood is completed, it is recommended to finish it with fine-grained sandpaper. This can be done manually or using a special machine.

Sharpening circular saws for wood with your own hands: geometry of corners, machine tools

Carbide-tipped circular saw blades may lose their original qualities during prolonged use. But this does not mean that you should purchase a new cutting tool. In most cases, sharpening can be done at home using any suitable machine.

Ways to Extend Saw Blade Life

The process of forming a new cutting edge is laborious and time consuming. Therefore, it is recommended that you fulfill a number of conditions to increase the life of the disk.

First of all, you should read the manufacturer’s recommendations. They indicate the number of revolutions (maximum and minimum) for different types of processed materials. For metal, this parameter should be less than for wood.

Hard solders have a long service life. However, they are more likely to chip and break off. The alternative soft is practically not subject to such defects. But its service time is shorter than that of a solid one.

The appearance of roughness on the cutting surface is not allowed. In the future, they can lead to the appearance of chips and cracks.

The material shows an example of a hand-made disc sharpening machine:

The need to sharpen the saw

First you need to decide whether you need to sharpen or not. There are several clear signs indicating the relevance of this procedure. If you ignore them, then in the future the disk may become unrepairable and cause the failure of an expensive machine.

The advantage of using a brazed saw blade is a longer service life. It is also designed for hardwood processing. Surfacing is made of steel 9KhF, 50KhVA, 65G and similar compositions. They are distinguished by high hardness, but at the same time, with significant operation, the likelihood of their breakdown will increase.

Timely sharpening of circular saws with a do-it-yourself machine is performed with the following obvious signs:

- Increased engine load. The reason for this is the deterioration of sharpening and, as a result, the power unit needs more power to cut wood. If protection relays are not provided in the engine design, it may fail;

- Deterioration in the quality of the cut. The first sign is an increase in the width of the cut, as well as the formation of chips and irregularities along its edges;

- Increase in the processing time of the workpiece. It takes longer than usual to form the cut.

How to determine the sharpening angle of a circular saw

The best option is to have an original template, according to which you can correct the geometry of the cutting edge. Often it is made of thin-walled stainless steel, less often of thick cardboard.

Carbide teeth are manufactured in accordance with GOST 9769-79. But their geometry and geometric dimensions are determined by the manufacturer based on the purpose of the saw. If the template is missing, you must independently determine the required sharpening angles. To do this, it is recommended to use a pendulum goniometer.

DIY template making technology.

- Take a new disc with solders, which is completely identical to the blunt one.

- Draw precise outlines on a hard piece of cardboard.

- Using the pendulum goniometer, determine the initial geometry of the carbide beads.

- Enter the data on the template.

In the future, it can be used for self-sharpening on a machine or provided as a sample for companies providing such services.

It is important to remember that the rake angle can be negative. Such models are used for cutting plastic sheets and non-ferrous metals.

Drawings and tooth geometry

Sharpening of circular saws must be carried out precisely in compliance with the norms and requirements for the geometry of the teeth of each individual blade. To properly sharpen a circular saw with your own hands, you need to know the shape of the tooth and its geometry.

Saw blade sharpening process

The saw is installed on a mandrel, clamped using a tapered (centering) sleeve and nut, then set in a strictly horizontal position using the mechanism (3). This ensures the bevel angle of the front plane (ε1) equal to 0. For machines for sharpening discs that do not have a built-in angular scale in the tilt mechanism, this is done using a conventional pendulum goniometer. In this case, check the horizontal position of the machine.

By turning the screw (4) of the mechanism that provides horizontal movement of the mandrel with the circle, the required front sharpening angle is set. In other words, the saw moves to a position where the front plane of the tooth is firmly in contact with the working surface of the wheel.

A marker is made to mark the tooth from which sharpening begins.

The engine is turned on and the front plane is sharpened. Bringing the tooth into contact with the circle and several movements of the saw back and forth while simultaneously pressing the tooth against the circle. The thickness of the removed metal is regulated by the number of grinding movements and the force of pressing the tooth against the abrasive wheel. After sharpening one tooth, the saw is removed from contact with the wheel, rotates one tooth and the sharpening operation is repeated. And so on until the marker mark makes a full circle, indicating that all the teeth are sharpened.

Front beveled tooth sharpening. The difference between sharpening a beveled tooth and sharpening a straight tooth is that the saw must be installed not horizontally, but with an inclination. With an angle corresponding to the bevel angle of the front plane.

The tilt angle of the saw is set using the same pendulum goniometer. First, a positive angle is set (in this case 8).

Then every second tooth is sharpened.

After sharpening half of the teeth, the tilt angle of the saw blade changes from 8 to 8.

And again every second tooth is sharpened.

Rear sharpening. To sharpen a tooth along the back plane, it is necessary that the saw blade sharpener allows the saw to be installed in such a way that the back plane of the tooth will be in the same plane with the working surface of the abrasive wheel.

Material and properties of carbide teeth

In domestic saws, sintered tungsten-cobalt alloys of grades (6, 15, etc., the number means the percentage of cobalt) are used as material for cutting inserts. At 6, the hardness is 88.5 HRA, at 15.86 HRA. Foreign manufacturers use their own alloys. Cemented carbide is mainly composed of cobalt cemented tungsten carbide. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Attach the carbide plates to the disc by high-temperature brazing. As a material for soldering, at best, silver solders (PSr-40, PSr-45) are used, at worst. Copper-zinc solders (L-63, MNMTs-68-4-2).

Basic principles of sharpening

When cutting massive workpieces, the side edges are also subject to rapid wear.

The saw should not be excessively blunt. The radius of rounding of the cutting edge should not exceed 0.1-0.2 mm. In addition to the fact that when working with a very blunt saw, productivity drops sharply, it takes several times more time to sharpen it than to sharpen a saw with a normal bluntness. The degree of bluntness can be determined both by the teeth themselves and by the type of cut they leave.

Correct sharpening of circular saws consists in ensuring the maximum number of sharpenings, which in the optimal case can reach 25-30 times, while ensuring the proper sharpness of the cutting edge. For this purpose, it is recommended to sharpen the carbide tooth on the front and rear planes. In fact, the teeth can be sharpened along one front plane, but the number of possible sharpenings is almost two times less than when sharpening along two planes. The figure below illustrates why this is happening.

The last pass when sharpening saw blades is recommended to be done along the back plane of the tooth. Standard metal removal rate. 0.05-0.15 mm.

Before sharpening, the saw must be free of dirt such as resin and the values of the sharpening angles must be checked. On some saws, they are written on the disc.

Equipment and materials for sharpening saw blades

When using abrasive wheels (especially diamond), it is desirable to cool them with coolant.

As the temperature rises, the microhardness of abrasive materials decreases. An increase in temperature to 1000C reduces the microhardness by almost 2-2.5 times compared to the microhardness at room temperature. An increase in temperature to 1300C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on the parts and assemblies of the machine. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.) are added to the water, which form protective films. For normal sanding, soap and soda solutions are most often used, and for fine sanding. Low-concentration emulsions.

However, when sharpening saw blades at home with low intensity of grinding work, they do not resort to cooling the wheel so often. Not wanting to waste time on it.

To increase the productivity of grinding with abrasive wheels and reduce specific wear, you should choose the largest grain size, which provides the required surface cleanliness of the sharpened tooth.

To select the grit size of the abrasive, in accordance with the sharpening stage, you can use the table in the article about sharpening bars. For example, in the case of using diamond wheels, wheels with a grain size of 160/125 or 125/100 for finishing can be used for rough sharpening. 63/50 or 50/40. Wheels with a grain size of 40/28 to 14/10 are used to remove chipping.

The peripheral speed of the wheel when sharpening carbide teeth should be about 10-18 m / s. This means that when using a 125 mm diameter wheel, the engine speed should be around 1500-2700 rpm. Sharpening of more brittle alloys is performed at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation of increased stresses and cracks, and sometimes to chipping of the cutting edges, while the wear of the wheel increases.

When using machines for sharpening circular saws, changing the relative position of the saw and the grinding wheel can be realized in different ways. Moving one saw (the motor with the wheel is stationary), the simultaneous movement of the saw and the motor, only moving the motor with the wheel (the saw blade is stationary).

A large number of sharpening machines of various functionality are produced. The most complex and expensive programmable complexes are capable of providing a fully automatic sharpening mode, in which all operations are performed without the participation of a worker.

In the simplest and cheapest models, after installing and fixing the saw in a position that provides the required sharpening angle, all further operations. Turning the saw around its axis (turning per tooth), feeding for grinding (bringing it into contact with the wheel) and controlling the thickness of the metal removed from the tooth. Produced by the worker manually. It is advisable to use such simple models at home, when the sharpening of circular saws is episodic.

An example of the simplest machine for sharpening circular saws is the system shown below. It consists of two main units. Motor with circle (1) and support (2) on which the sharpened saw is mounted. The turning mechanism (3) is used to change the angle of inclination of the blade (when sharpening teeth with a beveled front plane). The screw (4) moves the saw along the axis of the abrasive wheel. This ensures that the required rake angle is set. The screw (5) is used to set in the desired position the limiter, which prevents the wheel from excessively entering the interdental cavity.

Straight tooth. Typically used in rip saws where quality is not critical.

Oblique (beveled) tooth with left and right angles of inclination of the rear plane. Teeth with different angles of inclination alternate with each other, which is why they are called alternately cut. This is the most common tooth shape. Depending on the size of the sharpening angles, saws with alternating cut teeth are used for sawing a wide variety of materials (wood, chipboard, plastics). Both in the longitudinal and transverse directions. Saws with a large backplane tilt angle are used as scoring saws when cutting double-sided lamination boards. Their use allows you to avoid coating chips at the edges of the cut. Increasing the bevel angle reduces the cutting force and reduces the risk of chipping, but at the same time reduces the tool life and strength of the tooth.

The teeth can have an inclination not only of the rear, but also of the front plane.

Trapezoidal tooth. A feature of these teeth is the relatively slow speed of blunting of the cutting edges in comparison with alternating beveled teeth. They are usually used in combination with a straight tooth.

Alternating with the latter and slightly rising above it, the trapezoidal tooth performs rough sawing, and the straight one following it. Fine. Saws with alternating straight and trapezoidal teeth are used for cutting boards with double-sided lamination (chipboard, MDF, etc.), as well as for sawing plastics.

Conical tooth. Tapered saws are auxiliary and are used to cut the bottom layer of the laminate, preventing it from chipping as the main saw passes.

In the vast majority of cases, the front face of the teeth is flat, but there are saws with a concave front face. They are used for fine cross-cutting.