Disk thickness for corner grinder for cutting a profiled sheet. Tips and recommendations

The better to cut corrugated board

No one will argue that the corrugated board today is an extremely popular (and often simply indispensable) material for construction and decoration. In this regard, for many beginner builders, the question is very significant than cutting corrugated board, because, despite the acceptable cost of its sheets, damage to the profiled sheet can nullify all the advantages of using this material and significantly slow down the construction.

How to correctly cut corrugated board, what tools are used for this and how to process the cut to avoid corrosion is told in this article.

The profile is a rather thin product, easily subjected to damage during cutting. The second feature of the corrugated board lies in its coating with a layer of galvanizing and polymer, due to which the usual methods of cutting tin sheets become impossible.

The high.temperature methods of metal processing in this case are also not suitable, because the coating of corrugated board, no matter how durable and resistant to adverse natural factors it may be easily burned under the influence of high temperatures. It is impossible to cut a profaneist and abrasive circles, as they greatly spoil the coating, which leads to the formation of corrosion. So, how can and to cut corrugated board?

Cutting corpent decor

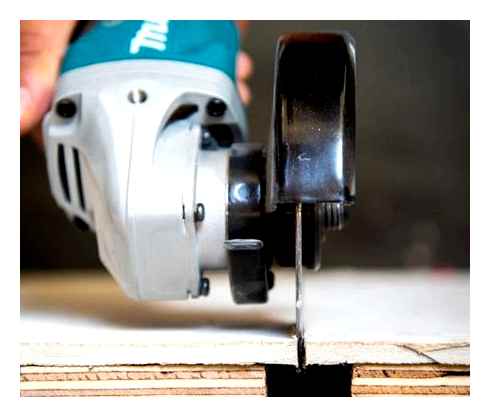

Since the corner grinder with an abrasive circle, as already mentioned, is not suitable for a profiled sheet due to severe damage to the coating, it is permissible to use this tool only with special discs for cutting corrugated board, which are thin cutting circles 1-1.6 mm thick with teeth From solid.melodious materials.

To avoid corrosion, after cutting the profiled sheet, the corner grinder must immediately process the edges with special colors.

The advantages of cutting corporate grinding corbine grinding are the speed of all operations and the relative ease of cutting a profiled sheet.

Disadvantages of cutting corporate grinders. torn edges and strong, very unpleasant sound accompaniment. Even if you use a special disk for cutting corrugated board, an angular grinder, in any case, is an abrasive tool, because the red.hot particles of the metal that form during cutting fall on the polymer coating and burn it, creating the prerequisites for the appearance of foci of corrosion.

In addition, the torn edges of the profiled sheet after cutting need to carry out additional work to eliminate the burrs. All this makes a corner grinder not the best tool for cutting corrugated board.

Cutting a profiled sheet with a hacksaw for metal

A fairly economical, convenient and popular way of processing corrugated board is a knife.haired woman.

The advantages of cutting the corrugated board are neat and fast cutting, the absence of zazubin and burrs, the possibility of independent work without special physical efforts. Usually, to work with fences, gates, small roofs and other designs that require small thickness thickness, builders use a hacksaw.

Disadvantages of cutting corrugation for metal. the impossibility of the implementation of curved cuts and the need to have a special inroof table to fix the material. Thus, in the case of complex crushing work, in addition to a hacksaw, the use of another tool should be provided. However, all the shortcomings of the scabbard for metal are successfully overlapped by the advantages of this method.

Cutting corrugated board with an electric jigsaw

Electrician is used for corrugated board, the height of the corrugation of which starts from 25 mm and is combined with a small length. Cutting with an electric jigsaw is carried out across or along the sheet, however, it is necessary to tightly press the profiled sheet so that it does not rattle.

Cutting should be carried out at high speeds using fine saws designed specifically for metal. In the case of high speed, the reciprocal mode of operation with the longitudinal inclination of the file is recommended.

Advantages of cutting corrugated board by an electrician. low cost of work.

Disadvantages of cutting corrugated board. the inconvenience of the transverse cut of a profiled sheet with a corrugation of 25 mm, the practical impossibility of cutting thin stripes, a strong burning of the edges of the metal sheet and protective polymer coating, heavy noise during operation.

Cutting corrugated board with scissors (ordinary and electric)

Simple scissors for corrugated board are used if necessary for small work related to the installation of flooring, the construction of garages, gates and fences. Electronics are used for wider Spectra tasks, however, when the smooth edge of the cut does not matter.

The advantages of both simple and electric scissors for cutting corrugated board are fast, light and high.quality cutting of thin and even stripes, as well as cutting across the wave without damage.

Disadvantages of scissors for cutting a profiled sheet are uneven and rough edges of the cut. In addition, low flexibility in the longitudinal direction greatly complicates the cutting of corrugated board along.

In addition to cutting, corrugated board can be flexible, which can significantly expand the possibilities of creating bent products for decorating walls of walls, cornices and roof skates.

To obtain a transverse-bent profile, corrugated board must be bent at right angles to the profile direction, and if a bending industrial unit is used when organizing mass production for this, then a simple manual leaf gigs will be enough for a small-scale production process.

The most common design of this tool is a rotary with a beam, and if desired, you can equip this device with any additional functions that allow not only to bend corrugated board, but, for example, cut it.

Proper cutting of corrugated board. than and how to cut a professionalist

Corrugated board is a modern facing material that is used to install roofs and the construction of barriers. The professionalist is in active demand due to many advantages, including high operational characteristics, such as the necessary rigidity and strength, attractive appearance, as well as ease of processing. The profiled metal sheet is light and small, which greatly facilitates the installation. Sheet material can be adjusted independently directly on the site, without professional skills and using mobile manual tools.

Cutting corrugated board may seem simple enough, since there is no need to use a special machine, but this procedure also has its own nuances. The profiled sheet consists of several layers, this is:

The cutting of the material should be carried out carefully, in compliance with the technology in order to avoid violation of protective qualities. The destruction of the layers of paint and zinc will entail corrosion and reduce the life. Therefore, you need to know how to cut a professionalist correctly in order to prevent serious damage and damage to sheets.

How you cannot process corrugated board

The use of gas cutting devices is completely excluded for cutting a profiled sheet, since strong warming up with a metal profile maximum harm. The corrugated board cannot be cut with a corner grinder due to the formation of sparks and the heating of the material at the site.

In the process of processing with a high.speed tool with an abrasive cutting element, the metal, the protective coating are burned, the damaged area is formed, where the bromary corrosion subsequently occurs. Sparks can damage the protective and decorative layer far from the site. You can cut a profileist with a corner grinding, in which a disk with small teeth is installed. However, this measure will only reduce the amount of harm, but will not prevent it.

Professor’s proper cut technology

The following tools use the following tools for cutting corrugated board:

- Electric saw with a profile processing disk. Due to the moderate speed of rotation, the metal does not melt, but is removed in the form of a metal chip. You can cut a lot of sheets with an electric tool. The nozzle for the profile is sold in the construction department, where there are abrasive circles. Observe safety precautions so as not to be injured by pieces of metal. Using the tool requires experience and skills.

- Hand hacksaw for metal. Suitable to cut several sheets. The tool is simple and safe for beginners, allows you to make any form. Obtaining a hacksaw injury is less likely to compare with other mechanisms. It will take more time to work, you need a table or a suitable support.

- Electric. Makes it possible to make curved cuts. The best option when adjusting the roofing material in places where house pipes come out of the roof. Before using an electric or manual jigsaw, it is necessary to carefully mark the profile. The use of electrolobesics is possible only for cutting a profile with a thickness of not more than 2 cm.

- Scissors for cutting corrugated board. Suitable for cutting thin sheet metal. It can be either an electric or a simple manual tool. There are three types. knife, cutting and slotting scissors (allow you to get the most neat slice). Electronics are considered one of the most comfortable tools when the profile must be cut daily on an industrial scale, as they are quite expensive.

- Battery Drill with a special nozzle. In the presence of certain skills, it is very convenient for fitting corrugated board in complex places.

Each solution has its own advantages that are optimal for performing a specific task. When choosing, you need to take into account the form of cut, profile thickness, access to the site, own preferences and skills.

When working with corrugated board with any cutting mechanism, it is always necessary to apply a special anti.corrosion mastic to the cut, unless it is a high.class professionalist in the protective layers of which there are molecules that prevent the alloy oxidation. You can also additionally process the cut location location in the color of the protective coating in order to protect the edges of the sheets and ensure the durability of the facing material.

Using various tools. Their pros and cons of

The industry for the production of cutting tools for metal is developing. Offers as cutting products:

- jigsaws;

- effective hacksaws;

- Small defense metal saws;

- electrified scissors;

- Corner grinder and other products.

The tools given in the text are actively used in practice, although it has obvious disadvantages. Let’s talk about the positive aspects first.

It is that the tools can be used to fit the profiled sheet. The cut is professional, satisfying the technological requirements. The process of cutting corrugated board is active, productive, convenient, although in some moments it requires additional processing.

They are created by the geography of the surface of the sheet. He is permanently convex. It has a corrugated look. System bods are simultaneously stiffeners. Not to deform them. the main task of the cutter. It is strictly forbidden to cut a sheet with gas cutters, since it is covered with an anti.corrosion composition that is easy to damage. In a word, cutting corrugated board preferably with a cold method.

Cutting profiled sheet with corner grind

Corner grinder is a universal construction tool.

Fixed disk fixed on it, it is easy to cut off metal pipes, channel, other products. It cuts the corrugated board perfectly, but heats it to the temperature at which it loses its anti.corrosion coatings.

In order not to weaken the profiled sheets before corrosion chemical reactions, after pruning, additional processing of the sections is carried out. They are finalized with “cold” tools:

For cutting profiled sheets, a corner grinder use the thinnest detachment disc, which is only produced by industry.

Working with thin cuts, heating a small part of the profiled sheet. It is advisable to cut this section by the length of with a millimeter. The cut end of the sheet is covered with special varnish, which the selling organization offers to buy, together with the corrugated board.

The anti.corrosion composition is used, identical to the factory model.

Guarantees the integrity of the material in any climatic region of the country.

A very progressive method providing for the pruning of a profiled sheet not on the rafter system, but on Earth.

If trimming directly on the roof, then hot abrasive particles will damage the hydraulic tank, violate thermal insulation.

Using various tools. Their pros and cons of

The industry for the production of cutting tools for metal is developing. Offers as cutting products:

- jigsaws;

- effective hacksaws;

- Small defense metal saws;

- electrified scissors;

- Corner grinder and other products.

The tools given in the text are actively used in practice, although it has obvious disadvantages. Let’s talk about the positive aspects first.

It is that the tools can be used to fit the profiled sheet. The cut is professional, satisfying the technological requirements. The process of cutting corrugated board is active, productive, convenient, although in some moments it requires additional processing.

They are created by the geography of the surface of the sheet. He is permanently convex. It has a corrugated look. System bods are simultaneously stiffeners. Not to deform them. the main task of the cutter. It is strictly forbidden to cut a sheet with gas cutters, since it is covered with an anti.corrosion composition that is easy to damage. In a word, cutting corrugated board preferably with a cold method.

Cutting profiled sheet with corner grind

Corner grinder is a universal construction tool.

Fixed disk fixed on it, it is easy to cut off metal pipes, channel, other products. It cuts the corrugated board perfectly, but heats it to the temperature at which it loses its anti.corrosion coatings.

In order not to weaken the profiled sheets before corrosion chemical reactions, after pruning, additional processing of the sections is carried out. They are finalized with “cold” tools:

For cutting profiled sheets, a corner grinder use the thinnest detachment disc, which is only produced by industry.

Working with thin cuts, heating a small part of the profiled sheet. It is advisable to cut this section by the length of with a millimeter. The cut end of the sheet is covered with special varnish, which the selling organization offers to buy, together with the corrugated board.

The anti.corrosion composition is used, identical to the factory model.

Guarantees the integrity of the material in any climatic region of the country.

A very progressive method providing for the pruning of a profiled sheet not on the rafter system, but on Earth.

If trimming directly on the roof, then hot abrasive particles will damage the hydraulic tank, violate thermal insulation.

Than cutting corrugated board: pros and cons of tools

Profiled flooring, this is nothing more than metal sheets covered with zinc and in some versions additionally painted with special compounds for protection against corrosion. Their feature is the special geometry of the plane in the form of alternating protrusions and the depths of the P-shaped shape with a width of 30 to 300 mm. Different depths. For the manufacture of corrugated board, steel is used with a thickness of 0.55 to 1.0 mm.

It is these characteristics that determine the features of cutting in the preparation of parts of the size you need. Three options for cutting corrugated board can be distinguished:

Below, we consider each of the options separately with a description of how to correct corrugated board, by listing the pluses and the minuses known to the masters of each way.

Manual tool for cutting corrugated board

In most cases, power tools are used, t.to. They are more convenient to operate and quick to use. The following power tool can be used for cutting Chishminsky corrugated board:

Corner grinder is a folk generally accepted name of manual corner grinding machines. The device is quite practical for cutting various metals, including profiled flooring.

The basic rule that must be observed with proper cutting of corrugated board is to apply the corresponding type of cut of the cut circle.

For Bulgarians, depending on their size:

How to cut corner grinding corbes? It is necessary to select circles corresponding to the diameter of the passport size of the tool. This is important to ensure the convenience of work.

In addition, the choice of size depends on the depth of the depressions on the profiled sheet.

Working with a small corner grinder with deep grooves on corrugated board, you cannot immediately cut the sheet in places of the lower corners. for this you will have to turn the sheet to the opposite side. Therefore, immediately choose a corner grinder on which you can install a circle of maximum diameter.

The second feature of cutting the corporate grinding corner grinding. the sheet should be put on lining at a certain distance from the ground or plane of the table on which you perform a cutter. Otherwise, the circle will “cling” the ground and raise a cloud of dust or simply spoil your desktop or workbench.

The use of corner grinder to cut the corrugated board in the hands of an experienced worker allows you to cut the parts of the desired geometric configuration, including in an arc with certain radii.

A completely acceptable method of cutting profiled sheets. But, again. only if you use:

Household classes, firstly, are not powerful enough to perform such operations. Secondly-there are practically no canvases for them, using which you can cut sheets with a thickness of 0.75 mm.

The professional class electric class can be cut by the C8 corrugated board, the technical characteristics of which are displayed by the purchasers, but you will have certain inconvenience in the work. The first. a sheet for cutting should be installed in an upright position, and this is not very convenient, so you will need to support the already cut strips, for which you will need one, or better two assistants.

The conclusion and opinion of professionals with experience is an electrician, this is not the best tool for choosing a tool.

Electronics. scissors for cutting corrugated board

It is quite convenient to use such scissors. they cut it quickly and for metal with a thickness of even 1.0 mm with a certain dexterity of the employee are quite suitable.

They also allow the cuts of various complex geometry, but after operation, electric knights are bending the leaf along the edge of the cut.

This will require you to perform additional operations at the end of cutting. the edges will need to be trimmed manually using a kiyanka or a hammer with wooden linings on a sheet so as not to damage the coating of the metal.

A manual circular saw, as well as a corner grinder is very convenient when cutting corrugated board if you have chosen a model with a large diameter of the cutting circle and used a special cutting circle for work “for metal”.

All work can be done in one tool on.

At the same time, it is also possible to cut the arc with a certain radius of rounding.

Summing up the use of a particular power tool for cutting profiled flooring, we can conclude that the most optimal and convenient should be recognized as an angular grinder and manual circular saw. Electron and jigsaw are more suitable for a small number of operations.

Power tools are used in any field of construction. A special need for them arises when you build a unique fence from a profiled sheet with your own hands. Especially if it is planned to decorate the fence with forging elements.

Uniqueness may consist of design. It is here that all possible types of fence from the profiled sheet, as well as ways of decorating it, are listed. Beautiful fences from corrugated board are an opportunity to stand out by emphasizing your personality.

Hand tool

A manual tool suitable for cutting corrugated board can be attributed:

Here you need to immediately make a reservation. the work with a hand tool is practical exclusively with very small volumes of operations performed.

Another case when a manual tool is needed. the creation of a complex geometry of cutting when finalizing individual lines after work by a power tool.

In general, the work with a hand tool for cutting profiled sheets is very laborious, takes a lot of effort and time. This allows us to conclude that cutting of corrugated board using a manual tool is ineffective and disadvantageous.

Protection of the edges of profiled sheets from corrosion significantly extends their service life. This event is especially relevant after cutting sheets of corner grinding or manual circular saw.

When working with a corner grinder, due to the increased speed of friction of the disk about a sheet of a leaf, a zinc or special paint-literally burns from high temperature.

The bare metal remains open before the influence of negative physical and chemical factors and is very quickly destroyed (rust). To protect it, special paints and varnishes should be used. Their consumption to cover the cut ends of the profiled sheet is minimal, it takes a little time and is easy to manually perform.

How to cut a profile: what disk, whether it is possible to cut a corner grinder, tools

Corrugated board. a popular material often used in construction. He has many advantages, one of which is the simplicity of processing. The profiled sheet weighs little and rather thin, and therefore the fitting in the place can be carried out right on the construction site on your own. For this you do not have to buy a special machine, because a hand tool is suitable for work.

But, despite the apparent simplicity, there are certain features that must be taken into account if the home master is about to cut corrugated board. Unlike simple metal, the profiled sheet consists of several layers that are easy to damage. Therefore, it is important to know which tool can be used for cutting to maintain the protective paint and a zinc layer on the metal surface.

Features of cutting corrugated board

Profiled material. a thin sheet of puff metal, which can be damaged with improper cutting. Since the material is covered with a special polymer and galvanizing on top, the use of the usual methods of processing tin sheets should not be allowed (cutting corrugated board or a tough hit is a bad idea).

It is also forbidden to use high.temperature methods of cutting (gas), since the sheet coating will immediately deteriorate, despite the initial factory protection methods. As a result of improper processing, the sheet itself will be damaged, and not just the external protective shell.

To cut corrugated board with a polymer coating correctly, you can not use a corner grinding with an abrasive circle, since there will be a risk of greatly spoiling the outer layer of the material, which will lead to an certainly rusty formation. The life of such corrugated board will decrease several times.

Features of the structure of the profiled sheet do not allow you to use any construction rude tool for cutting. Therefore, you need to know exactly how to process the material.

Is it possible to cut corporal grinding corral

An electric corner grinder is often used in construction, since it can be processed or cut as possible as quickly as possible. The device is also quite easy to operate, and the speed of processing surfaces is its main advantage.

But, it is worth noting that when cutting the profile of a corner grinder, specialists distinguish many minuses from using the tool. Corner grinder is an abrasive construction device that can quickly damage the sheet.

- The metal particles red.hot during operation spoil the coating, burning it. If after cutting is not processed with a protective coating, then corrosion is formed in these places.

- After processing the corrugated board, uneven edges remain, so you will have to additionally remove the burrs from the surface.

To avoid such difficulties, you need to select special discs for cutting corrugated board and timely cover the sheet of the sheet with protective colors.

Than cutting corrugated board

In order to correctly cut corrugated board, it is necessary to select a tool that will preserve the protective properties of the coating as much as possible and will not spoil the overall appearance of the building material.

There are several suitable tools that need to be learned in detail, and when working with them, some nuances will have to be taken into account.

Cutting corporate grinding disk for corner grinding

As already mentioned, an angular grinder with an ordinary abrasive and extremely rude circle cannot be used to cut corrugated board, since it greatly spoils the coating that have formed in the process of sparks, which will certainly lead to rusty.

Therefore, this tool can be used if you buy a specially adapted disk for cutting corrugated board. This is a very thin working circle (its thickness is less than 1.6 mm). Teeth should be made of carbide materials.

Some home craftsmen, in order to save time, prefer to cut a whole pack of corporate grinding corner grinder, putting a diamond disk on the tool. But experts do not recommend doing such things, since there is a risk of ruining the metal with the slightest displacement of sheets.

- The formation of torn edges cannot be avoided (additional alignment or closing of the “inaccurate side” of corrugated board will be required by another sheet).

- Light noise from corner grinder.

- Even in the presence of a correct detachment circle, the protective surface will be damaged under the influence of sparks.

- Fast cutting.

- Simplicity of work.

Nozzle for cutting corrugated board

Professional roofers often use special nozzles for cutting corrugated board to the drill to quickly and carefully process the surface.

But for such work, it is necessary to have certain skills and use only the battery drill. The nozzle will be convenient to use if you need to cut off the corrugated board in hard.to.reach places.

Hand scissors are used if it is required to cut off parts from corrugated board, but the number of sheets is small. The tool can be used in the construction of the gate or tightening with the material of the barn, garage.

But if the work is more global, then experts recommend using electric scissors for cutting corrugated board.

The advantages of the tool are quite light and neat cutting strips. The advantages also include the possibility of cutting metal across the waves.

Despite the presence of advantages, there are some shortcomings when cutting a profiled sheet with scissors for metal:

- It remains a rough, as well as an uneven and bent edge (you will have to straighten to give an aesthetic appearance).

- When choosing scissors, it must be borne in mind that when cutting in the longitudinal direction, the work is very complicated.

Battery scissors are the most preferred option for processing corrugated board. When cutting off parts of the metal, sparks are not formed, and therefore damage to the protective coating is minimal.

Lobzik. a tool for cutting corrugated board, which are often used by builders and home craftsmen. But this statement remains in force if you choose the right professional tool with a quality canvas.

Ordinary household jigsaws have small power for such operations. It is also difficult for them to find suitable canvases with which you can cut sheets with a thickness of 0.75 mm.

Therefore, for neat cutting, you need to buy only professional electrolobsics.

Cut the corrugated grinder corporate

According to the instructions for working with a metal profile provided by manufacturers, it is not allowed to use an angular grinder for cutting such products. The reasons why it is dangerous to use a corner grinder for cutting a profile sheet is several:

- Metal cutting is carried out hot. To perform this process, an abrasive cutting circle for metal is used. Rotating at high speeds, it creates friction and quickly heats the metal in the cut area. Overheating becomes the reason for the formation of scale. This, in turn, makes steel subject to corrosion and rapid through rusting.

- Overheating of corrugated board during cutting provokes detachment of a protective polymer coating or weakening the force of its adhesion. If after cutting is not noticed and this defect is not eliminated, then it can come up during the operation of the roof. A piece of paint simply falls off from the surface of the sheet. Bare steel begins to rust.

- When the abrasive detachment disc is operating, small heated metal particles will fly away from corrugated board in the form of sparks. If such a spark falls on a decorative protective surface, then with a high degree of probability it will be able to damage the paint. In case of a large number of such defects occur, it will be impossible to eliminate them. The spoiled sheet will need to be replaced.

When cutting a corner grinding of corrugated board, it should be remembered that this method is one of the quick. But it is more dangerous, in terms of the possibility of damage to metal profile. Therefore, work should be carried out carefully and in compliance with recommendations from professional builders:

Is it possible to cut corrugated board with a jigsaw

To cut the metal profile quickly and as efficiently as possible, you should use an electric jigsaw. Its peculiarity is to attach a thin canvas on only one side. Second. remains in a free position, without interfering with manipulations on the cutting of sheets.

The advantages of the electric jigsaw include the high speed of the drink of corrugated board. With it, you can make both direct and figured cut. Working from the motor, the load on hand is not created, which allows you to quickly cut a large amount of thin.leaf steel.

Security measures

Before starting work, you need to think about how cutting will be carried out (the position of the “corner grinding” in the space in relation to the site of the saw), determine the vector of the direction of the sparks, which will be accompanied by the immersion of the disk into the metal. Remove all flammable objects and substances from the spark flow line. If necessary, cover the finishing surfaces on which sparks will fall, with protective means.

Inspect the power tool itself for water, dirt, sand, as well as check the integrity of the power cord of power. Carry out a trial launch to check the uninterrupted operation of the unit and unhindered rotation of the cutting disk. Evaluate the object of the saw: it must be firmly fixed, not have a deforming voltage, to be far from electric wires.

It is strictly forbidden to start working with an angular grinder without observing safety measures and individual protection.

The eyes should be protected by special glasses that give a wide and clear review. It is not recommended to use glasses with darkened lenses. The safest face protection is a shield mask from a transparent plexiglass. In the case of the destruction of the disk during cutting, its fragments are scattered in the direction of the initial centrifugal force with high speed. This mask will protect the front part of the head from their hit. Hearing organs also need protection. For this, construction headphones or silicone bers are used.

The equipment of the operator is a corner grinder must meet the following safety measures:

- Rob from durable and natural material;

- Moderately free, but excessively long sleeves are unacceptable;

- gloves, tightly sitting on their hands, from strong material, capable of restraining primary tied;

- Closed shoes with composite inserts on socks.

Progress

At the time of turning on the “corner grinder”, it should be kept with the application of the effort sufficient to overcome the starting torque. The corner grinder, released from the hands at the time of launch, can cause harm to the health of the operator and damage the final surfaces. To keep the “corner grinder” directly, avoiding a sharp rotation of its body. Bring a rotating disk to a metal element slowly. Immerse without effort, giving your own weight the unit create the necessary friction coefficient.

Когда отрезной круг погрузится в материал на 10–20%, стоит обратить внимание на плавность распиливания. If the corner grinder twitches and seeks to break forward, it may be worthwhile to change the angle of inclination of its body or reduce the pressure of the disk to the metal. If the metal workpiece has an internal voltage, carry out the cut by 90% and complete the process manually. Otherwise, the release of the metal voltage at the time of sawing can lead to a sharp jamming of the disk and its destruction.

In the next video, you will find tests of cutting discs for a corner grinder and a comparison of popular brands.

Review of tools

Corrugated board is a sheet material that has a solid protection from several layers. The basis is steel up to 1.2 millimeters covered with zinc, with polymer spraying. The profiled sheet varies in the main parameters. width, height, shape. The wall sheet is used for lining fences, walls. Roofing is necessary for lining. A universal sheet can be used for any type of work.

Cutting corrugated board must be carefully, because its coating is sensitive to heating. Due to these features, processing is best done only in a cold way.

Now in the construction market you can find a variety of metal cutting tools. They can conditionally be divided into 3 categories:

Among other tools, the most popular are:

The positive aspects of such a variety are that the sheet can be carefully adjusted with all the ensuing technological requirements.

Cutting a sheet with such devices is very convenient.

After the acquisition of roofing material, assessment of its parameters, as well as operation methods, you need to solve the following nuances for yourself:

- determine the quality of cutting in a certain form of work;

- curly cutting or can be cut in a straight line;

- If you need to cut off a couple of sheets, then there is no need to take an expensive device;

- If, for example, the product is not needed, then use corner grinding;

- The budget, which everyone is ready to spend on equipment is of considerable importance.

But using all the tools, it should be remembered that the sheet must be cut carefully without violating its structure.

Lobziki

The jigsaw can make curly cuts on the sheet: no tool can boast of this. If small work is carried out, then you can use a manual tool. With large volumes of work, an electric jigsaw is used. This is a rather nimble tool, but it has its drawbacks:

- used only for a sheet with a wave of 25 millimeters;

- longitudinal cuts with a jigsaw will have to be performed for a very long time;

- The jigsaw operates at high speeds, so in the places of the cut it will need to be treated with paint or primer;

- Polymer coating is sensitive to processing tools, so after all manipulations it is necessary to process the edges additionally.

Effective hacksaws

Many specialists use a device like a hacksaw for work with metal. During work, less noise occurs, and individual details can always be purchased at any store. The hacksaw has a number of advantages:

- When cutting, the boundary of the sections is even without chips, so the sheet does not need additional processing;

- The employee does not need to make any efforts, ask for the help of another person;

- hacksaw can be used even when there is no electricity.

But the hacksaw can not make curved cuts. it cuts only in a straight line.

To make work alone for pleasure, it is better to use a table with fixed clamps for the cutting process.

Small defense metal saws

Manual circulation saw works on the principle of corner grind. Among its shortcomings, an uneven edge can be noted. The rough edges are treated with a file.

Electrified scissors

Several varieties of scissors are distinguished: slotted, cut, leafy. But the best option would be slotted scissors. they do not twist the sheet, after work the canvas remains even. You can even make a hole anywhere, start cutting the sheet. No burrs on the edge are formed, but for reliability it is still better to process the edge.

There is only one nuance of the tool. high price. If you work constantly with them, then the costs will pay off quickly.

Well, if you have to do one.time work, then such equipment is a little expensive.

corner grinding

A grinding machine or angular grinder is used, including for cutting a profiled sheet. Although the use of the device has its drawbacks:

- Such an abrasive tool often causes damage to the galvanized surface of the product. the occurrence of corrosion is inevitable;

- Sparks fly out from under the disk of corner grinding in the process, which often cause damage to the leaf surface;

- The finished product needs to process the edges.

For the operation of a corner grinder, it is recommended to purchase a disc 1.6 millimeters thick with teeth made of carbide materials.

Basic cutting rules

So that there are no problems in the cutting process, it is necessary to put a sheet with the same profile on the workpiece. Then take measurements correctly, make an incision first, and only then cut. At home, they use another way. also put a sheet on top, lean on it with an effort, and then cut off. When asked whether cutting is allowed on weight, professionals give a negative answer. There is a risk of injury, spoil the profiledist, cutting off crookedly.

In order to independently carry out trimming, it is recommended to use some recommendations.

- Always use protective equipment during the work process.

- In gloves, hands will not receive minor injuries and a splinter.

- Glasses perfectly protect the eyes from metal particles hit.

- Building headphones are needed in order to protect yourself from noise.

- From other damage, the special is protected.

- Use protective shoes.

- If you work with a corner grinder. use a protective casing.

- During work, follow all safety rules.

- When using electrical appliances, ensure emergency de.energization.

- If cutting is carried out by means of corner grinding, then it is recommended to use a plywood conductor. It can be made independently at home. Conductor. Protecting metal from tool sparks.

- If a scabbard is used for metal, then the above method is used during cutting.

- It is convenient to use an electrician when cutting a round hole. But the measurements should be accurate. Such a tool is best used to cut sheets of category “C” or not more than 21 millimeters.

- Scissors are suitable for cutting material for the roof. over, electric wizards will be able to work along and across the rib.

- When cutting the material with a small thickness, use the nozzle for the drill.

Other tool cutting tools

Other instruments for cutting a profiled sheet are also used today.

On the list of such products it is worth placing nozzles for corner grinders.

Included with it, an angular grinder is a productive cutting machine capable of working in different positions. She doesn’t care whether to cut a flat metal or with a complex embossed pattern that is inherent in a profile sheet. The qualification of the employee is important.

The spatial position of the corner grinder must be constantly changed. The cutting body of the nozzle should be in a perpendicular position to the carved material.

A longitudinal electric saw with a special disk quickly cuts a metal profile, leaving behind a smooth cut.

Cricket nozzle for a drill is a know-how in the processing of scrap metal.

The tool is safe to work. Productive nozzle.

The use of a metal profile in roofing systems, fences, fences, utility facilities of agricultural purposes require a certain procedure for processing it.

To date, the profile flooring of popular material in construction. Therefore, quite often questions arise about the possibility of independent cutting of sheets, the better to cut corrugated board and ways to prevent corrosion of their edges.

In this article, we will analyze the advantages and disadvantages of tools for cutting profileists known to the masters.

Corporals are steel sheets covered with zinc and a protective color layer of a polymer, easily bending and resistant to deformation, protecting steel from destruction and retaining color resistance.

In its appearance, it resembles slate, and has alternating trapezoidal, rectangular bulges and cavities, different widths and depths. Metal for the production of corrugated board has a thickness of up to 1 mm, which is the peculiarity of the cut of parts of the required size.

There are several options for a tribe cut: manually, using power tools, on machine tools.

How to cut corrugated board with an electrician?

If you cannot decide how to cut the corrugated board, we advise you to choose an electrician if you, of course, do not have already acquired other tools. As a rule, this is the best choice for those who decided to independently start the installation of the roofing in the country or the construction of a fence from the profiled sheet. It is desirable that he has a laser guide.

This tool is the most universal of what to cut the profile can without spending serious efforts and the availability of special skills. In addition, it can be used both for carpentry, and in order to cut down a few dry branches in the garden.

In addition, an electrician is very easy to maintain and use. The speed of work is high, the probability of getting an injury is minimal, if a saw breaks down. it can be easily replaced, and even a beginner can cope with a sharp. All these qualities make an electrician with an almost perfect tool for this task.

Now let us dwell directly on the technology of its use:

- Before cutting corrugated board with an electrician, draw a fishing line for a cutting trimmer. To do this, you can use a regular marker.

- Fix the sheet so that it is at least 10 centimeters from the surface and does not move when cutting. To do this, you can use ordinary goats.

- Now you can start cutting directly. Do not rely “by eye”. use a laser pointer so that the cutting line for the trimmer of the cut is even and exactly corresponds to your tasks.

- Try to tightly press the electrician to the sheet where it is possible. This will reduce the risk of canopy breakdown.

- Despite the fact that this tool for cutting corrugated board is safe enough and has many mechanisms that protect a person from injuries, be extremely careful. Hold the leaf by the edge, and do not rely on it with your hand. And even more so do not hold your hand on the cut line, even if the tool is still at a decent distance.

If you follow all these rules, then easily cope with a sharp corrugated board yourself. And you will do it quickly and without serious harm to cover the sheet.

Corrosion’s edges from corrosion

Even the use of special tools for cutting corrugated board does not guarantee complete protection against damage to the coating of corrugated board. Only in profiled sheets of galvanized steel of the 1st class of zinc coating thickness, the presence of molecules at the site of the section creates a barrier that prevents the oxidation of the metal.

Therefore, in order to avoid reducing the service life of corrugated board, it should be appropriate to the edges of the cut special anti.corrosion mastic. In addition, you can also paint these places with paint in the color of the protective coating of a profiled sheet. The fulfillment of these simple requirements will reliably protect the edges of the sheets of corrugated board in the fitting places, ensuring the reliability of the profiled sheet during the entire period of its service.

Полезная статья? Сохраните ее в соцсетях, чтобы не потерять ссылку!