DIY ceramic tile cutting

Diamond glass cutter

Domestic diamond glass cutter

The most common and quality ceramic tile cutting tool. Great for small tasks. When working with large areas and time to do the work in a measured way. no, this tool will become a burden for you. When using it, you constantly have to concentrate on cutting precision. In other words, if you are finishing a small bathroom or putting an apron in the kitchen, this tool will be enough for you. And if you plan to perform a large amount of work, then you should pay attention to another tool that is more suitable for laying tiles in large areas.

If you only need to tile the floor in one room, we still recommend purchasing a tile cutter. At the end of the installation, you can easily sell it to your friends or post it on the Internet bulletin board. Yes, you will lose a little in price, but all sides of the tiles you are laying will be perfectly flat.

Procedure:

What tool to cut?

Essential tile cutting tool

Before starting, estimate the amount of work, it will depend on which tool for cutting ceramic tiles is needed for work and what methods of cutting ceramic tiles to use. If the area of work is not large and not a lot of material is required, you can easily use a diamond glass cutter or a hacksaw for tiles.

There are a lot of tools for cutting tiles. Let’s consider some of them:

- angle grinder with diamond wheel;

- Electric tile cutter;

- “Ballerina”? special nozzle for a drill;

- Diamond glass cutter;

- Hacksaw for ceramics;

- Nippers.

Let’s look at some ways to cut ceramic tiles and choose which one will be most convenient for you.

What is the best tool to cut tiles and porcelain stoneware at home

Ceramic tile finishing has many advantages. which can be used in rooms with high humidity. In addition to excellent working qualities, the tile has a good appearance, allowing you to go for the most daring moves in terms of interior decoration. The most common use at home for the tile is in the cladding of bathrooms. If you decide in the same way, then you can surely face a typical problem, for example, if the task is to lay porcelain stoneware or tiles in the toilet on the floor, while you need to carefully go around the toilet bowl, or riser pipes, or build a beautiful ornament on the floor. You will need to cut ceramic tiles, without which, alas, you will not be able to get the desired result. This is one of the features of this material.

By and large, cutting ceramics will only be necessary when adjusting it to the desired size. bypass communications or or to install an outlet. For the docking to be successful, a fit is needed. Cutting ceramic tiles with your own hands is not difficult, you just need to have the right tool and know some of the features. We will tell you about all this now.

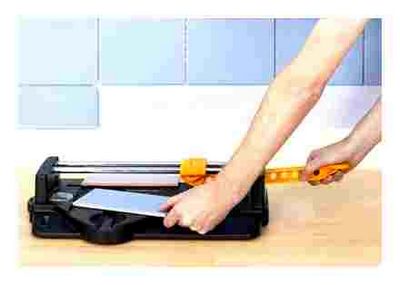

Manual tile cutter

This tool will greatly facilitate the work, even if there is not much of it. All work on this tile cutter should be done only on level ground, preferably on the floor, a stable table is also suitable.

The structure of the manual tile cutter

Before cutting the tiles into pieces, put them in water for a while. Wet material handles much better.

We place the wet tile in the tool, join the fishing line with the cutter and apply it with a certain effort. If for some reason the pressure turned out to be weak. you will not be able to break the tiles without chipping. The difference between a mechanical tile cutter and a diamond cutter is the thickness of the groove. The wider it is, the easier the tile will break off.

Angle Grinder

This is how the figures are cut out by the angle grinder

Bulgarka also perfectly fulfills the duties of cutting floor coverings. Almost everyone on the farm has such a tool, in extreme cases you can borrow from a neighbor.

For cutting ceramics, ordinary iron wheels are not suitable. For such a case, special discs are sold for cutting ceramic tiles with diamond dust, as well as for an electric tile cutter.

For a quality saw, the tool is held firmly and confidently. One not dexterous movement and the edge of the cut blade bursts. The cut itself, it is also recommended to wet it with liquid, to prevent overheating of the blade and remove dust.

Do not forget about the safety rules! Use safety goggles when working with an angle grinder. Small particles of ceramic can get on the mucous membrane of the eyes and cause serious injury.

Nippers

Tile nippers

There is a variety of tools on the market for cutting ceramic tiles, not steel and with the exception of ordinary nippers or pliers, they are useful for you to cut thin strips. In fact, it is an indispensable thing for breaking off small pieces of tiles, with narrow cuts. In short, if you need to cut a narrow strip, and the diamond glass cutter has not fully coped with its task, tongs will come to the rescue. The remaining burrs can be easily removed with them, and the edge can be cleaned either with a bar or sandpaper.

Ballerina

If, when cutting tiles, you need to get a round hole at the exit, you simply cannot do without a Ballerinka drill. The distance from the center to the cutter can be manually adjusted, thereby setting the required diameter.

For a neat appearance of the holes obtained, it is recommended to use a special tripod attachment. With only one ballerina, you can drill about 15 holes in the tiles.

Choosing a cut

Tile figures can be either straight or carved. For a straight cut, it is enough to use a simple tool: a glass cutter, a mechanical tile cutter, an angle grinder and a jigsaw. In this method, the cut is created in the form of a notch and the blade is split clearly along this mowing line. The decisive role, as in glass cutting, here will be played by the sharpness and strength of the cutting tool.

An example of what can be cut from curamogranite

When creating a curved cut, the task becomes a little more complicated. For such work, a machine for cutting ceramic tiles was invented, which easily copes with cutting tiles into any shapes. But it is not advisable to buy such a machine for one-time use, and do-it-yourself figured cutting of ceramic tiles is mainly performed using a glass cutter or an angle grinder. This technology implies a certain number of straight cuts and breaking off small pieces with special tongs. At the end of the work, the side of the notch is processed with a file or an angle grinder.

A kind of figured tile cutter

The order of work on a figured tile cutter:

- Mark the tiles with a pencil at the cut points;

- Fix the tile securely to the tile cutter’s working surface;

- We direct the cutter along the mowing line of the cut and take risks;

- We make more pressure of the cutter on the tile using the rotary knob;

- We do not move the cutter along the markings with abrupt movements;

- increasing the pressure, we cut through the enamel on the tile along the entire length;

- We take the cut tiles in our hands;

- Gently tapping with a wooden mallet until the cut part breaks off.

To determine the cutting method, it is worth considering not only your skills and characteristics of the material being processed, but also to think about what the quality of the edge should be. For example, if the side to be cut is laid against the wall and at the end of the work is closed with a plinth, then you can cut with anything, but if this cut will then be located in a conspicuous place, you cannot avoid buying a professional glass cutter.

How to cut with a manual tile cutter?

This tool is only used for making light straight cuts. With it, you can cut the tiles either evenly or diagonally. In this case, the direction does not matter. This equipment is very easy to use. At the same time, before cutting a tile with a tile cutter, you must have a general idea of its structure.

The tool is a base, where special tubular skids are fixed, along which a carriage with a hard alloy roller slides. After the marking is applied, the tiles are laid on this base in the required way. Then it is necessary to apply a roller on it and, using a special handle, make a neat cut.

In this case, only one cut is needed. Do not cut through the same place two or three times, as the result will be disastrous. the material will break completely in the wrong way.

We put the canvas tightly to the base and slide it over the tile 1 time

Also, precisely because of this, you need to carefully monitor the sharpness of the cutting device. on specialized professional models it is removable, therefore, if necessary, a dull roller can be easily changed.

It is worth noting that in order to obtain high-quality tiles when working with such a tool, you also need to be able to competently break the material.

On the basis of the equipment, in the course of the cut, a small tubercle is provided, which lifts the edge of the ceramic product clearly above the cut and then releases its ends. it is thanks to this that the tubercle, together with the slot on the tile, acts as a guide for breaking.

We gently break off half of the canvas using a T-shaped heel

In addition, the product also breaks with the help of a movable T-shaped heel, which is located in front of the roller. This heel must be set exactly in the middle of the cut so that when the lever is pressed, it presses on the blade. This tile cutter can also cut diagonally.

Diagonal cutting

How to properly cut ceramic tiles: 4 cutting methods

Ceramic tiles are a very durable and attractive facing material in all respects. However, the tiling process is not as easy as it sounds and requires patience and preparation. In order to successfully install this material on the floor, on the wall, around the edges of the room, around electrical appliances, window frames, pipes or various protrusions, it is necessary to use specialized equipment. However, before proceeding directly to work, you will definitely need to decide how and how to cut the tiles.

Tile cutter

This is a special device, in which a glass cutter and a “breaking knot” were originally connected on the basis of pliers. At a cost, they are very democratic, the price is from 250-300 rubles. And the speed and quality of the cut depend on experience.

They are used in the same way as with a regular glass cutter, only to break the cut tile, they use the “breaking knot”.

The advantages and disadvantages of this device are the same as those of the glass cutter (see below).

Tile cutter tongs

Tweezers are a very handy tool. It can be used to cut in almost any conditions. The tool itself looks like a pair of pliers. There is a cutting wheel at one end.

Thus, it looks like a glass cutter that is combined with wire cutters. At home, such a device is often simply irreplaceable. It is inexpensive, but at the same time it fully justifies itself in a small amount of work. Actually, all these works are reduced to a minimum:

- markings are made along the mowing line with a cutting wheel, which is installed on the tongs;

- the lips of forceps are brought to the edge of the product;

- the plate of forceps is placed on the front surface of the tile, and the central part is installed over the drawn groove;

- the tongs gently squeeze, after which the tile breaks off evenly.

This tool does its job much better than a glass cutter. But it is just as difficult to cut thin stripes with it. To do this, in any case, you will need more complex and expensive equipment.

Step-by-step instruction

Cutting tiles with a glass cutter is no different from cutting glass. Before cutting the tile with a glass cutter, you need to accurately mark the cut line with an erasable marker or pencil on its glossy side.

In order to work with this tool, it is advisable to use corners or metal rulers. Having applied a ruler along the mowing line, you need to run the glass cutter only once from the far edge of the ceramic product to yourself, trying to distribute the force as evenly as possible when pressing the tool.

Measure and cut tiles

Thus, you will get an absolutely even line. a depression that weakens the strength of the canvas. Then you need to place the tiles on the table so that the line of the notch on the product and the edge of the table completely coincide. Further, gently holding part of the tile on the table, you need to press on its other edge: the product will break gently and precisely.

Gently break it in half

The edges after all work can be sanded.

Cutting tiles with a glass cutter

Glass cutter is the simplest and most inexpensive tool. It is successfully used for processing thin tiles. At the same time, the method of cutting tiles, as seen in the video, practically does not differ from the technology of cutting glass.

The work is carried out as follows:

- markings are applied to the glossy side of the product using an erasable marker;

- having attached a ruler or corner to the mowing line, it is necessary to draw a glass cutter in the direction from the far edge towards you, while trying to distribute the pressing force as evenly as possible;

- tile or floor tiles are placed on the edge of the table along the cut mowing line, and, holding one part of it, gently press the other with your hand;

- the edges at the fracture point can be additionally processed with sandpaper.

Of course, working with a glass cutter will require some skill. Therefore, in the absence of proper experience, you should not train on expensive ceramic materials.

Manual tile cutter

A less expensive tool that is mostly used by hobbyists is the manual tile cutter. With its help, it is quite convenient to cut tiles with a thickness of no more than 6 mm.

It is not difficult to master the work with this equipment, and the cutting speed of the material will be much higher than when working with a jigsaw:

- marking is applied to the surface of the tile with a pencil or marker;

- the tiles are laid on the base, adjusting it so that the wheel coincides with the marking line;

- controlling the handle of the tile cutter, carry the wheel along the mowing line;

- the product is fixed by means of “wings”, which will allow dividing ceramic or clinker tiles into two even parts;

- after lightly hitting the handle of the device, the desired fragment is obtained.

The main advantage of a manual tile cutter is its independence from electrical energy sources. Its use is especially important in places where it is problematic to get to electricity. In addition, the hand-held device can be safely used in humid environments. And small dimensions and weight, as a rule, not exceeding 10 kg, make it convenient for transportation.

Hand-cut ceramic tiles: straight mowing lines

One of the simplest tile cutting tools is the glass cutter. This tool can only cut thin and small tiles that are not very hard. The operation is simple: with a glass cutter (diamond or roller), a couple of cuts are made on the front side of the tile along the planned mowing line, after which the tile is placed on the table so that the mark is exactly on its edge. Holding the tiled part that lies on the table, you need to slightly press on its other edge. after this simple action, the tile will crack exactly along the intended mowing line.

The manual tile cutter is designed for cutting wall tiles. Before starting to work with it, make sure that the cutting wheel is sufficiently secured, otherwise the cut will be uneven. It is also recommended to apply a couple of drops of machine oil to the wheel and the guide frame. The luster of the upcoming cut is applied to the tile with a special marker for the tile, after which it is placed on the base of the tile cutter so that the line of the cut coincides with the wheel. Raise the handle of the tile cutter until the wheel touches the cutting line, then start moving away from you. At the end, push the handle a little more, which can help break the tiles along the cut line. Uneven edges can be smoothed out with sanding pads or a grinding stone.

An angle grinder (angle grinder) with a diamond disc mounted on it is ideal for cutting porcelain stoneware tiles. The advantage of this method lies in its speed, however, the cuts on the tile after using the angle grinders remain uneven and ask for grinding. over, working with this tool requires sufficient specification and the strictest compliance with all safety rules.

Cutting ceramic tiles with your own hands and on a machine

When laying ceramic tiles, the master constantly faces the question of what and how to cut it to the required dimensions.

Cutting tiles can be made by all sorts of methods and tools, which will be discussed in this article.

Tile cutting: how to make bends and round holes

In order to fit the tiles to plumbing pipes, toilet protrusions, or any other obstacle, specialized cutting pliers can be used. Before using them, you need to use a marker to highlight the shape of the upcoming edge of the trim on the tile. Further, pressing small pieces of tile with the edge of the surface of the nippers and acting from the corners to the center, you should bite off the intended part little by little. the smaller the pieces that are broken off, the more chances are not to spoil the tile. After such a finish, uneven edges remain, which can later be sanded with sandpaper with a large and medium grain.

You can make a round hole in a tile using a hole saw, which is a specialized drill bit for a drill of various diameters, fixed in its holder, to which a 6 mm drill bit is placed for the tile. Since the contact of the saw with the ceramic tile surface (especially for glazed tiles) causes it to heat up, cracks are likely to form. To prevent this, the tiles must be dipped in water at least sometimes. Do not apply too much pressure on the drill during cutting, as this also leads to the destruction of the tiles.

Tile cutting machine: how to apply

The best cutting quality can be achieved by using an electric tile cutter to cut tiles. over, during the working period, there is rarely dust and dirt with it. This tool allows you to cut ceramic granite, marble, natural stone and glass, but it is not suitable for cutting stone tiles with carbide chips. you can use a traditional tile cutter for it. There is a saw blade for any material, supplied in a set with the device or purchased separately.

Electric tile cutters are available in two versions: top-mounted and bottom-mounted. The first of them belong to the category of equipment for professional work, occupy a fairly decent amount of free space and are expensive. In this type of model, cooling water is supplied directly to the disc. For their part, they are divided into machines with a movable table and machines with a movable disk.

In the variant that excelled, the tile is attached to the table in the required position and is brought to the disk, after which the disk is lowered to the tiled surface and the table moves towards it. On a machine with a movable disk, the tile is mounted on a static table, and the rail with the cutting disk is moved by the handle along it.

In electric bottom motor cutters, both the table and the blade are always stationary. During the working period with them, the tile is not attached to the table, but only placed in specialized guides and moves simultaneously with it in the direction of the disk. During the working period, the disc is immersed in water, which makes it possible to cool it. These tools are cheap and take up little space.

During the working period with machines for cutting tiles, it is necessary to take precautions and follow the instructions of the instructions for use.

Cutting ceramic tiles with a roller glass cutter

Using a conventional glass cutter, straight or curly cutting is performed, but the second option is very difficult to implement. To do this, you need to perform several sequential actions: apply the cut line with a felt-tip pen, then put the tile on a flat surface and hold it motionless with your left hand, and hold the glass cutter with your right hand, and draw the cut along the mowing line with constant effort towards you. The glass cutter is held vertically while maintaining an angle of 90 degrees, and we put the tile on the surface, at the same time aligning the cut line with the edge of the table, and sharply press on the free edge of the tile and the unnecessary piece of tile is broken off.

A cutting line is applied to the surface of the tile, along which the tile cutter is slowly drawn. The ceramic tile is held in place throughout the entire cutting time. When using stone tiles filled with fine carbide chips, the electric tile cutter is not used.

The use of this option is possible only with small volumes of wall cladding with ceramic tiles. A skilled craftsman uses a more modern construction tool, the electric tile cutter, which improves the quality of work and reduces the time to complete the work. The tile cut with this tool always has absolutely smooth edges and no chips.

Cutting ceramic tiles

When tiling work, cutting the ceramic tiles is inevitable. In the corners of the room it is not possible to install a whole tile, it becomes necessary to cut. Skilled cutting can also be done at home if you have the necessary construction tools.

Before starting to work on laying tiles, it is advisable to acquire some construction tools:

- ordinary roller glass cutter;

- manual and electric tile cutters;

- angle grinder (angle grinder);

- simple tile cutters.

Cutting ceramic tiles “angle grinder

With the help of an “angle grinder”, as a rule, they carry out straight cutting of tiles and curly cutouts. This equipment is compact, affordable and easy to operate. However, the obtained cuts of the edges of the tiles are of poor quality, require an additional operation, this is a thorough grinding of the edges of the tiles.

Manual tile cutter

This device is used to cut ceramic tiles with a thickness not exceeding five to six millimeters. It significantly reduces the operating time and quickly produces tiles of the required size. It must be remembered that the denser the structure of the tile, the better narrow pieces of tile are cut from it.

Tips: how to cut floor tiles

When cladding a bathroom or a bathroom, you may definitely need a curly cut for mounting tiles near the toilet, bath, sink, etc. Therefore, it will be interesting for the craftsmen to learn how to cut the floor tiles at home. For this purpose, it is possible to apply an original method. a drill with a nozzle. It allows you to make a rounding or a perfect hole for the floor.

As an attachment to cut, it is possible to take:

- Ballerina. A nozzle that is fixed in the center with the help of a foot.

- Crown. Round nozzles of different diameters with a straight or serrated edge.

- Tubular drill. Small diameter straight carbide tube.

- Traditional sharp drill.

To flatten the cut when using the drills, you need to use wire cutters. It is necessary to work slowly and very carefully, then the rounding of the tiles on the floor will turn out to be of high quality.

Glass cutter for ceramic tiles

If you need to cut just a few tiles, then it is irrational to buy a tile cutter.

It is possible to use the tools at hand for work:

- Glass cutter.

- Drill. You need to take a product with a victorious tip, since it is more effective.

- Nail.

- Construction knife.

It’s not hard to work. The ruler must be applied to the cut site and walked once with a glass cutter or drill. There should be a noticeable scratch on the glaze. If we are working with a knife, then it will be necessary to walk on the surface 2-3 times. Then the tile must be laid with a cut at a corner and sharply broken. The cut should be perfect, and you will not have to spend financial resources.

Cutting ceramic tiles with a tile cutter

To simplify the process of cutting the tiles and make the necessary breaking line, it is necessary to loosen the glaze layer. that is, cut it, and then break it.

There are 3 main techniques:

How to Cut Tile for Beginners

- Electric tile cutter or special tongs;

- Angle Grinder;

- Other sharp tools at hand.

The instruction looks like this:

- The tile must be inserted into the device, and the markings on the tile must be combined with a special mark.

- The handle must be lowered and held away from you. It must be driven at the same speed. You must also press evenly so that the roller cuts the glaze to the same depth. The video must be run once. If you drive more often, the breakage will be of poor quality.

- Next to the roller there are special paws, which, as soon as they go down, immediately break the tile into 2 neat parts. This happens after you sharply press a special lever. At the same time, all devices are based on a metal tubercle, and along the edge there are special non-rigid pads. When you press the edges of the material with your paws, in the place where the cut is made, maximum stress is obtained, and the tile breaks evenly.

High-quality tile cutters make it possible to cut without problems even ceramic material, the thickness of which is 1 cm. And it does not matter at what angle the material is cut: it will be at least 45 degrees or even 30 degrees. And how to cut a tile with the letter “G”?

Since the tile cutter can only cut tiles straight, many find it difficult to cope with L-shaped cuts. The easiest way. we cut the tile into 2 rectangles, and the resulting ugly seam of the short side we cut with an angle grinder, and the long side. with a tile cutter.

Many will also be interested in how to cut porcelain stoneware? It is believed that porcelain stoneware tiles are more rigid. It is possible to cut it in the same way as ceramic. Sometimes standard floor tiles are more difficult to cut than porcelain stoneware. There is a hardened material on which, after working with the tile cutter, it is almost impossible to see the notch. And even a diamond disc angle grinder cannot cope with it. the notch is crooked. Here you need to use an angle grinder, and file a 3 mm groove on the back side, thereby marking the place of the break.

Subtleties of the process: how to cut a tile

How to cut floor tiles at home: tile cutters and angle grinders

Tongs will cost the master about 400 rubles, and they can be used exclusively for small amounts of work with thin tiles at home.

Cutting is done like this:

- It is necessary to carry out the marking, taking into account all the gaps and seams, minus 5 mm.

- Then you need to attach a metal ruler to the marking and draw it once with a cutter. It is not necessary to press hard so that the result is a strip. It is recommended to lead from the far edge towards yourself.

- The tongs should be positioned with their feet along the break line close to the edges. The sponges are located on top of the glaze, and the straight part is on the bottom. the break line should be straight from the middle between the edges of the sponge on top. Next, you do not need to sharply press the handles, the cutting will be done. Do not lift high, otherwise the tile will split.

Cutting methods are different, for example, you can use an electric tile cutter. An ideal solution if the volume of work is large. The highest quality cut is obtained from the electrical tool. Here a diamond wheel is used and water is supplied to the place of the notch, due to which cooling occurs and there is no dust. The most inexpensive devices cost about 4,000 rubles.

You can cut tiles with an angle grinder. If the tile is curly, then you may need to cut a narrow strip of material 0.5–2 cm, and a standard tile cutter will not cope with this matter, because its legs are very wide.

Here it is necessary to draw a line of a break with a pencil and perform a wash down using an angle grinder with a diamond disc. But if you do not wash down, then during cutting, a narrow strip will break off in pieces. Therefore, it is necessary to carefully, slowly walk the angle grinder along the markings to make a cut of about 2 mm.

It is necessary to pass the disc along the mowing line, and not directly along it, then the width of the strip will be as necessary, it will not decrease. Cutting is performed in the same way, after several times. Now you can work with the device faster, but you need to try to press the angle grinder to the opposite side, then chips will not form. It is better to cut by weight, so vibration can be avoided. When it becomes noticeable that a narrow strip is about to fall, it is necessary to put a soft matter, then it will remain intact.

How to cut tiles with a glass cutter

What tool can be used to cut ceramic tiles

You can cut the embossed tiles using a special cutter, but there are many devices for carrying out this process. Among the many tools that are actively used in the preparation of finishing work, it is those with which tiles are cut that are the most unusual. They can differ in many ways.

In particular, by:

- Technical characteristics;

- Constructions;

- Size;

- The way of operation and not only.

The smallest of these can be as large as a ballpoint pen, and if the tool is used in industry, it requires a lot of space to place it. The main devices for cutting tiles are tile cutter, angle grinder and jigsaw.

Using an electric tool allows you to achieve an excellent effect in a minimum amount of time, and sometimes even special training is not required to work with it.

For easier cutting of tiles at home and in the absence of the need to process large volumes of canvas, you can use a glass cutter, pliers, sharp tongs, diamond wire. It is important to note that such materials are only suitable for soft and flexible tiles, especially those with a small thickness. Also, such devices are used to adjust the cut if it was made poorly and unevenly.

What is the best way to cut ceramic tiles at home

Cutting ceramic tiles is quite possible on your own at home. Basically, they prefer to cut the canvas using a special electric tool, as this allows all actions to be carried out quickly, efficiently and, most importantly, without oversights. Modern equipment allows you to cope, even if you need to cut a very thick and dense blade.

You can carry out the cut:

- Electric tile cutter;

- Angle Grinder;

- Jigsaw;

- If you use an electric glass cutter;

- Circular saw and more.

To cut the tile, you need to check how securely the canvas is fixed, first draw the cutting line, strengthen the base of the device or the working surface, bring the part that will be cut to the drawn mowing line and make a cut.

How to cut tile without a cutter or without a tile machine

It is best to cut the canvas in this way, as the process will be quick.

The likelihood that the edge of the tile will crumble or even break off is reduced. The most important thing is to pre-prepare protection for hands and eyes in order to observe the safety of such work.

Choosing the right tile cutting equipment

Any finishing work is carried out only after the base has been prepared, the material has been purchased, and it is prepared and cut into the necessary parts. In addition, the preparation of the necessary tool is required, with which it will be convenient and simple to work.

The choice of the tool depends not only on the budget and personal preferences, but also on a number of other criteria:

- If the tile is porous and soft, especially glazed, then you can use a hand tool in the form of a tile cutter and glass cutter. It will be enough ordinary human strength to carry out both cutting and breaking off a part of the canvas.

- If you intend to work not only with ceramic tiles, but also, for example, with a porcelain stoneware canvas, then you need to use a special electrical apparatus. The higher the strength, the more powerful the equipment must be.

- A cut of any tile, but with a relief surface, is carried out only on the front side. Here, the choice of tool must be done according to the same principle, or, to be more precise, by the thickness of the coating.

In addition to the tool itself, you need to use additional nozzles, each of which is selected according to the type of canvas that will be cut off and according to the tool used. You can cut ceramic tiles with diamond discs, which are installed on an angle grinder or drill.

A diamond-coated wire should be installed on a jigsaw, and a diamond stone is mounted in a glass cutter.

When it comes to working with an angle grinder, you need to use a dry cutting attachment to cut ceramic tiles. There are much more nozzles for electric tile cutters, since the choice will depend on the type of device, the principle of operation of the equipment, and the type of blade. A dry disc is sufficient just as with an angle grinder, however some tile cutters come with a built-in water tank. If you plan to use it, then the use of a dry disk is strictly prohibited. The advantage of the equipment is that you can cut without dust and dirt.

Hand-cutting ceramic tiles at home

Often, even craftsmen cut ceramic tiles with a hand tool, as it has a number of special advantages. Initially, it is worth noting its low price, availability and wide range. However, there is also a minus. If you need to cut a large number of tiles, then in this case, a hand tool will be far from appropriate. Basically, the processing and cutting of tiles is carried out by a glass cutter, which cuts both glass and ceramics.

To do this, you need to carry out:

- Marking so that the cut is of the highest quality;

- Laying tiles on the table to prevent slipping;

- Lay a straight edge along the mowing line;

- Cut along the mowing line;

- Tapping the reverse side of the canvas along the cut made;

- Moving the tile with one edge located on the other side of the cut to the edge of the table;

- Pressing on the edge of the tile.

This is how the canvas will break off. The edge must be flat and free of teeth. The handheld device does not take up too much space, and it can be used even in places where there is no electrical network.

If there is unevenness, then they are trimmed using tongs or nippers.

In order to use a manual tile cutter, you need to put the blade on the tool, after making a marking line, press the blade of the tool against the mowing line with the handle, gently press the handle to make a cut, remove the tile from the base of the tool, break the blade along the cutting line of the cut.

The better to cut ceramic tiles: 5 types of tools

Adaptations: how to cut ceramic tiles

In general, it is quite possible to cut a piece of ceramic tiles with your own hands, just like choosing a tool. It is worth noting that when buying and using an electric tool, one should not forget about personal safety and about checking the device for serviceability and the absence of defects in functioning, which can cause not only illiterate work, but also harm to the master.