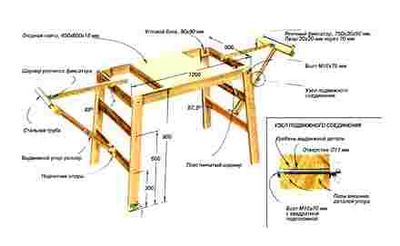

DIY circular device with drawings

We make a table for a circular saw with our own hands

Many carpenters have a wide variety of saws available. Some can be worked without additional devices, but the circular will be difficult to use manually. A table for a hand-made circular saw, made by yourself. this is a very real way to save money and provide yourself with a comfortable cut of a large amount of materials. over, it is not difficult to do it, the main thing is to draw up drawings correctly and provide yourself with the necessary tools.

DIY circular table with drawings

Stages of work

A circular saw is a pretty dangerous tool. The saw table must be positioned so that the saw is exactly in the center, without shifting the center of gravity. Based on the charts drawn up on the board, markings are made with a pencil, and then the base is cut out with a jigsaw. After that, the resulting tabletop must be carefully sanded to give smoothness.

After the work done, the tabletop is turned over and the markings are applied on the inside to deepen under the sole of the circular. Recesses are created with a milling cutter. The saw is installed in a homemade table, carefully fastened and tested for strength.

When making a table for a circular saw with your own hands, do not forget about stiffeners. They significantly strengthen the structure, especially in conjunction with self-tapping screws.

The legs for the hand circular are attached last. The dimensions, as well as the height, depend on the master, the main thing is to properly fix them on bolts and self-tapping screws. They need to be set slightly off guard, and the strength should be controlled with the help of the same stiffeners.

Blueprints

Scheme for making a table for a circular saw

Before starting work, it is recommended to go through the preparatory stage. Be sure to make a drawing. This will facilitate the process of creating the structure. First calculate the dimensions of the table, then transfer the obtained data to paper. The hole to be drilled in the structure must fit exactly the size of the saw. It all depends on the brand of equipment. Therefore, it is impossible to make a universal hole. The base must be stable and withstand well mechanical loads.

DIY circular table drawing

It is inadmissible to outweigh the structure to one side. The dimensions of the table top should be suitable for the cutting flow. The final version is determined based on individual desires. Some people work comfortably with a folding table or a product with small dimensions.

Drawing of a universal bench machine

An important point should be taken into account in the drawings. If you plan to leave tools or materials on the table during work, then the dimensions of the countertop need to be increased to a square meter in area. A suitable size would be 120 by 120 cm.A drawing should be done carefully and slowly in order to do everything correctly.

Circular table layout with detailed description

How to install the saw correctly

The next step is to properly position the saw on the top surface of the saw table. To do this, the contractor must perform the following actions:

The work of making a machine tool requires a lot of concentration and concentration. The slightest mistake can lead to the fact that you have to start all over again.

Adam Savage’s Favorite Tools: Awesome Circle Drawing Tools!

After fixing the structure on the table, you need to install a block to turn on and off the circular saw motor. A hole is cut in the housing, the switch is fastened with bolts and universal glue. There should be two separate cables from the block. One to the instrument, one to the nearest electrical outlet.

When self-assembling such a unit, it is worth considering the performance of the motor, as well as the maximum power of the electric motor. In this case, experts advise to opt for an engine whose power does not exceed 1000-1200 W, otherwise operation may be unsafe. And a more powerful saw means a heavier and more stable table.

Making a table for a hand-held circular saw with your own hands

The hand-held circular saw is a powerful machine with significant productivity. One of the key advantages of the circular is its excellent maneuverability. But there are also disadvantages, especially if it is necessary to cut large sizes of wood. In order to facilitate the process, you can simply make a table for the circular saw yourself.

Additional important information

Carpentry work requires special attention. In case you want to make a high-quality and highly reliable do-it-yourself table for a circular saw, then prepare well for work.

Do the following:

- Purchase all the materials and devices you need without exception.

- After installing the frame without fail, install it on a flat plane and check that the cover of the structure does not outweigh in any direction.

- It is better to install the table for the circular saw in the area where it will be located in the future in order to eliminate possible problems associated with uneven floors.

- If, due to the rough floor, the table vibrates during operation, then it is necessary to correct the length of the legs using compacted material or rubber.

- The table top of the product can be either single or folding. In order to form a folding saw table, it will be necessary to spend a little more time and the material itself and pay attention to increasing the strength of the frame, which is disassembled.

- The dimensions of the material used to create the table are formed empirically. Ideally, the level of construction should correspond to the growth of the master.

- The hole that will be made in the table top must match the dimensions of the specific saw available.

- To extend the service life of all the materials used, collected in a common structure, it is necessary to subject them to treatment with special chemicals that can increase the working properties of wood or metal (for example, to protect their surface from rust, decay, mold, etc.).

- It is more correct to process wood or iron outdoors, and not indoors, so as not to get poisoned by intense fumes.

Inspired by this article, you can make a sturdy circular saw stand in the form of a table.

Manufacturing of stops

The last step in making a do-it-yourself sawing table is the installation of stops. The standard part of most circular machines is the rip guide. Traditionally, the stop is made from an aluminum curtain rod or a wooden block. Its size is chosen so that the part passes over the entire table. parallel to the saw and from edge to edge.

Often used on saw tables and cross stops. With their help, parts are cut at an angle of 90 degrees and boards are trimmed. To make an emphasis, you should perform the following steps:

- Prepare an ordinary plywood sheet 1 cm thick.

- Fasten a block with a height of at least 2 cm on it.

- On the underside of the base, fasten the second rail perpendicular to the first.

- Cut off excess base.

The cross stops are attached to the workpieces to be processed using clamps or fastening devices made of wooden washers. These self-made clamps ensure that the rails are attached to parts of almost any width. If the bar on the bottom side of the base is fixed at an angle of 45 degrees, you get an angle stop. After completing all work, the surface of the circular table can be sanded and covered with a layer of protective varnish. This will save it from various mechanical damage, and in general will extend its service life.

Perhaps, outwardly, such a table does not look as attractive as a factory one. However, from a technical point of view, it is in no way inferior to him, so even a novice carpenter can safely take on its manufacture.

Possible options for small, hand-made circular saws

Any stationary circular, even a homemade one, requires a fairly spacious workshop. The space should allow not only to install the unit itself, but also to place the workpieces intended for cutting in the desired position. If the task is not to dissolve large wood, but simply, if necessary, you need to independently make a rail or a bar for repairing furniture, etc., it will be more rational to get a desktop circular mini-saw.

Such a device can be done by hand, using the same principles as when creating stationary machines from an angle grinder or circular saw. Only the stand will not be the goats, the support of which is the floor, but the bed, on which a small table is installed with a fixed hand tool.

Helpful advice! When making a circular of this type, it is important to take into account the overall height of the structure, that is, the plane on which the material intended for sawing will be located. Overestimation or understatement of the level will cause significant inconvenience.

The miniature machine is more functional and safer to use

If you need to create a circular mini-saw with your own hands for making workpieces of very small sizes (aircraft, ship modeling), you can assemble a tool using a PVC pipe as a body and borrowing an engine from children’s toys. In such a pipe, it is easy to make a hole for the shaft. A glue gun can be used as a joint material. Such a circular can be powered both from the mains and from a battery. To ensure autonomy of work, it is necessary to provide a special compartment for batteries in the case.

DIY circular table (with drawings)

This section offers a model of a universal table, on which you can place a circular having any technical characteristics and dimensions. For the manufacture of the structure, you will need the following materials:

- plywood sheet, preferably with a laminated topcoat, at least 10 mm thick and 800×800 mm in size;

- 4 sheets of laminated chipboard 16 mm thick (400×784 mm);

- bars 50×50 mm;

- bolts and screws.

To make a homemade circular saw and table, you will need blueprints

The manufacture of a circular table can be performed in the following sequence:

- The upper part of the future table is assembled from laminated chipboard sheets, which is a box without a bottom. The sides are attached to each other using bars, the length of which is much greater than the height of the sheets.

- The manufactured structure is turned over, the bars-legs of the future table in the lower part are fastened with additional jumpers.

- A tabletop is cut out of plywood, in which a longitudinal hole is made using a jigsaw. a saw blade will be inserted into it.

On the Internet, it is easy to find a drawing of a similar design, which will greatly simplify the manufacture. You can modernize the above version of the circular table with your own hands by replacing the bars with a metal corner or by making a so-called box made of boards. It is nice to make a shelf at the bottom of the structure.

Manual circular as the basis of a homemade design

One of the most popular tools on the basis of which homemade saw designs are created at home is a circular saw (hand circular). This electromechanical mechanism makes straight cuts in wood materials as well as in soft and thin metal using a circular disc. The tool is quite simple, it has all the basic elements available that allow you to make a circular saw out of a circular saw with your own hands.

The circular saw consists of the following parts:

- electric motor;

- one or two handles;

- protective casing;

Hand circulars make straight cuts in wood materials, as well as in soft and thin metal

- holding platform (for the possibility of exposing the disc);

- riving knife (prevents the saw blade from getting stuck in the wood).

Hand circulars stand out among other similar tools and some technical features. For example, the depth and angle of the cut can be changed directly in the course of work. Plunge-cut saws provide special opportunities. They can be used to make isolated fragment cuts of the required size.

Accuracy and quality of circular sawing depends on the number of teeth on the disc and on their sharpening angle. With a large number of teeth, the quality is higher, but productivity is slightly reduced.

When making a circular with your own hands from a hand-held circular saw, you need to pay special attention to the engine power. This is very important when intending to carry out significant amounts of work. The total weight of the saw is also important. Lightweight models suitable for occasional cuts.

The depth and angle of the cut can be changed directly during the operation of the circular

Super Easy 3D Printed Arduino CNC Drawing Machine | GRBL Plotter Elegoo

How to make a do-it-yourself circular shaft

In the general design of the circular shaft, the shaft is the main element that forms the whole machine. To make it, you will need steel round timber of grade 45. But you can only make this important part yourself only if you have your own lathe available or you can access it. The diameter of the workpiece must correspond to the dimensions of the saw blades to be used.

The main standard sizes of the bore of the discs:

- 16 mm;

- 20 mm;

- 22 mm;

- 30 m;

- 32 mm;

- 50 mm.

From the above indicators, the size of the shaft for the circular is selected.

For the manufacture of the shaft, you will need steel round timber of grade 45

The most common hole diameter is 32 mm. It is such a seat that the discs with different sizes of the outer diameter have. Alternatively, you can make a thinner shaft to be able to perform “jewelry” work. Then an adapter will be used to use large discs. In this way, it is worth complicating the design of a home circular only in those cases when it will be used by a professional.

Saw blades are installed between two flanges and pressed with a nut, which is screwed onto the thread made on the edge of the working surface of the shaft.

Important! The thread must be left-handed. During the inevitable jerk when starting the circular, the nut in this position will tighten, and not vice versa.

Bearing seats are determined taking into account the dimensions of the latter. The middle part of the shaft has the largest diameter. If the indicator is significant, an additional load on the belt will be created during rotation. To get rid of the problem, reaming will help, which will lighten the heavy part of the shaft.

The diameter of the workpiece must match the dimensions of the saw blades

Which discs should be used for circular

The performance and quality of work to a large extent depends on a properly selected disc for a do-it-yourself circular from an angle grinder, hand saw or assembled from separate mechanisms. It should be remembered that discs are different for wood and metal. Even if thin, soft aluminum is to be cut, the blade must be fitted appropriately. Cutting wheels have smaller teeth. There are universal disc options that are applicable to work with both wood and metal.

There are differences and discs designed for longitudinal and cross-cutting wood. Rip sawing is carried out with a cutting attachment with large sparse teeth. But transverse cutting will be of better quality in the case of using discs with fine, frequent teeth.

As for the material and method of manufacturing discs, they can be monolithic and carbide. Monolithic are made from a single piece of high-carbon steel. Such nozzles are inexpensive, but at the same time they have a significant drawback: they quickly become dull and need sharpening and wiring.

Circular discs can be for wood and metal

Tungsten carbide wheels are made from cobalt and tungsten soldered tool steel. They are more durable, but the price for such products is much higher.

The outer diameter of the discs for a homemade circular is limited by the size of the protective casing. The standard disc thickness is 3.2 mm. There are thinner and thicker saw blades. Thin ones are used when working with valuable wood species to make a clean cut. For coarser work, thicker discs are recommended.

Structural elements of a DIY wood sawing machine

To make a stationary machine for sawing materials at home, you first need to know what structural elements it consists of. Whether it’s a do-it-yourself machine made from a hand circular, an angle grinder or a tool assembled from disparate elements. the set of basic parts is the same.

The surface of the table must be made even, for a better product at the exit

The main elements of stationary circular installations are:

- Table for connecting and fixing mechanisms. If the circular is powerful and massive, it is better to use a metal table. Options from chipboard, wood, plywood are suitable, as long as the surface is smooth.

- Shaft. The most important detail. When making it, they use a lathe separately. The dimensions should be calculated accurately, this will avoid beating.

- Casing. This element ensures safe use of the circular saw.

- Engine. When using an angle grinder or circular saw, it is part of the power tool.

Helpful advice! If the design is supposed to be prefabricated, then when creating a circular with your own hands, an engine from a washing machine will be the most successful option.

In the design of the circular, there must be moving parts of the drives, and a button must be installed in the power supply circuit to stop the engine in emergency situations.

Circulars of any fixed type consist of main parts

Determining the parameters of a do-it-yourself circular at home

The primary task is to choose the capacity of the future stationary circular. Usually, devices with a power of up to 850 watts are recommended for home use. If it is not supposed to carry out repair work, but to build, for example, a bath or a summer house, as a result of which it will be necessary to saw a lot of material, then a 1250 W motor can be used. A device with a higher indicator is not recommended, since such powerful circulars require not only a solid table stand, but also fixing the latter to the floor by fixing or concreting.

The cutting depth is an important characteristic. In home devices, it should not exceed 8 cm.In fact, this figure is quite enough for sawing boards, plywood or wood-based panels.

When making do-it-yourself mini circulars or a full-scale sawing structure, be sure to take into account the speed. If it is supposed to simply cut boards for the manufacture of certain wooden elements, then you can limit yourself to a motor with a low or medium frequency. If you need perfectly straight and clean cuts, then it is better to use a high-speed motor. The optimal indicator for a household power tool is considered to be a frequency of 4500 rpm.

For circular, you can use the engine from the washing machine

Be sure to take into account the height at which the trigger button will be located. The place of its placement should be convenient for pressing.

Important! The control panel of a homemade circular saw must be accessible.

Making a carriage for a circular do-it-yourself

The functionality and high-quality work of a stationary circular is largely influenced by the availability of devices. One of these is the carriage. It is completely easy to do it at home, but the implementation of facing and sawing off material at an angle of 45 ° will be much easier.

You can make this device for circulars from a sheet of plywood as follows:

- plywood is cut out a bit wider than the circular table;

The carriage for the circular can be made with your own hands

Build a Geometric Drawing Machine. Tinker Crate

- in the lower part, guide bars are attached to it with glue or screws, the distance between which should be equal to the width of the table;

- from above in a similar way, using screws or glue, stop bars are fixed.

With the help of guides, the carriage is fed along the table onto the saw blade, which makes a through cut on the device. The height of the sides, which should be larger than the protruding saw blade, allows you to maintain the integrity and rigidity of the carriage. If the task is to cut at an angle of 45 °, it is necessary to use an additional bar, which in this device is a removable element. Cutting is done by pressing the workpiece against an angled bar.

In order for the plywood surface of the carriage to be easily cleaned of sawing waste, it must be varnished in several layers.

The plywood should be slightly wider than the circular table