DIY circular table with drawings

The second version of the circular table. Photo of manufacturing technology

A do-it-yourself saw-table is made of boards, as the most affordable material, quite often. To make this table you will need:

- plywood sheet (thickness 20 mm and more);

- boards 50 by 100 mm;

- bars 50 by 50 mm;

- several self-tapping screws;

- wood glue;

- one type of wood varnish.

A workpiece with a hole is cut from a plywood sheet with a jigsaw. a tabletop in which the saw will be placed. When marking the holes, they are guided by the dimensions of the saw sole. Stiffening ribs are made of the boards, which will be attached to the tabletop with self-tapping screws. In the process of fastening, the boards are pulled together using clamps. A start button is later installed on the front stiffener. For the manufacture of legs are boards about a meter long. They are bolted to the outside of the stiffeners.

DIY circular saw table

How to make a circular table from Laminated Particle Board? To make such a table for a circular, you need:

- a sheet of laminated plywood with a thickness of 9–11 mm (800×800 mm);

- 4 sheets Laminated Chipboard 16 mm thick (400×784 mm);

- several bars 40×40 mm;

- several bolts and screws;

- aluminum cornice.

Any hand-held circular saw with a large blade can be mounted on such a table. Drawings of this type of circular table can be easily found on the Internet.

Such a saw is made in several stages:

- The drawer of the future table is made from sheets of Laminated Chipboard. It does not have a bottom, and the walls are fastened with bars, which, in turn, must be fixed with bolts and screws.

- A cover is made of plywood with a hole into which you will need to insert a saw. The marking for the hole is carried out along the support shoe and the lower protective casing of the circular saw. The hole is cut with a jigsaw.

- The saw is fastened to the plywood with ploughshare bolts with a countersunk cone head. Fastening of the plywood cover to the body made of Laminated chipboard is carried out by a steel case 18 mm.

- Wiring is laid along the side of the tabletop and a start button is installed.

Circular saw guides are made of timber or aluminum curtain rod.

DIY circular saw table

A circular saw is used to cut wood along the solid wood. Its cutting base is a disc-shaped plane with a serrated outer edge. Such saws are not only hand-held, but fixed on the table. How to make a universal circular table so that this cutting tool can be installed on it? Below are several ways to make a do-it-yourself circular saw table.

The Jet JBTS-10 circular saw has a retractable table on each side, increasing the area suitable for work. Thanks to the belt wire, the sawing is quiet, and the service life of the electric motor is also increased. The presence of an eccentric clamp eliminates the displacement of the machine during operation, which makes it convenient to use in any conditions.

When using the table saw Caliber EPN-1100, it is possible to saw wood materials in the longitudinal and transverse directions, as well as at different angles. In this case, the level of inclination of the saw can be selected and fixed.

In the sawing machine Enkor Corvette-10M 90101, side and parallel stops are used, which greatly facilitates the work. The saw blade can be tilted up to forty-five degrees when cutting. An industrial vacuum cleaner can be connected to the machine to remove wood dust. At the same time, the device is characterized by lightness and small dimensions.

Using the stationary circular saw Einhell TC (TH).TS 820 allows you to work with sawn timber in a mass production environment. It is a suitable tool for processing not only wood, but also fiberboard blanks. The design of this model provides a hole into which devices that produce wet and dry cleaning of the machine are connected. At the same time, the equipment is so compact that it can be installed on any workbench.

DIY circular saw table. drawings

When processing wood, one of the most popular tools is the circular saw. This device, distinguished by productivity and convenience, allows you to significantly speed up the process of sawing molded timber or sheet materials. When carrying out work in significant volumes, it makes sense to think about the manufacture of a special stationary structure with a saw, which makes it possible to increase the safety, speed and quality of work.

DIY circular saw table. drawings

What is a circular saw

In everyday life and in production, a circular saw is necessary for sawing various materials (wood, slate, plasterboard, soft metal, plywood, etc.). This handheld power tool (standard) is designed for straight cuts from 40 mm to 140 mm deep (most manufacturers’ models allow you to cut at right angles up to 85 mm, but for construction sites there is a range of more powerful equipment). During the operation, the operator holds the device firmly in his hands and carries out the sawing, moving along the workpiece. At the same time, there are no restrictions on the size of the blanks in length and width. There is a possibility of sawing at an angle to the surface of the part.

Saw models differ in power. The most budgetary devices have a power of up to 1.2 kW and are designed for sawing workpieces up to 4.5 cm thick. They are excellent for household needs, for periodic work for short periods of time and are simple and unpretentious. If you need to cut up to 6.5 cm, and you need to do this often and for a long time, you will need a semi-professional tool with a power of up to 1.8 kW. To perform production tasks, professional equipment with a capacity of up to 2.2 kW is produced, withstands long-term loads and is capable of cutting parts up to 8.5 cm thick.In addition, a tool is produced for use in woodworking enterprises, capable of sawing workpieces with a thickness of up to 14, 1 cm.Its power reaches 5.5 kW, and weight. up to 100 kg.

Important! For home workshops, devices with a power of about 1 kW are usually sufficient. Before purchasing a model, this point is important to consider, since the overpayment for the saw itself and for the electricity it consumes, as a rule, is not justified by the need.

Coffee table with epoxy resin Homemade

When choosing discs for a tool, you need to pay attention to their technical parameters.

Making a ROUND DINING TABLE!

- Sharpening angle of teeth. Soft materials are sawn with discs that have teeth inclined in the direction of rotation of the disc. Negative angle models are required for metal cutting.

- Number of teeth. For cutting different materials, you should select blades with a different number of teeth: for soft. models with a large number of teeth, for hard. with a small number. For example, for wood, the minimum number of teeth is 24.

The marking of the discs includes data on its diameter and the size of the seat

To use the circular saw for a long period of time, it is important that it is not too heavy, is ergonomic, and that the blades are well sharpened. Holding the unit in your hand for a long time is not at all easy. Operator fatigue can result in poor sawing performance. Therefore, many craftsmen working with saws practice installing them on a table.

Circular saws are often placed on a table

The idea of such a device is to fix the saw body under the table top so that only the saw blade is above the table. The workpiece moves along the table top and is sawn with a rotating disc. Such a stationary device greatly facilitates work and allows continuous work without loss of quality and quickly. Manufacturers offer a large number of saw models placed on tables. Self-fabrication of the structure allows you not only to save money, but also to get the unit at your disposal in accordance with your own requirements.

Making a circular saw table is easy

What should be a saw table

When arranging a stationary site for processing materials, several nuances are required.

- The structure must be stable and rigid.

- The material from which the table is made must be durable and durable.

- It is important that the table surface is perfectly flat.

- It is necessary to provide grounding.

Circular saw table design

Considering the above, you can be sure of the reliability of the installed structure and the good quality of the workpieces being processed, regardless of the amount of work.

The main components of the table: a frame and a smooth surface for placing workpieces.

The material from which the structures are made differs depending on the purpose, place of installation and frequency of use. For domestic needs, you can make a structure from boards and plywood and install it, for example, in a garage. Working with large volumes of materials implies increased requirements for the strength and reliability of the structure. The best solution in this case would be a frame made of a metal profile. To reduce vibrations and increase stability, many even concreted the legs in the floor.

- the saw blade should be located strictly perpendicular to the table surface;

The saw blade must be strictly perpendicular

- the standard and optimal size of the table top is 1.2 x 1.2 m, but it can vary depending on individual requirements (if the table top is long, additional support legs may be needed);

- the height of the table depends on the height of the master, usually it varies between 0.8 1.2 m;

- it is more convenient for the operator if the table is installed on legs, and not on solid sheets, for example, plywood;

- the width of the slot into which the disc fixed from below is removed should not exceed the thickness of the disc by more than 2 mm, otherwise the tool may quickly fail due to clogging with chips;

Circular table from a hand-held circular saw with your own hands

- the circular saw should be located in the center of the table so that there is no strong shift in the center of gravity;

- it is recommended to bring the saw operation control buttons to the tabletop or the top of the table leg.

Important! In many saw models, the holes for fixing the sole on the table are already provided by the manufacturers.

An example of a reinforced workbench for a circular saw

DIY construction

After preparing the sketch of the structure (with the dimensions affixed) and purchasing the required materials, you can start working. You should start by making a frame under the countertop. It can be made from a shaped tube. Having a welding machine and an angle grinder on the farm, it is not at all difficult to do this.

- The necessary pipe sections are cut.

- Sidewalls are welded.

- Four pieces connecting the sidewalls are welded.

- All welding and sawing points are machined with a grinding wheel.

- Adjusting screws are attached to the ends of the legs, allowing you to set the table on a not very flat surface.

The structure must be painted in order to give it an aesthetic appearance and protect it from corrosion processes. It will remain in the frame to make holes for mounting the tabletop.

Also, the table can be made of timber or boards with a section of 10 x 5 cm.To assemble the frame, you will need metal corners, dowels and self-tapping screws.

Important! When using wood blanks, one should not forget about the obligatory processing of them from the effects of moisture and temperatures. For this, special formulations are produced.

Old furniture such as an office table can also be used as a base for a circular saw. It is only necessary that its base be solid. In most cases, the standard dimensions of such structures are quite suitable for wood sawing work. But it is recommended to install a new tabletop itself. Alternatively, glue two sheets of plywood with a thickness of 1.2 cm.This thickness will be enough to install a saw weighing about 5 kg.

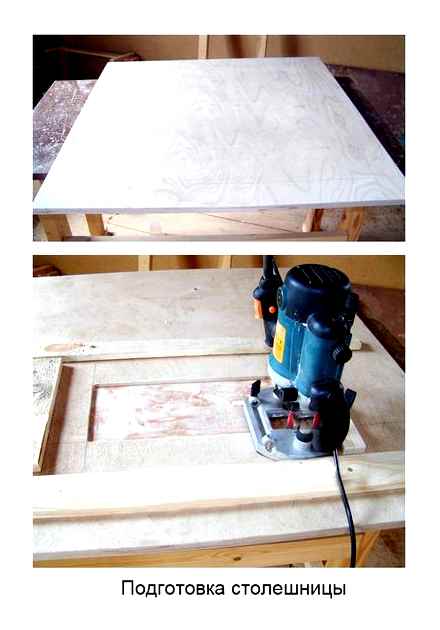

After making the base, you can proceed to the most important stage. surface preparation and saw installation.

Table. What you may need to carry out the work.

| Jigsaw | |

| electric screwdriver | |

| Drill | |

| Sander | |

| Milling unit | |

| Roulette | |

| Gon |

In the platform of the purchased unit, it is required to drill mounting holes (if the holes were not provided for by the design). It should be remembered that after such revision, the official manufacturer’s warranty for the purchased instrument will be lost.

Fiberboard (a board made from the finest wood shavings)

The table top is cut in accordance with the required dimensions. It can be made from plywood with a thickness of 1.8. 2 cm, fibreboard, old furniture or sheet metal, but this option is rarely used. Chipboard is not recommended in this case, since these boards are not highly durable. Plastic should also not be used as a countertop.

Important! The thickness of the cut directly depends on the thickness of the table. The larger this size, the shallower the depth the workpiece will be able to cut through the disc, since the working surface of the disc decreases.

It is advisable to mill the edges of the tabletop (no one canceled the aesthetics of the appearance even for working devices), after which one should go over the workpiece with a grinder.

A slot for a saw blade is arranged in the tabletop.

Marking is applied for hardware. The saw is attached to the bottom of the table top. Fastener caps should not protrude beyond its plane.

The saw is fixed to the bottom of the tabletop

Many do not use platform drilling when installing the saw on a tabletop, but fix it with pressure blocks and self-tapping screws.

The table top is turned over to the working position and fixed to the bed. For fixing, it is recommended to use not only self-tapping screws, but also metal corners, which provide the required structural strength.

Many craftsmen are not limited to simply assembling a factory tool under the table. To gain a few millimeters in kerf thickness, they completely remove the saw cover, sole, saw blade tilt adjustment (if not useful in the future). After that, a homemade platform is made, on which the saw is attached.

The power control of the instrument is displayed. To do this, you will need: a plug for an outlet, a plug for turning on the saw, a standard light switch, a piece of cable, clamps for clamping the power button on the saw, self-tapping screws and minimal wiring skills.

An outlet is attached to the inside of the table, from which a cable for the switch is taken out, which is installed where it is convenient. The device is powered from the nearest power source in the room. The saw switch button is fixed with clamps in the recessed position. Released saw start control allows quick and easy tool control.

To work on the table, it is necessary to make stops and a carriage.

Circular table guide carriage

The carriage for sawing small pieces or cross-cutting lumber can be made from a plywood base and two wooden walls. It will move along two guides, which are made of pieces of a metal pipe with a section of 2 x 1 cm and installed in grooves made with a router. The parts laid inside the carriage are very convenient and safe to saw.

Slides for working with workpieces can be made of boards, plywood or metal.

They should be able to adjust the position depending on the width of the workpieces being cut. Stops can be not only longitudinal, but also transverse, as well as helping to cut at an angle.

�� My Homemade Table Saw �� FREE Table Saw DIY Plans ��

If you do not want to tinker guides yourself, you can install a ready-made device.

You can put a ready-made device

To cut the workpieces, you cannot do without a marking ruler. A shallow groove is selected for its attachment in the tabletop with a router. It can be made with a chisel and a knife, but with a milling machine, it is much faster, more accurate and easier to do. All areas where work was carried out are carefully polished to eliminate the risk of splinters. Installation holes are drilled. The ruler is fixed with self-tapping screws.

Various devices can be provided to facilitate the operation of the tool: a bag under the table top for collecting chips, dust removal of sawdust flying over the table, a mechanism for lifting the table top for tool maintenance. A folding table top is convenient in small spaces.

The operation of a circular saw is a traumatic operation, therefore, the workpieces should be advanced to the disc not with your hands, but with a pusher specially made from a bar. The most frequent injuries that an operator can get when working with a circular saw are injuries to the fingers, as well as to the eyes when knots or chips bounce off. Always wear protective goggles when working.

Sawing table from hand-held circular saw

A well-made frame, a securely fixed saw and prepared work accessories allow you to cut the material quickly and safely.