DIY cutting of porcelain stoneware without chips

Cut off the plate without chips

Porcelain stoneware belongs to the materials of increased strength. There are practically no pores in it, it does not absorb water and does not crumble. It is very difficult to even scratch it. Therefore, home craftsmen have the question of how to cut off porcelain stoneware without chips and is it possible at all. It must be admitted that theoretically it is possible, but in practice it turns out very rarely. often, small chips remain on the cut, which have to be sanded.

To keep them as small as possible, experienced craftsmen advise following these recommendations:

- Cut the part from the top side. Most material chips appear where the cutter exits the plate.

- The smaller the thickness of the selected cutting disc for the grinder, the lower the likelihood of chipping.

- Decrease torch speed at the start and end of the cut line.

- When working with a mechanical tile cutter, apply more pressure to the lever than when cutting a regular tile.

- Make a cut slightly to the right of the marked line so that it remains on the cut off fragment. Then it will be possible to remove unwanted chips with a sander.

It is very important that the tool is of high quality and suitable for the selected material. Otherwise, it is almost impossible to get a beautiful cut without chips. If, nevertheless, they appear, which happens most often, the defects should be sanded down. You can use sandpaper or a diamond sponge.

The best option is a grinder with a special attachment. This is the so-called turtle or flexible diamond circle. They are distinguished by the diameter of the particles deposited on the surface of the diamond coating. The turtle can only work with a grinder, the model of which provides for the ability to regulate the number of revolutions. If it is higher than three thousand per minute, the nozzle may fly off the axis.

Cutting & Corners: National Tiles DIY Tiling 07

How to cut porcelain stoneware with a grinder without chips

Almost every home craftsman has an angle grinder, or a grinder. Therefore, it is she who is most often cut porcelain stoneware. Unfortunately, it is almost impossible to make such a cut without chips, but it is quite possible to minimize their number. For this, it is very important to choose the right disc. He must have:

- high-quality diamond dusting;

- marking confirming that the device is intended for cutting porcelain stoneware;

- the minimum possible thickness;

- continuous cutting edge.

The grinder is a potentially dangerous tool, so you should not neglect the safety rules. You should take care of the means of protection. The kit includes:

- Respirator, as a lot of dust is generated when cutting.

- Safety goggles to prevent possible exposure of disc fragments to the eyes.

- Special clothing.

- Earplugs or ear muffs to protect your hearing from loud noise.

It is not recommended to neglect protective equipment, even if it is planned to cut several plates.

Correctly cutting porcelain tiles with a grinder is quite simple if you follow the instructions:

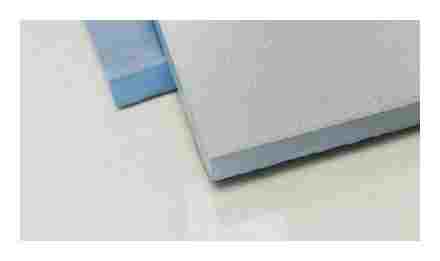

- Preparing a place to work. Lay a substrate on the leveled surface, which will protect the base. You can choose penoplex, polystyrene, etc.

- We put the part on the base with the front side up, mark the section of the cut on it. To make the chips less, we glue a strip of masking tape on it, draw a cutting line along it.

- We put a metal corner on top of the tile along the cut path, fix it with clamps. This will allow you to make an accurate cut. This must be done when cutting products with a large thickness.

- We start the grinder. We cut the part at a time, direct it “away from ourselves.” To get an even edge, cut off the fragment so that the marking line is preserved on the product. It will be removed during the sanding process, and the tile will retain the specified size.

- We remove the masking tape, if necessary, we grind the end of the part.

If the plate is thin or you don’t need a perfectly straight cut, you can make your job easier. The grinder does not make a cut, but only a cut. Then the fragment is broken off with a sharp strong movement.

It is very convenient to use a grinder to cut porcelain stoneware tiles. First of all, because it is the most affordable of all the devices that can be used. They can make cuts of various shapes, including any curved. However, the grinder is traumatic, you need to work very carefully. It is very dusty and noisy.

How and what to cut porcelain stoneware at home: 4 proven methods

How to cut porcelain stoneware with a glass cutter

This is the easiest tool to use. It also gives a minimal effect. Using a glass cutter, you can cut off porcelain stoneware, but provided that its thickness is small. This is how the wall cladding is most often cut. Glass cutter will not cope with floor tiles.

There are two types of tools: with a hard metal roller and with a diamond cutter. The latter option cuts better, but breaks down faster. Its cost is higher than that of a roller analogue.

With a glass cutter, you can make a straight or figured cut. In the latter case, you will also need special nippers. To cut a tile in a straight line, proceed as follows:

- We lay the cladding on a flat base. Determine where the cutting line will pass.

- We take a ruler, lay it along the future cutting line and press it with our fingers.

- Gently, but with strong pressure, draw a line along the ruler with the tool. We try to scratch a deep enough groove at a time. Otherwise, chips cannot be avoided.

- We put the part on the edge of the table or workbench and press firmly on its edge. So that the veneer splits along the intended line.

- Grind the edge if necessary.

If you want to make a curved cut, a line is drawn with a glass cutter. Then you need to take pliers and use them to remove sections of the tile. The closer to the cutting line, the smaller fragments should be chipped off. The edge with such processing will turn out to be sharp and not entirely even, so it must be sanded.

How to cut porcelain stoneware with a tile cutter

The principle of operation of the tool is somewhat similar to the glass cutter. There, too, there is a cutting roller that moves along the guides. In addition to it, there is a bed on which the part is laid, a lever and guides. It is very important that the diameter of the cutting element matches the height of the tile.

In addition, when choosing a device, pay attention to:

- The base of the device. The metal from which it is made must be thick enough so that the base does not vibrate or bend during the cutting process.

- Strength of guides and supports.

- Smooth movement of the carriage. It is desirable that this is ensured by special bearings.

- No backlash when advancing the carriage. If it is available, it is impossible to make a straight cut.

Tile cutters vary in length and it is best to choose a long model. This will make it possible to cut porcelain stoneware of different sizes, not only along the side, but also diagonally.

To cut off a piece of porcelain stoneware tiles in a straight line with your own hands, you need to follow these steps:

- We put the tile cutter on a solid, even base.

- On the product we outline the cut line.

- We lay the part on the bed so that the trajectory of the roller goes exactly along the basting.

- We make an incision by pressing on the carriage and moving it away from us.

- We release the handle and break the part with strong pressure.

- We grind the cut to remove possible chips.

Working with a mechanical tile cutter is very simple, even a novice master can handle it. There are, however, some disadvantages to be aware of:

- A fragment already 6 mm wide cannot be cut in this way.

- It is also impossible to chamfer or make a curved cut with a mechanical tile cutter.

- If the cut falls on the edge under the glue or the surface of the material is ribbed, there is a very high probability of chipping.

Tools for cutting porcelain stoneware

Before determining how and how to cut porcelain stoneware at home, it is worth understanding its features. It is a composite material that successfully combines the properties of natural stone and ceramics. It is made by pressing a mixture pre-fired at high temperatures. The result is a highly durable and wear-resistant material. In the production process, it can be given a wide variety of colors and textures.

The surface of ceramics can be matte, glossy, structured, etc. Consider this when choosing a cutting method.

You can cut a fragment of a tile using various tools:

- glass cutter;

- electric tile cutter (aka wet cutter);

- mechanical tile cutter;

- grinder;

- waterjet cutting attachment.

The latter method is not used in a home workshop, since it is assumed that special expensive equipment is available.

How to cut porcelain stoneware with an electric tile cutter

In the recommendations on how to cut porcelain stoneware tiles at home, you can read that it is convenient to do it with a wet cutter. This is the name of an electric type tile cutter, for which a diamond cutting disc is used. To cool it down, water is supplied to the part during the cutting process (hence the name of the device).

There are two types of equipment: with the upper and with the lower supply of tiles. The first ones make the cut as accurately as possible and are more expensive. For household work, budget devices are more often purchased that feed parts from the bottom.

Devices of any type make it possible to make cuts not only straight, but also curved. To cut a piece of porcelain stoneware tiles, do the following:

- We outline the cutting line.

- We fix the part on the bed using special clamps. If you have to make a curved incision, you will have to hold it with your hands.

- We start the device. First, we select the minimum speed of the disk, so the part does not deform.

- Increase the cutting speed gradually. Make sure that the element does not move from vibration.

An important point. The product should be stacked so that the cutter starts to cut its front side. That is, on equipment with an upper cutter, the part is laid face up. On a bottom disc appliance, place the tiles face down.

Cuts made with such equipment are more accurate and better than with a mechanical device. It is especially appreciated by beginners, as it is able to completely neutralize the so-called shaking hand factor. In addition, the device allows you to cut fragments less than 6 mm wide, does not generate dust or noise. The main disadvantage of the device is the high price of quality models.

Bulgarian

You can also cut porcelain stoneware at home with a grinder. To do this, you need to purchase a diamond-coated disc with a thickness of 2 mm and an edge width greater than the thickness of porcelain stoneware.

REMEMBER! When working with a grinder, you should install the disc on the right side and be sure to protect your eyes with glasses, since many chips are formed during processing. Cutting should be done in one step, otherwise the cut will be uneven. You also need to leave a margin of a few millimeters to sand the edge.

Little tricks

These two methods do not exhaust all methods. With their help, you can get an acceptable result of any cuts at home. Round holes in the material are made with an ordinary tool without any special nuances: tungsten carbide drills, ballerinas, crowns. The only difference is that, due to the hardness of the material, the cutting tool will fail faster.

To solve the problem of laying tiles, you can use an integrated approach:

- The easiest way to cut tiles is a manual tile cutter. It is recommended to cut the bulk of the tiles;

- Tiles with cut edges, covered with skirting boards or overlays. In this case, it will be enough to use a manual tile cutter or grinder (in limited cases);

- Tiles with a precise fit are few. Fit by sanding;

- Install all complete tiles. Depending on the tool you have, adjust the tiles that are covered with skirting boards and trims. The remaining elements must be accurately measured and marked on the tiles. Either rent a professional tile cutter, or take it to the nearest construction company with such equipment and cut.

Technology

- Mark the tiles, it is recommended to use a construction marker.

- Lay the tiles on the cutter exactly according to the line.

- Gently draw a line away from you with light pressure. At the same time, it is important to maintain the same pressure force throughout the line. Important! On porcelain stoneware, the line is drawn once. Multiple strokes are unacceptable. Otherwise, the rift may not go along the line.

- Place the foot on the tile and press to break along the line.

- Grind the cut if necessary.

How to cut porcelain stoneware

The processing methods for this material are primarily divided into two types. Each of them has its own indications for use.

How to cut porcelain stoneware

There is an opinion that porcelain stoneware differs little from ordinary tiles. Therefore, it can be cut with the same tools as ceramic tiles.

But this is not entirely true, porcelain stoneware is distinguished by its high density and hardness. Using hand tools to process it is ineffective.

How to cut porcelain stoneware at home? It is good if the household has an electric tile cutter. With its help, you can quickly process a large number of tiles.

A regular grinder is also suitable. LBM performs not only straight cut, but also figured.

If there is no tile cutter and grinder, then you can use a circular saw. It is enough to replace the toothed disc with a diamond disc for porcelain stoneware.

Attention! When choosing a tool, you should take into account the thickness of the tile, which can range from 3 mm to 30 mm.

Waterjet cutting

An expensive installation is used that supplies a thin stream of water (with a diameter of tenths of a millimeter) under significant pressure with the addition of crumbs from a solid material. The cut is performed quickly and efficiently, but such equipment is available only to large workshops.

How to cut porcelain stoneware without chips

Porcelain stoneware is highly durable and resistant to wear and tear. Excellent performance properties have made this finishing material popular. But they are also the reason that it is quite difficult to process it.

Some types of porcelain stoneware are so similar to natural stone that it is difficult to believe in their artificial origin. However, this material is a product of modern technology. It was invented not very long ago. in the 70s of the last century. Clay, quartz sand and feldspar are used as raw materials for its manufacture. Various colors are obtained using metal oxides and other components.

Porcelain stoneware has a hardness index on the ten-point Mohs scale of 7-8 points. The surface of such a hard material is almost impossible to scratch. Therefore, it is used for finishing floors in places with a very high operational load, such as train stations, airports, shopping centers, etc. In a residential area, the coating will also look organic and will last for many years.

In this article, we will take a closer look at how and what is the best way to cut porcelain stoneware at home.

Varieties of porcelain stoneware

Porcelain stoneware was originally produced for technical use. But in recent years, the range has expanded significantly and new types of tiles have appeared.

How to cut ceramic tiles in small pieces (tips and tricks)

To understand how to properly cut porcelain stoneware, you need to understand the varieties of this material.

Products differ in the way they are painted

The simplest option is the salt-pepper texture. The unassuming appearance of the finishing material is compensated by its relative cheapness.

The partially colored coating consists of a pigmented layer on the surface of the tile and the substrate.

In the production of homogeneous porcelain stoneware, the entire mass is pigmented. The pattern is retained even when the top layer is abraded.

Several pigments are mixed to create tiles that imitate the pattern of natural stone or other natural material.

Porcelain stoneware also differs in surface treatment methods.

Matt. not processed additionally and has the texture that was obtained during the firing process. Unpainted matt porcelain stoneware with a thickness of more than 8 mm is considered technical. It has an increased thickness (up to 30 mm). Strength is not inferior to self-leveling floors.

Polished tiles have an attractive glossy surface. But beauty has to pay with a deterioration in technical characteristics, in particular. a decrease in wear resistance.

The lapped porcelain stoneware is an Italian know-how. For its manufacture, surface grinding is used with the help of special stones. As a result, on the surface of the finished tile, areas with a polished and matte texture are adjacent.

Finished with lappated or ground-in porcelain stoneware

To obtain a satin-finished surface with a soft shine, a layer of mineral salts is applied to the tiles before firing.

Structured porcelain stoneware is produced using molds, giving the product the texture of various materials. sand, wood, etc.

Glazed tiles are covered with enamel before firing. This allows you to give porcelain stoneware a similarity to any material without using an expensive method of through painting.

What discs are used for cutting tiles

For cutting ceramics, special discs are required, which can be stone or metal with diamond coating. Stone ones are rarely used, since they are quite thick and quickly grind off, and during work they generate a lot of dust. The cost of stone discs is several times less than metal ones, but experts prefer to work last.

Metal discs can be:

- solid;

- segmented.

It is preferable to process ceramics with solid discs. When working with such discs, there is a time limit: they cannot continuously cut for more than 1-1.5 minutes. Then you should let it cool while the grinder is idling.

Segmented for cutting paving stones, porcelain stoneware, natural stone or concrete.

The segments are designed for better cooling of the tool during operation.

Angle 45 0

Docking is often necessary, which means cutting the material at an angle of forty-five degrees. This angle can only be obtained with a large workout. But you can use this technique: first, cut the workpiece in a straight line, and then gently process the edge at the desired angle with a disc, sandpaper or sharpening stone.

Straight cut

It is not difficult to master it, at the same time the cutting line is clean and without chips. When performing the work, the tiles are securely fixed on a flat surface, marked with a pencil or felt-tip pen. The part to be cut should hang freely from the table. The cutting tool is at right angles to the workpiece. Carefully, without jerking, slowly lead the angle grinder along the marked line. The tool should be moved towards you so that the marked line is visible.

Cutting tiles and porcelain stoneware with a grinder

Every master who is engaged in wall cladding with ceramic tiles knows that it is impossible to lay them without cutting. This is true both for wall cladding and for laying porcelain stoneware on the floor. But not everyone knows that you can use an ordinary grinder (angle grinder) for pruning. Let’s consider how to perform this operation correctly and without chips.

Notched neckline

Such holes, as a rule, are cut for sewers or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth, without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will appear on the cut line.

Cutting porcelain stoneware

When performing repairs, not only walls are faced. Ceramic granite tiles are laid on the floors in the bathroom and toilet. an artificial material that replaces granite and marble. Its cost is several times less than natural, but in terms of hardness and abrasion parameters, porcelain stoneware surpasses them. Recently, it has become widespread. It can also be cut with a grinder.

To do this, you need to know the basic methods of processing material at home.

- Choose the right cutting tool. It should be written on what it is used for: porcelain stoneware, hard ceramics, etc.

- To reduce chips, choose a disc with a continuous cutting edge. The thickness should be minimal.

- Choosing a cut-off wheel with a high diamond coating height.

- The grinder must have a speed controller.

After choosing the tool, they prepare the workplace and begin to cut the porcelain stoneware with a grinder. To do this, you need to perform the following steps.

- Place material on a flat surface with thin foam or similar material underneath.

- Fix the tiles securely to the surface with clamps.

- To reduce chips, glue masking tape and make markings along which it is necessary to cut off the excess part.

- Prepare the vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended to cut not along the marked line, but slightly to the side. This is done for the subsequent grinding of the end face of the porcelain stoneware to remove irregularities and chips.

Following these simple recommendations, you can cut the floor tiles with your own hands.

Cutting ceramics

To cut a tile with a grinder, you need to master three cutting directions.

Cutting porcelain stoneware with a grinder: how to saw off without chips

in Building materials 02.06.2020 5 Views

Everyone who has had a chance to cut faience, ceramics, porcelain stoneware with a cutting disc knows perfectly well that the problem is not how to cut. Such an operation is not particularly difficult. The problem is to learn how to cut porcelain stoneware with a grinder without chips. At the same time, control the process at any stage, otherwise the expensive material will go to scrap.

It is best to cut porcelain stoneware using a guide bar as a support for the grinder body

How to get rid of dust when cutting porcelain stoneware with a grinder

If the tiles are cut on a table, then before starting work, a small piece of loose fabric must be pulled under the cutting line or a polypropylene bag must be hung. In this case, most of the dust flies down from the disk, so the amount of work on cleaning the room is reduced several times.

If you cut porcelain stoneware on a substrate directly on the floor, then the best solution would be to use a regular vacuum cleaner. The tip of the hose is attached along the line of movement of the grinder at a distance of 10-15 cm. It turns out not very convenient, since the pipe has to be rearranged, but the dust is removed quite effectively. Immediately after the end of the work, you need to blow out the grinder and collect some of the dust remaining on the surface of the porcelain stoneware.

Useful Tips

There are all sorts of models of attachments for the grinder on sale, some of them provide connection of the vacuum cleaner nozzle to the protective casing of the tool. At first glance, the thing is quite convenient, but it is better not to use such devices, since the hose greatly interferes with work and often only worsens the quality of the seam.

In addition, it is necessary to cut porcelain stoneware, be sure to hold the grinder body with both hands, while the left hand should rest on the stand or guide rail, and the right hand is directly moving the tool. This method provides not only partial unloading of the hands, but also allows you to more accurately align the position of the cutting disc in the vertical plane.

Regardless of which disc and how to cut the porcelain stoneware, after the completion of the work, the edge must be rubbed with hand or tape emery. In this case, you just need to slightly align the lower edge of the porcelain stoneware and in no case touch the upper front edge with an abrasive, otherwise chips will appear, and the quality of the seam will noticeably deteriorate.

What disc to cut porcelain stoneware with a grinder

Sawing of porcelain stoneware tiles can be done in two ways, it all depends on the thickness of the material and on how complex the seam is to be cut. Since porcelain stoneware is still not granite, but just an artificial imitation of it, two types of discs can be used for cutting:

- Vulcanite discs based on synthetic superhard ceramics. With such a circle, you can cut thin grooves, corners, trim the edges. In order to cut the expanded clay with a grinder over a length of more than 10 cm, they are not suitable, but they are quite suitable for small jobs;

- Diamond cutting wheels. With this tool, you can cut seams of unlimited length. The only drawback of diamond is the rapid rubbing of the cutting edge, which will need to be restored and cleaned periodically.

The optimum circle diameter for a grinder is 115 mm, in this case it is easier to control the tool by holding the body with both hands. For a larger diameter blade, you will need to use a more powerful tool, such as a circular saw.

Diamond cutting wheels in themselves are quite an expensive and capricious tool, therefore they try to do most of the work with vulcanite discs, only the most delicate operations, such as trimming and adjusting the plane, are performed with diamond powder.

Advice! It is best to cut porcelain stoneware with specialized circles, which have a designation for cutting hard materials, natural stone and rock.

In addition, discs for cutting porcelain stoneware with a grinder must have a solid edge without a notch or turtle profile. Such a tool cuts well natural granite, rubble stone, but at the slightest attempt to cut porcelain stoneware tiles along the cutting line, a huge number of enamel chips appear on the front surface.

If there is no specific preference for a well-known brand of cutting disc manufacturer, then it is best to buy discs from leading hand tool manufacturers. Simply put. bought a grinder made by Makita, buy cutting discs with attachments manufactured by the same company.

Is it possible to cut porcelain stoneware with a grinder

Of course, an angle grinder can cut anything you want, with the possible exception of glass or particularly complex ceramic products. But it is not so easy to cut porcelain stoneware with a grinder so as to achieve a perfectly straight cutting line.

Of all the reasons that prevent high-quality cutting of porcelain stoneware, the most important ones are distinguished:

- A grinder is a hand tool, and often it is necessary to cut the material, as they say, by weight, as a result, the disc deviates from the cutting plane, this leads to the formation of chips, and sometimes cracking of porcelain stoneware;

- The cut-off wheel is not selected correctly. In the first experiments, beginners try to cut porcelain stoneware with cut-off vulcanite discs over stone and concrete. With this material, you can cut off a small part of the tile, but most often the result is negative;

- Incorrect cutting mode or lack of cooling of the cutting line. The desire to cut faster leads to excessive pressure on the tool, as a result the circle and the tile itself breaks, not to mention the fact that the entire cutting line remains covered with chips and microcracks.

In theory, cutting porcelain stoneware is no more difficult than any other facing material, you just need to choose the right mode, cutting speed, pressing force and choose the right cutting tool.

If you cut with a grinder by weight, then chips must appear

Advice! In addition, the problem of tool support will need to be addressed. For example, use a homemade aluminum shoe sole.

Cutting with a grinder on weight is possible only for those who have strong enough hands. If you have to saw at least 20 cm in length, then even experienced and strong craftsmen get tired hands very quickly, the circle begins to deviate from the vertical plane, as a result, the seam begins to wag, and chips appear.

Sole-based cutting

Direct cutting of porcelain stoneware

It is considered correct to cut a porcelain stoneware slab on a table or workbench. The material is laid on the tabletop, fixed with clamps with rubber tips. The cutting line should be outside the table surface. In this case, it is possible to cut porcelain stoneware with a very small angle of inclination, only 15-20o. The master simply pulls the grinder towards himself, only lightly resting his hand on the stand.

How To Cut Porcelain Tiles by Hand with Grinder without Chipping. Testing Diamond Blades 4 Tiling

Option for cutting with a grinder in pull mode

Why this method is good:

- The minimum load on the hands, if you need to cut a sufficiently long seam, this will not be difficult to do;

- The cutting line turns out to be smooth, it seems that the cutting was carried out not with a grinder, but with a tile cutter.

The only disadvantage of this method is that most of the dust escaping from under the disc falls on the floor, and the largest parts fall into the face and hands of the worker. Therefore, it is necessary to cut porcelain stoneware with protective goggles and using devices for collecting dust.

How to cut correctly with a high-raised grinder

Most beginners and DIYers prefer to cut porcelain stoneware with a tool with a very large angle of inclination relative to the plane of the tile. The angle can be 45-60 °.

The tool can only be lifted high if there is a supporting surface on the cover.

In this case, the grinder has to be held with both hands and at the same time perform small oscillatory movements with the cutting disc. It is as if the porcelain stoneware had to be cut with a hand saw. This is not very convenient, but the method really improves the quality of the cut and prevents the formation of chips.

On the one hand, with such a movement of the grinder, it is easier to control the cutting line, on the other hand, the tool is in an unstable position relative to the marking, which negatively affects the quality of the straightness of the seam.