DIY goose feet for a tiller

Why does a tiller need “crow’s feet“?

There are several types of cutters. The most common are saber-shaped, with a speaking shape of knives. As a rule, this is a collapsible design. On the contrary, the nozzle for the crow’s feet tiller is not disassembled into parts, but has a cast configuration. They are made from carbon steel. The main feature of the “crow’s feet”. the triangular shape of the knife ends to ensure sufficient crumbling and mixing of the soil. Such a continuous configuration is due to the need for strength when working on solid ground, virgin lands, and its cultivation. This can be considered areas where land with large lumps.

Features of plowing “crow’s feet” tiller

Basically, the described nozzle is used for plowing a plot for potatoes, when it is necessary to remove large clods of soil or to prevent the development of the Colorado potato beetle. By the way, gardeners note the fact that weeds are perfectly wound on the “crow’s feet”, but they are not cut down. In this regard, speaking about whether it is necessary to sharpen the “crow’s feet” on the tiller, we can recommend this procedure. The fact is that manufacturers do not sharpen the edges of the knives of this attachment. After sharpening, you will notice that medium-sized weeds are easier to cut, and work on hard ground is much easier.

“Crow’s Feet” for Tiller

a tiller is a full-fledged assistant where manual labor in the field or in the garden takes too much time and requires a lot of physical effort. Today, a small-sized unit can be found in almost every yard or farm, so it is a useful “thing”. And in fact, the range of tasks that a tiller can easily perform is quite wide, all kinds of land cultivation, cultivation of beds and even harvesting. And the presence of additional hook-on attachments only enhances the capabilities of a miniature tractor. One of the most effective acquisitions can be crow’s feet for a tiller.

How to choose crow’s feet cutters?

When choosing this important component of the tiller, first of all, it is important to pay attention to the size of the “crow’s feet” for the tiller. This is more concerned with matching the diameter of the nozzle axis for the landing shaft of your machine model. They are produced in sizes 30 mm and 25 mm. over, on cutters with a diameter of 25 mm, three rows of three knives are installed. Such products are suitable for tillers such as “Texas”, “Neva”, “Caiman”, “Mole” and others. Models of “crow’s feet” with an axis diameter of 30 mm are selected for tillers such as “Cascade”, “Salute”, “Caiman Vario”, “Master Yard” and others. On such a product there are not three, but four rows of knives. over, the width of the treated surface is increased.

Another criterion that you should pay attention to when selecting crow’s feet cutters for a tiller is the outer diameter, which, accordingly, depends on the plowing depth. The larger this diameter, the deeper the knives are able to cut into the soil. Meanwhile, the quality of the “crow’s feet” must be at the same level, otherwise metal breakage cannot be avoided.

How to choose and use crow’s feet for a tiller?

the tiller is an excellent assistant in cases where it is necessary to constantly cultivate the soil in the field or summer cottage. A large number of models are presented on the modern market, thanks to which each person can choose the best tiller for himself.

To improve the functionality of the device, you need to use additional attachments, which are also presented in a large assortment. One of the most effective are “crow’s feet”.

Purpose and features

“Hound’s feet”. one of the most popular types of cutters, which is designed to provide high-quality plowing of the land on the site. This element is a small axle on which knives are put on. It is they who create the effect of cutting the land, carrying out plowing in a similar way. It should be noted that when using a tiller with similar cutters in a summer cottage, not only soils can be processed, but also plants on them. Therefore, a lot of summer residents use this unit for weed control.

The peculiarity of “crow’s feet” is that they are not disassembled into parts, but differ in a cast structure. In the production process, exclusively carbon steel is used, which ensures the reliability and durability of the unit.

Another advantage of the element is its triangular shape, which guarantees excellent mixing of the soil. This configuration is extremely relevant, given the strength of solid ground.

“Crow’s feet” are simply irreplaceable when processing areas where the earth lies in a large lump.

Most summer residents use tillers with similar cutters to process the area where potatoes will be planted. Some believe that such a finish can even protect the future crop from the Colorado potato beetle.

If you plan to use the nozzle not only for cultivating the land, but also for killing weeds, then the edges of the knives will need to be sharpened first, since they are initially rather dull.

Selection rules

The choice of the “crow’s feet” nozzle must be approached with all responsibility, since it depends on this whether the model is suitable for cultivating the land in your summer cottage. In the selection process, first of all, you need to pay attention to the size of the nozzle. The element must be selected in such a way that its diameter fully corresponds to the size of the seating shaft. The peculiarity of the latter is that three rows of knives are installed in them. Such “crow’s feet” are perfect for tillers from the “Texas” or “Neva” series.

In addition, in the process of buying crow’s feet cutters, you need to carefully study the outer diameter of the element. This is an extremely important indicator, because it has a direct impact on the plowing depth.

Of course, the quality of the knives is also an important indicator. If these are Chinese cheap fakes, then after the first processing they will begin to bend and break. It is best to give preference to models during the production of which carbon steel was used.

The main advantages and nuances of the assembly

The massive use of such cutters began in the second half of the last century, when the mechanization process gained momentum. Immediately after the appearance of “crow’s feet” showed efficiency in use. The main advantage is that the structure is divided into several parts, which can be created separately. In addition, in the event of a failure of a certain element, you can simply replace it, then the device will again become suitable for use.

Before assembling “crow’s feet”, you need to decide on the type of construction. This is extremely important, as each tiller has its own suitable options. Only after selecting the optimal type can you start choosing the materials used.

During the assembly of such a cutter, it is extremely important to take a responsible approach to the installation of all elements, regardless of their purpose and other features. Under no circumstances should any deviation or error be allowed. This can not only cause a complete breakdown of the tiller, but also negatively affect human safety.

During the installation process, you will have to use a hexagon, which will greatly simplify the work and allow you to correctly install the elements. The dimensional characteristics of “crow’s feet” can be different, however, most of the models on the market differ in dimensions of 300x400x23 mm.

Most users are interested in the question of whether it is worth sharpening knives when installing these cutters. There is no definite answer to this day. There are several factors to consider. First of all, manufacturer’s recommendations are of great importance in this matter.

Some companies that specialize in the production and sale of crow’s feet do not advise additional sharpening, as this can negatively affect the efficiency of the cutters. Others advise sharpening before the start of each season so that the knives can cope with their task without problems.

The main advantage of sharpening is that the cultivation process will become easier, as it will be much easier to work the soil with such knives. However, every time you sharpen, you will have to dismantle and install new equipment, which takes a lot of time and effort.

Thus, crow’s feet are one of the most popular options for tiller cutters. High quality, durability and efficiency of use make these cutters stand out from others.

Find out more about the tiller’s crow’s feet below.

How to make “crow’s feet” for a tiller with your own hands

Tiller’s crow’s feet cutters are usually supplied from the factory along with the unit itself. But they are not universal. Some types of work cannot be performed with their help. Many tiller owners make “crow’s feet” with their own hands.

Assignment of cutters for tiller

Regardless of the type, the cutters are designed for agricultural work:

- loosening and leveling the soil;

- crushing earth lumps;

- mixing soil layers;

- mixing fertilizers;

- weed control.

Initially, the kit included only universal collapsible cutters with saber knives. They handled almost all types of work on soft soils.

Tiller’s “crow’s feet” appeared recently. This non-separable device has proven itself effectively in the processing of hard soils due to the peculiar shape and mechanical strength of the material and the entire structure. They are favorably distinguished from saber cutters by the fact that they uproot weeds.

Often, with their help, plots are cultivated during the first frosts to destroy weed shoots and insect pests that have lain over the winter.

Disadvantages of industrial cutters “crow’s feet”:

- Roots and stems of weeds are constantly wound around them. Since the cutter has a non-separable design, it will be problematic to clean it after cultivation.

- Often, cutters are made of low-quality material, so they often break during work.

How to make homemade cutters with your own hands

If the cutters are worn out or there is a need to modernize the cultivator, for example, to increase or decrease the depth and width of cultivation, you can do them yourself.

In many cases, such an improvement allows you to improve the quality of soil cultivation, to get the job done faster.

The design of these parts is simple, so you can make them yourself.

The easiest way to design homemade crow’s feet cutters for a tiller with your own hands is to study the device of industrial cutters and make your necessary changes.

It should be noted that when the “crow’s feet” cutter is made by hand, drawings for different types of tillers are developed individually.

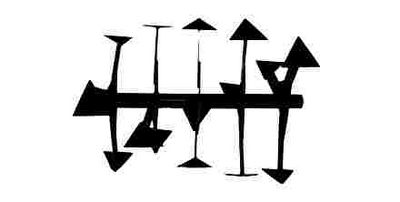

The illustration shows the classic version of the 4-row industrial cutter.

- Sleeve. For its manufacture, you will need a pipe with a diameter of 50 mm and a wall thickness of at least 4 mm.

- Flange. It is made of steel sheet 5-15 mm thick. Can be circular, but easier to make square.

- Rack of a knife. Material. steel corner with 63×40 mm shelves. Vehicle springs can be used. Often the rack is made of steel strip. This is the cheapest option, but also the most unreliable. During operation, the stand plays the role of a vertical plane cutter.

- Far left knife.

- Medium knife.

The knives are made of tool steel. Many craftsmen use car springs to make knives. Knife shapes can vary considerably. Their sharpening angle is usually 45 °. In the process of work, the knives become dull, so periodically they need to be sharpened.

Using a welding machine, the knives are welded to the posts, the posts to the flanges, and the flanges to the sleeve. This is how a non-separable structure is assembled. Some craftsmen prefer bolted connections. This design is less reliable, but makes it easy to remove and change the stands. The collapsible cutter is easier to clean of dirt and weeds wrapped around it.

One of the drawbacks of crow’s feet is that they go deep during operation, which is not always necessary. There is an additional effort on the tiller motor, the operator gets tired. To reduce the depth, wheels are installed on both sides of the axle, which act as limiters.

In this case, only the topsoil is cultivated. This method of processing is very convenient for heavily overgrown and soddy soils. After the first pass, the sod is destroyed. Then the wheels are removed, re-cultivation is carried out to the required depth.

If the “crow’s feet” cutters are made by hand, the drawings are carefully thought out and the materials are correctly selected, then they are not inferior in quality to industrial.

“Drawing of the device of the rotating mill” Hound’s feet “”

You can view all photos, drawings, pictures and diagrams from the category “Step-by-step instructions for making cutters” by clicking on the link. You will find even more materials with descriptions of how to make a motor-cultivator and accessories for it in the section “Diagrams and drawings of attachments” or by making a selection from all materials on the motoblok.populjarno.com website using the following MARKINGS:

cutters, drawings, equipment, dimensions.

Perhaps what you are looking for is in one of the most viewed sections of our website:

Comments on the material “Making a rotary cutter for a tiller with your own hands” are at the bottom of the page. here you can express your opinion, ask for advice from visitors to our site, share interesting materials, tell about your positive or negative experience while assembling tilers and trailed equipment with your own hands. If you have questions or suggestions regarding this material. please leave your comment below.

For those who want to share their photos by keywords “rotary cutter, drawing with dimensions, crow’s feet, do it yourself, how to make, instructions, device” or for any other questions about diesel, gasoline, light, medium or heavy homemade tillers, motor cultivators and attachments to them. you need to register and use the link “Add photo. “(Visible after registration on the page of all Photo Albums of tillers and attachments).

Views: 26872 | Dimensions

Which is better

Milling cutters for a motor-cultivator are selected for each type of work and depending on the structure of the soil. Saber cutters, loosening the soil to a depth of 35 cm, raise weeds to the surface. At the same time, they do not cut them into small parts, but wind the shafts around themselves. Than do not allow them to reproduce. In addition, the soil is coarser. But on dense or virgin soils, saber knives do not go well into the ground. Large and curly weeds quickly wrap around the work section and slow down processing.

Homemade dethatcher attachment for tiller or cultivator (Under 20)

The crow’s feet cutters are perfect for tough soils and all kinds of weeds. However, due to the fact that they cut them into pieces with a sharp edge, weeds multiply. There is an option for combined use. In the fall, you should go through the site with these cutters, and in the spring and during the season, work with saber-shaped incisors.

Tiller Rotary Cutter Dimensions

Open the photo Enlarged dimensions of the rotary cutter for the tiller. If this is a drawing or a diagram of a device, you can download it to your computer by opening it in large size and using the “Save picture as. “(Right mouse button).

Please rate this material by marking the appropriate number of stars.

Most often with this material

Drive sleeve

It is advisable to start making a soil cutter from this element. Since the bushing is subjected to heavy loads, it is manufactured on a lathe with a wall thickness of at least 5 mm, optimally 7-8 mm. An inner hole is machined on one side so that the cutter can be easily fitted onto the shaft without excessive play, a tolerance of about 0.5 mm.

On the other hand, a groove is made for the landing of the axial pipe with a depth of 30-40 mm. This will allow you to get an axis-aligned connection without any problems. A hole is drilled for the fixing pin.

Manufacturing of crow’s feet soil mills

Cutters of this type began to be widely used from the middle of the 80s of the last century. This was due to the development of self-made small mechanization at that time. Since then until our time, this design has fully proved its right to exist. Structurally, this module can be divided into several main elements, which are manufactured separately and carry different functionality.

Cutting element (knife)

It is made of strong non-brittle steel type 65-70G, 3-5 mm thick. The triangular shape of the knife is considered optimal for the least resistance when entering the ground.

As a knife, DIYers often use the triangular cutting element of a segment mower. Since the steel of the rack and the segment has a different composition, welding must be performed after tempering, followed by quenching. Cutters with such knives are used on clean work areas. For heavy, virgin soils, it is recommended to make cutting elements from thicker steel, which will make a high-quality welded joint.

As practice shows, the optimal knife width is 50-80 mm. Larger dimensions create increased soil resistance.

Cutting element stand

It is most optimal to use the same steel that was used in the manufacture of knives, but it is quite possible to use strong, alloyed steels with lower physical and technical indicators.

The stand of “crow’s feet” is made of a straight or curved strip along the edge. An edge that is in direct contact with the ground should preferably be sharpened.

Holes are drilled in the rack for fastening to the axle pipe flange. Cutting elements are welded on with subsequent hardening.

How to adjust the plowing depth

The coulter is an important element in soil cultivation. It fits into the rear bracket of the tiller. To adjust the plowing depth by increasing it, you need to increase the pressure on the handlebars from top to bottom, driving the device into the ground.

If the depth is still insufficient, the coulter must be lowered. For cultivation at the level of the shovel bayonet, the movement of the device should be set by swinging it from side to side.

Active saber

The name of the cutters is determined by their appearance. knives are large and have an elongated curved shape. On cutters of this type, there are several sets of four knives located at right angles to each other.

Usually, two or more sets of knives are placed on one axis. This rather powerful design of the equipment has high strength and perfectly copes with the processing of heavy soils and virgin lands, is not afraid of stones, roots.

Which cutters are best for tiller: saber or “crow’s feet

Choosing the option of a rotary tiller for your unit, one should proceed from the characteristics of the soil. Of course, saber knives can easily cope with the cultivation of previously cultivated soils. When it comes to cultivating virgin lands or lands densely overgrown with grass, the basic mill cutters sometimes do not cope very well with the load due to the insufficient quality of materials and assembly (bolted and welded joints). The processing of heavy soil with such cutters is a rather heavy load for both the tiller and its operator. Purchased or home-made cutters with knives made of high-quality metal cope with their task much easier.

As for the version of the “crow’s feet” cutter, you can install the desired number of sections on the tiller, adjusting its performance to the needs of your own farm and the power of the unit. This type of equipment handles hard soils and vegetation debris more easily and provides easier control of the device during operation. Many users mark this particular design as optimal in terms of practicality and reliability.

Assembling a tiller cutter: tips and instructions

Auto mechanic specializing in agricultural machinery

Soil milling cutters can be called the most popular type of attachments for Tillers, used in farms and private households. They are indispensable for soil cultivation, chopping weeds, mixing and leveling the soil and are actively used on land plots with heavy and waterlogged soils. Often, work with a tiller with milling cutters is provided initially when purchasing a unit.

However, if the cutters are included in the kit for some devices, they are not for others, and this has its advantage. Many experienced small farm equipment users prefer to decide on their own which cutters are needed for their farms. In such cases, the cutters for the tiller are purchased separately and of the desired type, or they are assembled by hand. Often, additional cutters are required to the existing ones. The quality of land cultivation depends on the choice of equipment, so it is important to understand its features as best as possible.

Tiller cutters help you with soil cultivation

Making an active cutter

Now let’s look at how to make saber rototillers. The assembly of this option is also not particularly difficult. As with the previous option, you should first carefully study the design and create a drawing.

The set of parts from which the device is assembled includes:

- rotor axle (one-piece or split, length is determined individually);

- fixing component;

- knives;

- fasteners (bolts, nuts).

When assembling, it is important to take into account that the movement of the cutting elements is counterclockwise. In general, the process is similar to the manufacture of crow’s feet. Only the question of the technology of creating knives requires special attention. They should be bent after heating at an angle of 90 degrees. The length of the part of the knife after bending should be about 8 cm.After production, it is necessary to quench and mount on the flange.

“Crow’s Feet“

“Crow’s feet” on the tiller is another version of the equipment, the name of which is also determined by the shape of the knives. triangular, similar to crow’s feet, and located at the ends of the racks of cutting elements. As in the previous version, the number of knives determines the quality of cultivation and varies depending on the power of the unit.

There are three-row and four-row “crow’s feet” with different axle diameters. Three-row rotary tillers on an axle with a diameter of 25 mm are installed on tillers Texas, Neva, Krot, Cayman, and four-row tillers are suitable for units of the Salyut, Farmer, Favorit brands. Equipment on an axis of 30 mm is compatible with Cascade, Master Yard devices, some models of Neva tilers and a number of others.

“Crow’s Feet”. cutters for tiller, which show high efficiency in the processing of heavy, clayey soils and virgin soil, but can clog when working in areas abounding in roots.

How to sharpen cutters

First of all, we note that sharpening of a rotary cutter is not necessary in all cases. For example, if heavy soil is being processed with a powerful unit on which reinforced cutters are installed, there is no point in sharpening. you will not notice the difference in the quality of cultivation, just waste your efforts on sharpening.

At the same time, when working with lighter equipment, sharpened cutting attachments can improve cultivation efficiency for a while. But you need to be prepared for the fact that there is not enough sharpening for a long time, after a few hours of active use the knives become dull, and you will have to sharpen them again, which is quite laborious. In addition, too sharp knives crush the root systems of weeds, which does not help the fight against them, but, on the contrary, accelerates their reproduction.

However, you can sharpen soil knives if you wish. To do this, remove the cutter from the tiller, clean it from dirt and carefully sharpen each knife with sandpaper.

Classification of cutters

The rotary tiller consists of soil knives fixed on an axis, which, rotating around it during the movement of the tiller, crush the soil and weeds. The designs of cutters differ, therefore, in order to find the best option, it is worth understanding their varieties. First of all, cutters are classified according to the type of aggregation:

- side-mounted;

- with installation by means of a hinge.

Side mills, when installed as a running gear, essentially replace the wheels and are powered by their drive shafts. Thus, they simultaneously drive the machine and cultivate the soil.

Mounted cutters differ in rear position. they are installed behind the tiller, they work from the power take-off shaft and perform only the function of cultivation. It is with such cutters that the Neva (MB 1 and MB 2), Celina and some others are equipped.

In addition to the type of installation, the cutters also differ in the types of knives:

- active saber;

- crow’s feet.

In this video, we will consider the tiller cutters:

Cutting element stand

It is most optimal to use the same steel that was used in the manufacture of knives, but it is quite possible to use strong, alloyed steels with lower physical and technical indicators.

The stand of “crow’s feet” is made of a straight or curved strip along the edge. An edge that is in direct contact with the ground should preferably be sharpened.

Holes are drilled in the rack for fastening to the axle pipe flange. Cutting elements are welded on with subsequent hardening.

Cutting element (knife)

It is made of strong non-brittle steel type 65-70G, 3-5 mm thick. The triangular shape of the knife is considered optimal for the least resistance when entering the ground.

As a knife, DIYers often use the triangular cutting element of a segment mower. Since the steel of the rack and the segment has a different composition, welding must be performed after tempering, followed by quenching. Cutters with such knives are used on clean work areas. For heavy, virgin soils, it is recommended to make cutting elements from thicker steel, which will make a high-quality welded joint.

How to Make A Tillering GIZMO (To Get A Perfect Tiller)

As practice shows, the optimal knife width is 50-80 mm. Larger dimensions create increased soil resistance.

How to assemble an active cutter

This type of homemade tillage equipment is most common due to the simpler manufacturing technology. With this arrangement, the cutting element and the stand are one piece and are made from a single piece of high-strength steel strip.

You can read about the reverse gear in this article.

Up to the “axial tube with flange” step, the process is identical to the production of a crow’s feet cutter on a tiller. For this reason, consider the manufacture of directly cutting elements.

The pre-sharpened strip is bent 90˚ when heated. The length of the folded part usually does not exceed 80 mm. It is advisable to combine the cooling of the workpiece with its release for comfortable drilling of the fastening holes. At the end, quenching is carried out and installation on the flange of the axle pipe.

When cultivating the soil with a milling cultivator of any type, some spread of the soil is obtained, which makes it a little difficult to determine the boundary between cultivated and untreated soil. To avoid these problems, marking discs are installed on the edges of the cutter.

Active (saber)

Knife blocks on such cutters consist of four cutting elements spaced 90˚ apart. There can be 2, 3 or more such blocks on one side of the drive. The number of knives and the width of the module depends on the weight of the tiller and its power.

The knives are curved strips of tough alloy steel. For self-production in the presence of heat treatment with subsequent hardening, spring steel of the 50HGFA type has proven itself well. The bends of the knives have alternately different directions.

The design of the active cutter allows for cultivation in areas with stones and roots without the danger of breaking the knives. But it is advisable to use this type of equipment on light processed soils.

Manufacturing of crow’s feet soil mills

Cutters of this type began to be widely used from the middle of the 80s of the last century. This was due to the development of self-made small mechanization at that time. Since then until our time, this design has fully proved its right to exist. Structurally, this module can be divided into several main elements, which are manufactured separately and carry different functionality.

Drive sleeve

It is advisable to start making a soil cutter from this element. Since the bushing is subjected to heavy loads, it is manufactured on a lathe with a wall thickness of at least 5 mm, optimally 7-8 mm. An inner hole is machined on one side so that the cutter can be easily fitted onto the shaft without excessive play, a tolerance of about 0.5 mm.

On the other hand, a groove is made for the landing of the axial pipe with a depth of 30-40 mm. This will allow you to get an axis-aligned connection without any problems. A hole is drilled for the fixing pin.

“Crow’s Feet”

The cutting elements of such cutters are made in the form of a triangle made of strong steel, located at the end of the rack. This location was the reason for the emergence of such an extravagant name.

As in the case of active cutters, the width and number of knife blocks is determined by the weight and power of the cultivator. The number of cutting elements located around the circumference in the knife block is from 4 or more. An increase in the number of knives implies a better crushing of the soil, but the power of the power unit will also need an increased.

These types of milling cutters are designed for processing heavy types of soil and virgin lands. The presence of branched root systems in the soil leads to frequent clogging of the module.

Both types of tillage cutters have their own advantages and disadvantages. When choosing an option for self-production, it is necessary to take into account the soil structure, the required degree of soil crushing, the layout and power of the power unit, the complexity and manufacturing method.

Knife block

By connecting the knife racks and axial tubes, an interchangeable modular cutting element is obtained. Only two blocks with welded-on drive bushings remain individual.

With the appropriate qualifications and the availability of the necessary equipment, the manufacture of this element will not be difficult. In order to avoid damage to materials and to prevent unnecessary body movements, it is advisable to draw up a detailed drawing before manufacturing or use a ready-made one.