DIY motoblock press

Step by step description of work

To create a convenient round baler for a walk-behind tractor, you need to follow the following steps:

1. First of all, you need to assemble the chassis. this is the basis on two pneumatic wheels.

2. Then install the front head and the pick-up with the conveyor.

3. Separately mount the bale chamber with rollers and a pressure grid installed in its lower part, and a plate with a spring for pressing the pressed layers in the upper part, so that the roll winds up more tightly.

4. Assemble the drive, with the help of which the movement of the working parts of the machine is ensured. To do this, you need to connect the cardan and a two-speed gearbox. from it the chain drive will go to the rollers and the pick-up conveyor.

5. On the mechanism of the device that picks up hay, install gears with a diameter larger than on the drums. This will increase picking speed and simultaneous pressing force.

To get better results when assembling hay with a walk-behind tractor, you can use a simpler, long-term, and effective option. to divide the work. First, the grass mass is collected using a walk-behind rake, then it is pressed with a separate manual or electric device.

Below is a video with a homemade baler made by hand.

How balers work

The principle of operation of the structure directly depends on its type and device. A roll for a walk-behind tractor collects a roll of straw, after which the material enters the chamber, where, under the influence of the pressing mechanism, it is twisted into rolls. As soon as the bale of straw reaches the required density, the driver of the walk-behind tractor hears a sound signal, after which the twine must be fed. Then the wall at the back of the chamber is pulled back and the roll is rolled out.

The baler works in the same way. The only difference is that during operation, the straw is directed into the baling chamber under the influence of the auger.

Self-assembly of the round baler to the walk-behind tractor

Such a device can be assembled with your own hands, for this you just need to choose the right dimensions and use the tools at hand. With the help of a homemade baler, which is used with a walk-behind tractor, you can collect small bales that are easily loaded onto a transport trolley, and so are easily carried on the farm by hand.

DIY homemade hay press. drawings:

The round baler design includes the following main parts:

forehead, which is the basis on which all units are installed, as well as an attachment element to the traction unit.

undercarriage with a base for a press chamber with two wheels on which the unit moves across the field;

a pick-up with a conveyor that collects masses of hay or straw from the field;

cylindrical casing chamber with a pressing mechanism;

cardan transmission with mini gearbox to increase revs.

It should be noted that the baler is the most important component in a self-made baler. The device consists of such parts as rollers, a pressure grid, a spring-mounted forming plate, which replaces a factory device with hydraulics in a homemade product.

Baler for walk-behind tractor: types, principle of operation and do-it-yourself manufacturing

A baler for a walk-behind tractor is a design that allows you to quickly collect straw and compress it into compact bales or rolls for their further transportation and storage. This allows the farmer to save his time and effort, and also make good money on the sale of the collected feed material.

Exploitation

In operation, the efficiency of the equipment is assessed by its durability, dynamism and economy. In order for the device to work without interruption and to extend the service life, it is necessary to strictly adhere to all recommendations from the manufacturer. Be sure to carry out maintenance on the unit before starting seasonal work, in which case you will eliminate the causes of premature malfunctions. Before winter storage, you need to check all places that have a liquid composition.

A square baler for a mini tractor, as well as a round baler for a mini tractor, have their own advantages. In addition to the basic functions, it can be used to dry windrows, pick up and bale straw. The tractor driver has the ability to independently adjust the device. You can clearly see the work of the baler on a mini tractor in the provided video.

Unlike manual harvesting of hay, the use of a pick-up will cost more, but at the same time, you will significantly save your energy and time.

Remember that when choosing this mechanism, it is very important to consider the size of the treated area. This will help you calculate the required power. For faster assembly and large volumes, choose the model that will appeal to you and your requirements.

11 comments on the entry “How to choose a baler for a mini tractor”

Hello! mini baler price

what is the price of a roll press for a mini tractor?

what is the price and how can you get.

Пресс подборщик для мотоблока, или мототрактора

what is the price of roll pickers for a T-25 tractor and how will the swami contact

Hello. Interested in a round baler on the mini tractor T 25.

Тюкуем сено мотоблоком. самодельный пресс для сена от мотоблока (сенозаготовка часть 3)

If you sell balers for mini tractors, please contact me urgently.

Tell me which round baler will fit the Uralets XT.180 tractor!?

availability and cost of a mini roll press, ready to purchase

what is the price of round balers for a T-25 tractor and how will the swami contact

Need a baler price. And then somehow everyone asks, you are silent

Where is the phone. How to call.

The heart of any chainsaw is a two-stroke internal combustion engine.

The trimmer is not a complex household appliance, so most of its floor.

There was a need to purchase a reliable and reliable mechanical tool.

Gone are the days of Soviet agro-industrial gigantomania. Gig gone.

The walk-behind tractor is an economical tractor option for small-volume work.

In order to make such a nozzle as harrows, with your own hands, in addition to ph.

Round baler design

You can make a press for a mini tractor with your own hands. You first need to prepare tools and materials, carefully study the drawings with the dimensions of the devices.

Small bales are collected using a homemade pick-up that can be easily loaded onto a transport trolley and carried by hand.

The round baler consists of a drum, a pressing belt, knitting and tensioning devices, movable rollers and conveyors. The electrical system is simple with turn signal lights and audible lighting devices. The press gets enough power from the minitractor shaft.

Key parts of the roll press design:

- Lobovin. It acts as a base to which all nodes and an element for attaching the device to the minitractor are attached;

- Chassis. Serves as the basis for a bale chamber with two wheels. It is on them that the equipment moves around the site;

- Pick-up. His task is to collect hay and straw from the field;

- Cylindrical casing chamber with pressing mechanism;

- Cardan transmission with mini-gearbox, increasing revs.

The press includes rollers, a pressure grid, a forming plate on a spring (it acts as a home-made factory apparatus with hydraulics).

The pressing apparatus is regarded as one of the most important parts. Considerable attention is paid to the fact that the tractor itself (walk-behind tractor) is quite powerful to fulfill the task assigned to it.

Baler for walk-behind tractor

Round balers for a walk-behind tractor greatly facilitate the work of an agronomist. With their help, a person simplifies the difficult process of collecting dried grass from the field. What’s more, the device rolls it into tight rolls that are much easier to transport and save.

Advantages of the press

The hay picking machine is considered one of the most popular among modern farmers, which is not surprising, because it:

- has convenient settings;

- carries out gentle baling;

- does not crumble the plant mass;

- provides the ability to form rolls of small sizes, which can be transported even by a person alone;

- easy to repair due to the simplicity of the mechanism;

- can be created at home.

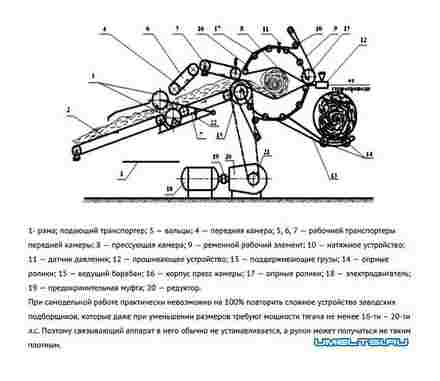

The structure of a baler for a walk-behind tractor can be seen in the following diagram

frame; feeding conveyor; 3. rollers; 4. anterior chamber; 5, 6, 7. working conveyors of the anterior chamber; 8. pressing chamber; 9. belt working element; 10. tensioner; 11. pressure sensor; 12. stitching device; 13. supporting weights; 14. support rollers; 15. driving drum; 16. press chamber body; 17. support rollers; 18. electric motor; 19. safety clutch; 20. reducer.

Most of these objects are created for large and heavy mini-tractors, therefore, purchased presses are not particularly suitable for a motoblock system, because it is rather difficult for the unit to pull a bulky part and supply it with a lot of energy. Therefore, the inventive craftsmen decided to build a practical hay press for the walk-behind tractor with their own hands.

We do the press step by step

- To begin with, you need to assemble the base on 2 pneumatic wheels;

- The aforementioned pick-up with a special conveyor and a forehead is mounted on it;

- Separately, the press chamber is installed (the clamping grid and rollers are attached below, and a plate on the spring is attached above);

- Then you need to assemble the drive, which drives the functioning parts of the unit. To do this, connect the 2-speed gearbox to the cardan;

- On the baler itself, the baler owner can install large gears for better compaction.

There is no need to hope that the resulting device will be completely identical to the factory one, but its performance will be very high, even though in some cases the roll may not be very dense.

Repair of the Polish rotor scythe

HELP THE CHANNEL! Webmoney Wallets: Hryvnia U272084624279, Rubles R152481596726, Dolar Z395829708019, Qiwi.

The KamAZ 4308 operating manual, which you can find here, can significantly reduce the risk of unit breakdown.

The Polish rotary mower, like similar models from other manufacturers, is designed for a wide range of agricultural activities. Mowing grass for livestock feed, harvesting various crops. all this is included in the scope of rotary mowers. However, as in any other technique, there are also several nuances that you need to pay attention to first of all when purchasing such a mower.

Device complete set

Among the main points and characteristics to which you should pay attention are the following:

- minimum and maximum cutting height of the mowed grass;

- the area that the unit processes;

- rotation frequency of knives;

- the width of the strip of the processed surface, produced by the mower in one pass.

Paying attention to these points, you can buy yourself a reliable unit that will last for many years. However, there are already quite popular models in which all these characteristics are combined in optimal proportions.

For a general view of the mower, see the video.

Nevertheless, there is an even more convenient assistant, which bears the proud name “self-propelled lawn mower with a seat”, you can get more detailed information here.

Homemade baler for hay to a walk-behind tractor with your own hands: instructions, photos, videos, drawings

Balers for walk-behind tractor

A baler for a walk-behind tractor is an indispensable device for those cases when, after harvesting from the fields, it is necessary to pick up hay and straw. This hay is used to prepare animal feed for the winter, so the pick-up is a very useful special equipment for small lands and huge agricultural fields.

- Features of the

- Hay press

- The principle of operation of the baler

- The advantages of using this technique for making hay are:

- Types of balers for mini tractors

- Roll

- How to make a baler for a mini tractor with your own hands?

- The principle of operation of the baler

- The advantages of using this technique for making hay are:

- Types of balers for mini tractors

- Roll

- How to make a baler for a mini tractor with your own hands?

- Are the walk-behind tractor rakes a much-needed equipment??

- How to make a do-it-yourself rake for a walk-behind tractor and what is needed for this?

- Working on the wheel axle

- We install the drawbar and stands

- Reinforcement system check

- Work on the rake bar

- Technical features of the rake tedders

- Design features

- Can I do it myself?

- Brand history

- Repair of the Polish rotor scythe

- Wirax. 1.65m

- Wirax. 1.85m

- Similar posts

- Features of operation

- The press attached to the walk-behind tractor provides quick collection of hay and straw;

- The use of a mini device minimizes the cost of collecting hay, allows you to get the maximum profit or benefit from the harvested hay;

- A home-made picker is often used, but compared to factory mini-presses, the former are inferior in terms of technical characteristics, operational capabilities;

- The baler can be rolled and baled;

- It is convenient to transport and store bales and rolls of hay in warehouses;

- Mini models installed on a walk-behind tractor are widely used on farms, cattle-breeding enterprises. The mini baler is able to handle large enough areas, providing the farmer with high quality, speed and economy of hay collection into bales or bales.

Brand history

The company began its formation in 1994, when the first serial models of various agricultural machinery began to be produced. Specifically, such a vector of development aimed at farms and their provision was approved, which was the right decision at that time.

Over time and the growth of production rates, the company began to open its factories in other locations in Europe. This decision allowed not only to increase the creation of technology, but also gave a large number of jobs where these factories were located.

Thus, the company, in addition to its own main activity, also does a certain social function, which is very important in today’s difficult times.

Popular manufacturer

In 2012, Wirax merged two of its own branches located in Turkey and Romania, making one huge corporation. The company cooperates with many Turkish manufacturers of equipment and related devices to them, which allows it to respond in a timely manner to constant changes and new trends in this market segment.

Wirax. 1.85m

Wirax. 1.85m is designed for mowing various crops, grass and much more. In addition, the Polish rotary mower 1.85 is an effective method of combating weeds and weeds that sprout abundantly in the fields.

Due to its design, the mower can handle large areas, which is very beneficial for large agricultural enterprises. Rotary mower Polish, will become an indispensable assistant in rural life.

Characteristics of “Wirax”. 1.85m:

- weight. 380 kg;

- dimensions (l / w / h). 320cm / 105cm / 100cm;

- width of the treated surface. 1.85 m;

- speed. 10 km / h;

- the total number of knives. 6;

- tractor requirements. at least 40 hp;

- number of disks. 2.

Wirax. 1.65m

“Wirax”. 1.65m is an excellent option for farms and individual farmers who value reliability and efficiency in the unit above all. Thanks to high-quality parts and a durable body, the mounted rotary mower Polish 1.65, will serve its owner for more than one year, regularly performing its main tasks.

Characteristics of “Wirax”. 1.65m:

- weight. 300 kg;

- width of the mowed surface. 1.65 m;

- height of the mowed grass (min). 3.2 cm;

- height of the mowed grass (max). 4 cm;

- rotation speed. 540 rpm;

- number of disks. 2;

- the total number of knives. 6;

- drive type. BOM.

Hay press

When harvesting hay, it will not be superfluous to use a device for obtaining bales. This bale press ran for three seasons. With this simple device, we completely feed our livestock. Pressed hay gives clear advantages during loading, transportation, loading into storage, as well as better retains its nutritional qualities.

The loading chamber has the following dimensions: length. 2500 mm, height. 500 mm, width. 400 mm., Made of a profile pipe 20 by 40 mm. and sheet iron 1.8 mm thick. The piston is made of 20 x 40 mm shaped tubes, the piston rod is two shaped tubes welded together, 30 x 30 mm in size. The piston moves on guide rollers. The winch force is transmitted to the piston rod through a pulley with a steel cable with a diameter of 5 mm.

After compressing the hay, the piston returns to its original position with a nylon cord. The winch is made of a shortened conveyor roller. The winch reel width is 130 mm. The coil has two sections. a steel cable is wound on one, and a nylon cable on the other. A driven sprocket is welded to the side of the winch. having 45 teeth. Winch shaft 30 mm thick. The winch rotates on ball bearings.

There is a 14-tooth drive sprocket on the steering wheel. Handwheel arm length 1680 mm. It is made of a 20 x 40 mm profile pipe, cross-welded to each other. Rotation to the winch is transmitted by a roller chain from agricultural machinery. Loading door from the same 20 x 40 mm profile tube.

First, a frame was made, and then it was sewn up with wood, and from the front side with sheet metal. The press moves on wheels from the IZH motorcycle.

The principle of operation of the baler

The essence of the work is as follows. This equipment performs technical processing of the crop cut by the mower. It collects freshly cut grass or hay, and forms windrows with cut dry stems with a residual moisture of 26%. The pick-up collects the material into compressed bales.

The advantages of using this technique for making hay are:

- labor costs are reduced by 3-4 times;

- such attachments can be independently adjusted;

- the use of a pick-up reduces drying time and hay loss;

- in the future, the quality of hay during storage and transportation is significantly increased.

Types of balers for mini tractors

Most often it is used to harvest dried stems. The pick-up picks up hay in the windrows with spring tines. After each portion of hay is rolled tightly into bales. The roll is fed by spring fingers into the pressing mechanism. As the mass of hay increases, so does the density of the bale.

The hay rotates in the bale chamber. The pick-up will beep when an even bale of the desired density is formed. The take-up mechanism is activated when the desired bale size is reached. And then wraps it with twine. As a result, the packed hay is pushed out.

This equipment packs hay into rectangular briquettes. They can be of different sizes. The grass is gripped by the spring tines and sent to the baling section. The size of the briquette can be adjusted. The bale is sweaty packed, tied with twine and thrown out.

How to make a baler for a mini tractor with your own hands?

It should be said right away that you will not get a perfectly similar pick-up with factory equipment. It is technically very difficult to implement such a mechanism. Therefore, a binding device is not installed in a home-made unit, and the roll does not get the required density.

- We assemble the chassis on a pair of pneumatic wheels.

- We install on it a front head and a pick-up with a conveyor.

- We mount the press chamber separately. At the bottom of the press mechanism, we install the rollers and the pressure brush. In the upper part we put a plate on a spring. She will subsequently press the compressed layers for a tight winding of the roll.

- We assemble the drive that drives all the working units. We connect the cardan with a 2-speed gearbox. A chain drive will go from the gearbox to the rollers, as well as the pick-up conveyor.

- Install the gears on the hay picker mechanism. The gears should be larger in diameter than on the drums. This will increase the pick up speed and simultaneous pressing force.

In order for you to get such a device, we will probably add a couple of drawings necessary for the work.

The principle of operation of the baler

The essence of the work is as follows. This equipment performs technical processing of the crop cut by the mower. It collects freshly cut grass or hay, and forms windrows with cut dry stems with a residual moisture of 26%. The pick-up collects the material into compressed bales.

The advantages of using this technique for making hay are:

- labor costs are reduced by 3-4 times;

- such attachments can be independently adjusted;

- the use of a pick-up reduces drying time and hay loss;

- in the future, the quality of hay during storage and transportation is significantly increased.

Types of balers for mini tractors

Most often it is used to harvest dried stems. The pick-up picks up hay in the windrows with spring tines. After each portion of hay is rolled tightly into bales. The roll is fed by spring fingers into the pressing mechanism. As the mass of hay increases, so does the density of the bale.

The hay rotates in the bale chamber. The pick-up will beep when an even bale of the desired density is formed. The take-up mechanism is activated when the desired bale size is reached. And then wraps it with twine. As a result, the packed hay is pushed out.

With the help of such equipment, 20 tons of hay can be prepared in 20 summer days.

This equipment packs hay into rectangular briquettes. They can be of different sizes. The grass is gripped by the spring tines and sent to the baling section. The size of the briquette can be adjusted. The bale is sweaty packed, tied with twine and thrown out.

How to make a baler for a mini tractor with your own hands?

It should be said right away that you will not get a perfectly similar pick-up with factory equipment. It is technically very difficult to implement such a mechanism. Therefore, a binding device is not installed in a home-made unit, and the roll does not get the required density.

- We assemble the chassis on a pair of pneumatic wheels.

- We install on it a front head and a pick-up with a conveyor.

- We mount the press chamber separately. At the bottom of the press mechanism, we install the rollers and the pressure brush. In the upper part we put a plate on a spring. She will subsequently press the compressed layers for a tight winding of the roll.

- We assemble the drive that drives all the working units. We connect the cardan with a 2-speed gearbox. A chain drive will go from the gearbox to the rollers, as well as the pick-up conveyor.

- Install the gears on the hay picker mechanism. The gears should be larger in diameter than on the drums. This will increase the pick up speed and simultaneous pressing force.

In order for you to get such a device, we will probably add a couple of drawings necessary for the work.

Are the walk-behind tractor rakes a much-needed equipment??

First, let’s figure out what they are for. With this device, you can level a dug garden, collect mowed grass and hay, and also clear the area of weeds and debris.

The above work takes a lot of time and effort if done manually. Therefore, such attachments as a rake for a walk-behind tractor are an integral assistant. However, not everyone can afford to purchase this device, and then there is another option, to make them yourself.

How to make a do-it-yourself rake for a walk-behind tractor and what is needed for this?

First, let’s figure out what they are for. With this device, you can level a dug garden, collect mowed grass and hay, and also clear the area of weeds and debris.

The above work takes a lot of time and effort if done manually. Therefore, such attachments as a rake for a walk-behind tractor are an integral assistant. However, not everyone can afford to purchase this device, and then there is another option, to make them yourself.

How to make a do-it-yourself rake for a walk-behind tractor and what is needed for this?

Tools you can’t do without when creating a rake:

- 1. Drill of good power;

- 2. Varnish and chalk;

- 3. Profile pipe and wire;

- 4. Ruler;

- 5. Welding equipment;

- 6. Solid oil;

- 7. Seeder.

Next, there will be instructions with drawings for creating a rake.

Farmers who create attachments for a walk-behind tractor with their own hands never regret their venture, since such equipment serves for a long time and efficiently. The main thing in this matter is to follow all the rules and not deviate from the instructions. A drawing of a rake for a walk-behind tractor is presented below.

Working on the wheel axle

- Metal wheel production. We need a disk with a diameter of up to 40 cm. After knocking out the inner bearing, you can not get it and place a metal rod in the same place. Then we wrap the disk with a strip and carefully weld it. The result should be a wheel with a wide tread.

- Creation and installation of the axis. The rod is threaded through the wheels, while a few centimeters should remain. It is very important that the retaining ring is welded on the inside and a hole for the cotter pin must be drilled from the outside. The drill creates a seat in the center of the rod. If there is no cotter pin, a 3 mm electrode can be used instead.

- Creates a location on the axis to attach to the wireframe. To make the homemade rake easy to use, we make special fasteners for the metal frame. Namely, two plates located 10 cm from each wheel. Using welding equipment, we attach metal strips to the axis by weight, therefore reinforcements should be installed.

We install the drawbar and stands

- Installation of oblique supports. We weld several metal squares strictly parallel to each other to the axis. The difference in length can be removed with a grinder.

- Drawbar attachment. Having measured the distance from the support to the support, we determine the center where the drawbar will be located. To do this, you need a pipe with a thick wall with a diameter of 3 cm. The height can be set at will. The pipe must be necessarily thick-walled, since a large load acts on the rake.

- Drawbar hook making. Here, everything is done at the request of the master: weld on an ordinary straight pipe or bend it. It is important that the drawbar itself is well attached.

Reinforcement system check

The average weight of the finished rake is about 15 kg. Therefore, in order to avoid unexpected breakdowns, it is necessary to fasten the weak areas with 15×15 squares. This method of strengthening is suitable for racks located in the middle, and after fastening together in the center of the parallel reinforcement, we weld the brace. The lowering and raising equipment pull rod is also an overhead reinforcement. Thus, the rake will not roll over on its side.

Work on the rake bar

- Rake axle fasteners. We make a working grip of the device, cutting 150 cm from the pipe. Then, two pipes are welded horizontally to the racks, where the axis will be located. As a result, we get a pipe rotating in a circle in the mount.

- Making an eyelet. In this case, the rod must be welded to the upper corner of the pipe. Its second end will be located on the eccentric, in contact with the center of the drawbar. By applying slight pressure on the handle, you can raise or lower the rake.

- Welding springs. Springs are bought or independently bent out of the wire. Then we weld them to a corner or install them in a hole made with a drill. Photos of the finished rake can be viewed below.

After the rake has been assembled, it is necessary to lubricate all rubbing parts with grease. And then over time this procedure should be repeated to avoid breakdowns. You can also watch the video “Rake to the Neva walk-behind tractor”.

Technical features of the rake tedders

Harvesting hay has always been considered a promising direction of agricultural activity. After all, this is the most practical way to provide feed for livestock in winter.

At the dawn of technological progress, this event was carried out in two stages: the men mowed the grass, which was then raked into swaths. This hay harvesting scheme looks quite costly. Currently, tedders are used to rake hay.

It is worth noting that this equipment has nothing in common with the usual rakes that are available in every subsidiary farm. In fact, this is a multi-purpose complex operating in automatic mode and forming hay into neat swaths, convenient for transportation and storage.

Please note that the equipment is serviced by one operator. In this article, we will consider the technical parameters of such units, and tell you how you can make a tedder rake yourself.

The mounted tedder rake is a finger-type unit mounted on an all-metal frame. The design is based on rotating rotors, each of which is brought into a separate unit.

The rotors are mounted on tapered bearings, the power required for rotation is transmitted through the propeller shaft of the tractor. Each rotor is equipped with raking fingers made of high strength steel.

There are about forty fingers per rotor. So that the working elements do not receive mechanical damage, the fingers are attached to a spring suspension.

The tedder rake is classified in several ways:

- By the type of tractor used. There are two categories here: tractor and horse. The first group performs the function of mounted or semi-mounted equipment for tractors, the second is designed for motoblocks.

- By the way the roll is formed. Here you can distinguish transverse and lateral aggregates.

- By the design of working elements. There are three types of tedder rakes on sale. Finger-wheels: they have a system of shock absorption of working elements, therefore they are optimally suited for fields with difficult terrain. Drum: robust and reliable construction with independently rotating rings. Toothed: units with variable angle of rotation and inclination of teeth.

- By the type of attachment to the vehicle.

Due to the design of the working elements, these units are called “sun rake”. This equipment is available in several modifications. The key differences between the models are the number of rotors installed: 4 or 5.

The covered area directly depends on this, and, accordingly, the performance of the equipment. The average productivity of the tedders is 6-8 hectares per hour. Recommended moisture content of hay should not exceed 70%.

An exception is the GVK-6 model, which is capable of forming plant mass in rolls with a moisture content of 85%.

Мотоблок с пресс-подборщиком.

The tedder rake is operated and maintained by one tractor driver. Due to the absence of complex elements and independent installation of rotors, replacement of damaged working elements can be carried out in the field.

The advantages of the tedder rake include the ability to adjust and double the rolls. In addition, the equipment can shake up ready-made swaths, which eliminates the risk of grass spraying. Among the shortcomings can be noted a weak chassis. This problem is especially noticeable on trailed models.

Can I do it myself?

We have already mentioned that the tedder rake does not have technically complex assemblies and elements in its design, therefore, if you wish, you can make such a unit with your own hands.

On the Internet, you can find various schemes and drawings of tedders designed and developed by home craftsmen. Considering that not every farmer has a tractor, we will give an elementary design that is quite suitable for working with a walk-behind tractor.

Please note that a three-wheel tedder rake is enough for a walk-behind tractor. If the equipment will be used with a tractor, the number of rotors can be increased to 5.

A metal pipe is used as the basis for homemade rake tedders, on which brackets are installed for attaching the rotors.

To allow the working elements to rotate freely, two tapered bearings and a hub (for each rotor) are required. This element can be borrowed ready-made from a VAZ car.

In addition, a hitch is installed on the frame to aggregate the mechanism to the traction device. The unit can be supplemented with a hydraulic system, which will allow the rake to be transferred to the transport and working position.

Impeller discs are made of metal sheet, about four millimeters thick. Steel wire up to 7 millimeters in diameter is used as raking fingers.

The resulting design is practically not inferior to the factory models. At the same time, in terms of build quality, homemade modifications sometimes surpass industrial counterparts.

Overview Build a Gas Cutter Huter

Overview Assembling HUTER brushcuttersAuthor: 220 VoltsPublished: May 31, 2017 Views: 5,735I liked it: 23I didn’t like it: 4You can find out the current price for HUTER brushcutters right now at the link: HUTER GGT-1300S. for cutting grass on.

Rotary Mower Gear Lubricant.

Gearbox lubrication. Rotary mower The instructions say that the mower is ready for use. But it is better to check and add the required amount.

Ratios of Oil And Gasoline For Mower.

Chainsaw oil and gasoline ratios, oil selection, instructions Observance of the correct proportions of oil and gasoline for a chainsaw avoids the vast majority of problems that arise with this tool. At the same time, it is necessary to choose.

Assembling the Diesel Engine 9 HP F-186.

assembly of diesel engine 9 hp F-186 Author: Andrey Sivochub Published: 13 oct. 2017 Views: 22 073 I liked it: 110 I didn’t like it: 19 subscribe don’t miss new and interesting videos))) youtube tags: # diesel engine assembly9l.

Features of the mower in the photo.

Model Wirax 1.85m

So, we examined the technical characteristics of the main models of Polish rotary mowers. The indicators are largely identical, but there are still a couple of differences that affect the final price difference. Which one you decide to purchase, it all depends on what area you have at your disposal and what specific requirements for the unit are important for you.

Features of operation

Polish rotary mowers, as mentioned earlier, do an excellent job with their main job. mowing the grass surface over large areas of the area. But in order for this to last as long as possible and the operation of the mower was stable, it is necessary to follow some rules that can significantly increase the service life of a single unit.

Initially, after the very purchase of the unit, the mower is disassembled. The package includes detailed instructions with drawings that allow you to clearly see the entire assembly process. It is extremely important, at this stage, to carefully study the entire instruction, paying attention to all the assembly points, and only after that proceed to collecting the finished unit.

User’s manual

It is clear that a Russian person is not used to relying on pieces of paper, and he himself knows everything and knows how, but this is still not the case where one can treat the matter so naively. After all, not only the quality of the work performed, but also the safety of you and the people around you will depend on whether you assemble the Polish rotary mower correctly.

After the product is assembled and ready for use, you need to study all safety precautions from start to finish. This is no less important stage than the assembly of the unit, because the design of the Polish rotary mower contains cutting elements, from which almost anyone who will be in close proximity to the operating unit can suffer.

Next, you need to install the assembled unit in the correct position, i.e. so that the discs with cutting elements are parallel to the earth’s surface. Then, we set the main frame of the device strictly perpendicular to the axis of the tractor.

We put on the end of the propeller shaft on the PTO of the tractor, i.e. to a unit that transfers rotation from the engine to various attachments and trailers. The unit brought in this way into the working position will perform its main work on mowing the grass with high quality.

Specifications

In operation, the Polish rotary mower, the device of which we described earlier, does not present any special difficulties. You just need to follow certain measures and manipulations, including:

Regularly check the cutting system, which consists of knives, for galling and wear. If necessary, they can either be sharpened on the machine, or replaced with new ones.

It is important to monitor the condition of the belts, whether they are punctured or cut, and whether they are properly tensioned. If you are still not familiar with lawn mower belts, please click here.

Periodically, you need to check the level of the transmission oil, which is in the gearbox on the unit frame. To do this, you just need to unscrew the cap and check the condition, as well as the presence of oil.

Rotary mower for tractor

By observing these simple steps, you can significantly extend the service life of Polish rotary mowers, and also avoid possible breakdowns, which may be completely inappropriate, especially in the midst of the summer season.

By observing these simple steps, you can significantly extend the service life of Polish rotary mowers, and also avoid possible breakdowns, which may be completely inappropriate, especially in the midst of the summer season.