DIY potato planter for tiller sizes

How to make a do-it-yourself potato digger for a tiller

A conveyor potato digger can also often be called a belt digger. This is due to the design features of the device. Do-it-yourself tape potato digger for the tiller is made according to the following plan:

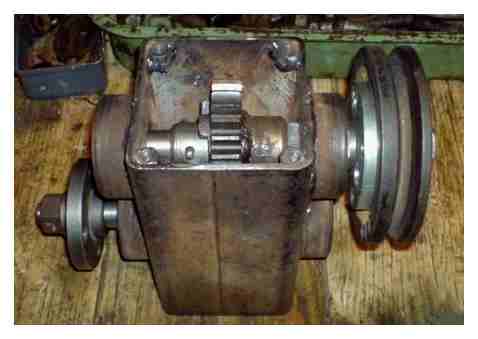

- First of all, you need to assemble the gearbox. It consists of a body, two shafts and gears. The device can be borrowed from any unnecessary or worn out equipment.

- Next, you need to make a conveyor that will move the fruits along the belt. It can be assembled from metal rods and a chain consisting of links. With the help of it, the structure will be set in motion.

- In the front of the structure, fix the shaft, and on it there are three hubs. two at the edges and one in the middle.

- Install the second shaft at the rear. Also attach stars to it, in the amount of two pieces. The total length of the conveyor must be 50-70 cm.

- Install the units on a frame consisting of metal sheets and struts. Attach wheels to the structure.

- Make a scoring knife from the springs, which will deliver the earth with fruits to the conveyor.

- The design is driven by a chain from a bicycle, therefore, depending on the size of the sprockets, the speed of the conveyor can be adjusted.

Conveyor

Another type of device that is rarely found in the personal use of landowners is the conveyor potato digger. It is a bucket and belt structure. Together with a piece of soil, the fruits are placed in a container, and then move along a conveyor. In the process, the tubers are cleared of the ground and laid on the soil surface, where they are subsequently harvested by hand.

With the help of a conveyor potato digger, it is possible to process several beds at once

Despite the variety of units, the fan and roaring potato diggers are considered the most versatile devices. They are suitable for all types of soil and do the job well. Also, it is often possible to find a drum potato digger in the use of farmers, however, for its operation, it is necessary to take into account the requirements for operation.

How to set up and adjust the potato digger on the tiller

When starting the potato digger for the first time, it is necessary to adjust the depth of immersion of the shares in the ground. According to the standards, the knife of the device must enter the soil below the level of the fruit. Thus, the crop will not be damaged and will be delivered to the topsoil intact. The optimal immersion depth is 12-15 cm.

The knife is adjusted by means of the hitch bracket and support wheels. With a shorter length of the struts, the depth of travel increases, otherwise it decreases.

The device and how potato diggers for tillers work

The main principle on which the potato digger is based is to dig up tubers and loosen the soil. Despite the fact that these steps can be repeated manually, the use of equipment can speed up the process several times.

The classic design is simple. As a rule, the device consists of teeth, bipod, tip and bar. Depending on the type, the unit can be equipped with a vibrator, wheels or a gearbox.

The potato digger works on an elementary principle. With the help of tines, the device plunges into the soil to the required depth and digs out the tubers. Then the fruits are moved to the top layer of the earth, having previously sifted from excess soil.

The classic potato digger is mechanized only partially; when harvesting, the dug tubers must be harvested by hand

How to make and set up a homemade potato digger for a tiller

During the harvesting season, the problem of the speed of processing plantations becomes urgent. This criterion is especially important for owners of large plots or agricultural fields. You can speed up the pace of harvesting by making a potato digger for the tiller with your own hands.

- The device and how potato diggers for tillers work

- Types of potato diggers for tiller and which one is better to choose

- Fan

- Rumbling

- Tympanic

- Conveyor

- Conveyor

- Drawings, diagrams, sizes of potato diggers for tillers Neva, Krot, Cascade, MTZ-09N, Salute, Agat

- How to make a vibrating potato digger for a tiller yourself

- How to make a do-it-yourself potato digger for a tiller

- How to make a drum potato digger for a tiller with your own hands

- How to install and connect a potato digger to a tiller

- How to hook a potato digger to the Tiller Cayman

- How to set up and adjust the potato digger on the tiller

- Top 5 best potato diggers for tillers

- KM-4

- KKM-1

- KVM-3

- DTZ-2V

- “Poltavchanka”

- Conclusion

How to make a vibrating potato digger for a tiller yourself

The vibrating potato digger is considered one of the most versatile devices of this type. The design of the unit allows you to install it on any trailer or mini tractor and use it on all types of soil.

Before you start making a potato digger for a tiller with your own hands, you should stock up on the following materials:

- metal rods;

- steel channel;

- a piece of steel;

- opener from 5 mm;

- metal corners (40 and 60 mm);

- profile pipe;

Before making a roaring potato digger, you need to stock up on fasteners and bolts

Algorithm for making a roaring potato digger for a tiller with your own hands:

- The first step is to build the frame of the device. To do this, the pipe must be cut into four parts. In pairs, they should be 120 cm and 80 cm long.

- Weld the resulting segments in the shape of a rectangle.

- Weld jumpers, they are mounted on a quarter of the base length.

- Parallel to the lintels, install two pieces of wheel mounts. To do this, you must use pipes 15 cm long and 3 cm in diameter.

- Next, you need to weld the vertical posts. At a distance of 5 mm from the edge of the frame, in the place where the jumpers are located, fix a pair of sheets 50 cm long.

- At a distance of 20 cm, it is necessary to mount segments with a length of 4 cm. Retreat 40 cm from them and install a third pair of racks 30 cm long.

- Make a ralo from a sheet of metal. Its size should correspond to the parameters of 40 cm by 40 cm (thickness from 3 mm). Mount the first workpiece to the bottom of the construction sites. Weld the second part (size. 70 cm by 70 cm, thickness from 4 mm) to the first and use a sledgehammer to shape into a cone.

- Weld the lattice of rods to the rail, its ends should go beyond the frame. The number of segments can vary from 10 to 15 pieces, depending on the type of crops that are planned to be processed.

- To strengthen the grating, two more pieces of rods are welded across it.

- Install wheels on previously prepared mountings.

Rumbling

The main difference between the roaring potato digger and other types of devices is the presence of a lattice compartment. It is angled relative to the ground, which allows the tines to sink into the soil with less effort. Also, due to the additional support point and a pair of wheels, the screening unit has a more stable structure than a fan potato digger.

The roaring potato digger got its name from the noise and vibrations produced during operation.

The advantage of the screening device lies precisely in the grate. Due to the constant oscillatory movements of the compartment, the harvested tubers are better and quickly cleared of the ground.

In the video about potato diggers for the tiller, it is the roaring version of the device that most often appears in work, since it is most applicable when processing both small and large plots of land.

Tympanic

The drum potato digger is a fully mechanized device that can make the harvesting process as easy as possible. Thanks to this unit, the fruits are not only dug up and cleaned of the ground, but also transported to a separate box.

The design of the device implies the presence of a sieve drum. In it, the fruits come across directly after digging with a plow. Due to continuous rotation, the tubers are cleaned of excess soil, and then sent to a pre-prepared container.

Most often, they resort to making a potato digger for a tiller with a drum with their own hands in order to facilitate harvesting, but this condition is not always feasible.

The drum unit can only be used on soft, loosened soil.

How to make a potato planter hopper

In order to make a container for bulk materials, you need plywood with a thickness of about 1 mm. You need to cut out the parts with a jigsaw according to drawings, pictures or ready-made templates. Then everything is processed with linseed oil. An already finished product can be painted with paint, but it should be borne in mind that it must be waterproof. The inside of the hopper should be covered with rubber, this will help to avoid deformation of the tubers.

Then the holder is bolted to the frame. The axle must consist of a pipe. When choosing, make sure that it has thickened walls, since the frame will have to take on considerable loads. When the mechanism is fully assembled, you will need to weld the pins.

DIY potato planter for a tiller: drawings, video

For a farm, a potato planter for a tiller is simply an indispensable device. Its functions include not only planting potatoes, but also fertilizing the soil. With this equipment, you can evenly distribute the planting material and facilitate agricultural work. You can save money on buying a tiller potato planter by making it yourself according to sizes, drawings and pictures.

Potato planter for mini tractor and tiller

This potato planting equipment is simply irreplaceable for farmers, as it saves a lot of time and labor. The structure can be assembled at your discretion, taking into account the dimensions, drawings and pictures (meaning the number of rows). It is important to provide an adjustment for the row spacing.

The Tiller Potato Planter is best used on previously treated surfaces. Planting depth should also be adjusted according to dimensions and drawings. Tiller attachments are widely used for small summer cottages and for large fields.

The potato planter can be used not only specifically for planting potatoes, with its help it is easy to plant other vegetables, the main thing is to choose the correct adjustment. Before proceeding with the manufacture of a potato planter, it is necessary to make a drawing and detailed measurements. Whatever the mechanism is, it should always have its own frame to which all subsequent parts will be attached. In other words, the frame is the foundation.

- In the case of a planter, a part of a steel channel is taken as a frame, something like a pair of spars is made from it, which are connected by pieces of steel.

- In front, a steel arch is attached by welding, as well as two rings that will serve as an attachment to the lower link.

- On the sides of the frame, plate supports are attached, which will be the vas deferens.

- After all that has been done, it is worth fixing the frame with steel strips.

- The arch can be reinforced with a gusset plate made of steel sheets. They should be cut in the shape of a triangle.

- The hopper clings to the bracket with bolts.

How to make a tiller potato planter yourself

You need to start the manufacture of agricultural equipment in order to assemble the frame. This requires a steel channel of the eighth standard size. Since the potato planter is designed for small equipment, the bunker itself should be small, no more than twenty kilograms.

- It is necessary to install a vertical lift inside. It should have bowls with a diameter of about eight cm.In order for the mechanism to work, it must be attached to a wheel where the chain transmission will work.

- In this mechanism, according to the drawings and pictures, there should be a pipe for withdrawing seeds, which is fixed under the elevator with a raking part.

- The sprocket with a diameter of eighteen cm must be connected by a chain with the sprocket of the tiller, thus the coupling transmission will be carried out.

- The transmission chain can be removed from the bike. Thanks to this, the distance between the holes with potatoes will be approximately 35 cm.

See DIY Potato Planter for Tiller

The potato planter for the tiller is assembled with his own hands. We hope that the dimensions, drawing, pictures and videos will help you to correctly assemble attachments for a mini tractor or tiller of any model. Make it easier for yourself to farm by making accessories yourself.

Manual

Potatoes are the most popular culture not only in our country, but all over the world. It is nutritious, tasty, but difficult to plant.

But large fields should be cultivated with agricultural machinery. So for digging and planting potatoes on a plot of 10 acres, the farmer needs to process about 20 tons of land with his own hands. This labor is comparable to unloading an entire train. The easiest way to solve this unpleasant problem is to make a manual potato planter. This is a very simple device that almost anyone can do.

The manual device is a pipe (inside empty) with an opening at the top and a sliding valve at the bottom. For a deeper understanding (including sizes), we will study in detail the adaptation diagram.

Crusher Drawings and Dimensions

The pipe must be cut at an angle from the bottom to form a sharp cutting, the task of which is to sink into the ground. The bevel contains a sliding valve. The task of the valve is to open only at the moment when the tuber is already inside at the required depth.

To avoid different planting depths, place a mark at the desired distance from the bevel. A special flat device that rests on the ground and does not allow the pipe to move deeper can serve as such a mark. This is very convenient, because such a limiter allows you to deepen the tuber downward, helping with your foot (like a shovel).

The upper part of the device is open, there can be a special container with potatoes and a dispenser that does not allow sending several pieces underground at once.

[attention type = yellow] Important! We advise you to select the diameter of the pipe so that the tuber can move inside and not get stuck. The optimum diameter is 7 cm or more. [/ attention]

The practicality of the device is its most important characteristic. Many people try to make a potato planter compact, convenient and even work on its design. This is all important, but you should never forget about the main task of the device. The potato planter should not be large and heavy, so the pipe should be taken no more than a meter in length and always thin-walled.

It should be remembered that the pipe must easily withstand immersion in the ground and pressure from the black earth, so the material must be very strong. Cooking it from a sheet of tin is not the best idea, because deformations cannot be avoided.

The valve is usually made of steel. Using a conventional door curtain, you can make a simple hinge for attaching the valve. You can make a footrest from a metal corner.

After all the components and tools are prepared, you should proceed to the direct assembly:

- Using an angle grinder (angle grinder), we cut the pipe at an angle, achieving optimal sharpening (the sharper the end of the pipe, the better it will enter the ground).

- We make a valve cover, which should close the pipe tightly enough at the right time.

- We fix the hinge mechanism to the pipe body.

- At a distance of 200 mm from the tip of the pipe, using welding, we install a footboard (its length corresponds to the distances between bushes that are expected in the future).

- Handles and tubing container must be attached to the pipe (do not install a huge container).

[attention type = red] Important! To fix the handles, containers and footrests, avoid fastening with bolts, the most optimal in this matter is welding, since a significant load will be applied to all these components. [/ Attention]

For tiller

If you have a tiller or want to purchase one, then it makes sense to abandon the manual potato planter and go straight to the design of a device designed specifically for the tiller. You should always start with the frame, since this is the basis on which all further components and assemblies will be fixed. For the frame, channels are used (material. steel) type 8 (dimensional standard).

Such a device faces not only the task of automating potato planting, but also ensuring that the bushes are evenly distributed and covered with the correct amount of soil. In addition to making work easier, such a potato planter also raises the quality of planting.

Since the tiller is designed for small equipment, it means that there are no special requirements for the bunker in terms of strength; you can use ordinary plywood 1 cm thick. The carrying capacity of such a device will be about 0.25-0.3 centners.

The part of the device in which the tubers will move is called the container. The main requirement for the container is the presence of an elevator, which is fixed vertically and is supplied with special bowls with diameters of 50-80 mm. The operation of the entire mechanism is carried out thanks to a chain transmission to the drive wheel. An elevator must be installed in the container, it must be equipped with bowls. In order for the mechanism to work, it is attached to a drive wheel with the participation of a chain drive.

In order for the tubers to enter the ground, a special seed tube is used, which must be placed at the bottom of the elevator and be pressed by the component that performs the zagreb.

An 80 mm sprocket is embedded in the mechanism, which guarantees the transmission through the chain. In this case, a star is used on the tiller with a double diameter of 160 mm.

Single row pot planter

To implement such a system, you can use a chain from a regular bicycle or moped. With the help of such automation, the distance between future potato bushes will be about a third of a meter.

DIY potato planter

Spring has come, which means it’s time to prepare potatoes for planting. It is believed that a potato planter can increase the productivity of the planting process by 10-20 times. This does not mean at all that a tractor or a tiller is needed for this device, potato planters can also be manual.

Such equipment is a necessity these days, because cultivating fields and vegetable gardens in the age of high technologies and automation with your own hands is not the most rational occupation. We will figure out how to properly make a potato planter with our own hands, get acquainted with the drawings and sizes of devices and its components.

For mini tractor

A mini tractor is already a more powerful technique and a more complex potato planter is needed for it. However, you can still use plywood. it is much lighter than steel and even aluminum, does not require welding and allows you to simply fix all the fasteners.

[attention type = green] Important! You should not over-complicate and weight the structure. The most optimal should be such a weight of the potato planter, at which the mini tractor will not experience loads in traction. [/ Attention]

To create a device, you need a jigsaw. With its help, all the required parts are cut out of plywood (the optimum material thickness is 15 mm.). All components should be treated with linseed oil. When the product is ready, it should be painted with waterproof and anti-corrosion paint; oil paint is suitable for these purposes.

The container (hopper) should be abundantly pasted over from the inside with a rubber sheet or filled with silicone glue. This is done in order to avoid damage to the tubers due to friction against a wooden surface.

When the frame is ready, the holder for the openers and the axle for the future wheels of the device should be fixed to it.

The axle is a thick-walled steel tube. It should be remembered that it has a very heavy load. Wheels can be used ready-made (commercially available for large carts and mini tractors) or made by yourself.

Oddly enough, but homemade wheels, as a rule, turn out to be more suitable and reliable. It’s all about the design. such wheels have a cylindrical shape and are made of steel (as a rule, steel sheets are taken as a basis, bent on special machines or at home).

Holders for openers are special square rods that are assembled by welding from metal corners. Standard squares can be subject to strong deformations, which is why the most rational is to use corners.

The planting devices of planters for tractors are pipes with a diameter of 10 cm.The pipe must have thick walls, otherwise there will be strong deformations in contact with the soil.

Also, for filling furrows and creating ridges, special discs may be required. For self-made planters adapted for a mini tractor, you can use the disks of the SO-4,2 seeder. The disc should be slightly modified. The holes in the hubs must be widened and the bearings must be larger. Model 160503 should be used, these bearings are ideal for the intended purpose.

Consider some of the specifics of the operation of self-made potato planters. The mass of the device turns out to be quite large, because of this, the center of mass of the device shifts to the rear. In order for the center of mass to correspond as closely as possible to the geometric center of gravity, the front of the device must be equipped with special ballasts. Farmers, who did not want to make the structure heavier again because of such a “banal” reason, subsequently complained about the loss of stability of the unit.

If there is a desire to create a device in such a way that the process of planting potato tubers takes place with maximum comfort, the planter must be equipped with seats and special adapters for the tiller. The seat should be assembled separately and the geometry of the main frame does not need to be complicated. The seat frame is separately assembled from the metal corners, then upholstered with canvases, foam rubber and leatherette.

The rules for using homemade potato planters are no different from the rules for using factory models:

- tubers must be poured into the potato container;

- mini tractor with a speed of 1 km / h. begins to move, the speed should not be changed, the movement should be as uniform as possible;

- the sowing mechanism delivers one potato per unit of time to the seed tube, and due to the uniformity of the movement, the tubers are located along the site with an equal distance;

- with the help of special modified discs, the tubers are dusted and a special ridge is formed. Due to the angle that is formed between the discs and the furrow, filling is carried out evenly.

Adjustment is often required. For example, when the filling of tubers is not carried out properly. Then it is necessary to adjust the angles of the discs and their distance from the hopper. By loosening the ladders and sliding the racks, you can adjust the depth of the discs. The angles of their position are regulated by changing the angle of inclination of the racks. With the help of 4 special pins, it is possible to adjust the position of the discs in the plane. Each disc can be shifted relative to the other.

Another important problem is the wheel marks that remain on the site. Despite the fact that they were manufactured in an optimal, cylindrical shape, under the pressure of the device’s own weight, the wheels can compact the soil too much. To avoid such a nuisance, you can fix special paws (used in cultivation) to the potato planter. They are able to loosen the ground after the planter has passed, eliminating wheel tracks.

Features of creating a potato digger for a tiller with your own hands

- Required tools

- Manufacturing process

- Fan

- Rumbling

- Conveyor

- How to attach to a tiller?

A good harvest with minimal losses is important for both farmers and summer residents. If the plot is quite large, then a potato digger can come to the aid of harvesting potatoes. for a potato digger can range from 6.5 to 13 thousand rubles. It makes sense to make a potato digger on your own for small sown areas. Industrial equipment is usually bought from various trading platforms.

Rumbling

The screening mechanism is based on the vibration principle and consists of a share and a sieve.

With the help of a ploughshare. a “knife”, sunk in the ground to a depth of 25 cm, a layer of earth is undermined together with root crops. Soil with tubers remains on the trellis. Due to vibration impulses, the soil flies around the tubers and rolls down, and the peeled potatoes enter the container.

The scheme is efficient, but it is technically quite difficult to make such a unit, since certain qualifications are needed.

The design consists of three blocks:

- knife;

- dynamic grilles;

- frames.

You will need the following tool:

- drill;

- hammer;

- set of drills;

- bolts;

- nippers or pliers;

- reinforcement (10 mm);

- hinges;

- eccentric;

- marker.

First, the profile of the required dimensions is cut to make the frame, which is then welded. Supports are mounted from below, wheels are put on them. In the frame itself, the hinge fasteners are mounted on which the screen is placed.

Fasteners are welded to the frame. a gearbox is placed on them, special devices that provide vibration. The mesh of the box is welded from the reinforcement, which is fixed inside the frame. A gearbox is installed. it provides the required vibration. It is connected to a rumble. Through the lever device and the connecting rod, the impulse from the rotation of the shaft is fed to the roar, as a result of which vibrating impulses arise that generate rotational movements of the eccentric.

A ploughshare is cut out of steel, which is attached to the bottom of the frame. Wheels are attached to the unit. The knife can be both concave and slightly convex.

The cutter lifts the soil with root crops, after which they fall into a roar, along which they roll, freeing themselves from the ground. Then the tubers fall from the surface of the trellis to the ground. The advantage of this device is that the gripping takes place with a width of 0.45 meters. The depth of penetration into the ground is almost 0.3 meters. The yield loss is relatively small. up to 10%.

The disadvantages of the unit are that there is increased vibration, which is transmitted to the operator, and this gets tired quite quickly. Also, before starting work, all tops should be removed from the site in order to ensure the normal passability of the tiller. In some cases vibration is reduced by installing two eccentrics.

How To Make Custom Sized Potato Grow Bags & Planting PT 1

Fan

The fan digger is attached to the unit (it is also called the “arrow” and “foot”). In the professional language, such a unit is called “dolphin”, due to the corresponding shape of the plow. a plowshare. The device of this unit is not complicated, while it has quite good performance. You can make such a unit with your own hands in a short period of time.

Principle of operation: the cutter opens the earthen layer, the roots roll onto the reinforcement, move along it. During this “journey”, the tubers are cleared of soil. Before the start of harvesting, all vegetation must be removed without fail. To make such a structure, you will need the following tools and materials:

- turbine;

- welder;

- drill;

- hammer;

- set of drills;

- roulette;

- marker;

- bolts;

- nippers or pliers;

- steel sheet 3 mm thick. it is necessary to make a ploughshare from it;

- bolts (10 mm);

- rectangular profile;

- steel sheet to create a rack;

- bracket;

- reinforcement (10 mm).

There are times when the reinforcement is bent in the form of steps. A holder-stand is attached to the share itself, the height of which depends on the tiller’s design. The holder stand can be welded to the plow itself, without bolting.

Among the shortcomings, we can mention a relatively narrow strip of cultivated land. it is only 30 cm.

Using such a structure, you can lose a significant part of the crop. up to 22%. Also, some of the tubers are damaged. this will lead to the fact that such a product cannot be left for winter storage.

Manufacturing process

Drawings of a potato digger are drawn up by analogy with diagrams that are easy to find on the Internet. When buying a tiller, an instruction manual is attached, which indicates the dimensions and other parameters of the attachment (weight, digging depth). Based on these data, you can find the necessary information and, on its basis, compose your own version of the potato unit. This option seems to be very rational, since each tiller has its own characteristics.

The algorithm for creating an aggregate is as follows: a pipe with a diameter of 45 mm is cut into four parts. For example, this can be done in this way: two pieces of pipe measuring 1205 mm each and two pieces of 805 mm each. Then a rectangle is drawn up on a flat plane, the joints are welded by welding. Jumpers are also welded, which will serve as control rods. Then it is necessary to create vertical mounts. they will ensure the installation of vertical rods, which are responsible for control.

After that, the racks are attached, which must hold the vertical load. The lintels are attached at a slight distance from the edge of the frame. The squares should have parameters 35×35 mm, and the length should be 50 cm.The racks are connected to each other with jumpers.

Then you need to mount the shaft. Stainless steel sheets are used, the thickness of which should be 0.4 mm. The sheets are bonded to each other by welding. After that, it is the turn of the rods. they will implement the work of the “strainers”. This technique makes it possible to effectively harvest a good harvest of root crops in the shortest possible time.

The standard design consists of the following elements:

- metal frame (from pipes or corners);

- plow. cutter;

- device that transports the product;

- connecting pulley;

- connecting rod;

- drive belt;

- support rack;

- wheels;

- springs;

- bevel gear transmission belt.

Conveyor

Self-made conveyor potato digger can be of different sizes. These units are usually large in size to handle large areas of cultivation. To work on a personal plot, there are enough small potato diggers, which it is not very difficult to do with your own hands. The principle of operation is simple: the tubers are removed from the soil and fed to the separator via a conveyor belt.

The tape itself is a grid, which is made of reinforcement welded in parallel. It is attached to a movable conveyor belt. Also, the tape is made of mesh and rubber, which is attached to dense fabric. The soil adhering to the tubers, separating, falls, and the potatoes enter the storage.

The conveyor moves as a result of the rotation of the shaft, which is attached to the tiller.

In this case, the following elements are used:

- reducer;

- chain;

- gears.

The cutter is a crescent-shaped metal tool. It sinks into the ground by almost 20 cm. Such a device works much “cleaner”, the unharvested crop remains in the fields no more than 5%. The cutter is fastened using bolts with lock washers.

Before you start making a potato digger, you need to think about the question of whether you have practical skills. You should also carefully read the drawings. there are a huge number of them on the Internet.

The main elements of a potato digger:

- welded skeleton. made from a profile;

- steel cutter;

- rollers for belt movement;

- assembly from steel strip reinforcement;

- fasteners.

The “drum” potato digger has successfully proven itself in the processing of vast areas.

The apparatus is made of the following elements:

- skeleton with wheels in the form of a frame;

- cutter knife;

- drum-shaped containers made of reinforcement.

The cutter is mounted to the base using special hinges. Its function is to remove soil below the tubers that enter the rotating container. The spinning hollow container removes the tubers that remain in the container from the soil. Then the vegetables move to the end of the container and fall on the ground in a peeled form.

The drum is attached to the tractor shaft by means of a gear train and a reducer. a torque impulse is received from it. The crescent cutter allows the soil to be opened to a decent depth, which ensures the preservation of the crop. Such a device provides insignificant yield losses, tubers are also practically not subject to mechanical defects.

Required tools

For work, you will need the following materials and tools:

- alloy steel pipes with a diameter of 4 cm;

- corners of the “six”;

- reinforcement with a thickness of 10 mm;

- chain;

- gears;

- turbine;

- welder;

- adjustable wrench;

- drill;

- bolts with nuts and lock washers.

Good steel is essential for making a share. it should be quite thick (at least 4 mm). The design has a welded frame, suspensions, rods, which will allow you to adjust dynamic elements. wheels and hooks.

Making the unit yourself is not particularly difficult. Such a potato digger can really be used on any, even very dense soils.

Craftsmen independently design two types of potato diggers.

- fan-shaped;

- thundering.

The situation with the creation of conveyor and drum units is a little more complicated, since their designs will be a little more complicated, but technically, it is quite possible to implement the creation of such units.

If you have to harvest on vast areas, then you should pay attention to the roaring or conveyor potato digger. For a summer cottage or garden plot of 10 acres, a fan digger may well be suitable.

The disadvantages of all potato diggers are that they do not “take out” the entire crop. Tubers that grow away from the cultivated strip do not fall into the field of action of the plow.

How to attach to a tiller?

Different units may be suitable for different tillers. If the tiller has a mass of up to 150 kg, then it can be used on a par with ordinary potato diggers. The potato digger moves around the site at a minimum speed, so the unit must have sufficient pulling power.

Not every engine will be able to “keep” the minimum speed. gasoline power plants often stall at a speed of 1-2 kilometers per hour. Diesel tillers are better at such tasks. such devices are suitable for vibration units of average parameters. Heavy tillers can work with any type of aggregate. Based on the parameters of the tiller, you can select the desired unit.

the tiller can have both a universal mount and only attach to a certain type of mechanism. Vibrating diggers are commonly used.

When creating a potato digger (or buying one), consider the width of the cultivated soil strip and the depth. The speed of the device usually does not exceed two kilometers per hour. this is the maximum value.

It is also worth considering the quality and nature of the soil on the site. For example, the KKM potato digger can work only with soils, the moisture content of which does not exceed 30%. Typically, the productivity of a potato digger is no more than 0.21 hectares per hour.

For how to make a potato digger with your own hands, see the next video.

Instructions

DIY potato planters for tillers are an ordinary cart on wheels, which is attached to the tiller. The apparent simplicity is a little deceiving, because the design of this unit has its own nuances and features that are worth paying attention to.

You need to start the assembly with the manufacture of the frame structure. It will consist of channels welded together, as well as longitudinally located spars, which are connected by three transverse elements.

Thanks to the lawnmower, you can trim the grass and remove weeds. it is a suitable device for mowing unnecessary plants near the fence, at home, between rows in the garden on a flower bed, and so on. Find out how to wind the line on your lawnmower here.

MAZ-500 can rightfully be considered one of the iconic vehicles of the Soviet period, which became the first cabover truck produced in the Soviet Union. MAZ-500. a Minsk legend from the 60s.

Cultivation is a top priority for any cultivator because it helps prevent weeds, at least in large quantities, and helps oxygenate the land through loosening. Here’s how to make a cultivator yourself.

An arch and a fork will be located in front, and on the sides of the structure there will be racks of elements for planting and burying holes. Potato planter wheels must be equipped with lugs. Between them is a wooden disc 6 cm thick with four semicircular grooves located on it.

This disc will grab the potato tubers, moving them into the dug holes.

Next, you need to make a container for potatoes. a bunker. It can also be made of plywood, but for the strength of the structure, it is best to use sheet metal with a thickness of 3 mm.

The four sides of the hopper are measured and then cut out. They are connected by welding. The bottom can be covered with rubber so that the potato tubers are not damaged. It is necessary to reinforce the frame with steel strips, placing them from the middle cross section to the arch located in front.

There you also need to weld pads and corners with a thickness of 4 mm. DIY potato planter drawings for a tiller, which can be found on the Internet, describe this process in sufficient detail. Next, you need to attach a support and a footboard to the side members, consisting of a sheet of metal with a thickness of 5 mm.

We make a seat. To do this, we need a metal corner measuring 4.5 × 4.5 × 0.4 cm. Boards covered with foam rubber must be attached to this support for greater comfort. For the wheel axle, you can use a steel tube that fits the frame.

At the ends of it there should be spikes fixed with steel pins. As wheels, you can use any wheels from old equipment that have served their time. A 5x5x0.5 cm metal rod is used to support the rippers.

On the sides of this rod, there are elements that hold the blade struts. They are made of metal plates with a thickness of 0.5 cm.As a seeding device, you can use an ordinary 10 cm pipe, the wall thickness of which will be about 0.3 cm.

A furrow cutter will be located at the bottom of this structure. Burying elements, in the role of which the disks from the seeder can be used, must have two bearings in their presence. In principle, this description is rather schematic, with an approximate indication of dimensions and parameters.

On the Internet, you can find a lot of detailed drawings, where other markings are indicated, so there are no strict recommendations in this process.

Necessary materials

In principle, for the manufacture of a homemade potato planter, the materials that many summer residents have on the farm are enough. At worst, you can go to the nearest landfill, where you can find a lot of parts and related materials that can be useful to us when assembling.

Here’s a rough list of what we might need:

- sheet metal of various widths;

- bolts and nuts;

- welding machine;

- Angle Grinder;

- wheels;

- channels, etc.

As we can see, we need a lot of metal, which in itself implies the use of a welding machine. Therefore, if you do not have the skill of working with it, then the assembly of a homemade potato planter will not be available to you.

The list of required materials does not include various components, which will be discussed in detail in the process of describing the design technology of this device.

Device

A potato planter for a tiller can be easily made at home using fairly traditional tools, as well as those component parts that almost every villager has on the farm (read about spare parts and details for ccm 4 here).

The principle of operation and purpose of a homemade potato planter for a tiller is identical to factory counterparts, such as a potato planter for a mini tractor, for a tractor, bomet, l 207, for mtz.

In general, this device has the following structural elements, which we will need to make:

- frame structure, on which the remaining elements of the unit will be located;

- the container in which the planting potatoes will be located;

- a mechanism that will activate the system for planting tubers in the holes;

- rippers that dig holes;

- wheelbase;

- elements that bury the holes, after planting potato tubers in them.

In principle, this is the minimum that we need to make a rather simple design of a potato planter at home.

The very process of assembling such a device implies a rather large scope for action, because an additional reservoir can be added to the design, which will contain fertilizer, and also make not one, but two elements for planting tubers.

Of course, this will lead to an increase in the weight of the entire structure, slightly reducing its maneuverability and performance. Therefore, you need to think several times before supplementing the potato planter with additional elements.

For more information on the homemade tiller potato planter, see

Additional tips and warnings

Due to the fact that the weight of a homemade potato planter is quite impressive, it is necessary to install additional weight on the tiller, which will not allow it to be thrown back. In addition, there are certain recommendations to help make the process of planting potatoes easier.

You can additionally put a couple of bags of potatoes on the container in which the tubers for planting will be located, so as not to waste time filling in a new one. It is recommended to drive at a low speed, about one kilometer per hour.

The closing discs can be adjusted by rotating them along the axis of rotation. In addition, you can adjust the row spacing and the arrangement of potato tubers from each other.

For this you need:

- Loosen the ladders with which the racks are pressed against the supports.

- Slightly adjust the angle of entry of the planting elements into the soil.

If we consider that the average, then making it at home is becoming more and more justified.

DIY homemade potato planter for a tiller. dimensions and drawing

The process of planting potatoes seems to be a rather laborious work, especially if the garden area is quite large. Here you can no longer do without outside help, because it is not only difficult to do this alone, but also for a long time.

And what about those who do not have the opportunity to involve their friends or relatives in the planting? The answer is simple. you need to use those automated units that specialize in such purposes.

Recently, Tilleri have become widespread, they are real “helpers” of farmers in managing their farms. With the help of this unit, you can not only plow land, but also plant potato tubers.

But not everyone has extra funds to buy such equipment, so a reasonable question arises. how to make a potato planter for a tiller with your own hands? Let’s try to answer this question in this article.

The process of planting potatoes is a rather laborious process that requires sufficient physical strength and free time. With the advent of partial automation in agriculture, this work can now be performed using a special device. a potato planter.

At the same time, its acquisition will be completely optional. you just need to make certain efforts necessary to make it with your own hands.

Considering that almost every summer resident has most of the necessary consumables on the farm, designing a homemade potato planter is not such a difficult matter.

You may also be interested in how to make a potato planter with your own hands: drawings and dimensions are presented in the article.

You may also be interested in a garlic seeder.