DIY Stihl 180 Chainsaw Carburetor Adjustment

Frequent breakdown of the Stihl carburetor and how to avoid it

A common prerequisite for the failure of a carburetor on a Stihl chainsaw is a sticking valve in the nozzle. The reason for sticking is a violation of the storage of the chainsaw, or rather the instructions of the manufacturer Stihl 180 for proper preparation for storage.

As follows from the instructions, before long-term storage, it is necessary to drain the fuel from the tank, after which it will start dust and burn the gasoline from the carburetor. Failure to comply with this elementary rule entails the following consequences. The forksnuy valve, being in direct contact with the fuel, sticks to the body, since the gasoline evaporates little by little and only sticky oil remains. It is impossible to replace the nozzle, because they are not in the repair kit, you can only try to knock it out and rinse it, which is not always possible to do, but without damaging the nozzle.

When to adjust the Stihl 180 carburetor

To begin with, it is worth deciding why it may even be necessary to adjust and repair the stihl ms 180 carburetor. So, this must be done in the following cases:

- If the chainsaw is idling;

- Repairs may be required if the saw does NOT start;

- Power loss is observed;

- Increased fuel consumption;

- The chainsaw develops maximum speed.

- Stalls when accelerating.

This list can be continued for a long time, but we have identified the main reasons. Before proceeding with the adjustment, you need to know what are the main parts of the carburetor on the Stihl 180 chainsaw, and who makes it.

Nozzle

The fuel injector is mounted in the carburetor body in such a way that it is a connecting link between the distribution chamber and the cavity in which the throttle valve is installed. Simultaneously with the fuel, air is supplied to the nozzle and an air mixture is formed. The nozzle has a check valve, which blocks the flow of air in the reverse sequence, that is, from the throttle chamber to the distribution chamber.

Adjusting the Stihl 180 carburetor

The carburetor of the Stihl 180 chainsaw, indiscriminately, can only be adjusted by the number of idle revolutions. It is impossible to increase or decrease the fuel supply in different modes with the help of Special screws. The manufacturer restricts access to the adjustment and does NOT install these screws. How to adjust the carburetor to the correct idle speed is described in great detail in the manufacturer’s instructions.

In the event of certain malfunctions, and with experience, you can increase or decrease the fuel supply by increasing the clearance when opening the needle valve.

To increase the flow, the rocker arm of the needle valve in the distribution chamber must be bent up, and to decrease, down. This regulates the stroke of the needle and accordingly the throughput of the valve.

Fuel pump

A fuel pump is installed directly in the carburetor body, which works under the action of an air pulse from the crankcase of the chainsaw, which is transmitted through special channels. A diaphragm is installed in the pump, it is she who is responsible for pumping fuel under the action of an impulse. A gasket is installed between the diaphragm and the body, which is responsible for the tightness of the fuel pump.

Removal and installation algorithm

In cases where it is necessary to clean the Stihl 180 carburetor or disassemble it, first you need to remove the assembly from the chainsaw. This must be done in compliance with a certain algorithm of actions:

- Put the protective cover for the chainsaw on the tire.

- Remove the top cover of the chainsaw.

- Remove the two nuts securing the air filter and carburetor.

- Remove the air filter housing.

- Disconnect the wire from the engine control lever.

- Carefully remove the lever from its seat in the housing, at the same time disconnecting the air damper rod from it.

- Pull the carburetor towards you and disconnect the fuel supply as well as the throttle rod.

To facilitate dismantling, you can additionally untwist the rear handle and disconnect the throttle rod first from it, and then only from the carburetor. This may be required, because without some experience, disconnecting the rod from the carburetor is quite problematic and it is easier to first disassemble the handle.

To install the part in place, follow the reverse order of the algorithm.

Air damper

The carburetor choke is installed on the opposite side of the throttle and is responsible for starting a cold engine, it is controlled by the engine control lever. Air damper is fully closed for cold start and open for normal operation.

Dismantling the carburetor Stihl 180

In order to purge, change the gaskets or the needle valve, the carburetor must be disassembled. To do this, unscrew 4 screws on the expansion joint cover and one on the fuel pump.

Having opened the case, you should be extremely careful, because if debris gets inside the carburetor, it will make its work impossible. The thickness of the channels in it is comparable to the thickness of a thread or even a human hair.

Repair of the Stihl 180 carburetor, can be seen below. In it, the master tells in detail about the problems and clearly demonstrates the entire repair process.

Throttle flap

The throttle valve, installed in the carburetor body, is responsible for increasing the supply of the fuel mixture directly to the engine cylinder. At the moment of pressing the gas, the throttle valve opens slightly, thereby increasing the throughput of the channel and fuel from the carburetor cavity, rushes into the cylinder in a larger volume.

Combustion of a larger volume of fuel increases the amount of generated energy, which affects the power and speed of the processes. The damper is installed on the shaft passing through the entire carburetor body. At the exit of the shaft from the housing, a mount for the gas cable is installed, next to it is a cone-shaped adjusting screw responsible for adjusting the idle speed. By tightening the screw, you can slightly adjust the position of the shaft and the damper installed on it, thereby increasing or decreasing the idle speed, slightly opening or vice versa closing the damper.

Mechanic at home: adjusting the carburetor of a chainsaw with your own hands

Any internal combustion engine requires periodic maintenance, It doesn’t matter if it is the engine of a simple moped or a powerful multi-ton tractor. Such a tool as a chainsaw was no exception. After all, it is equipped with a single-cylinder two-stroke internal combustion engine, which also requires serious maintenance, although it is much easier to perform the necessary actions here. In today’s article we will talk about how to adjust the carburetor of a chainsaw with our own hands, find out how difficult it is, and figure out whether you need to be a professional mechanic to do this kind of work.

How does the carburetor of a chainsaw work, on what principle does it work

Modern car engines are no longer equipped with a carburetor. Meanwhile, before, almost every driver knew how to adjust it. Today, chainsaws with injection engines have already begun to appear on sale, but the carburetor models will hold the palm for a long time, because their cost is 5-15 times lower than in the modernized version.

The carburetor consists of several main parts:

- Aluminum body;

- Diffuser and air damper at the inlet;

- Nozzles (valves for adjusting the fuel supply);

- Sprayer (it is he who provides injection)

- Fuel (float) chamber.

The principle of operation of a chainsaw carburetor is quite simple. Fuel is supplied continuously, and its quantity is regulated by a jet. Air enters through the air damper due to the air vacuum generated by the piston. The diffuser mixes fuel and air. It is this fuel-air mixture that enters the cylinder, forcing the engine to work.

Determining the need to adjust the carburetor on a chainsaw

Before you start adjusting the carburetor on a chainsaw, you need to make sure that it is generally required. It would seem an absurd phrase. However, in 90% of cases, when an inexperienced craftsman considers such an action necessary, the unstable operation of the instrument is associated with other reasons, including:

- Problems in the fuel lines and the filter. blockages, depressurization;

- Exhaust system malfunction;

- Clogged or damaged air filter;

- Unstable operation of the ignition system;

- Violation of the tightness of the engine crankcase.

Only if these problems are excluded, and the engine is unstable, it is safe to say that carburetor adjustment is required.

How to sharpen a chainsaw chain: tooth configuration and sharpening angle, templates and tools for sharpening, the frequency of the procedure; how to sharpen a chainsaw chain at home with a file, using an angle grinder, on a machine, additional recommendations.

How to adjust the carburetor on chainsaws

To understand how to properly adjust the carburetor on a chainsaw, you need to see it, and then suggest it to the reader Pay attention to the example below.

To make the adjustment, you only need a slotted screwdriver, however, it will NOT be possible to fine-tune the carburetor without a tachometer (of course, if the person is NOT a minder or a professional driver with experience). Now let’s try to understand how to adjust the carburetor in a given situation.

How to set up a chainsaw carburetor if it won’t start at all

Quite a common problem in cases when a “master” from the “I know everything” series tries to get into the settings with his hands, growing NOT from the shoulders. In such cases, there are standard screw positions from which you can “dance” further. First, you need to completely tighten both screws (do not overdo it). Then Unscrew:

- Screw L. one turn;

- Screw H. one and a half turn.

As for the idle screw, the throttle must first be completely closed (screw T removed). After that, it must be turned one and a half turns clockwise and try to start the engine. If it did not work out, it is gradually added by a quarter of a turn before starting. When the engine starts to work, the position of the idle screw is adjusted so that the GIS is not GLH, but the chain is still in place.

Machine for sharpening chainsaws: selection criteria, design features, technical and operational characteristics of equipment, the principle of operation of manual and automatic devices, an overview of popular models of sharpening installations.

How to correctly and accurately adjust the carburetor: Step by step instructions

In order to make the information easier to perceive, we propose to consider it on the basis of photo examples with a description of actions in tabular form. The basis is a chainsaw with Initial settings.

Read more You can get acquainted with the master class on adjusting the carburetor of a chainsaw in this.

Device and principle of operation

Before starting the adjustment, it is recommended to study in advance the device of the chainsaw carburetor. Most often, it does NOT depend on the model, the only exceptions are Chinese-made chainsaws. But you can always spy on the instructions.

It is important that the proportions are observed, otherwise there is a risk of engine failure, which may be manifested by excessive fuel consumption or a complete stop of the device.

The main parts of a gasoline saw carburetor are:

- Tube. performs the function of air transfer, portioned supply is possible due to the presence of a damper;

- Diffuser. this part is located directly in the inlet, through which fuel is supplied, capable of accelerating the air flow;

- The atomizer is capable of injecting gasoline into the created air stream;

- The float chamber is a cavity that serves to maintain the fuel at the same level, from which gasoline is fed through a nozzle to the sprayer.

The principle of operation of a chainsaw carburetor is simple. Its structure allows air to pass through the tube, while the speed can be controlled by a damper. After the tube is open, the float is activated. This causes the air to pass through the diffuser and mix with the fuel. Then this mixture moves into the cylinder. Due to the difference in pressure (in the chamber with the float, it is almost equal to atmospheric, and in the tube it is rarefied), the fuel is sucked into the tube, and the more there is, the greater the speed of the chainsaw engine.

Carburetor repair and cleaning option without the use of repair kits

In some cases, the following method gives excellent results. Take out the carburetor, remove all the membranes (top and bottom), and then leave what is left to soak in acetone for several hours. Often, foreign objects and substances simply get into the jets and channels (sometimes, for example, traces of sealants are found there!). Therefore, simple cleaning has an excellent effect. No costs and no membrane changes. Although the decision to replace them must be made locally, guided by their condition.

The procedure and sequence for disassembling and adjusting the carburetor of the Stihl 180 chainsaw

Distribution chamber

In the distribution chamber, as in the fuel pump, there is also a membrane that opens and regulates the fuel supply by pressing a special rocker, while raising its needle valve.

The cover of the chamber is the compensator body, which is attached to the carburetor with four screws, a gasket is installed between the body and the cover, which increases the height of the chamber and is responsible for sealing.

Frequent breakdown of the Stihl carburetor and how to avoid it

A common prerequisite for the failure of a carburetor on a Stihl chainsaw is a sticking valve in the nozzle. The reason for sticking is a violation of the storage of the chainsaw, or rather the instructions of the manufacturer Stihl 180 for proper preparation for storage.

As follows from the instructions, before long-term storage, it is necessary to drain the fuel from the tank, after which it will start dust and burn the gasoline from the carburetor. Failure to comply with this elementary rule entails the following consequences. The forksnuy valve, being in direct contact with the fuel, sticks to the body, since the gasoline evaporates little by little and only sticky oil remains. It is impossible to replace the nozzle, because they are not in the repair kit, you can only try to knock it out and rinse it, which is not always possible to do, but without damaging the nozzle.

Stihl 180 chainsaw carburetor: DIY adjustment, repair, device

The Stihl 180 chainsaw (aka Stihl MS 180) is the most popular and recognizable model of the German brand. This chainsaw is simple and reliable in operation. The only knot that requires close attention is the carburetor. This article will cover carburetor adjustment, repair and maintenance.

How to remove a carburetor from a chainsaw

Before adjusting, you need to remove it from the Stihl chainsaw. For this you need:

- Return the retainer to the left to remove the cover.

- Remove the filter, for which Unscrew the two nuts that hold it. For ease of use, it is recommended to use special screwdrivers with suitable bits.

- Remove all rods, including the carburetor lever.

- Remove the carburetor and then disconnect the fuel hose.

It is recommended to remember the location of the parts, so that you can then put the carburetor in place and at the same time there are NO extra fasteners or distortions and cracks.

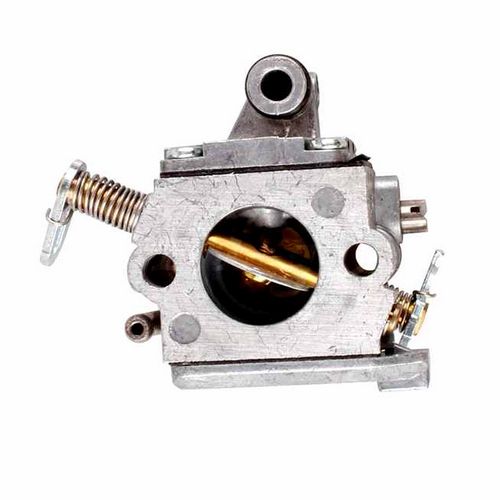

What carburetor is used on the Stihl 180 Chainsaw

The Stihl 180 Chainsaw is equipped with a Japanese membrane-type Zama carburetor. Some users are confused by the China carburetor inscription. Yes, indeed they are going to China. But the plant is owned by Stihl (Stihl), and the quality is still high. However, there are also Chinese copies in chainsaws with corresponding carburetors. But these saws are usually cheaper than the original.

Stihl 180 carburetor device

So, the stihl ms 180 carburetor is developed and manufactured by a subsidiary of Stihl called Zama. Original Carburetors, on their body have a company logo that guarantees product quality.