DIY tiller cultivator dimensions

Hiller

To make it, we need a couple of ordinary metal pot lids (enameled ones, in this case, will not work). Their diameter should be about 500 mm. Next, we sharpen the edges of the covers on a grinding machine so that they better enter the soil.

The disc hillers must be attached to a homemade cart with wheels. They are made from ordinary bushings and pipes welded together.

Attachments for tillers and motor-cultivators, homemade products of which you can completely make yourself, are of various types:

- Weeding equipment.

- Potato diggers and potato planters.

- Snow blowers, etc.

Engine

- Gasoline 4-stroke engine. This engine is used for units belonging to the light and middle class of devices.

- Diesel 4-stroke engine. This type of motor is used on heavy and powerful chillers, designed to work on the most difficult terrain.

About the tiller device

Next, you will find out which tiller is better to choose. To make it clearer what the principle of home-made tiller and its additional components consists in, you need to consider in detail the tiller device itself as a means of small mechanization. So, this unit includes several main working units:

- The main driving force, i.e. engine.

- Transmission.

- Chassis.

- Basic controls.

DIY tiller tools

I would like to start the analysis of homemade products with the direct manufacture of tillers with our own hands. This does not mean that we will make the unit from scratch, because it is technically impossible for home conditions.

The main working units will be taken from other equipment, we just have to prepare a certain base on which it was possible to successfully connect all the tiller’s organs.

I would like to tell you about diesel tillers on 4 wheels, the homemade of which will be discussed later. In essence, these units are similar in appearance and in their technical data to full-fledged mini tractors.

To help farmers, companies produce a variety of special equipment to facilitate the work and maintenance of the farm. Here is everything about the device and characteristics of the Piggy grain crusher.

Millions of people in our land are engaged in gardening and farming. Garden cultivators. save your time, health and strength.

Those who have their own household should find out what the milking process is like with a milking machine. Click on the link to get acquainted with the milking machine AID 2.

The only difference is that the tillers do not have a differential lock, but otherwise they are very similar. both the presence of the driver’s seat, and the steering, and the presence of two pairs of wheels.

It is clear that the alteration will be based on the addition of several additional units to the existing tiller. an additional frame to the second pair of wheels, the installation of a steering wheel and a seat, under which the speed control should be located, etc.

The finished version costs about 120 thousand rubles, so not everyone has the means to purchase it. Here homemade production becomes expedient, which is gaining popularity every year.

For more details on the operation of a diesel tiller, see

Of course, 2-stroke engines are also found in the configuration, but they are used in rather old tiller models, significantly inferior to 4-stroke ones in terms of power thrust. However, most consumers get exactly 4-stroke gasoline engines. Their device includes the following systems:

- The system responsible for the supply of fuel. Consists of fuel tank, carburetor, air filter and fuel hose.

- Lubrication system that lubricates those parts that rub against each other.

- Starter for crankshaft cranking.

- Cooling system that removes heat from the engine block using airflow.

- Ignition system that produces a spark at the spark plug.

- Gas distribution system, which ensures the flow of the air-fuel mixture into the engine cylinder, and is also responsible for the exit of exhaust gases.

It is important that the engine is already sold with all the main working systems, which greatly facilitates the process of making a homemade tiller.

Basic controls

The tiller control is located on the handle of the unit, responsible for changing the speed and direction of movement of the device. Among the controls are:

- Levers, steering wheel and speed switches.

- Clutch control.

- Lever or engine stop button.

- Gas supply, etc.

In the design of the tiller there is no seat for a person (as in the tiller Salyut), therefore the control itself is carried out by a person with his own hand.

Chassis

The undercarriage includes not only the wheelbase itself, but also the frame structure to which these wheels are attached, and where the main working units of the tiller are located.

In more modern tiller models, a change in the distance between a pair of wheels is provided, which allows you to adjust the size of the tiller track.

Today, there are two types of wheels. pneumatic and metal with grousers.

Benefits

Creating a plow for a tiller yourself has certain advantages. The parameters of the share and blade will meet all the requirements for the processing of a particular type of soil. These parameters include:

- blade angle;

- quality and depth of plowing of the land;

- capture area;

- efficiency.

Considering the power of the tiller, it is possible to make a plow that will not cause excessive loads on the engine and slip, but at the same time will have the maximum grip. It is necessary to use only high-quality materials, which will make it possible to significantly increase the life of the plow. It is also possible to provide for the attachment of various attachments, which will significantly expand the functionality, making it possible to achieve a full range of land cultivation.

Manufacturing and fastening of plow working elements

The main elements of the single-body design are the blade and the share, for the creation of which durable sheet steel with a thickness of 3-5 mm is required. First of all, a ploughshare is made, for which it is worth using an old disc from the “circular”, since it is made of high-strength steel. To sharpen the cutting edge of the share, it must be beaten off on the anvil.

Next, you need to make a dump from a metal pipe with a diameter of 50-60 cm and a wall thickness of about 5 mm. A template is created from cardboard or thick paper, which is applied to the metal and traced around the entire contour with chalk. Then, according to the lines obtained, a workpiece is cut out by gas welding, which is brought to the required size using an “angle grinder” or a hammer and emery.

Plow design

There are several types of plows installed on the Neva tiller, and each of them has its own design features. Currently, single-hull, rotary and revolving structures are used to cultivate the land on personal plots.

The single-body plow is the most popular design and a large number of drawings of this particular variety can be found on the net. In addition, it is considered the most optimal option for those who do not have the appropriate skills.

The most difficult to manufacture is the rotary plow design. It looks more like a cultivator, since not one, but several plowshares are provided, fixed on one axis. In the process of cultivating the land, the axis is scrolled, due to which the soil layer turns over. The advantage of the design is that the soil can be cultivated to a depth of 30 cm with little effort. In addition, the rotary plow allows you to plow the area along different trajectories.

Video of this plow

Plow coupling

Tiller hitch parsing

The hitch is an important structural element that ensures reliable fastening of the attachments with the Neva tiller. The most popular option is the U-shaped mount from the channel, and which is installed under the wheel of the tiller.

When creating the hitch, you will need to drill holes for attaching the bracket and mounting pin. The bracket for attaching to the tiller is either at the top or at the bottom, so as not to interfere with hanging.

Plow shank attachment

To secure the plow stand, 31×16 mm holes are drilled or cut out on both sides in the wide part of the pipe that was used to create the frame. Through holes of 10.2 mm are also made in the narrow walls of the frame for fastening, using M10 bolts, a handle.

The plow arms must be made separately from a pipe, about half an inch in diameter. You can use an old water pipe, which needs to be flattened with a sledgehammer on both sides. Drill holes with a diameter of 10.2 mm in the planes obtained and fasten them to the frame with bolts. To give greater rigidity between the handles, weld the cross member.

How to make a plow for a tiller with your own hands? just use our drawings and photos

Description of assembly work

First of all, you need to make a frame for which you can take a metal pipe with a cross section of 52×40 mm and a wall thickness of about 7 mm. For the fork, it is necessary to cut off the wide sides of the frame located opposite each other. Further, mark the middle on the frame, where the transverse traverse will be installed, as well as welded struts, to which the drawbar is attached.

In the front of the frame, at the beginning of the fork, there is a hole that is welded tightly to avoid dirt.

How to make a cultivator for a tiller with your own hands. The main stages of creating a cultivator and the importance of their indispensable observance

How to assemble a cultivator on a tiller with your own hands? This lesson is quite simple for those who have the skills to work with similar devices and understand their design. To further simplify the work, there is a certain structure, implying a breakdown of the entire process into certain stages, different in their purpose and functional performance. These subsections look as follows and characterize the entire procedure for creating a device in the best possible way:

- drawing up a plan for the future device;

- collection of the necessary tools;

- assembly of the device.

A home-made cultivator, assembled in accordance with these criteria, will have the best qualities and will become an indispensable assistant both in the summer cottage and in your own garden.

At the same time, a self-made device will be convenient and practical, since in the process of assembling all the parameters and design features should be performed based on your own anthropometric data, in addition, based on your own preferences and desires.

Cultivator for Tiller Neva. Equipment for plowing land

Most often, a motor unit is bought to be used as a motor cultivator for performing the most difficult work on the earth: autumn plowing and cultivation of the fertile layer. Due to the very high torque at the output of the power reducer of 7-10 hp. enough to process even loamy or saline soils in several passes.

To restore the soil structure, the manufacturer offers the following tool options for work:

- The plow for the tiller neva with a hitch is most often equipped with a standard or universal design of a hitch with a frame. the tiller allows you to plow medium-weight soil, roots and young growth of trees;

- Cultivators and cutters for the tiller “Neva MB 2” allow for deeper and more thorough plowing of the soil, chopping down weed roots, turning the remains of vegetation into mulch, using the tiller as a multicultivator.

In addition to the single design, there are paired plows that allow processing with a pair of cutting edges with a dump of soil in two rows, as in the photo. But it is recommended to work with such serious devices on motor units “Neva MB 23” or “Neva MB23SD”.

You should not expect to plow virgin soils with a tiller, medium-heavy soil with a large number of roots and weeds, as a rule, “too tough” even for heavy MB 23 tillers. The Neva was created to work on already plowed soil. In this case, milling cutters, cultivators and plows work great.

On salt marshes and clay soils, the lug rotation power and their weight are not always enough to plow the compacted soil layer. Often, the hooks are welded with additional weights, for example, flywheels from trucks, which lowers the tiller’s center of gravity, makes it more stable and makes it 20-25 kg heavier. The width of one lug wheel is 210 mm with a diameter of 460 mm.

With the help of a nozzle on the motor unit of the hiller, it is possible to quite successfully loosen the soil, both before planting and to remove weeds in the rows between plants. But it is quite difficult to work with such a device; knowledge of the specifics of the instrument setting is required.

Disadvantages of MTZ tillers

- High cost compared to analogues from other manufacturers;

- Fuzzy gear fixation (as noted by the owners);

- The need to apply effort to switch the differential;

- Compulsory running-in before use.

- The weight. It can be attributed to the advantages and disadvantages at the same time, because with such tillers it is rather difficult to manage on wet soil.

Tiller cultivator

Cultivator for Tiller Motor Sich photo

Tiller mounted, tiller cultivator.

A cultivator for a tiller, this is an attachment for cultivating the land.

Cultivators are used for continuous tillage before sowing and for cultivating crops, loosening, weed control, moisture conservation, hilling.

The difference between a cultivator and a plow. the cultivator performs loosening without turning the soil layer.

Cultivators consist of a cultivator rack and a cultivator arrow photo.

- flat-cut duckfoot cultivator share

- universal cultivator share

- loosening rigid cultivator share

- loosening spring cultivator share

The arrows of the cultivator paws are made of steel grade 65G, when sharpening the cultivator arrows, the metal must not be overheated.

Cultivator

It is also possible and necessary to harden the cultivator arrow, heat it. For hardening, the paw is heated to 820 ° (light cherry red heat), after which the arrow is cooled by lowering it into an oil bath. After cooling, the cultivator arrow is released, that is, heated again to 400 ° (gray tarnishing) and slowly cooled in air.

After such operations, the file does not leave any trace on the cultivator arrows and the cultivator paws normally perform their work on tillage.

Do-it-yourself flat cutter for a tiller: a simple method of manufacturing

If the tiller has quite impressive characteristics, it is advisable to make several flat cutters and place them on the device. Thus, an even more productive unit will be obtained, which will not only save time, but also energy.

For excellent cross-country ability of the created plane cutter, you need to take care of the appropriate wheels. Almost any material is suitable for them. An iron tube is an excellent choice as an axis.

Then, on both sides of the concrete cutting, it is advisable to weld two circles. Several wires must be attached along the diameter (using a welding machine), the diameter of which does not exceed 8 mm.

On the axis from the inside, it is necessary to leave room for placing the bearing and further installing the homemade flat cutter. Since the tiller body is not always made of a very durable material, the main focus is on the axle. After the bearing is attached, a plate should be welded to it.

Plier cutter knives can be crafted from split sections of the mower. Their lightness and compactness make them ideal components of the cutting element. It is important to make sure that they are securely fastened, otherwise the structure will walk from side to side and not perform its task efficiently.

Small wheels are often used to limit the immersion depth. An excellent “donor” can be a standard children’s car.

The wheels themselves can be supplemented with iron parts so that the plastic does not deteriorate while driving. The immersion depth must be at least 5 cm.

Any part of the weight can be welded on to increase the weight on the cultivator cutter and increase the pressure to enter the soil. In the case of a lack of necessary components, you can use a basket with bricks, but such a solution is not very convenient.

For a better understanding of the design features, it is suggested that you familiarize yourself with the drawings. The videos presented can also become a guide, because on these materials many craftsmen share their experience with users and reveal the secrets of creating truly durable and reliable attachments for a tiller.

It is worth noting that the created plane cutter is suitable both for Neva tillers and for equipment of the Centaur, Salut and others brands. The versatility of the product allows you to create a truly excellent assistant at home and without special financial costs.!

- Do-it-yourself cultivator for a tiller drawings and dimensions. How to make a tiller cultivator

- Cultivator for a tiller do it yourself drawings. DIY manual cultivator

- Homemade cultivator for a tiller with your own hands. For mini tractor

- How to make a cultivator for a tiller with your own hands. The main stages of creating a cultivator and the importance of their indispensable observance

- Tiller cultivator

- Do-it-yourself cultivator for the tiller. Do-it-yourself flat cutter for a tiller

- Flat cutters on the tiller: advantages and disadvantages of operating the device

- Do-it-yourself flat cutter for a tiller: a simple method of manufacturing

- Cultivator for MTZ tiller. Description

- Cultivator for Tiller Neva. Equipment for plowing land

- The cultivator before the tiller is self-propelled. What is a tiller

Homemade cultivator for a tiller with your own hands. For mini tractor

To make a homemade cultivator for a mini tractor or for a tiller with your own hands, you need metal plates, square. 1515 centimeters in size, rectangular. 254 centimeters and a steel pipe. You need to start making a cultivator with cutters.

In order for the cutters to be reliable and suitable for processing all types of soil, and not only loose chernozem, they must be assembled with bolts. holes must be drilled in the blanks, the number of which depends on the size of the metal strips, which will serve as blades.

The longer their length, the more holes are needed in order to securely fix them. Further, the strips are fixed on the workpieces, overlapping each other in a circle, and clamped with bolts.

Welding can also be used for these connections. but in this case, they will not be strong enough, and repairing and replacing the knives will be a difficult process. Welding is used here to connect the cutters together. For this, holes are made in the workpieces, the diameter of which must correspond to the outer diameter of the pipe.

The cutters are put on over it and fixed with tacks, or short seams. This product can now be put on the shaft of a mini tractor and used as intended.

How to make a do-it-yourself mounted flat cutter cultivator for a tiller

It’s good to have a house in the country.

You rummage and rummage all your free time in the garden, in the land. Something turns out, but even more I want to plant, grow with my own hands. And how amazing these plants are: you treat them with kindness and soul, and they immediately respond to it. And everything would be fine if not for the weeds. Fighting them can drive an unprepared person crazy. But this must be done in any case. The question is how exactly.

Long and difficult. Flat cutter? There are doubts.

And now, on the basis of trial and error (or, more simply, by typing), I approached the creation of a universal flat cutter-cultivator, on which you can easily and naturally install various devices for cultivating the land.

To do this, you only need to loosen four bolts with a diameter of 10 mm using a 17 × 19 wrench, remove the nozzle, put another one and tighten the bolts again (in fact, the whole structure is perfectly visible in the figure). Previously, of course, each such replaceable nozzle must be set to the desired height or depth.

To create a universal flat cutter, materials were used that can be found in any shed. For example, the spokes in the wheels can be reinforced with nails or wire 6 mm in diameter (after all, working in the ground requires a certain margin of safety for all parts). And forks for the same wheels (by the way, I took them from an old baby carriage) can be made by ourselves from a pipe with a diameter of 15 cm or a pipe with a square section of 20 × 20 cm.

But the steering wheel was used from an adult bicycle, but you can easily make it out of a pipe, if that.

It is mounted on the cultivator in such a way that it can be easily adjusted to suit your height using two 6 mm diameter bolts. I constructed a plow for planting potatoes, hilling and weeding row spacings from the boom of a conventional cultivator, to which I welded the sides. The angle of the rack in it was made at 90 ° in relation to the ground.

And again, such a plow can be made on your own if you wish. over, in combination with a device called “digger”, it helps out great when digging up potatoes.

For this, a hitch is placed on two wheels.

x and is adjustable to the width of two furrows (approximately 65 to 70 cm). I dig potatoes across the row. It is more convenient to choose it after that. Yes, and before planting potatoes, I loosen the ground with my universal device.

I also have a device for trimming a mustache on beds with strawberries: vertical stripes to the bottom are sharpened under a knife on both sides.

They are adjustable to the width of the row and are used in tandem with a hitch. After that, I put one wheel and a narrow rake on the cultivator: the aisles are loosened, and the mustache overgrowth is removed. For the same work, you can use rollers with a flat cutter.

For cutting furrows in the beds, I use a device where the row spacing is freely adjustable. On my station wagon, you can install any rollers and flat cutters of various widths, as well as a rake. This machine justifies itself, and even very much. It’s quite simple to manufacture: a little skills, an angle grinder, welding and improvised material, metal.

I think many will be interested in my proposal. It is a pity that there is no camera, I had to paint.

I will add: the corner of the weeding tool itself is the most obtuse.

The width of capture for any garden bed is from 15 to 40 cm. The steel strip is thick (spring from the old “Moskvich”) plus the steering column torsion bar from the “Zaporozhets”. It is welded at a slight angle to the ground. The angle grinder is sharpened from the top side, front and back. That’s all.

I did this technique to my brother and neighbor. A friend of mine has already assembled it according to my drawing: they say that neighbors went to him all day to look at this miracle.

In general, the owners of the station wagon are in seventh heaven. They unanimously say that they have lived on earth in vain for half their lives without such a unit. The vegetable garden weeds very quickly! Therefore, I propose. Whoever takes an interest and makes such a station wagon will thank himself. Well, dear summer residents, good luck in the garden!

With your own hands. How to do it yourself

Universal homemade flat cutter cultivator: drawing

© Author: V. Khudobin Belgorod region.

How to do something yourself, with your own hands. home master’s site

CULTIVATORS OWN HANDS REVIEWS AND TIPS: READER REVIEWS

Do-it-yourself flat cutter mounted cultivator for a tiller (drawing)

ADVANCED CULTIVATORS

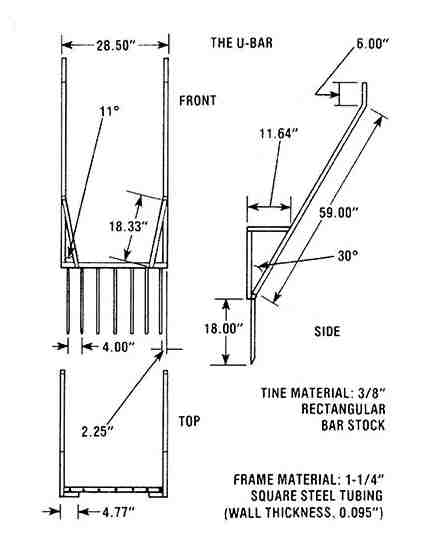

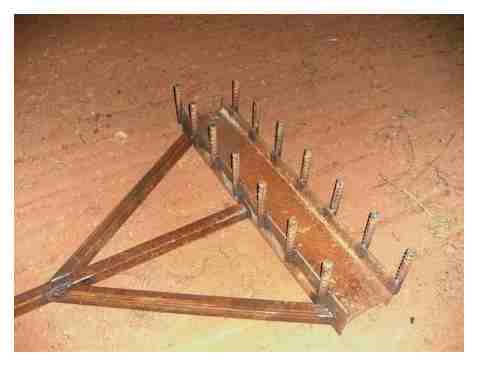

Variants of cultivator designs (Figures 1-3) performing several operations at the same time.

The cultivator shown in Figure 1 loosens the soil to the depth of the pins and chops the weeds with disc blades. U-blade cuts soil and weed roots.

The cultivator shown in Figure 2 loosens the soil to the depth of the cone knives, moves the soil to the side and chops the weeds with the disc knives. U-blade cuts soil and weed roots.

The cultivator shown in Figure 3 cuts the soil to the depth of the disc blades and chops the weeds. U-shaped knife cuts soil and weed roots.

When the cultivator is turned 180 ‘relative to the fork in the vertical plane, the U-shaped undercutting knife is removed from work and only the remaining operations are performed.

Figures 1 and 2 show the diggers. The designs provide for the adjustment of the depth of the holes from max = 12 cm to min by turning the fork with paired wheels. In the construction in fig. 2 added a plow for throwing mulch and soil to a depth of 5 cm. In this case, the excavator is used as a marker, and the seeds are placed on a solid substrate of soil. Backward on the bed, one of the side wheels closes the holes or presses the seeds into the soil. The angle adjustment of the paired wheels determines the depth of the holes.

Installing the hitch on the tiller

The hitch brace is installed on the tiller bracket, and is secured with pins. It is advisable to fix the hitch bracket with M12x60 spacer bolts, swivel to the tiller frame.

Do-it-yourself hitch to the tiller, photos, drawings

One of the important components of the units, which ensures a reliable connection of the trailed equipment with the tiller, is the hitch. There are different types of hitch assembly. However, the most commonly used is the U-shaped tiller hitch assembly. This unit is manufactured both industrially and independently. If a do-it-yourself hitch is made to the tiller, it must be strong in order to be able to withstand heavy loads.

Do-it-yourself hitch to the tiller

The U-shaped mount is at the heart of the tiller hitch, therefore, to make it, a channel of suitable thickness and size is perfect. This mount is located under the tiller’s handlebars.

When making a do-it-yourself hitch mount, you need to drill several holes in order to fix the bracket and the mounting pin in them. Therefore, the holes must be of the correct diameter. The pin also needs to be made of high strength steel.

You will need a bracket to attach additional accessories to the tiller. The long end of the bracket should be either downward or upward to avoid interference with connected equipment. In this case, the end of the bracket should not touch the surface of the soil that we are processing.

When making a homemade hitch assembly, we used a standard sample. Often, additional devices are used for the tiller, with non-standard types of coupling. To connect them to the tiller, you either need to purchase a special adapter, or make an adapter yourself. As a rule, these are U-shaped brackets.

Attaching the implement to the hitch

A removable hitch axle must be installed on the implement rack bracket.

Insert an axle with an M16 thread into the hole in the hitch body and screw a screw into this thread.

It is necessary to match the holes for the M16x40 bolt on the tool stand and on the hitch body. Then this connection is fixed with an M12 nut and an M12x40 bolt.

Tiller Hitch Drawings

Consider a drawing of a universal hitch for the following types of tillers: “Pubert Quatro”, “Honda”, “AGRO”, “OKA”, “KASKAD”, “MB-90”, “NEVA”, “FAVORIT”, “SALUT”.

Purpose of the universal hitch in conjunction with the tiller of attachments: excavator, plow, one- and two-row hiller, etc.

Recommendations for work

Attached implements are individually configured and regulated, depending on the type of soil and the power of the tiller. The special design of the hitch can be adjusted in different ranges. Using the initial settings, you need to set the radius grooves of the hitch to zero, the transverse grip angle, and fix it with an M12 nut and an M12 bolt. Also set the longitudinal grip angle to a minimum. The first 3-5 meters of movement, carefully observe how the tiller works with the implement.

If you need to deepen or raise the implement, stop the tiller movement and adjust the implement by turning the screw handle. Then you can continue driving and evaluate how the tiller works with the gun. Also, if you need to adjust the transverse grip angle, you need to loosen the M12 nuts and M12 bolts.

Then adjust the angle in the required direction and tighten the nuts and bolts. Before starting work, all threaded connections must be tightened firmly. After the work on the soil has ended, the threaded connections must be cleaned and lubricated daily. To do this, use Litol 24.