Do -it -yourself electric saw chain replacement. Characterization of teeth

Installation of the circuit on electric saw

Not all modern chainsaws are equipped with a installation wheel, which significantly simplifies the installation procedure of a saw canvas. Systems with a installation wheel among household chainsaws are generally a rarity

Therefore, it is very important to know the technology and sequence of installation of the chain on the chainsaw

The main points should be paid to:

- Prepare a flat surface on which you will put together a chain and a tire. This will minimize the chance of damage to the chainsaw or loss of small details. A tire is laid out on the prepared surface and a chain parallel to the next parallel.

- Remove the protection of the sprocket, on modern chainsaws, it is enough to unscrew the lamb nut, on older models, you may need a unit key of the corresponding size.

- At the base of the guide tire, turn the stretch asterisk to the right to the right. Only in this position is the chain set.

- Then the chain sequentially the link behind the link is placed on the fixing groove on the guide tire. Install the chain from the top of the guide, gradually turn it so that the tire is always on top, and the chain from below, this will always be in a stretched state and go to the guide groove without problems. When you perform this item, be sure to put on thick protective gloves, because your fingers will touch the cutting edge. If you look from above, then the cutter is always located forward by the end of the guide tire.

- And put on the tire and chain on the leading star.

- Fasten the cover of the chain star in your place. Make sure that all mounting pins coincide with holes. Incorrect installation with distortions or not to the end may be the cause of extraneous noise, rattling.

- Make sure that the guides “go” into a special mounting gutter.

- After installation, check the fixation of the chain on the chainsaw and on the tire. Everything should be reliably fixed without backlash.

An important point is the degree of tension of the circuit after installing it. Setting the correct tension is very simple and will take no more than three minutes. First you need to loosen the nuts on the protective cover. Using a freely rotating adjusting screw, catch the correct tension so that the chain does not pull from the edge of the guide tire of more than 3-5 mm.

It remains only to tighten the nuts and control the tension. If you need adjustment, to set the tension again.

How to install a tire and a chain on a chainsaw, watch in the next video that presents a clear algorithm of actions:

Ways to check the degree of tension

Checking the degree of tension is an important point, since the consequences of incorrect adjustment can be fatal for the sawmill. The quality adjustment quality of the chain tension can be determined by:

- When moving the product manually, it should not seize or there are signs of the severity of its movement.

- The cutting element must be checked for the weakness of the tightening, for which to take up the link and try to pull it up. The normal value of the tension should correspond to the exit of the shanks from the tire (in its middle) no more than 2/3.

- In the process of moving the device, there should not be creaks and other extraneous noises.

In conclusion, it should be noted that the chain should never be adjusted to the hot, as this will necessarily lead to a number of negative consequences. As a result of such actions, not only the tire and chain, but also the leading star may be replaced.

How to replace the cutting part of the saw?

To sharpen the chain, use special tools. In such work, one should take into account the originality of the form of the teeth themselves

Taking into account the fact that one of the cutting parts has a slightly beveled, the device should be sharpened 2-3 times

The movements of the cutting part in contact with the ground blunt it. Understand that the saw should be sharpened, you can by the education of fine chips, as well as the rapid fatigue of the master with zero result of the work. How to shorten the circuit of the longitudinally located engine on the power plant Fiolent. To put the pointed base in order, you should prepare tools:

A file with a round base is used when taking into account the edge of the base of the teeth and the features of the metal in chain links

The edge of the file is important for high.quality sharpening of the edge. Correctly select the chain

The failure of the chain is not uncommon, so before asking the question of how to pull the chain on the chainsaw correctly, you need to know which chain. How to sharpen a chain of a chain of corner grinding, why sharpen a chain on a chainsaw. This device should be kept by observing the right angle in an upright position and 30 ° regarding the horizontal position. The holding is fixed on the tooth, and the device should be located as close as possible to it, which helps the file to be at the height necessary for work.

The start of the measures is associated with the moment of fixing the tire with smooth, irrevocable movements. How to pull the chain on. opilah.com. At first, the teeth looking in one direction should be updated, the opposite parts are trapped next. It should be noted that these small elements should experience the same number of files of the file.

The limiting deep device protects the template from washing, it should be installed in the cut part by applying additional tools. The moving mechanism is protected from grinding the depth limiter, which is not recommended to touch, you should not replace the links in it. Otherwise, the work of the saw may be violated. For this, special devices are used that allow sharpening with high quality, evenly processing the teeth.

By installing a wood cutting tool according to all the requirements, you can significantly reduce costs, make the event itself safely and comfortable. Cutting natural breeds will be carried out without unnecessary problems.

Alteration of the electric saw

You usually think about the modification of the chain saw when something is missing. For example, a milling apparatus. This will need:

The procedure is such. Weld the wheel at the end of the base of the boom, cutting off the arrow so that the wheel accurately enters the cut circuit to prevent the tension or weaken the chain. A removable adapter is attached to the wheel to the wheel.

We hope that, having read the information briefly presented in our article, you can independently eliminate the small malfunctions that have arisen and operate this tool as a confident user.

What are the electric saws. types and description

Nowadays, electric cars are used not only for working in the garden, but also as assistants in performing various household, repair and construction tasks. Depending on the area of application and functions, such types of electric saws are distinguished:

- Chain saws. tools of this type are used for giving for trees care and harvesting the required number of firewood for heating. The working element of such saws is a saw set, which includes a tire and a chain. The market also presents tape garden electric saws, the working body of which is a steel tape instead of the chain. If necessary, to work with chain and tape tools, you can use various nozzles for electric saws that will allow you to cut metal or foam concrete;

- circulation electric saws. among their main advantages, the maximum accuracy of the saw. Thanks to this, circulation saws are often used for home for the manufacture of various wooden and metal parts. Tools of this type can be used for cutting wood, metal, polyvinyl chloride and other materials;

- Lobzic electric saws. tools of this type are intended for accurate curly cutting of laminate, wood, PVC pipes and metal. Among the features of such electric saws, high fluctuations in the cutting part should be distinguished. Thanks to this, when using electrolobsics, longitudinal and transverse cutting of materials can be performed;

- Sable electric saws. equipment of this kind allow you to carry out repair and cutting in hard.to.reach places. Sable electric saws can saw not only wood, but also metal or foam concrete;

- Electric hacksaws. equipment of this kind in shape and functions is very similar to the tools of the previous type. The only difference between them is that the hacksaws are more powerful and hardy, which allows them to be used to cut more solid materials.

Each of the listed types of equipment is presented on the market with models with different characteristics. Powerful tools are suitable for use in industry and construction, and small models with more modest indicators can be successfully used in everyday life.

Independent replacement of the saw chain

Elekid companies do not prohibit the replacement of the chain with their own hands, on the contrary, often complete new products with instructions for the repair and replacement of individual parts. You should start by buying a new chain.

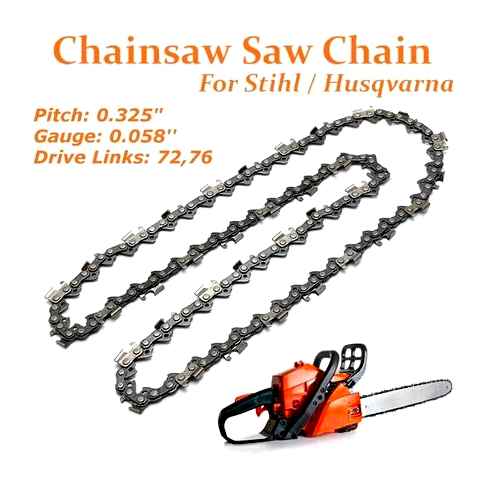

We check the circuit for compliance, that is, we study its characteristics: length (depends on the tire), the size of the step (relative to the stars), the thickness of the drive link

One of the common designs of budget saws is with lateral tension. To change the chain, we perform the following actions alternately:

- We pushing the protective shield, at the same time lowering the brake;

- rotate the control tension screw with a screwdriver, unscrew the nut, thereby weaken the tension;

- Remove the lid;

- separate the tire with a chain from the star;

- Remove the old chain from the tire, set the new one in its place;

- We perform actions in the reverse order.

Put the chain smoothly, without jerking. We finally pull it after closing the plastic cover with a screw and nut.

There are modern systems of non.closing chains, but many masters prefer a traditional side stretch, somewhat problematic, but proven and reliable

Modern electric spil models have the so.called lamb nuts for a soperative tension of the chain

Thanks to this element, the replacement process occurs faster. and this is important with large volumes of work. Dropping the brake, unscrew the nut and remove the lid

Having slightly pushing the tire back, remove the old chain, put on the new one. first on the asterisk, then along the entire length. Then install the asterisk in place, tighten the nut. We turn the tension wheel in the direction indicated on the case and finally tighten the “lamb”.

The last step is to check the chain tension. It should fit tightly to the tire with a released brake, but scroll under manual exposure. For a more effective check, it is recommended to drive the saw at low speeds

You can look at more than more about stretching the chain at

How to install a saw chain and tire

The installation of the chain provides for checking its tension after each tool dressing session. The poorly fixed part slides from the surface of the tire and injures the working. Examine the tension with their hands, protecting them with the help of mittens. In addition, new chains change their length during operation, so the check should be carried out very often.

Sometimes an important detail arises in the process: it is not possible to set the chain without additional heating and its corresponding deformation from the lower part of the tire. No working professional will disregard the tension of the chain in the chainsaw. Slightly pulling the caterpillar, he instantly assesses the size of stretching the chain.

The sound that appears at the time of the blow can be deaf and short. The tension of the caterpillar is carried out sequentially, performing several simple operations. Inspect the fuel valve. The worker needs to make sure that the fuel system is blocked. You can remove the candle wiring or open the decompression valve. Elekpila plug is pulled out of the outlet.

The chain is turning in the direction of its rotation during operation. The chain tension defects are visually visually: the lower sagging of the caterpillar is formed. Control is carried out by adjusting the circuit through certain time intervals.

In the upper part of the tire there should be a constant supply formed when the circuit is delayed. With very strong pulling, the caterpillar barely turns and quickly stops its movement. It is not allowed to adjust the circuit in the working position. Such negligence leads to the deformation of the tire or breakdown of the crankshaft. The trace of the caterpillar during operation is carried out without tools. The maximum cutting depth is mm, the weight of the cutting equipment is 9.4 kg.

It remains only to tighten the nuts and control the tension. If you need adjustment, to set the tension again

What is important to know: when the chain is in operation, due to the friction forces, its metal heats up and expands, and the length increases. Therefore, it is important to regularly check the tension and adjust it in time. How to install a tire and a chain on a chainsaw, watch in the next video that presents a clear algorithm of actions:

When removing the old or when dressing a new chain on the guide tire of the chainsaw, it may get confused

How to install a tire and a chain on a chainsaw, watch in the next video that presents a clear algorithm of actions:. When removing the old or when dressing a new chain on the guide tire of the chainsaw, it may get confused.

It can also happen when inaccurate transportation. When the chain is confused, it turns into rings. Due to insufficient flexibility in the transverse direction, it is very difficult to unravel it with naked hands, because when trying to unravel one ring, a new ring forms in another place in another place. It is necessary to put the chain of the chainsaw on the horizontal surface and spin the rings in different directions, while pulling the canvas in such a direction that the diameter of the rings increases.

Sooner or later, the chain will turn into its natural position. There is another way. you can flare up one link in the chain and straighten it, then connect in the ring and stuck the blurted links back. Many, even the most experienced chainsaw users, came across a situation in their life when the chain jumped off the guide tire during operation. The most common cause is the insufficient stretch of the circuit or its wear.

Although sometimes the problem appears due to the incorrect position of the asterisk relative to the axis of rotation or a certainly fixed saw tire on the chainsaw.

Chain. an important element of the chainsaw structure. It is on it that the greatest load is on the time, so high.quality and systemic care is required.

Now on sale there are many models of chains for chainsaws. Click to cancel the answer. Now they are discussing. A plastic border in the country is beautiful, practical and economical!

Using a car alternator with a bike to power my home? How much energy can I produce?!

Why the chain flies, find out the reasons

How the oscillation spindle machine works. How the oscillation spindle machine operates what is tableted salt and why it is used by a flat.grinding machine: the advantages and disadvantages of an eccentric grinder: the main points of vitamin greens at any time of the year: the garden on the windowsill how to choose the right electrodes when welding inverter.

How to choose a sandblasting apparatus for home use. We tell you how to repair an inverter welding machine.

How to properly put a circuit on an electric saw. stretch, adjustment

When performing an impressive volume of carpentry and agile work, a reliable electric saw is required, regardless of where the wood is cutting: in the house or outdoor air.

The quality and serviceability of the tool directly depends on the state of its main elements: chains and tires. Correctly put the chain on the electric saw is the main task facing the user, significantly facilitates subsequent operation.

Practical recommendations will help to perform this action even to those who have never done like that before.

The choice of chain

The electric engine circuit is the same important element as the engine. And its choice should be approached as responsibly as possible, this will help to avoid many problems during the subsequent operation of the tool. You need to choose a chain for electric saws, focusing on the following parameters:

- Compatibility with the electric saw model. Despite a large number of alternative options, it is best to purchase a part of the same company that produced the tool itself.

- The purpose of use. If the electric saw will be intended for household work at home or on a garden plot, then it is optimal to choose a part with a step of chain links 0.325 ”. With large volumes of work, a high.performance chain with 3/8 steps will be needed ”.

- In length, it should coincide with the length of the tire. Stretching or sagging of the part during long.term operation is eliminated by removing part of the links.

- With large volumes of work, it is recommended to use high.performance saw elements with a sharpening angle of 30 °. With complex processing, for example, wet or frostbitten wood, sharpening of teeth under 10 ° is used.

It is also important to consider the material with which it is planned to work, and the method of cutting it. So the circuits with a lower angle of sharpening are suitable for a longitudinal saw. Their performance will not be so high, but the operational period increases significantly.

The choice of tires for electric saws should also be very thorough. Pay attention primarily to the material: the stronger it is, the longer the part will last, without leaving the system. The following parameters are no less important:

- Length (distance between emphasis and toe). the larger this indicator, the larger the tree will be able to cut. Mostly used lengths 12-20 “.

- PAZ width. for household saws, parts with grooves up to 1.3 mm are used; 1.5-1.6 mm on a more powerful tool.

- Saar. determines whether the tire is suitable for a specific electric stove model. It is better to purchase a proprietary part, although the tailings of different manufacturers are often interchangeable.

Only with the correct selection of saw elements, the further operation of the electric saw will be effective, safe, not requiring additional cash or temporary investments.

Sharpening of teeth

Do not assume that Makita chainsaw will work efficiently for a very long time. The tree, even the softest, is a very strong material that causes a gradual erasing of cutting elements.

After a certain period, which depends on the operating mode of the electric saw and the wood of the wood, the chain will necessarily be dull, which means it will be necessary to sharpen it.

If the teeth are sharpened at the wrong time, then they may lose shape, and it will not be necessary to repair, but to replace the cutting element.

Manually

Most experts drag Makita chains with their own hands. Когда возникают первые признаки затупления звеньев, они при помощи напильника подправляют угол режущей поверхности. But at all, any tool is not suitable for this purpose. It is necessary to purchase a specialized set, which consists of such devices:

- flat file for high.quality correction of a link depth limiter;

- round file with special lines for a guide;

- caliber;

- mandrels for the exact determination of the angle of sharpening.

For high.quality sharpening, the chain must be left on the bus, which must be squeezed in a vice. The file used must correspond to the factory diameter of sawing teeth.

If a round file is used, then you need to ensure that it protrudes very little above the links. The very first tooth should be placed specially so as not to start sharpening it a second time. All movements should be very accurate, strong and only in one direction.

After sharpening a dozen teeth, it is necessary to carefully process the installed limiter, which may lose its shape. A special caliber is pressed to the edge, the front side to the installed limiter.

In cases where the limiter greatly protrudes beyond the caliber, then it must be corrected with a small file. The tool used must be kept perpendicular to the bus.

To find out the quality of the work performed, it is worth carrying out several trial cuts.

On a special machine

It is strictly forbidden to use a file for editing the cutting edge, because uneven grinding will lead to a fairly rapid wear of the chain. Produced devices for sharpening saw teeth can be divided into electric and manual.

The latest devices have a simple structure, and outwardly similar to an electric jigsaw. In order to quickly sharpen the chain with a manual machine, you need to fix the tire well in a vice, and then process all the teeth alternately.

Small weight, compactness and ease of transportation allow you to quite simply transport the machine to any distance when there is a need for this.

When using an electric machine, an electric current is necessary. In other words, you can not sharpen saw saws far from the power source. However, the quality of sharpening will be very high. In addition, electric machines have such useful functions:

- sharpening of various types of chains;

- adjusting the step of the cut and its depth;

- very accurate location of the limiter;

- adjustment of the required angle of sharpening.

Before starting work, you must definitely read the instructions and try to sharpen one saw tooth. Next, all parameters for a trial tooth are exhibited so that the rest exactly corresponds to it. This approach to work guarantees high.quality sharpening of teeth and greater performance of Makita electric saw.

Electric saw circuits: how to choose, replace and sharpen yourself

As in the case of chainsaws, the main working organs of an electric garden tool is a tire and a chain.

The operability of the chain power saw, the volume of fuel regularly consumed by it, as well as the quality of the cutting line, depend on their quality and technical parameters.

In order to constantly maintain stable work of the garden tool, its owner must study the rules for choosing, installing, maintenance and repair of the cutting headset. This will maintain the operability of the tire and circuit of the electric saw in the manner before the end of their operation.

How to choose a chain for electric saw?

To choose the best version of the cutting headset for a particular electric saw, the gardener needs to study several important parameters and chain criteria:

- length. must necessarily correspond to the length of the installed metal guide. Some novice users try to install shortened cutting organs on the tires of their tools, believing that over time they will still stretch and will stand tightly onto the tire. This is a big mistake, since the length of the guide and the new headset should be the same. If the chain sags as a result of operation, then it is easy to shorten by removing several links;

- The angle of factory sharpening. parts sharpened at an angle of 30⁰, are easier to carry increased loads. For regular work with frozen and raw wood, the headset with an angle of 10⁰ will be most effective;

- Manufacturer-so that the cutting body perfectly stands on the tire, you need to choose the products of the manufacturer of the installed guide and the electric saw itself. For example, for electric saws and tires manufactured by Makita, you need to choose the chains of the same manufacturer.

To choose a chain for the electric saw, the owner of the equipment must take into account the goals for which the cutting headset will be used. For the possibility of sawing relatively large wood, chains with 3/8 ″ steps are suitable. If the loads are low, then for installation on the power tool it is better to choose cutting sets with a step of 0.325 ″.

Installation of the chain

During operation, especially on impressive volumes of work performed, the circuit on the electric saw wear out and weakens. If you do not take care of its replacement in a timely manner with subsequent adjustment of the tension, the part can make the operation of the tool unsafe, for example, jumping right at the time of the saw.

To install the chain on the electric saw, its characteristics should be taken into account, in particular the type of tension in a separate tool. With lateral tension, the sequence of actions is as follows:

Fuel filter replacement stihl

- Lower the brake, pulling the protective bar towards yourself until a characteristic click is heard.

- Use the screwdriver unscrew the tension screw, weakening the tension of the circuit. The clamping nut will begin to rotate freely.

- Remove the old detail. Open the compartment where the saw elements are located, lifting the lid on the housing, and then remove the chain from the guides (stars), the tire will also have to be dismantled. When it is not possible to extract the details, you still need to loosen the tension screw.

- The interchangeable part is installed on top of the asterisk, you need to start from the upper section of the tire. After, focusing on the guides, insert back into the compartment.

Replacement may seem difficult, but it guarantees the reliability of the entire system, compared with tools equipped with fast.and.packed cartridges.

Change the saw element on electric saws with a quick tension system in this order:

- Remove the tool from the brake.

- Open the handle to the stopper.

- Rotate the lamb nut counterclockwise. This element serves simultaneously the cover of the cover and the guide clamp.

- Removing the guide protection, move the tire in the opposite direction. Release the driven star, remove the old chain.

- Install The entire length of the tire, starting with a sprocket, a new chain, so that the cutting edge is facing the housing of the electric saw.

- Using the control of the guide, set the tension.

- When the sprocket cover is installed, tighten the fastener, without tightening.

- According to the direction indicated on the case, the arrow rotates the stretch wheel, after which the lamb nut is tightened.

The process of changing the parts on a electric saw equipped with a lamb nut does not take much time, but allows you to quickly adjust the tension.

How to put a chain on a power plant correctly?

Most often, for the possibility of independent installation by the operator of a new cutting organ, a side tensioner is provided in the device device. To install a circuit on an electric saw with such a mechanism, its owner must perform the following actions:

- Lowering the brake lever, push the plastic shield of the operator’s protection with the second hand;

- Gently turn the built.in tension screw using a screwdriver;

- Unscrew the nut to weaken the tension of the cutting organ;

- Carefully dismantle the cover cover of the tool;

- Remove the metal guide from the asterisk;

- Dismantle the worn old chain;

- Put the chain on the guide and install the cutting organs back to the electric saw.

The tension of the electric saw circuit should be smooth, without jerking. To do this, slowly tighten the headset, install the protective plastic cover of the saw, and pull the saw organ with a nut and a screw.

Installation of the circuit on electric saws of some modifications is carried out using built.in lamb nuts, which allows you to quickly put and pull the headset. Replacing the circuit on the electric saw with this type of mount should be this:

- First, the operator will need to lower the brake lever, unscrew the fixing nut and dismantle the factory protective cover;

- Next, you need to push the guide back and carefully remove the old headset;

- After that, you will need to install a new chain, putting it on first on the asterisk, and then along the entire length of the guide;

- Then it remains to install a built.in sprocket in a regular place and tightly tighten the nut.

A step.by.step installation algorithm

Not all modern chainsaws are equipped with a installation wheel, which significantly simplifies the installation procedure of a saw canvas. Systems with a installation wheel among household chainsaws are generally a rarity. Therefore, it is very important to know the technology and sequence of installation of the chain on the chainsaw.

The main points should be paid to:

- Prepare a flat surface on which you will put together a chain and a tire. This will minimize the chance of damage to the chainsaw or loss of small details. A tire is laid out on the prepared surface and a chain parallel to the next parallel.

- Remove the protection of the sprocket, on modern chainsaws, it is enough to unscrew the lamb nut, on older models, you may need a unit key of the corresponding size.

- At the base of the guide tire, turn the stretch asterisk to the right to the right. Only in this position is the chain set.

- Then the chain sequentially the link behind the link is placed on the fixing groove on the guide tire. Install the chain from the top of the guide, gradually turn it so that the tire is always on top, and the chain from below, this will always be in a stretched state and go to the guide groove without problems. When you perform this item, be sure to put on thick protective gloves, because your fingers will touch the cutting edge. If you look from above, then the cutter is always located forward by the end of the guide tire.

- And put on the tire and chain on the leading star.

- Fasten the cover of the chain star in your place. Make sure that all mounting pins coincide with holes. Incorrect installation with distortions or not to the end may be the cause of extraneous noise, rattling.

- Make sure that the guides “go” into a special mounting gutter.

- After installation, check the fixation of the chain on the chainsaw and on the tire. Everything should be reliably fixed without backlash.

An important point is the degree of tension of the circuit after installing it. Setting the correct tension is very simple and will take no more than three minutes. First you need to loosen the nuts on the protective cover. Using a freely rotating adjusting screw, catch the correct tension so that the chain does not pull from the edge of the guide tire of more than 3-5 mm.

It remains only to tighten the nuts and control the tension. If you need adjustment, to set the tension again.

What is important to know: when the chain is in operation, due to the friction forces, its metal heats up and expands, and the length increases. Therefore, it is important to regularly check the tension and adjust it in time.

How to install a tire and a chain on a chainsaw, watch in the next video that presents a clear algorithm of actions:

How to adjust the tension of the chain correctly

Pull the chain on the saw in the following cases:

During operation of the electric saw, the circuit should not be sagged. It also cannot be pulled over excessively. A sagging equipment can jump off the tire and damage it. A strongly tattered equipment can break off or lead to a quick failure of the stars and stirring up the tire.

This Guys So Strong, No One Can Beat Him

Advice! The tension can be proceeded only after cooling the chain. If this recommendation is ignored, then the equipment begins to compress and deform the tire when cooling.

To tighten the chain on the unit, you need to do the following.

- Release a screw or a nut that fixes the tire (depends on the model of the unit).

- Using the adjusting bolt, enhance the tension of the equipment. The correctness of the equipment tension is checked in a simple way: pull the chain in the center of the tire and look at the leading link. Normal 1/3 shank (its top) should not leave the groove of the tire.

- Having achieved the correct tension, tighten the clamping screw (nut).

How to adjust the tension of the chain correctly

The level of tension of the electric saw chain directly affects the safety of the tool, efficiency of work, service life. Checking the tension level is very simple: closer to the center of the tire, take a tooth of a saw element, pulling it upstairs. With a normal tension of 1/3 of the tip should remain inside the seat, and the chain can be calmly rotated manually.

Different models of electric saws have a chain tensioners in the form of a lamb nut or screw:

- Adjusting on tools equipped with a fast tension system is carried out by rotating a special wheel located under the sprocket shield. Rotation clocks the saw element clockwise, against it weakens. With the help of such a mechanism, the tension can be changed in the course of work.

- Tension adjustment in screw electric saws a little more complex. You need to loosen the tension screw and the side nuts, after which you can rotate the screw. With the extension of the tension, the chain must be turned forward to check the smoothness of the stroke, eliminate the backlash of hinges.

All work is done, making sure that the electric saw is disconnected from the network.

Page 12

Before involving the tool in the outlet, always

The switch operates properly and returns to the “Off” position if it release.

To prevent uncontinally turning on the trigger switch, there is a button without blocking. To launch the tool, press the button without locking,

Before carrying out any work with the tool

The tool is turned off, and the power cord is taken out of the outlet.

Before installing or removing the saw chain is mandatory

turned off and its fork is turned off the outlet.

When installing or removing the saw chain, always put on gloves.

To remove the chain, set the lever in a vertical position.

Click on the lever and, holding it in a pressed position, turn counterclockwise to turn off the nut so that you can remove the star lid. (Pressing on the lever leads to its installation on the nut.)

Turn the tension adjustment handle counterclockwise to weaken the saw chain.

To install a saw chain, put one

The end of the chain on the guide tire, and the other end of the chain on the asterisk.

At the same time, install the chain as shown in the figure, since it rotates in the direction indicated by the arrow.

Turn the tension controller clockwise to move the control pin in the direction shown by the arrow.

Install the sprocket cover on the chain saw so that the ledge on its back enters

Click on the lever and holding it in the press

position, turn clockwise to the end to tighten the nut. Then turn it counterclockwise by a quarter of turning to weaken a little nut.

Press 2. Weaken 3. Asterisk 4. Adjusting

How to choose a chain for electric saw

You should know that there is no difference between chains for benzo and electric saw. For both types of tools, the chains are made of the same materials, and are installed on tires, the same for both electrical and gasoline units. To select a chain for electric saws, several parameters should be taken into account. Some of them must correspond to the technical characteristics of the installed tire.

The size of the chain

This parameter always corresponds to the exchange of the tire of your unit. If you purchase a saw chain smaller than the tire, then you will not be able to wear it. Also, the equipment exceeding the size of the tire will not stretch on it properly. In both cases, it will be impossible to use electric poll. The dimensions of the sawing for sawing are customary to indicate in inches and they may have the following values: 10 ″, 12 ″, 13 ″, 14 ″, 15 ″, 16 ″, 18 ″ and above.

The step of the chain

Determined by any three rivets of the chain. The figure below with the letter “A” shows precisely this distance that is measured in inches.

The chain step can have the following values: 0.325 ″, 0.375 ″ and 0.404 ″.

Step with a size of 0.375 ″ is often recorded with a shot, like 3/8 ”(3: 8 = 0.375) so as not to be confused with the number 0.325.

You should know: the greater the step of the saw chain, the greater the power should have the unit engine. On amateur and semi.professional units with a capacity of 1.84 kW are installed chains with a step of 0.325 ″. Such equipment can be cut off by non.weed branches, trim the knots, as well as use it during construction work, for example, cut the boards. With a saw with a 3/8 step (engine power is required about 2.94 kW), you can already bring down non.weed trees and cut the boards of medium thickness. Equipment with p. 0.404 ″ (engine power from 4.41 kW and above) is used only on professional equipment and is designed to perform work of any complexity.

The thickness of the leading link

The thickness of the shank (also called the leading link) is a very important parameter when choosing equipment for electric saws.

To choose the right saw outlet for the unit, it is necessary that the thickness of the shank corresponds to the width of the groove of the tire. The thickness may have the following values.

- 1.1 mm (0.043 ”), 1.3 mm (0.05”). The equipment is carried out with minor loads and use it on small electric saws. The equipment has a step 0.325 ″.

- 1.5 mm (0.058 “). Chains with this value of the thickness of the shanks have a step 3/8 “. They are able to withstand significant loads and are installed on semi.professional and household apparatuses.

- 1.6 mm (0.063 ”), 2 mm (0.08”). Tires and saw equipment with such values are used to perform complex work with large loads only on professional equipment.

The number of links

By the number of links (shanks), the length of the equipment is determined. When choosing equipment, you can rely either on the values of the length, or on the number of links. Since different manufacturers in the description of the product can indicate only the number of cutting elements, it will not hurt to know both information.

Type of cutting links

According to the configuration, the cutting elements of the equipment are divided into 2 types: chipper and cheese.

Chipper.type cutting tooth is a sickle.shaped cutter with a large area of contact with the material. Sickle.shaped teeth increase the load on the unit engine and do not differ in good cutting characteristics. But, thanks to this form, the teeth easily cope with pollution, and their editing does not require special accuracy.

The stimulus profile of the teeth resembles the number “7” and is popularly called “seven”. Equipment with such a tooth profile is characterized by speed of sawing, cutting quality and is used mainly on professional devices. It is quite difficult to sharpen the equipment with cheesel teeth in everyday life, since even the slightest non.compliance of the angles of sharpening nullifies all the advantages of the chisel profile of the cutter.

The material of cutting teeth

When choosing equipment for electric saws, ask what material its incisors are made of. For sawing soft wood, chains with chromicel, alloy steel incisions are suitable. For sawing frozen, contaminated and solid wood, equipment with cutting elements made of alloy steel is not suitable. For these purposes, incisors are used, reinforced with carbide attacks, characterized by increased resistance to wear.

Profile height

The cutting depth and tool performance depends on the height of the cutter profile. The higher the profile of the cutting tooth, the stronger it will delve into the material. Teeth having a small height of the profile will remove the thinner chips during sawing. The depth of cutting of the cutter into the material is regulated using the limiting of the limiter available in each cutting link.

There are 2 types of chains in height of the profile:

This information can also be found in the instructions for the unit (the types of equipment applicable on this model of the saw are indicated). It will be useful if you will grind the teeth yourself. On professional units, both high.profile and low.profile equipment is used, but on household ones. only low.profile. High.profile chains are highly productive equipment. But when it is used, the vibration and aggressiveness of the tool increases.

To reduce the aggressiveness of the chain, the developers resort to small cunning: with a large step in the chain, a low cutter profile is made and, conversely, when a step is reduced, the profile increases and the profile is increased. This technique allows the unit to process the material simultaneously and with less aggressiveness.

Type of cut

It is no secret that wood has a structure consisting of longitudinally located fibers. Therefore, for sawing this material along or across the fibers, a different sharpening of the teeth of the chain saw is required.

When you need to change the chain

The need to replace the chain mainly occurs with its wear and excessive stretching. If you can’t take a stretch of equipment using an adjusting screw, then it should be replaced. But installing a new part on an old, worn star and the same tire is not recommended, since this will lead to its rapid wear.

Many electric saw owners know that the circuit wear is 2-3 times faster than the production of the tire and sprocket resource, and resort to small cunning.

- Having a new electric saw, you should buy 3 saw chains at once.

- Having worked with one chain for several hours, it should be replaced with a new. Further, the second chain changes according to the same principle.

- After each replacement of equipment, you need to turn the tire for uniform wear.

Performing these simple manipulations leads to uniform wear of all parts and extends their service life.

Proper operation of the electric saw

Many amateur gardeners, as well as professionals who are engaged in work with wood and harvesting of wood, use saws, and a chain saw of electric. As the name understands the working part of it has a chain, which during operation moves along the bus.

Electric saw Karcher CS-330BP

In terms of functionality of saw, the electrical is no different from the chainsaw. The only difference is in the type of engine and attachment to the place where there are rosettes with alternating current. Electric saws are also different and the consumer can choose, based on the tasks that he plans to solve with this tool.

How the electric saw is arranged

The speed of rotation is often not indicated. It is clear that there is a collector engine inside, but how fast it is. Pay attention to the parameter of the speed of the circuit. It is expressed by meters in sec (13.5) and shows how quickly the links move. It is known that the length of the tire is 14 inches (35.5 centimeters). For reference: the electric engine tire is called the metal frame, the chain runs along it.

The total length of the links is about 85 centimeters. We take a reserve for the tension mechanism and the transverse size. This means that in a second the full number of revolutions is n = 13.5 / 0.85 = 16. About 950 it turns out per minute. This is not the engine frequency, but the number of revolutions. But there is information on the drive asterisk, it is written: 6t x 9.53. This means that Zubtsov is 6, and the distance between the teeth is 3/8 inches (9.53 millimeters). It remains to change these two digits to obtain the length of the circle: 6 x 9.53 = 60 millimeters (rounded).

It turns out that the drive star makes a circle 85/6 = 15 revolutions, which gives the speed of rotation of the shaft about 14000 rpm. Provided that there is no gearbox inside. Inside there is a high.cost collector engine (you can’t bring asynchronous to such a speed), which means that there is no choice. Sometimes a gearbox is used, in other cases the drive of a direct. In the second case, the electric saw weighs less and there are fewer details that can break.

The motor lies in the transverse relative to the movement of the plane circuit for obvious reasons. The shaft star extends out and the chain is put on. It is pulled around the tire, and then attached to the body. Important mechanisms are located here:

For this purpose, long slots under the spikes of the case are made on the plane of steel. Further, the mounting systems begin to vary. Electro-saw manufacturers solve the problem in their own way. For example, the tension is provided with a symmetrical spiral screw, like Champion, or a lonely spike, like Makita.

It is usually delayed by the key. But Makita has a special folding screw. It is good that it is part of the design, but users complain that the elasticity of the springs is reduced, and the head begins to hang out. Pay attention to what is said if you consider it important. It’s good if there is a rubber nest under the mentioned key on the cord.

But there is in addition to the on.duty mechanism of adjustment. During operation, the chain is weakened, and it would be inconvenient to constantly remove the casing, turning the screw. The mechanism on duty is implemented in different ways. For example, the champion needs to be pulled with a screwdriver, and the nest is located from the side of the canvas.

Sparky does not have a screw, but there is a large diameter plastic tuning wheel. It is convenient, located on the side. In the duty mode, pulling the chain does not take much time. In appearance, the wheeled is fragile, there are fears that the mechanism is prone to breakdown. When choosing an electric saw, pay attention to the on.duty tools for maintaining the tension of the chain.

So the friction coefficient is reduced, and heat release decreases. Users complain that Makita pumps easily fail, and the oil either stops serving or injects too quickly. To control the level on the lateral part of the electric saw, the observation window is located. The type of oil is indicated in the instructions. If during the cut of the logs the smoke from the tire of the electric saw appeared, it is recommended to stop work immediately.

The electric saw usually has two pens. The first is located in the front of the case on the left. Arched and durable. In this place there is a shield, an employee both to protect against flying chips and as a spare switch. In many cases, during the operation of the electric saw, the so.called reverse blow occurs: the tire with a moving chain bounces up towards the lumberjack. As a result, the shield hits hands and crosses the switch that breaks the supply of power to the engine. Electric saw stops immediately, blocking the possibility of an accident.

In this sense, all devices are designed the same, but the part has additional protection against seizing the chain. In practice, the electric saw refuses to cut thick wet logs. In the case of fatal locking, the motor will be saved from imminent death. The chance that the chain will get stuck on the tire minimal, but it is present. If it jams, then the gearbox may fail. Products of this type without additional measures are not recommended.

The back handle is designed for the right hand. Having taken the electric saw in your hands, try whether it is well balanced. Modern 2 kW models weigh a little more than 2 kg, which facilitates the work. Electric saw should lie freely in the hands, for convenient cutting. The technical data provides maximum log diameters. The size is limited by the length of the tire.

You can not touch the objects with the end of the working electric saw, in this case, the chain in the arc bounces towards the head of the master. What can end sadly. Similarly, you do not need to try to saw logs whose diameter exceeds the indicated in the instructions.

In the off state, the electric saw chain is hidden in the casing, removed during operation. The front case of the electric saw is equipped with plastic or steel teeth. They need to rest against the workpiece, and then rock the blade up and down. It’s easier to cut, and the teeth serve as a limiter from this side. The last thing we want to say is food:

Varieties of links drank

The links in the chains can be three types: cutting, connecting and driven (shanks). They are connected by rivets between themselves. Teeth in chains are left and right. They are installed in turn; Production material. Highly alloyed chromium.nickel steel. In addition, the saw chains are equipped with restraints.

Depending on the size of the cutting teeth and the limiter of the depth of the chain are divided into:

Low profile with a smaller clearance; Less effective, but at the same time more safe due to the fact that they are less susceptible to reverse shocks (rebound saw), as a result of which the saw can break out of the hands and injure;

High profile with large clearance; less safe, therefore, only experienced users are recommended, while on household saws you can use only low.profile circuits.

The main parameters of the circuits for the electric saw are as follows:

The number of links. Each circuit on the electric saw is designed for saw tires of a certain length.

Chain step. Determines the distance between rivets connecting the links (more precisely, the distance between the first and third rivets is halved). The greater the step of the chain link, the higher the performance of the chain, but also the higher load on the saw.

The thickness of the link rod. Must correspond to the thickness of the groove of the rod.

The depth of cutting. The speed and performance of the cutting depends on this.

Cutting tooth profile height. Saws, depending on this parameter, are divided into low.profile and highly profile. The shape of the tooth profile can be rounded, semi.sized, chisel and with carbide plates.

Features of the adjustment of the chain tension

During the operation of an electric saw, it is necessary to carefully monitor the degree of tension of its circuit. The easiest way is to pull the chain up to the tooth up (the upper part of the tire is chosen for verification, approximately in the center). The normal level of tension allows you to remain inside the seat during a stretch of 1/3 of the tip (provided that the chain rotates freely by hand).

To adjust the chain tension in different models of Makita electric saws, tensioners in the form of a screw or lamb nuts can be used:

- In the first case, a screwdriver is required to tighten the tension screw: its rotation is allowed to carry out with relaxed side nuts. In the course of an increase in the stretch, it is necessary to turn the chain forward to eliminate the hinged backlash and check the smoothness of its course.

- On the instruments with a “quick tension”, the sprocket panel is fixed with a lamb nut. There is a special wheel under the lid: to pull the chain, it must be rotated to the right, to weaken. to the left. This type of tensioners is more convenient, as it makes it possible to adjust directly during the work.

To replace the chain on an electric saw or adjust its tension, it is not necessary to contact the service center. These manipulations can be carried out independently, observing the above recommendations.

The tire and the chain is the working “duet” of the electric saw, which is responsible for the effectiveness and accuracy of the saw cutting. The modern market is literally overwhelmed by all kinds of tires and chains that are suitable for one or another purpose. How to choose the right details from the entire assortment presented? We will give answers to this and other questions together.