Do-it-yourself hinge for the tiller adapter

Homemade devices for the tiller

The list of accessories is not limited to a mower, plow or harrow. This list is long enough, and no other tiller has such a strong package. After calculating the amount that will cost to purchase all the necessary equipment, many refuse this venture. It should also be remembered that not every model can be considered universal.

Simply put, when purchasing units for one tiller, it is very difficult to guarantee their operation on another. However, if there is a desire and a certain baggage of knowledge, many additional devices can be made independently.

Their drawings are often found on the Internet, but it is important to make sure that they are compatible. When developing attachments from scratch, you need to focus on the available tiller model.

DIY trailer adapter

With the help of this unit, the tiller can easily be converted into a mini tractor, which makes it possible to automate a large number of work on the processing of the personal plot. The design of the trailer adapter consists of the following elements:

- Metal supporting frame.

- Hitch.

- Cross bar.

- Braces.

- Chassis.

- Governing bodies.

- Seat.

To make a supporting frame, you should use a pipe of any section, the length of which ranges from 1.5 to 1.7 meters. On the one hand, a device for attaching to the tiller is welded, and on the other, a transverse beam. The width of the second element is selected in accordance with the dimensions of the tiller’s wheelbase. Then braces are attached to the bar to increase the rigidity of the structure and wheel stands.

Most often, additional units are attached to the tiller adapter by means of a single hitch. You also need to think about controlling the equipment, and the best option in this situation will be a lever, switching which will lead to a change in the position of the auxiliary devices.

The final step in creating a trailer adapter is to install the seat, and for this, a stand is attached in the middle of the crossbeam.

How to make attachments for a tiller with your own hands

the tiller is one of the most useful and demanded technical devices among those used on the personal plot. However, this statement is only valid with optional equipment. If the size of the cultivated land plot is small, then it is advisable to purchase branded units. That is why the question of how to make attachments for a tiller with your own hands is popular.

- Homemade devices for the tiller

- DIY trailer adapter

- Homemade disc hiller

- Making a potato digger

Homemade disc hiller

The optimal type of hiller for a personal plot is disc. When working with it, it is not required to apply great efforts, and when the speed of movement is reduced, the power increases. Do not forget that the disc hiller is a universal tool, because it can be used not only after planting crops, but also during their growth.

The design of this type of attachment is not very complex and includes:

- Ramu.

- Disks.

- Screw type talers.

- Racks.

Thanks to the presence of talers, it becomes possible to adjust the angle of inclination of the working discs. It is this factor that affects the depth of their immersion in the soil and the force applied during work.

Discs can be taken from worn-out agricultural equipment, for example, an old seeder, or made of high-quality steel, the thickness of which is 1.5-2 mm. The outer edges are bent, and a hole is drilled in the center for attaching to the frame.

Making a potato digger

This unit is able to significantly facilitate the work of harvesting all tuberous crops, not only potatoes. Among the main structural elements of the unit, it is necessary to highlight:

- Welded frame.

- Ploughshare.

- Drum cleaner.

- Editorial node.

A ploughshare is a movable element of a potato digger and can be made of sheet iron. The cut plates should be sharpened, but at the same time all edges should be blunt so as not to damage the tubers. Frame fabrication should also be straightforward. To solve this problem, you will need a corner, channel No. 8 and a profile pipe. Frame sizes are selected on an individual basis, and the required amount of materials is determined on site.

The main element of the entire structure of the unit is the editorial unit. To make it, you need two metal cylinders, into which the connecting sleeves are then installed. After that, it is necessary to make the hubs from a metal pipe, the diameter of which is 25 mm. They are used for attaching sprockets, pre-fastened to bushings by means of dowels.

The most difficult to manufacture is the cleaning drum, which consists of two roller chains with 94 links each. The chains, in turn, are mounted on special rods, and then the finished element is attached on two axes. The result is maximum mobility.

The torque from the tiller motor is transmitted to the share connected to the casing. During movement, the angle of inclination changes, and digging movements are performed. To adjust the angle of inclination of the working element of the structure, and, consequently, the depth of the dig, you can make a slider. An excellent material for the manufacture of this part will be fluoroplastic.

What attachments for a tiller can be made by hand?

It all depends on the qualifications of the home craftsman and the set of tools that he has. We advise beginners to start their experiments with the simplest designs. a fan potato digger or a hiller.

The design of the device for digging potatoes is shown in the sketch. It consists of a wide bent plate (paw) welded to the vertical bipod and the field bar. Teeth from reinforcement are welded to the trailing edges of the paw.

It is easier to make a disk model from hillers. Its main elements are discs that can be cut from the ends of old gas cylinders. They have the right shape, diameter and metal thickness.

A lot of design solutions for the device itself have been invented, you can be convinced of this by watching videos of self-made people, as well as various assembly diagrams.

In addition to discs, you will need:

- two posts made of steel strip;

- two rolling bearings;

- bolts for attaching the struts to the frame and adjusting the pivot sectors;

- cross member from a profile pipe;

- T-shaped leash.

The main condition for the high-quality operation of such a mechanism is the accuracy of manufacturing of all parts and the symmetry of the installation of disks. Otherwise, it will be taken away from the furrow while driving.

Agricultural activity means any physical or mechanical labor. Of course, it is extremely difficult to do without mechanization, since manual labor takes a lot of time and effort. There is a tiller that can become a cultivator on your land. Thanks to the modification of this device with any attachments, this assistant can be adapted for any job. And the installation of the adapter allows the summer resident or farmer to use this homemade product with comfort for himself.

Among other things, the tiller can be operated when transporting goods, for example, if you additionally install a homemade adapter on it. A ready-made adapter for the Neva Tiller is on sale. It already has a comfortable steering, which makes it much easier to use. But there is also the possibility of making an adapter of a similar type on your own. This way you can save a lot.

Harrows

The land overturned by the plow is a “semi-finished product” that requires fine-tuning. For this work, a harrow is used, which breaks up large clods and levels the soil.

There are two types of harrows:

It should be noted that disc structures perform better harrowing and cleaner toothed.

Cutters

They can perform several operations:

- loosen and level the ground;

- crush lumps of soil and mix its layers;

- mix fertilizers;

- weed out.

The set with a tiller usually comes with universal cutters equipped with saber knives. They are comfortable to work on soft soil. For dense and overgrown with weeds, mechanisms are designed, called “crow’s feet”.

High mechanical strength and a special shape of the cutters allow them to loosen neglected areas, pulling out weeds with their roots. In autumn, with their help, they destroy insect pests that have lain in the ground for the winter.

Snow blower

Many owners do not put their tiller on a joke in winter. With its help, you can free large areas of the estate from the snow cover. Snow removal devices aggregated with it can be divided into several groups:

- blade shovels;

- rotary throwers;

- brush mechanisms.

Where the shovel is helpless, as is often the case with high snow runs, the rotary snow blower will get the job done. It is connected to the power take-off shaft of the tiller. The screw-rotor design has high performance and confidently clears the area from snow cover up to 50 cm high.

The brush mount is used to clean areas with expensive decorative coatings that require the most accurate work.

For irrigation of plots located far from power lines and close to water bodies, motor pumps have been created. This type of tiller attachment is connected to the PTO shaft. The average productivity of motor pumps is 20-40 m3 of liquid per hour. The generated head reaches 4-5 meters with a suction depth of up to 10 meters.

Device and principle of operation

In fact, the adapter is presented in the form of a cart that attaches to the tiller. After that, the structure turns into a mini-tractor. The main details of such a unit:

- a frame to which other constituent elements are attached;

- driver’s seat with a lift lever;

- 2 wheels;

- clutch device;

- wheel axle.

In this video, we will analyze the front adapter:

It is one of the most important elements of the device, since other elements are connected to it. Therefore, it must be made of high quality and durable materials.

Tiller design with adapter

This homemade tiller is simple and consists of only a few components:

- Wheels and wheel axle.

- Adapter Hitch and Tiller Hitch.

- Seating area for control.

In simple terms, the adapter is a trolley with a seat on wheels. When the adapter is connected to the tiller, then we can say that this is already a mini tractor. Of course, the power, its much less, but the functionality is the same. Additional attachments turn such a structure into a multifunctional tiller, expanding the list of possible jobs. Few will refute the dignity and necessity of having such a mini tractor on their site.

Assembling the device

Having everything you need at hand, we proceed directly to the assembly of the unit:

- It is necessary to prepare a metal sheet 180 cm long.

- Across this sheet it is necessary to weld a smaller sheet, about 60 cm. There will be mounts for wheel struts here. The height of the posts must be at least 30 cm.

- We carry out welding work on the braces, which will be installed to the frame and wheel hubs (their location can be any).

- We weld the beam to a large metal sheet. This will strengthen the frame structure.

- A frame for mounted installations is welded from the channel. In a perpendicular position, we weld another small pipe of 30 cm, which will serve as a blank for the seat. We weld two more smaller pipes on it to make a stand. You can take a ready-made seat and install it on this stand, or use plywood as a seat, having previously covered it with a soft inflated material. Bolted seat.

- The final stage: setting the control lever on 3 knees (35, 55 and 20 cm). To adjust the gain, another lever is installed at 80 cm.All levers must be bolted together.

In fact, there is nothing complicated in this design, it is only important to have welding experience. On some of these models, steering is installed. Such a tiller will be convenient to use in arable work.

Plows

The evolution of swing devices has been embodied in the following types of devices:

- The plow is standard. A wide knife. a ploughshare of such a device, when plowing, loosens the ground, cutting off the roots of weeds. Bent sheet. the dump turns over the layer of earth.

The way of attaching a standard plow to a tiller is illustrated in the figure.The main parts of this device: a share, a blade, a stand, a heel, a field board are visible in the figure.

- Reversible (swivel, double-sided) plow. Two plows are mounted on a common frame at an angle of 90 or 180 degrees. Their dumps are directed in different directions. In the working position, one of them plows the ground, and the second is on the side. After the passage of the furrows, they are reversed by pressing (or removing) the latch and turning to the side. Thanks to this, the operator does not have to return to the beginning of the section every time, making an idle run.

- Zykov’s plow. An improved version of the classic plow. It differs from it in the changed geometry of the ploughshare-moldboard surface. Thanks to refinement, it turns the soil layer well and crumbles it.

Designed and manufactured in Ukraine, Zykov’s plow is still rare in Russia. Only a few DIY enthusiasts are trying to reproduce it in home workshops.

Overview of attachments

Compact tractors are used in almost all branches of agriculture. A variety of attachment devices are specially designed for soil cultivation. There are different attachments for soil cultivation, plant care and farm animals.

How to Attach a Tiller to a Riding Mower

Attachments for a mini tractor

Note! For installation on a tractor of frontal and other attachments, a mechanical three-point hitch is used on a mini tractor.

Plant maintenance equipment

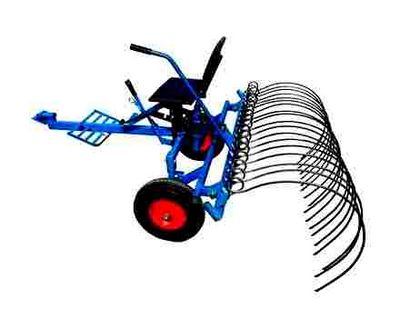

For tedding, as well as raking hay into rolls, a rake is hooked to the mini-tractor. Such equipment is more in demand by farmers and private owners, who have large areas for haymaking. The tedding rake is produced in various modifications. To a mini-tractor with a power of 12 hp. model 9 GL or 3.1G will do. The equipment is characterized by a strip width of 1.4-3.1 m and a weight of 22 to 60 kg.

Cultivators clear the field of weeds, loosen the soil, remove the roots of unnecessary vegetation. The equipment is used after planting germination and during the entire period of their growth. Of the common models, KU-3-70 and KU-3.0 can be distinguished.

Mounted sprayers help control crop pests in fields and gardens. The models SW-300 and SW-800, produced by the Polish manufacturer, are universal. The equipment is suitable for all models of mini tractors. At a liquid solution flow rate of 120 l / min, the jet covers up to 14 m of the treated area.

Attachment manufacturing

Buying tiller sheds for a small summer resident will be very inconvenient. A summer resident or farmer can make all the equipment on his own at home, using a little ingenuity. Most of the equipment is quite simple, and it is made almost from what is at hand.

Before you make a plow for a mini-tractor with your own hands, the drawings and dimensions must be carefully learned and the most optimal one must be selected. It will be easier to make equipment if you have a ready-made factory scheme.

Do-it-yourself mini tractor attachment

A mini-tractor is a very useful thing in the household. Without attachments, its efficiency and productivity are close to zero, because in this case, you can only move on the tractor. In order for a mini-tractor with four-wheel drive to be useful on the farm, they buy specialized attachments for it. Some units can be made by hand.

General overview of prefabricated equipment

Mini tractors work in all industries, but most of all they are in demand in agriculture. This is taken into account by the manufacturer, therefore, most of the attachment mechanisms are designed for soil cultivation, caring for animals and plantations, as well as planting and harvesting operations. To connect most of the equipment, a three-point hitch is installed on a mini-tractor, but there is also a two-point version.

Do-it-yourself mini tractor attachment

Preparatory stage

often a cylindrical plow is made. Such a hitch for a mini tractor is used when processing various types of soils. The soil is crushed well, but it does not penetrate deeply into the stratum. Such units are recommended for use on unplowed land during primary cultivation.

Simple plows, in contrast to the ploughshare type, are easy to manufacture. With the help of a semi-screw design, the earth can be turned over without loosening. The share plow is a sturdy and reliable attachment for a mini tractor that can be used all the time. The structure works the ground with cutting elements. The soil is tilted to the sides with two blades. Such a technology for manufacturing a plow provides a high level of loosening and depth of soil cultivation.

The drawing of the plow is carried out taking into account the type of construction. The one-body model is presented in the form of a rectangular metal tube. On the opposite side of the side of the product, the cutting element is attached, and on the other side. the wheel and fasteners to the minitractor.

To process a large area, a two-body hitch for a mini tractor is assembled. The product is made from several frames equipped with different tools. Each component of the structure performs specific tasks (harrowing, plowing).

HOW TO MAKE DOOR HINGES ON MODEL CAR KITS

If the drawing is completed, then the device is detailed. Then a pattern of parts is performed. This will require a sheet of steel and scissors. The shape of the blade depends on the tools used and the availability of equipment. Plate bending machines will allow you to achieve high accuracy.

Solution to the problem

Assembly Instructions for Simple Tiller Adapter

Do-it-yourself attachments for a tiller can be made by almost any home craftsman. If you want to make an adapter, then it can be a steel frame made of pipe. To do this, you need to take the one that has a rectangular section, while the length should be 1.7 m.

To one of the ends, it is necessary to weld a pipe perpendicularly, the length of which is 0.5 m. This part will become the basis for fixing the struts under the wheels. The height of the struts from the axle to the top point will be 0.3 m. At the next stage, it is necessary to fix the braces to the central tube and the wheel hub. The length of the products will depend on the slope and angle.

The square frame can be of any size. In this example, the following dimensions will be considered: 0.4 x 0.4 m.If you decide to make such attachments for the tiller with your own hands, then you need to strengthen the channel to the rear end of the frame, the length of which will be 0.4 m. a single design is possible with bolts. To be able to adjust, a lever should be welded to the frame, which should have three knees, their length will be as follows: 20, 30 and 50 cm, respectively. In order to increase the applied forces, the arm should be supplemented with a 75 cm arm. The hitch assembly can be purchased or manufactured by yourself. The duration of the operation of the attachment will depend on the quality of the coupling. It is necessary to fix the seat on a metal support, which is welded to the central tube. On this we can assume that you managed to make attachments for the tiller with your own hands. Its advantages are low cost and simplicity of construction.

Do-it-yourself attachments for the tiller. Drawings, assembly instructions

If you have a land plot, then you are familiar with how difficult it is to work on digging, loosening and hilling. It takes a lot of time and effort. In order to facilitate the solution of such problems, you can purchase auxiliary special equipment, it can be a tiller. Using this equipment, you can perform a wide range of works. This can be the cultivation of the land, cleaning the site, as well as the transportation of crops and any other cargo.

Making a plow

Before making this attachment, it is necessary to prepare drawings. In them, you can designate the main nodes. share and blade. For working elements, 3 mm steel should be used, but first, experts advise working on a removable share. The most suitable material for it will be a disc borrowed from a circular saw. In the absence of, you can use ordinary steel that has not been heat treated.

The cutting part will be the working element of the scythe, which beats off on the anvil. A mounted plow should also have a blade in its composition, you can start making it after you finish with a share. As a material for this, you can use a 50 mm pipe, the thickness of which will be 5 mm. The blade can be blank using a gas torch. To begin with, a template is cut out, at the next stage, the workpiece can be brought on an anvil, and then on a grinder.

Plow assembly

Attached homemade equipment in the next step can be put together. To begin with, you should use the option of assembling the layout, which is made of thick cardboard. Parts are glued together, while you need to adhere to the required angles. After finishing the blade, share and auxiliary parts, a 2 mm square steel sheet with a side of 500 mm can be prepared. An indent of 40 mm is made from the edges, then a ploughshare is applied and spot welding is done on both sides.

The stand guard should also be docked with the share, the joint should be in a vertical position. The guard must be positioned slightly higher than the share blades. The offset is necessary for cutting the soil. It is important to tightly dock the share with the blade, there should be no gaps. As a result, the structure should turn out to be almost cast. Between the upper edge of the shaft and the share blade, an angle must be set within the range from 6 to 8 ° С.

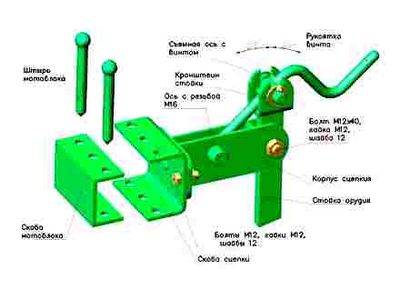

Recommendations for the implementation of the coupling unit

If you decide to make attachments for the tiller with your own hands, then you should familiarize yourself closely with the instructions for making the coupling assembly. The simplest design will be a 15-centimeter pin that fits into the hole in the drawbar of the tiller’s towbar. The disadvantage of this option is a rather quick wear, because under the influence of a rotating trailer, the holes for the hitch are broken. The hitch can be lengthened to reduce the wear rate.

Making a mower

A do-it-yourself mower for a tiller can also be done. It is used for lawn care, mowing grass for hay. For work, you should prepare the chains from the chainsaw gearbox, as well as a couple of discs borrowed from the grain seeder. The knives can be made from hardened metal, and you need 4 knives per disc. Drill holes on the discs with a diameter of 6 mm. The knives should be reinforced on the disc using shanks. The gap between the knife and the shank should be 2 mm larger than the thickness of the knife.

When making a do-it-yourself mower for a tiller, the knife attachment axes can be made of carbon strong steel, the diameter of which is 8 mm or more. The axle must be tightened to the stop with the disc so as not to impede the movement of the knives.