Hand Circular Saw With The Possibility Of Stationary Installation

Selection Criteria for Fixed Mount Circular Saw

Although the choice of models with stationary fasteners is NOT rich, among them you need to choose the most suitable.

Saw assembly

Each manufacturer offers many options for completing their products. The most important additions are:

- Stopper. used to remove even edges of the material, turn an unedged board into an edged board, sawing off long strips of material from a piece;

- Ruler. bolts to the platform and helps measure the width of the cut.

Overview of hand-held circular saws with the possibility of stationary installation

A hand-held circular saw is a must-have in the arsenal of everyone involved in construction or carpentry. The most convenient models, which are installed on a workbench or table and are used stationary.

The first circular saws were developed by SKIL in the twenties of the last century. Since then, the appearance of the instrument has undergone significant changes. Manufacturers are constantly working on improving the design, which to this day withstands fierce competition. What are the structural differences of the tool with a stationary mount and which models are on the market.

Cutting depth

This is also an important parameter, although it does not differ much in large and small dust. Special attention should be paid to the maximum cut at an angle. In modern models, there is the possibility of cutting by degrees. The value of the cut per degree is always much less than in a straight line, it is this indicator that you should pay attention to when looking for a small hand saw.

Fixed mount for circular

This simple device slightly increases the cost of the saw, but significantly expands its functionality. This is especially true for powerful heavy devices. The stationary mount is:

- A couple of clamps that fix the mechanism on the workbench;

- A couple of legs;

- Plate fixing protection;

- Clamp for start button (button is clamped in the “ON” position).

Holes are provided in the upper part of the tool body for fasteners. After installation, three points of support are formed, which reliably and firmly hold the dust up the cutting teeth. It turns out a mini-circular machine with a working surface equal to the platform. Very convenient for cutting a large number of small parts.

Installing the saw on a stationary mount

- We attach the legs: We take out the plug-bolts and instead of them we screw in the bolts to fix the legs.

- We attach the plate securing the protection. The protection must be embedded in the body and pressed with a plate.

- Using clamps we attach the tool to the workbench, insert hooks into special holes.

Install “upside down” only specially designed models! Otherwise, the tool may be overloaded or the blade is jammed, resulting in costly repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. For information on this, see the operating instructions.

There are few models on the market with the possibility of stationary installation. These are mainly domestic products. Distinctive features. large circle diameter and powerful electric motor.

| Soyuz TsPS-50200 | Caliber EPD. 2100St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope GP-2000 | |

| Power, W | 2500 | 2100 | 220 | 1500 \ 1800 | 2150 | 2000 |

| Idling speed, rpm | 6000 | 4800 | 5500 | 3700 \ 4100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. Cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Tilt angle, degrees | up to 45 | up to 45 | – | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6.6 | – | 5.7 | 6,7 | 7.8 |

Table 1. Characteristics of some models of table-mounted circular saws on the domestic market

Power

Sawing wood requires considerable effort, so powerful dust is more efficient. And the service life of the tool will be longer, because a powerful motor requires less effort, It does not overheat. However, the more powerful the device, the heavier it is. But the issue is partially solved by the presence of a table stand.

The smallest and weakest mechanisms have a power of 1200 W, the largest. 2500 W. The choice should be based on the mode of use of the tool.

Additional accessories

A laser pointer is a convenient option that allows you to cut a part with markings covered with sawdust. Increases the cost of equipment, but is welcomed by professionals.

Disc Replacement. Modern models are equipped with a spindle lock, which allows quick and easy removal of the disc for replacement. Otherwise, the disk is removed with two keys. a long and inconvenient procedure.

Circular device with stationary installation

The circular saw is designed for cross and longitudinal cutting of soft materials: wood, wood-based panels, plastics, non-ferrous alloys. Hand tools work quickly and accurately, therefore they are widely used in various carpentry works, as well as in:

- Roofing works;

- Floor covering;

- Furniture making.

By replacing the blade with a manual circular, you can cut soft metals and profiles. And installed it on the workbench using a special device. Turn it into a machine.

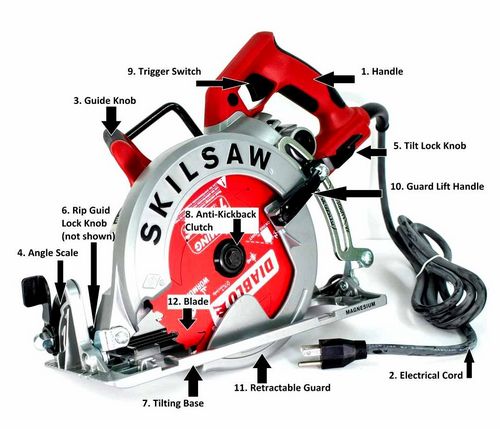

The main elements of the circular saw:

- Electric motor;

- Reducer in the housing;

- Guide;

- Platform;

- Protective box;

- Stationary mount.

The body of the tool is made of durable plastic and only in a few models of metal. Since a lot of dust and shavings are produced during work, manufacturers anticipate a chip removal system. As a rule, this is the outlet for connecting an industrial vacuum cleaner. There are models with a built-in dust container. a convenient solution for one-off work.

On modern hand-held models, only collector electric motors with a capacity of 750. 2500 W are installed. This indicator determines the number of revolutions of the disc and the capabilities of the tool. The most powerful models have a speed of up to 5000. A powerful motor requires cooling, which is provided by the ventilation system of the case.

The platform is of great importance when choosing. She may be:

- Stamped. cheaper, suitable for the hobbyist;

- Cast aluminum. does not deform, strong and resistant.

Often, a graduated scale is applied to the platform to help cut workpieces more accurately.

Guide bar. serves to make a straight cut. Some manufacturers equip their tool with a guide rail. But this is not always the case.

Required functions

In order not to be mistaken with the choice of a circular saw, it will be useful to consider the presence of the following functions.

- Soft start capability. This refers to a condition in which the disc begins to reach maximum speed gradually. This function prevents high starting currents, which positively affects the service life of the motor.

- The ability to maintain a preset speed at any load. If you have to work with high density material, the engine automatically starts to increase the power of work to maintain the preset number of disc revolutions.

- Anti-jamming protection. The best solution to this problem is the slip clutch. If the disc is still jammed, the motor will operate as before, and the disc will stop rotating. While this option does not prevent kickback from the instrument, it still helps to reduce the force of the instrument, which reduces the likelihood of injury.

- Motor overload protection. If during operation the load on the motor reaches a peak level, it will automatically shut down, which prolongs the life of the tool.

- Fast disc brake function. If you disable the button, the disc will immediately stop, which will happen rather quickly.

- Possibility to adjust the disk rotation speed. When working with a variety of materials, professionals have to adjust their rotational speed to achieve the most productive spray.

- The ability to adjust the cutting depth. This option is provided in any modern model of circular saws, the presence of which simplifies the process of setting an accurate depth value.

- Presence of a riving knife. There is space behind the saw blade for this unit and avoids the workpiece being pinched.

- The ability to connect a vacuum cleaner. Any circular saws are equipped with such an option. To use it, a special plastic pipe is provided on the tool body. Although it does not hurt to make sure it is available when buying.

- The vast majority of dust also has a laser pointer. The owner can get the benefit from it if there are no high requirements for the quality of the cut.

- A useful option is the LED, which is able to provide better illumination of the working surface.

Hand-held circular saw with the possibility of stationary installation

If you have ever been to a sawmill or to an ordinary carpentry workshop, then you probably paid attention to the presence of a machine there, with a disc with teeth peeking out in the center. This is exactly what a stationary circular saw has. It is used to perform high-quality and accurate longitudinal sawing of wood of different densities.

Nowadays, many ordinary amateur builders are beginning to show interest in most of the Special devices. They also did not disregard the circular saw. At the same time, not only a stationary model is available for sale, but also a conventional hand-held circular saw. In this regard, it does NOT hurt to dwell in more detail on the features of choosing a circular saw, its varieties and basic characteristics.

This tool is used to solve the same problem for which the industrial version was created. We are talking about making longitudinal and cross cuts in wood, drywall, plastic and other materials. Of course, an ordinary jigsaw can also be used for such work, however, taking the High intensity of work and stringent requirements, which the created spray must meet, it is much more logical to use a circular saw, which can perfectly cope with this task.

It is quite simple to use it, but it will be useful for a start Pay attention to its design. The role of the main unit in the device of this tool is performed by an electric motor, on the shaft of which the saw blade is located. To eliminate a minimum of discomfort when working with such a tool, it has two handles, one of which has a start button, and thanks to the second, it becomes possible for the user to fix the tool with the other hand. The blade is equipped with a protective cover, the presence of which helps prevent injury to the operator. If necessary, the protective cover can be opened by gaining access to the intent disc, for which it is necessary to press the start button.

The action of this tool is as follows: to start the engine, you need to press the power button, after which the saw blade starts spinning, as a result the main task is performed. the material is cut.

Adjusting the slope of the cut

Although this characteristic is mandatory for all modern circular saws, not all of them provide for the ability to tilt the tool in both directions. Tilt angle limited to 45 degrees.

Disk rotation speed

This parameter is directly influenced by power. Increasing the rotational speed allows for a more accurate cut. At the same time, it should be remembered that when cutting plastic, it is advisable to choose a low cutting frequency, since otherwise you may encounter such an unpleasant phenomenon as the melting of materials caused by a high rotational speed of the blade. The standard figure for this parameter for professional models is 5000 rpm.

Cutting depth

The value for this parameter ranges from 0 to 85 mm. The exact figure is determined by the class of the saw. Saws offered today can provide different cutting depths depending on engine power.

Power Tool Care Tips

Don’t forget that you have to deal with a dangerous tool. Because of this, you need to be very vigilant and careful. Only in this case you can not only do a good job, but also protect yourself and the health of your family.

It is necessary to work with a circular saw only in protective clothing, gloves and glasses.

Before plugging in the dust, check that it is off.

If you need to turn on or off the dust, it is advisable to do it at idle speed. If done under load conditions, it can shorten tool life.

Make sure that the load does NOT exceed the permissible level. For this, it is recommended to take breaks after every 15-20 minutes of work. This will prevent engine overheating.

Before operation Make sure that the workpiece is securely fixed. It is unacceptable for it to dangle and bend. Otherwise, it can be fraught with serious consequences for you.

Make sure that there is no moisture near the workplace.

Tips for choosing

When considering different models of circular saws, it should be remembered that this tool poses a health hazard. For this reason, it is important to select this tool with special care, taking the following points.

Particular attention should be paid to the economic component. When choosing dust, you should take it in hand, try to understand if it is comfortable enough for you to hold it.

Do not think that the same model can be suitable for two people, since each of us has a different body structure, skills and habits. And here it does not even play a big role, whether a circular saw is considered by a proven manufacturer or not.

You should also take into account the material from which the protective casing is made. It must be characterized by high strength, the ability to resist deformation in the event of a tool fall.

Test in operation the regulators located on the model body. Set up several different angles. Find out if they just twist and twist just enough.

Make sure you can easily get to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, as neglecting these points can lead to serious injury in the future.

Types of circular saws

There are several features on the basis of which circular saws can be classified.

By scope

- Standard circular saw. It can spray wood with a density ranging from 0 to 85 mm.

- Mini circular saw. It features a high power rating of 400-800 watts. This saw has a saw blade of about 65 mm. The model is small in size and weight, which is about 2 kg. The cut created with its help has a depth of about 16 mm. Based on the above, we can conclude that this tool is suitable for cutting thin materials.

- Cordless circular saw. It has much in common with the standard modification, except that the battery acts as a power source for it. This explains why the saw is less powerful and is offered at a higher price, although this is all offset by higher mobility. A similar tool is ideal for owners of suburban areas who plan the construction of a summer house.

- Plunge saw. Most of it is used to cut material from the middle. It will bring the greatest efficiency when the task arises of cutting holes inside a material or making blanks from any material. Cope with such tasks it allows the submersible mechanism, thanks to which the saw blade can move in a vertical plane.

- Diamond circular saw. The main working element is a diamond saw blade. It can be used to spray any kind of artificial and natural stone, as well as ceramics and tiles. The possibility of a water supply increases the productivity of the tool. This saw can cut to a depth of 50 mm and can also cut material at an angle.

Depending on the class:

- Household;

- Professional.

The difference between these models lies in their power. For household models, this parameter is in the range of 1100-1800 W. Against the background of small dimensions, the weight of this saw is about 4-5 kg. It can work with material of normal thickness. 50-55 mm. The saw blade used in such modifications has a diameter of 160-200 mm.

The power displayed by professional saws ranges from 1800 watts and above. They differ in a rather significant weight, which is 8 kg or more. With their help, you can saw a bar, the thickness of which does NOT exceed 70-85 mm. Equipped with discs up to 250 mm. The quality demonstrated by these saws also determines their higher price.

Main characteristics

Considering various models of circular saws for a stationary installation, first of all, it is necessary to pay attention to their performance characteristics, which determine the effectiveness of their use in solving a particular problem.

Power Tool Care Tips

It is necessary to work with a circular saw only in protective clothing, gloves and glasses.

Before plugging in the dust, check that it is off.

If you need to turn on or off the dust, it is advisable to do it at idle speed. If done under load conditions, it can shorten tool life.

Make sure that the load does NOT exceed the permissible level. For this, it is recommended to take breaks after every 15-20 minutes of work. This will prevent engine overheating.

Before operation Make sure that the workpiece is securely fixed. It is unacceptable for it to dangle and bend. Otherwise, it can be fraught with serious consequences for you.

Make sure that there is no moisture near the workplace.

Types of circular saws

There are several features on the basis of which circular saws can be classified.

By scope

Depending on the class:

- Household;

- Professional.

The difference between these models lies in their power. For household models, this parameter is in the range of 1100-1800 W. Against the background of small dimensions, the weight of this saw is about 4-5 kg. It can work with material of normal thickness. 50-55 mm. The saw blade used in such modifications has a diameter of 160-200 mm.

The power displayed by professional saws ranges from 1800 watts and above. They differ in a rather significant weight, which is 8 kg or more. With their help, you can saw a bar, the thickness of which does NOT exceed 70-85 mm. Equipped with discs up to 250 mm. The quality demonstrated by these saws also determines their higher price.

Disk rotation speed

Hand-held circular saw with the possibility of stationary installation

Nowadays, many ordinary amateur builders are beginning to show interest in most of the Special devices. They also did not disregard the circular saw. At the same time, not only a stationary model is available for sale, but also a conventional hand-held circular saw. In this regard, it does NOT hurt to dwell in more detail on the features of choosing a circular saw, its varieties and basic characteristics.

This tool is used to solve the same problem for which the industrial version was created. We are talking about making longitudinal and cross cuts in wood, drywall, plastic and other materials. Of course, an ordinary jigsaw can also be used for such work, however, taking the High intensity of work and stringent requirements, which the created spray must meet, it is much more logical to use a circular saw, which can perfectly cope with this task.

It is quite simple to use it, but it will be useful for a start Pay attention to its design. The role of the main unit in the device of this tool is performed by an electric motor, on the shaft of which the saw blade is located. To eliminate a minimum of discomfort when working with such a tool, it has two handles, one of which has a start button, and thanks to the second, it becomes possible for the user to fix the tool with the other hand. The blade is equipped with a protective cover, the presence of which helps prevent injury to the operator. If necessary, the protective cover can be opened by gaining access to the intent disc, for which it is necessary to press the start button.

The action of this tool is as follows: to start the engine, you need to press the power button, after which the saw blade starts spinning, as a result the main task is performed. the material is cut.

Adjusting the slope of the cut

Although this characteristic is mandatory for all modern circular saws, not all of them provide for the ability to tilt the tool in both directions. Tilt angle limited to 45 degrees.

Tips for choosing

Particular attention should be paid to the economic component. When choosing dust, you should take it in hand, try to understand if it is comfortable enough for you to hold it.

Do not think that the same model can be suitable for two people, since each of us has a different body structure, skills and habits. And here it does not even play a big role, whether a circular saw is considered by a proven manufacturer or not.

You should also take into account the material from which the protective casing is made. It must be characterized by high strength, the ability to resist deformation in the event of a tool fall.

Test in operation the regulators located on the model body. Set up several different angles. Find out if they just twist and twist just enough.

Make sure you can easily get to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, as neglecting these points can lead to serious injury in the future.

Cutting depth

The value for this parameter ranges from 0 to 85 mm. The exact figure is determined by the class of the saw. Saws offered today can provide different cutting depths depending on engine power.

Required functions

In order not to be mistaken with the choice of a circular saw, it will be useful to consider the presence of the following functions.

- Soft start capability. This refers to a condition in which the disc begins to reach maximum speed gradually. This function prevents high starting currents, which positively affects the service life of the motor.

- The ability to maintain a preset speed at any load. If you have to work with high density material, the engine automatically starts to increase the power of work to maintain the preset number of disc revolutions.

- Anti-jamming protection. The best solution to this problem is the slip clutch. If the disc is still jammed, the motor will operate as before, and the disc will stop rotating. While this option does not prevent kickback from the instrument, it still helps to reduce the force of the instrument, which reduces the likelihood of injury.

- Motor overload protection. If during operation the load on the motor reaches a peak level, it will automatically shut down, which prolongs the life of the tool.

- Fast disc brake function. If you disable the button, the disc will immediately stop, which will happen rather quickly.

- Possibility to adjust the disk rotation speed. When working with a variety of materials, professionals have to adjust their rotational speed to achieve the most productive spray.

- The ability to adjust the cutting depth. This option is provided in any modern model of circular saws, the presence of which simplifies the process of setting an accurate depth value.

- Presence of a riving knife. There is space behind the saw blade for this unit and avoids the workpiece being pinched.

- The ability to connect a vacuum cleaner. Any circular saws are equipped with such an option. To use it, a special plastic pipe is provided on the tool body. Although it does not hurt to make sure it is available when buying.

- The vast majority of dust also has a laser pointer. The owner can get the benefit from it if there are no high requirements for the quality of the cut.

- A useful option is the LED, which is able to provide better illumination of the working surface.

Main characteristics

Considering various models of circular saws for a stationary installation, first of all, it is necessary to pay attention to their performance characteristics, which determine the effectiveness of their use in solving a particular problem.

Scope of application

The presented type of power tool is designed for direct longitudinal cutting of various materials from wood, as well as plywood, chipboard, fiberboard, MDF panels. She can also cross cut.

Dense building materials (brick, plaster, concrete) are usually outside the competence of the presented equipment. Hand circular saw with the possibility of stationary installation Makita (some models, for example, 4101RH) are supplied with diamond discs and a water supply system. But this is rather an exception to the rule. An ordinary average statistical instrument of domestic or foreign production cannot boast of such qualities. But it can be easily used for cutting sandwich panels, plastic, laminate or even plexiglass. Quite often, modern models provide the ability to cut slate.

Protection system

Many manufacturers anticipate different systems for protecting the operator and equipment during operation. These are important options that a hand circular saw with the possibility of stationary installation should have. Doing various actions with your own hands will not only be easy, but also safe.

It is highly discouraged to save on the security system. Circular. Equipment that is classified as a hazardous power tool.

Protective elements include a device that maintains a constant speed. Soft start prevents overheating of the unit and its motor.

A very useful option, provided in some models, is to shutdown the system at increased loads.

The electrodynamic brake is able to instantly stop the rotation of the disc when the master releases the rotation button.

Engine power

Here the power class of the equipment motor depends on the stability of its functioning, as well as the duration of continuous operation. This, accordingly, affects the speed of cutting materials.

For household purposes, an 800 W device is suitable. Models of 900-1200 watts are considered universal. These include, for example, a hand circular saw with the possibility of a stationary installation “Interskol” GP 165, which is quite popular today among craftsmen of different levels.

For professional activities, it is customary to purchase equipment with a power of more than 1200 W.

Circular disc

The very first selection criteria for a stationary circular saw. These are cutting discs. Their diameter, shape and material determine the type of work for which the equipment is suitable.

This element defines the depth of the cut. Engine power directly depends on it. The larger the blade diameter, the more complex the principle of the equipment systems. For larger cutting elements, a more sophisticated stabilization system is used.

This affects the weight and cost of the tool. For professional processing of materials, it is necessary to purchase circulars with a disc diameter of 165-240 mm. For home use, products of 140-150 mm are quite suitable. Discs 150-165 mm are considered universal. They are suitable for almost all types of work.

Consumer reviews

Today, the power tool market presents many copies of equipment from foreign and domestic manufacturers. Their cost is quite different.

Users noted that inexpensive domestic copies are quite suitable for work at home. Hand circular saw with the possibility of stationary installation “Baikal”, as well as “Fiolent”, “Interskol” have proven their reliability, which earned popular recognition.

Professionals choose models of foreign brands Bosch, Makita, AEG, etc. This is due to the greater specialization of such equipment, which is excellent for industrial production.

Rpm

The speed of rotation of the disk is one of the main parameters, which is characterized by a circular hand saw with the possibility of stationary installation. Which model to choose will be easier to understand after a detailed consideration of this characteristic.

Together with the shape of the blade and the size of its teeth, the speed affects the cleanliness of the cut. The higher the speed, the more torque.

This parameter also affects the heating temperature of the material during processing. If the speed is too high, plastic panels and blanks will NOT be cut with this technique. The edges will just melt.

If the model provides for speed control, then this is a more versatile device. Otherwise, the torque is selected strictly for the conditions of work.

General information

The advent of the circular saw in the twentieth century has greatly improved the labor-intensive activity of woodworking. Since then, this device has been supplemented with various elements and improved.

The first company that managed to create a truly affordable circular for the consumer was the German company AEG.

The hand circular saw with the possibility of stationary installation is a high-class tool. She owes her ability to work from a household network (220 V) to the first German-made equipment.

The process of adding various functions and innovations to the device is almost complete. Nowadays, manufacturers of electric tools are only improving the quality of their products, the safety of its operation, as well as the accuracy of settings. Increased requirements are being put forward for these parameters.

Hand circular saw with the possibility of stationary installation: how to choose the right one? Additional accessories

With the invention of various network-powered tools, the work of professional craftsmen and hobbyists has become much easier. The result is more in line with modern requirements.

Hand circular saw with the possibility of stationary installation Indispensable for people whose activities are related to woodworking. Today there are many manufacturers offering the consumer this technique. Expert advice will help you choose the best option.

Some tips for choosing

Hand circular saw with the possibility of stationary installation due to this feature is recognized as a tool of a higher class. This possibility is provided even in light models. This approach facilitates the work of the master, who does NOT need to always hold the unit in his hands.

When choosing this technique, you need to pay attention to several nuances. The power cord should be positioned so that it is difficult for it to get under the blade of the disc. Its length should be 3-4 m.

The type of device must be selected purely for the conditions that exist in this case. Anyone needs to acquire an expensive professional dust for household use. But it is not recommended to save on the quality of parts, the protection system. The safety of the work depends on it.

Having familiarized yourself with such equipment as a hand circular saw with the possibility of stationary installation, it is possible to choose the right model of power tool. It will serve for a long time and fruitfully for the benefit of its owners.

Stationary tool types

Circular saws vary in power and purpose. Professional tools of large dimensions are used in woodworking plants, sawmill, for example, sawing logs into planks and beams.

For small production volumes, smaller saws are used. Their size fits in a volume of up to 8 m³. This is the most common type, which is used in private households, small and medium-sized businesses.

Such machines are divided into three groups:

- Domestic use. have a cutting depth within 40-50 mm

- Tabletop. cutting depth 50-55 mm

- Stationary, with installation on the bed. cutting depth 60-140 mm.

Stationary saw specifications

- Electric motor power. With the growth of power, the capabilities of any unit increase. For a circular saw, this means:

- Increasing the cutting depth

- Ability to process very dense materials (oak, beech, larch)

- As the power increases, the operating time of the saw increases.

- Negative factor. the increase in power increases the total weight of the machine, makes it difficult to transport the circular saw.

Hand circular saw with the possibility of stationary installation

Examples of using dust. Cons of desktop machines. Circular saws: device and varieties

All circular saws, without exception, work according to the same principle. the electric motor rotates the disc, which is responsible for dusting and cutting various materials. Circular saws can differ solely in design. there are stationary models and hand-held ones. In addition to their dimensions, they differ in the way they transmit torque from the engine to the cutting disc. In stationary saws, a belt serves as a transmission link, and in manual saws this link is absent altogether (the disc is mounted directly on the shaft, which makes the tool less powerful).

An integral part of hand-held and stationary circular saws is the support platform, which in almost all models has the ability to adjust. an exception may be a stationary model designed for unfolding boards. But all the others have the ability to adjust the depth and angle of cut. quite convenient additions that increase the functionality of this tool.

Circular saw hand photo

In addition, battery models can be distinguished into a separate subgroup of hand-held circular saws. they, of course, are inferior to their wired brothers in many technical characteristics, but they surpass them in mobility and allow you to work away from power lines. Cordless circular saws are widely used in the construction of country houses.

Cordless circular saw photo

The advantages of bench-top machines. The advantages of machine tools on the bed

Stationary circular saw: advantages and disadvantages

Circular saw, in the old fashioned way. circular saw, circular. This is a machine designed for woodworking and woodworking. The main operations are the dissolution of boards, bars along or across the long side, as well as sawing of plywood, fiberboard, OSB and other similar materials.

The circular saw is of two types:

- Manual execution. characterized by low weight, mobility. It can perform almost all functions of a circular saw. This limitation is imposed by the dimensions of the power tool itself.

- Stationary execution. a machine mounted on a massive bed. Characterized by the ability to perform operations with large-sized workpieces.

This article is about the stationary tool. It discusses the working conditions, characteristics, advantages and disadvantages of circular saws.

Circular saws: device, varieties and selection criteria

How to choose a circular saw

The advantages of bench-top machines. Advantages and disadvantages

Consider the pros and cons of stationary circular saws on the bed and tabletop.

Disadvantages of machine tools on the bed

Hand circular saw with the possibility of stationary installation

Circular saws: device and varieties

All circular saws, without exception, work according to the same principle. the electric motor rotates the disc, which is responsible for dusting and cutting various materials. Circular saws can differ solely in design. there are stationary models and hand-held ones. In addition to their dimensions, they differ in the way they transmit torque from the engine to the cutting disc. In stationary saws, a belt serves as a transmission link, and in manual saws this link is absent altogether (the disc is mounted directly on the shaft, which makes the tool less powerful).

An integral part of hand-held and stationary circular saws is the support platform, which in almost all models has the ability to adjust. an exception may be a stationary model designed for unfolding boards. But all the others have the ability to adjust the depth and angle of cut. quite convenient additions that increase the functionality of this tool.

Circular saw hand photo

In addition, battery models can be distinguished into a separate subgroup of hand-held circular saws. they, of course, are inferior to their wired brothers in many technical characteristics, but they surpass them in mobility and allow you to work away from power lines. Cordless circular saws are widely used in the construction of country houses.

Cordless circular saw photo

Sale. Saws

Reciprocating saw AEG US 400 XE

Reciprocating saw AEG US 400 XE is designed for cutting various materials, it is convenient for cutting flush to the wall and with outstretched arms. Versatility of use due to the possibility of setting the blade up or down with the teeth. Saw AEG US 400 XE.

Stationary saw specifications

- Electric motor power. With the growth of power, the capabilities of any unit increase. For a circular saw, this means:

- Increasing the cutting depth

- Ability to process very dense materials (oak, beech, larch)

- As the power increases, the operating time of the saw increases.

- Negative factor. the increase in power increases the total weight of the machine, makes it difficult to transport the circular saw.

Stationary circular saw: advantages and disadvantages

Circular saw, in the old fashioned way. circular saw, circular. This is a machine designed for woodworking and woodworking. The main operations are the dissolution of boards, bars along or across the long side, as well as sawing of plywood, fiberboard, OSB and other similar materials.

The circular saw is of two types:

- Manual execution. characterized by low weight, mobility. It can perform almost all functions of a circular saw. This limitation is imposed by the dimensions of the power tool itself.

- Stationary execution. a machine mounted on a massive bed. Characterized by the ability to perform operations with large-sized workpieces.

This article is about the stationary tool. It discusses the working conditions, characteristics, advantages and disadvantages of circular saws.