How long can you cut the polyurethane foam

10 rules for using polyurethane foam

Polyurethane foam is a versatile tool that is used to fasten parts of structures, seal, insulate and soundproof a room. Such versatility is associated with the ability of the foam to expand during hardening and, accordingly, fill all cracks with itself.

10 rules for using polyurethane foam:

Before working with polyurethane foam, it is imperative to protect your hands by wearing gloves, since it is very problematic to clean the skin of foam.

Before using the container, be sure to shake it, otherwise, instead of foam, when pressed, resin will appear. Shake the cylinder only after removing the cap and attaching it to the gun, in the case of using professional foam, or after putting on the adapter tube, if the work is carried out with semi-professional foam.

Gaps and cracks needing to be filled should be slightly moistened so the foam will set better.

During operation, the cylinder must be upside down, so the gas can push out the foam, otherwise the foam will remain in the cylinder and the gas will spray.

Slots larger than 5 cm should not be treated with foam, it is better to use polystyrene, otherwise the expansion of the foam can lead to displacement of parts of the structure.

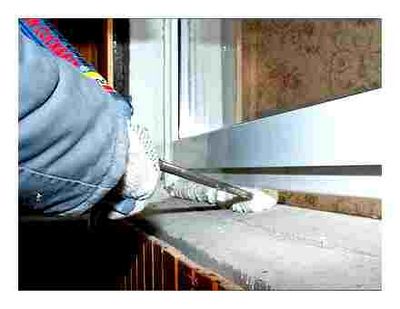

Filling the cracks should be carried out from the bottom up, foaming no more than 1/3 of the cracks, because the foam will expand further when it dries and spread to the entire depth.

When working in the cold season, the foam, namely its winter appearance, must be lowered for a while in a container with warm water (about 40 ° C) so that the balloon heats up.

After finishing the work, the filled cracks should be lightly sprayed with water, so the foam will harden and grab faster. But in the cold season, this should not be done, since this procedure will not give the desired effect, the water will simply turn into ice.

If foam accidentally gets on any surface, it must be immediately removed with a cloth soaked in a special solvent. After all, after the foam has set, it will be very difficult to remove it without damaging the surface.

It will be possible to cut off excess foam only half an hour after foaming; this can be done using a construction knife.

How does household foam differ from professional?

Tytan Professional STD (Selena) summer (pack 750 ml. 315 rubles).

The household foam cylinder is equipped with a special applicator tube. Thanks to this device, no additional tools are required to exit the viscous mixture. Household foams are generally disposable products. The mass yield is difficult to dose, and it itself is distinguished by its high density and low polymerization rate. Professional foams are designed for repeated use and better sealing. In them, the supply and metering of the foam jet occurs using a plunger pistol. It is screwed onto a special ring on the cylinder. It is professional foam that should be preferred when installing doors and windows.

Which foam is better, household or professional

It is very easy to distinguish between household polyurethane foam and professional one. It is enough to look at the balloon. if a nozzle in the form of a thin plastic tube is attached to it, then it is intended for household needs. However, it is impossible to say unequivocally that only beginners use such foam, and professionals necessarily use a nozzle in the form of a pistol. Consider the main differences that will help you decide and choose the appropriate type.

- The first thing that is immediately noticeable is the size of the packaging. Household foam is sold in cans with a capacity of 300 ml and above, while professional foam. from 750 ml and above.

- An important indicator is the release of foam from the cylinder. In the case of a household aerosol, not the entire composition can be blown out completely. Usually some part remains inside, and from the volume declared by the manufacturer you will get a somewhat average value. Thus, instead of the required one cylinder, two may be required, and this already affects the costs associated with the repair. In this regard, professional foam proved to be much better, which is blown out almost completely.

- The secondary expansion coefficient for household compounds is very high. In the process of final hardening, they can increase in volume up to two times. The same coefficient for professional foam is practically zero. Good or bad depends on the nature of the work being performed. For example, if you are faced with the task of filling a large gap in the wall or eliminating the creaks of an old wooden floor by blowing foam under it, then a significant indicator of expansion in this case is a plus. If you install slopes, plastic windows or doors yourself, then it is better to fill the space around them with a composition with the lowest expansion coefficient. Otherwise, there is a possibility of surface deformation. Only with proper skills in working with this material can you use household foam for such precise work. Usually, specialists fill only 1/3 of the gaps with foam, knowing that once it has finally hardened, it will fill the entire space without changing the geometry of the adjacent surfaces.

- The shrinkage rate of household foam is 5-7%. Professional. 0-3%.

- Regarding the need to use an additional device in the form of a mounting gun, household foam, of course, wins. It is enough to screw the supplied tube onto the cylinder, shake well, and the foam is ready for use. Professional formulations work only with a pistol, the cost of which is several times higher than the cost of the foam cylinder itself. For a single use at home, such a waste is impractical. Indeed, in addition to that, it will be necessary to purchase a special solvent that will clean the pistol nose of the foam residues.

- The possibility of reusability is undesirable for household cylinders, but possible. If it was not possible to use the entire cylinder to the end, clean the inner cavity of the tube from the remaining foam with a propellant gas and store in a cool, dark place. Professional foam can be used partially. But at the same time it is necessary to store it with a pistol on the cylinder. In this case, the foam inside does not harden and is suitable for further use. The gun nozzle must be cleaned with a special solvent.

- And the most important difference is the nature of the work performed. Household foam is used for one-off, rough work that does not require precise dosage. Professional formulations are distinguished by the possibility of high-precision application and are used for sealing joints or thermal insulation.

Main characteristics

Like any building material, polyurethane foam has a number of characteristics, on the indicator of which the quality of the product depends. All the main points will definitely be indicated on the label. So, what you should pay attention to when buying:

- The degree of primary expansion is an indicator of how many times the volume of foam at the outlet of the cylinder will increase upon contact with air.

- The degree of secondary expansion is an indicator of the increase in the volume of the material after the period of complete crystallization.

- Foam density. It is she who affects the expansion rate. For household foam, this indicator is lower than for professional foam. To obtain a very tight seam, it is necessary to purchase foam with a low secondary expansion rate.

- Viscosity is a property of a material that ensures that the foam does not flow over the surface.

- Shrinkage. indicated as a percentage and implies a decrease in the final volume of the composition by the specified value.

- Foam outlet volume. On each bottle you can see the numbers. “50”, “60”, “70”. What do they mean? This is the number of liters of foam produced at the outlet of the cylinder. But the indicated amount can be really obtained only under the condition of operation under the correct temperature conditions and controlled humidity parameters. Usually, the actual amount of foam will be less.

- Adhesion to materials. in other words, the ability of the composition to “stick” to various surfaces.

- Time of complete hardening and trimming. given these indicators, you will be able to have an idea of the time it will take to carry out the work, and understand how many hours it will take to plaster, grind or give the seam to other influences without harm to it.

- The weight of the balloon is very important. Keep in mind that if the volume is 750 ml on the bottle, then it must weigh at least 850-920 grams. If it is lighter, then the composition inside is much less than stated. This can often be found among unscrupulous manufacturers. For clarity, you can hold in your hands cylinders of different brands with the same volume. It is possible that one of them will be clearly heavier. It is worth acquiring.

How to use polyurethane foam correctly

Consider situations when it is advisable, and when not very, to use polyurethane foam:

- Do not use foam to seal cracks less than 1 cm wide. For these purposes, sealants or more plastic materials, such as putty, are better suited. In addition, these materials do not have secondary expansion.

- If the width of the gap exceeds the 10 cm mark, before filling it with polyurethane foam, it is better to additionally reduce the space with the help of wooden beams, bricks or any other sealant. This will significantly reduce foam consumption and increase its adhesion to the surface. Otherwise, under its own weight, it can simply slide along the walls of large slots.

- The optimal size of the gaps for filling with polyurethane foam is 2-8 cm.

- For faster polymerization and better adhesion of the foam to the adjacent surface, many recommend slightly dampening the walls before applying. And then, spray the assembly joint with water from a spray bottle after initial hardening.

- It is not recommended to use foam on surfaces such as Teflon, silicone, polyethylene and other greasy or dusty walls. She just won’t stick to materials like this.

- Be sure to consider the primary and secondary expansion ratios. This will help you understand how thick the seam needs to be applied in a gap of a certain width.

- Before using the cylinder, be sure to clean the surface according to the instructions on the package.

- If the bottle is too cold or you brought it from the cold, keep it in warm water (no more than 20 ° C).

- To ensure better mixing of the components with each other, turn the can upright and shake for 1 minute.

- Use protective gloves. Dried foam is very difficult to clean.

- Never touch freshly applied foam until it has set. You will not only get dirty, but also break the structure of the material. This can lead to poor hardening or incomplete expansion.

- To achieve the full volume of foam from the cylinder, be sure to hold it upright and upside down until the end of the work.

- The polyurethane foam should have a pale yellow color throughout its entire service life. But you can see that it can darken over time. This is caused by the harmful effects of ultraviolet rays, which destroy the structure. If possible, it is better to plaster or paint the seams, thereby protecting from sunlight.

It is very easy to use a can of household foam. It is enough to screw on the tube and the working attachment is ready. But if you do decide to purchase a professional foam and a special gun, you need to be able to use it correctly. The principle of its operation is very simple. the pistol is screwed onto the cylinder, after which the foam enters the barrel through the supply valve. There it remains until you pull the trigger. After that, the material is released with a predetermined volume. Let’s consider the main points:

- Choose guns that are only made of solid metal.

- To facilitate cleaning and replacement of parts, it is better to purchase collapsible rather than monolithic models.

- Purchase a dedicated cleaner immediately.

- Before installing the pistol on the cylinder, you need to unscrew the fastening screw, lubricate the socket with technical vaseline and only then proceed with its fastening.

- First, you need to set the adjusting unit to the minimum rate of foam consumption.

- Flip the bottle over and do a couple of test presses. So you can visually assess the need to increase the flow and adjust the volume to suit your needs.

- Make sure that during operation the cylinder is always in an upright position.

- At the end of work or when changing the cylinder, be sure to thoroughly clean the gun.

How to Make Large Composite (Fibreglass) Patterns by Hand

By adhering to these key recommendations, you can easily cope with the use of any type of polyurethane foam.

What is polyurethane foam?

Maxi (Profflex) all-weather (pack 750 ml. 218 rubles).

One-component polyurethane foam is an aerosolized polyurethane sealant. The base of the foam is a prepolymer (prepolymer) synthesized from polyol and isocyanate. As a result of a polymerization reaction, partly taking place inside the cylinder, and mainly in air, after exiting, these substances form polyurethane. Coming out of the balloon, the prepolymer sharply increases in volume (20–40 times) and turns into foam. Expanding, it penetrates into hard-to-reach cavities, fills the voids. Then the cellular mass gradually polymerizes (hardens), absorbing moisture from the air or from a previously moistened surface. After a day, it becomes a chemically stable substance. polyurethane. It is non-toxic, does not deteriorate for a long time, and is resistant to moisture. This rather rigid, finely porous material consists of closed cells and serves as a good insulator.

Whether to wet surfaces before applying the foam?

A relative humidity of more than 50% is sufficient for the normal foam polymerization process. In such conditions, it is not necessary to moisten the surfaces. However, at low humidity (less than 50%), which is typical for the cold season and hot summer days, moistening the joints and cavities will increase adhesion and improve foam hardening. This should be done without fanaticism, so that there are no drops on the surface and no water accumulates, otherwise its excess will prevent the foam from connecting to the surface.

The construction gun must be cleaned of foam immediately after removing the empty cylinder, avoiding hardening of the mass inside the gun.

Briefly about manufacturers

Description

Polyurethane foam is classified as a sealing agent, without which it is almost impossible to do in the construction process. It is used in cases where there is a need to seal seams or joints with a depth and width of more than 3 cm.Before using this material, builders wonder how long it takes for the foam to dry completely, but it turns out that this question has been posed incorrect. First of all, it should be said that the main secret of the complete transformation of the material into strong polyurethane foam is the degree of wetting. But we will pay attention to this fact.

First you need to decide why builders prefer polyurethane foam:

- its application is very simple;

- pricing policy is available;

- long service life.

In addition, this material has qualities that isolate sound and make it possible not to lose heat from the room.

Most often, foam is used in the process of installing balcony blocks, windows or doors of various types. When applied, the composition begins to expand and at the same time fills all the voids, thereby gluing the desired surfaces. It should be noted that the curing time also depends on how thick the layer was applied. If it is not more than 5 cm, then within 3 hours after leaving the cylinder, the foam will reach the required density.

Foam is also so popular for the reason that, when frozen, it is not subject to the effects of temperature, moisture and even electricity, in addition, fungus does not appear on it. It should be noted that the foam can undergo changes from the influence of ultraviolet radiation, but this defect can be eliminated by using decorative plaster.

Requirements

Polyurethane foam is a material for which, like any other, a number of requirements are put forward.

These requirements include:

- good adhesion of surfaces;

- elasticity;

- after solidification, the material should not crumble, even when exposed to sub-zero temperatures;

- shrinkage of a solution that has already dried should be moderate.

We draw the attention of users to the fact that the foam is very afraid of direct sunlight. For this reason, after complete hardening, the excess is cut off, and all sealed places are treated with paint or plaster. And in order not to disturb the density of the material and to make the application sequence correctly, you need to know how long it takes to completely solidify.

To eliminate gaps between door frames and openings, only a third of the sealant will be required. The material will begin to solidify on the surface within half an hour after application. You may notice that a film will appear on the surface.

Final drying can be expected 8 hours after application. The fixing process occurs due to the expansion of the substance that comes out of the container and solidifies.

Conventionally, this is divided into several stages:

- primary, which is carried out immediately at the exit from the package;

- secondary, which is not completed until the final transformation of the foam into a solid composition.

If the material is of high quality, then at the second stage the expansion rate can reach 30%, this must be taken into account in the process of work. Most often, it takes a third of the material to fill the space, this is enough to fill all the cracks when expanding.

But you should also pay attention to the fact that the foam should shrink, you should not be afraid of this action, it will not bring problems. In high-quality materials, shrinkage can reach 5%, and this is invisible externally. If shrinkage still occurs, and this is clearly visible from the side, it means that the polyurethane was purchased of poor quality.

How much polyurethane foam dries?

- Description

- Material characteristics

- Requirements

- Polymerization time

The drying process of polyurethane foam depends on many influencing factors: the quality of the material, its composition, the temperature of the external environment and its humidity. All this must be taken into account before starting to seal seams or openings.

Material characteristics

With the help of polyurethane foam, various types of work are carried out, this does not necessarily apply to windows and doors, with the help of this sealing consistency, builders close up large gaps, eliminate voids and fasten structures. If you familiarize yourself with all the qualities of the material, you can understand that it can be compared to sealants due to its ability to seal the required surfaces.

Before disassembling the drying process in detail, you need to familiarize yourself with the main characteristics of the material.

- Output volume. This indicator shows what changes have occurred with the material in comparison with its original state. The unit in which this volume is measured is liters. The main aspects that affect this indicator are the temperature and humidity of the treated surface.

- Clutch. This characteristic allows you to determine how well the material will adhere to the surface. Exceptions in this case may be surfaces such as polyethylene, ice, greasy bases, Teflon and silicone.

- Viscosity index. These data will depend on the quantity and quality of the components used to prepare the foam. In addition, the outside temperature will also affect this property. It is recommended to use the material only when the indicator is from 5 to 30 degrees.

If you apply foam outside the established boundaries, then it will lose its main qualities, and the original product will not meet all the requirements put forward.

If the consumer needs to purchase a sealing foam, then, in addition to the drying rate, you need to pay attention to several more main parameters.

- Porosity index. The smaller it is, the better the foam quality. This parameter is determined by the number of pores in the closed state on the surface.

- Volume. In this case, you need to pay attention to the mass of the polymer already in a solidified state.

- The quality of the packaging, in our case, the bottle. It would seem that this is not such a serious criterion, but it is the design and integrity of the container that can affect the quality of the material inside and the final result.

Polymerization time

So, at the beginning we pointed out that water plays a rather important role in the use of polyurethane foam. This is due to the fact that it is the liquid that increases the adhesion rate, for this reason, experts recommend wetting the working surface before carrying out work. It is not necessary to pour a large volume of water onto the walls; it is enough to use a conventional spray bottle.

If we consider the process of installing door structures, then, as already mentioned, the drying process will be affected by the thickness of the layer and, of course, the temperature indicator of the environment. Under normal conditions, the excess foam can be cut off after 3 hours, and after that you can start plastering. Speaking of the final hardening, it should be noted that it will come after about 12 hours.

Many people wonder how much foam dries when installing windows or doors in an apartment, and if it has already been applied, then why does it take a long time to dry. Foam dries for a long time for various reasons. One of the main ones is to use it at the wrong temperature.

If the foam has been used in cold or too dry conditions, the cure may be delayed indefinitely. But experts warn that in this situation you should not rush to trim and finish, you need to wait for the full hardening.

To make the process faster, a special winter foam must be selected for work, its qualities correspond to the conditions in which it will be used.

In the event that you are unhappy with the drying time, it can be accelerated by spraying the material with liquid. You can use any method you like. If the work was carried out on windows, do not forget that direct ultraviolet light negatively affects not only the drying process, but also on the material itself, therefore, if possible, the places of embedding should be hidden.

See the next video about what polyurethane foam is and about its features.

Ways to dissolve cured polyurethane foam

Installation foam has a complex chemical composition. It hardens for several hours, after which it becomes a solid substance. Some installations require a small amount of foam. If the gun is removed from the container and cleaned immediately, while the mass is still liquid, there will be no problems.

How To Evenly Remove Thickness From A Large Piece Of Cushion Foam

Many people forget about the “hygiene” of the device and in the process of the next use they face a nuisance: the gun is clogged with a hardened agent. It is not possible to squeeze it out, you have to buy a new unit. Is it possible to dissolve dried polyurethane foam at home? And what you need to do? Explain in detail.

What products dissolve foam

You can purchase special products that quickly remove the hardened mass from plastic. The pistol is made of plastic material. Until the building foam has dried, it can be easily removed with acetone. It is enough to moisten a cotton pad and wipe the outlet of the device. Or, soak a cotton swab in acetone and drip from its end into a thin hole. The liquid will clear it and the next use is not difficult.

Wiping the foam tube

Only professional chemicals will help dissolve the polyurethane foam in the gun when it has dried:

- PlatinaCleaner;

- Peno-OFF;

- Hobby;

- Purex;

- Russian professional.

The methods of using these products are explained on their packaging. You need to shake the container well (usually they are sold in cylinders), spray on the tip of the gun and leave for ten minutes. After this time, wipe the area with a cotton cloth. If the problem is more serious. dry mass inside the device, it should be disassembled. Remove from the bottle and pour the chemical into the tube from below. Shake to dissolve the dry mixture in the tube, turn it over and leave. Cured foam should dissolve.

Polyurethane foam solvents

Safety precautions are important when using cleaning chemicals, including acetone. Work with gloves. Try to avoid contact with skin and respiratory tract. Better to use a mask. Do not spray the substance near fire.

Traditional methods

You can dissolve the polyurethane foam at home with medications. For example, “Dimexid”. Sold in pharmacies without a prescription. Dimethyl sulfoxide is not an expensive drug. It should be used gently by people with sensitive skin. The medicine is able to be absorbed into the bloodstream through the skin and affect well-being. Better to put on seals before work.

The solution should not be diluted. The concentrate is applied to the area of hardened material and left for up to 30-40 minutes. After that, it is wiped and cleaned with a sharp object (brush, knife). You can dissolve the polyurethane foam that has dried in the gun inside the outlet tube by pouring Dimexidum inside it.

The drug is also used to clean clothing from assembly building materials. Also, apply for 40 minutes and clean with a dry cloth. After the procedure, clothes must be washed!

The oil solution is used to clean the plastic. Vegetable oil is applied to the device and kept for half an hour. Then the same manipulations: wiping and stripping.

Mechanical cleaning methods

If you don’t have a professional “tool” at hand, you can get rid of the polyurethane foam on the gun by mechanical methods. But they are only suitable for external cleaning. Get a metal brush, knife or scraper. Cut off large dried pieces first. Then scrape off the remaining areas with a sharp object. At the end, wipe with sandpaper.

Dismantling the mechanical cleaning gun

Mechanical methods are inconvenient to clean the device, so they are used in extreme cases. If there are large pieces of dried building material on the pistol.

How to keep a nailer in order

Despite all possible methods of cleaning the gun, it is very difficult to dissolve the frozen polyurethane foam in it. Many do not undertake this business, but immediately buy a new device. To avoid such problems and save money, you should properly take care of the instrument after each use. Do not leave a used cylinder open with a pistol inside, even for a short time.

If the work with the foam is finished, the structure should be disassembled. Rinse the tube while the foam is fresh. Acetone or white spirit will help with this. If the substance inside has time to dry out, the gun must be disassembled. Unscrew the crown in the seat. Pour the solvent inside it. Then the mechanism is assembled.

The dried consistency can be removed from the tube with a long wire. The dry mass must be crushed, then shaken out of the tube. It is important that the wire is stiff.

Applying the recommendations, you can keep the device in proper shape throughout the installation work. You don’t have to buy a new gun every time.

Consider some of the ways how you can wash polyurethane foam

The polyurethane foam can be easily washed, trying not to waste time, since when it hardens, the removal process will be much more difficult. Here are some examples of how and how you can wash polyurethane foam:

- a solvent that is likely to be found in any home (white. spirit, gasoline or acetone);

- nail polish remover;

- dimexidine. a drug for external use, can be purchased at any pharmacy;

- for absorbed foam, you can purchase a hardened polyurethane foam cleaner;

- kosmofen 20. professional cleaner for polyurethane foam or glue from varnished surfaces, on window profiles or window sills.

The most difficult way to wash your hands with home remedies is that you cannot apply solvents to them so as not to damage the skin. In such cases, oil or some kind of fatty cream is used, or the foam is cleaned by mechanical actions.

When using oil, it is necessary to thoroughly smear the contaminated area with oil or cream and after 20 minutes quietly remove from the skin.

After the foam gets on it, the skin will remain red and irritated, therefore, after rinsing off the remnants of the cream or oil with warm water, you need to smear this place with cream.

In the event that you have to use a mechanical method, the foam will leave the skin of the hands along with skin particles, so then this place must be processed and bandaged.

How can you clean the foam in an apartment after repair

If during the repair you accidentally left polyurethane foam on your hands, clothes or on any objects, do not be upset. The polyurethane foam is peeled off and washed, you just need to know what and how.

If foam gets on your clothes

If foam gets on clothes or upholstered furniture, smear an inconspicuous area with one of the solvents, wait 10. 15 minutes. If the result is positive, start treating the contaminated area:

- with a sharp thin knife, gently peel off the adhering foam from the fabric, without touching the fabric itself;

- moisten a clean napkin in the chosen solvent and wipe the stained area or moisten it abundantly and simply apply for 5.10 minutes;

- remove the napkin and make sure that the foam has completely disappeared;

- wash the clothes or wipe the damaged area on the furniture with a clean rag and dry them.

If foam gets on the linoleum, you can remove it with plain water. First you need to cut off the frozen piece of foam with a knife, then thoroughly wet the area and after a few minutes just remove the softened foam with a clean napkin.

In order not to get rid of the consequences of working with polyurethane foam, it is necessary to cover those surfaces on which it may get into and use rubber gloves and overalls.

Cleansing foam from various surfaces

Various cleaning options

Polyurethane foam refers to substances, the removal of which causes certain difficulties. Until recently, acetone was considered the only cleanser. Now, many alternative cleaning methods are used, which we will analyze in this material. Foam acts differently on different materials, so you need to use different means selectively.

We list the means with which you can deal with traces of polyurethane foam:

- Acetone, as well as a liquid based on it, used to remove nail polish. Dissolves liquid foam very well. May stain glossy and varnished surfaces.

- Foam removers. There are a large number of such products on the market, some of which are suitable for removing traces of fresh foam, while others are designed to remove an already cured composition. For example, ULTIMA Professional, PENOSIL Foam Cleaner are used for fresh substance. For cured foam, it is advisable to use PENOSIL Premium Cured, Isofoam R621, Cosmofen 5.

- Dimexide. This is a pharmaceutical preparation that, when interacting with foam, destroys its structure. After a while, the remnants of dirt are easily removed from any surface. Gloves are required when working with the drug.

- Vegetable oil. Softens the composition, resulting in a delicate removal of dirt. Oil should be applied to stains left after removing the main foam mass.

- Water. Plain water can soften a thin layer of foam. After a certain time after the beginning of soaking, the solution can be removed mechanically.

- Cold. A negative temperature binds foam molecules, leads to their solidification. In this form, the composition can be removed from some surfaces.

Tip: If you decide to use some kind of foam cleanser, first treat a small area with it. If there are no effects on the surface, you can use this product for a complete cleaning.

How can you wash polyurethane foam from various surfaces

Almost no type of construction work can do without mounting foam. With its help, gaps are closed, window and door openings are filled, some types of products are glued together, and a lot of other useful actions are performed. In the process of work, it is very rarely possible to do without getting the sticky contents of the container on various types of surfaces in the immediate vicinity, as well as on hands and clothes. The main question of this article is how to clean the polyurethane foam, which is in a liquid or already hardened state.

How to Cut Polyurethane Foam

Freeing the gun from foam residues

After the end of the work, if the gun was used, particles of polyurethane foam remained in it. How to clean the gun from polyurethane foam? This can be done in two ways:

- Mechanical cleaning. With the help of a knife, flat screwdriver or awl, the remains of the frozen composition are removed;

- Dry cleaning. For this, a bottle of foam solvent is inserted into the gun. For example, PENOSIL or OPPA. After that, you should pull the trigger until a clear liquid comes out of the gun.

After such cleaning, the device will restore its performance.

Note: There are different types of solvents for liquid and cured foam. Each of them copes better with a specific composition of the substance.