How much lubricant in the gearbox Ushm. DIY grinding gearbox

Lubrication for the gearbox of the grinder. Which one to use, how much to lay

Angle.Grinding machines (Ushm), which are popularly called Bulgarians, were widely used among lovers of lovers. With their help, a home master can not only carry out grinding work, but also cut metal, plastic, stone. Angle.Grinding machines are produced by various manufacturers, including domestic.

An angle grinding machine is a reliable tool that can work, with proper operation and timely replacement of lubrication and coal brushes for a long time.

The correctly selected lubricant for a grinder not only extends the life of the tool, but also improves operational characteristics.

Knowing the rules for choosing a lubricant for a grinder or it with your own hands, you can perform maintenance without contacting service services.

Dense lubricant for a motorbear gearbox

We constantly see sighs and ahi of “specialists” on the forums, which, immediately after the purchase, for some reason open the motor gear and then begin to write nonsense about a small amount of lubricant in the gearbox, misleading other people in misconception with their illiteracy. But none of these figures had yet written a post, about the wrong type of lubrication in the motorcycle. This is probably because “specialists” are not interested in the quantity of quality.

Nevertheless, lubricants in any of our mechanical motorized cars are enough to immediately start work after the purchase and continue it for at least a year, and only then you should think about checking the lubricant. We have already told how to change the lubricant, and in this article we will tell you more about the lubricant itself.

And this will not be liquid oil that “specialists” regularly try to pump through the press olycum inside the gearbox. To lubricate the coaxial gearbox, a thick lubricant is required, which is sometimes called by reducing the American National Institute of Plastic Lubrices NLGI (National Lubricating Grease Institute, USA). This is not a corporate name for lubricant, it is the name of the certification body that has developed tolerances for the use of this lubricant. And the blue lubrication color is only one of the colors of this lubricant.

Most of the leading oil companies produce a lubricant of the NLGI type, and each has its own trade name, Mobil has a GADUS shopping category lubricant, in Shell, such a lubricant is called nautilus. Our native and well-deserved domestic lubrication of Litol-24 did not test the requirements of National Lubricating Grease Institute, but in its properties it is very similar to NGLI 2, which is stuffed into gearboxes at the motorcycle factory.

Why ngli 2, not 3 or 4 ? The fact is that this lubricant is divided into its classes, which are designed for different applications in mechanisms. For a motorbike with a coaxial gearbox, class 2, which has the number of penetration 265-295. But this is not what some thought). According to the National Lubricating Grease Institute, according to the laboratory method of “working penetration”, a grease density is measured. Penetration is translated from Latin into Russian as penetration. The measurement of this value is made using a penetromometer with a cone, which is lowered for five seconds in grease at a temperature of 25 ° C. The measurement method is similar to our domestic GOST 5346-78 for plastic lubricants, according to which Litol-24 is made. The depth of immersion of the cone is measured and expressed in tenths of the fractions of a millimeter. Typically, the ability to penetrate is determined both in struck and not stirred lubricant. The difference in these indicators characterizes the stability of the lubrication and the ability to withstand mechanical loads. In addition, the greater the numerical value of the penetration, the softer the lubricant.

In any mechanical coarse motorburst gearboxes, NGLI 2 lubrication is used. Lubrication can be painted in blue, red, gray or to be natural yellowish color. And to replace after washing the gearbox, you can safely use lititol-24. These lubricants work perfectly within the temperature of the environment from. 40 to 120 degrees Celsius. At a temperature below zero, the lubricant thickens, but 30-40 seconds after the engine starts and the reducer, the lubricant heats up less thick and acquires the desired viscosity for penetration between the gear wheels and into the working cavities of the bearings. That is why it seems that there is little lubricant in the gearbox, talkers from the forums do not even realize that when heated by friction, the lubricant becomes a slurry.

The lubricant in the volume of 100-120 ml is laid at the plant in the gearbox and the quantity is enough for painless work, despite the angry Комментарии и мнения владельцев of the “specialists”. Therefore, there is no need to open the gearbox and add grease. The lubricant does not change often, with daily use of a motorcycle, the lubricant must be changed no earlier than the second year of use.

Homemade mixtures

In the absence of the desired lubricant or, if the user considers the price of the goods unreasonably high, you can try to make a lubricant yourself. There are several recipes using different foundations. One and them. Common CITIMI-221.

TAD-17 transmission oil is added to the container with cyatim. Stirring continuously, add oil one drop until the necessary consistency is achieved. The mixture should be well adhered to the details, not to be too thick and not flow like liquid oil.

Another basis may be a lubricant for a shrug in combination with liquid oil MS-20.

Varieties of lubricants for a grinder

Before lubricating the grinder, you need to familiarize yourself with the main types of lubrication. The following mixtures are most often used to process the Ushm gearbox:

The better to lubricate, which one to use for ushm

Many are interested in what lubricant is needed for the gearbox of the grinder and what is better to use. To deal with this, you need to familiarize yourself with the features of choosing lubricants for tools from different brands.

Bosch

Bosch is a rather popular manufacturer of drums, perforators, bells and other power tools. People who use devices from this brand can use their proprietary lubricants. They are sold in small tubes with a capacity of 50-100 ml. This is enough to carefully lubricate the gearbox 3-4 times.

If you fail to purchase a lubricant from Bosch, you can look for universal mixtures. Sololidol or a mixture for CV joints and Ushm Metabo is also suitable.

Makita

Lubrication Makita is one of the most expensive in the market

This company, like Bosch, is also engaged in the production of power tools and lubricants for them. Despite the fact that the catalog of lubricant in Makita is small, you can still find a suitable composition for processing the gearbox.

Most often they are sold in large plastic containers of 500 ml. In rare cases, you can find small disposable tubes for 30 ml.

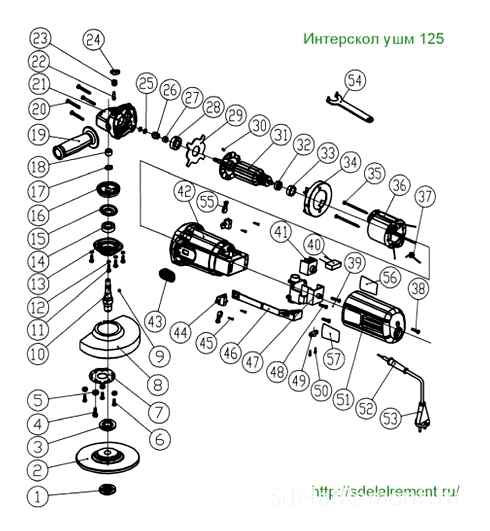

Interskol

This is a famous Chinese-Russian manufacturer, whose popularity is growing rapidly. It is worth noting that the intercol makes not only Ushm, but also lubricants for them. The brand catalog has at least ten items. They are used to process tail drills, gasoline engines, gearboxes and saw structures.

Devolt, DeWALT

Devolt is a popular American brand specializing in the production of high.Tech electrical tools. This manufacturer does not create brand lubricants and therefore will have to independently select the appropriate composition. It is allowed to use solidol, lithola and lubricants for cries.

Chips on the choice

Lubrication for gearboxes and bearings (for example, conical) differ in properties. Materials for bearings must have increased adhesion. It is necessary that the lubricant be held tight on the gearboxes during operation. The gearbox is lubricated using spraying.

Suspensions of the lubricant during operation form a kind of fog. In addition to adhesion, there should be other qualities. For example, it is important to resist high lubrication temperatures. She must withstand high temperatures without problems and not melt with them.

Characteristics and features of lubricants for bells

When servicing any manual tool, where there are mobile parts, a lubricant is used that has the following characteristics and features:

- It should not have solid particles that can cause painting mobile parts of the mechanism.

- The temperature at which the lubricant becomes liquid, should be more than 120 degrees.

- Oil should not absorb moisture, must form a strong film that protects the parts from corrosion.

- And also, most importantly, the oil should be such a viscosity that he has the opportunity to stay on mobile details.

The consistency or viscosity of the lubricant is divided according to NLGI (National Lubricating Grease Institute), while in certain cases it is necessary to use the oil of a certain density. The viscosity of the oil is selected depending on the speed of rotation of the gearbox, the higher it is, the more liquid should be oil. So, depending on the tool, viscosity is selected:

- Drills, perforators, jigsaws, where the gearbox has a low rotation speed. Lubrication with the NLGI-2 index which is soft.

- Light punch and shock drills. Class NLGI-1, in consistency very soft.

- Ushm, circular saws, motorcycles. Class nlgi-0, half-liquid in consistency.

- Heavy perforators, junk hammers. Class nlgi-00, in consistency is liquid.

What grease to choose

There are several ways to reduce the friction impact on the interacting elements of the grinder gearbox. The choice than to lubricate the friction nodes is made from the following options:

- The use of expensive special lubricants for gearboxes from known brands;

- The use of universal compounds suitable for any power tool;

- Lubrication of the gearbox with lithol or solidol;

- Using self.Made lubricants.

Application of special materials. The optimal solution. When choosing a lubricant for the gearbox, it is recommended to give preference to the compositions produced under the same brand as the Bulgarian itself. For example, if AEG machine machine, then the lubricant must buy the same brand.

When using specialized products, the service life of Ushm is significantly increased, since the manufacturer takes into account all the features and nuances of the operation of their own equipment. The minus of the use of branded materials is their high cost, which may affect the family budget.

Specialists and service masters recommend purchasing any budget non.Branded composition designed specifically for gearboxes. You can also use a lubricant used for a CHIR. Joint.Wheel drive joints operated under significant loads. It can be purchased without problems in any car shop. This option is much worse than using branded materials. This is due to the fact that the specifics of the operation of the friction nodes of two different mechanisms are not taken into account.

The most unfavorable solution is the use of lithola or solidol, since both of these materials are not designed to grease the friction nodes heating to high temperatures. Some owners of the Bulgarians use only these compositions, which is why their cars cannot last during the service life declared by the manufacturer. In an effort to gain profit here and now, they do not take into account future expenses for the acquisition of a new tool or replacing expensive parts.

Block: 5/6 | Summer characters: 2303Source: https: // wikimetall.Ru/oborudovanie/Smazka-Dlya-Creduktora-Bolgarki.HTML

The procedure for applying

The process of servicing a grinder consists of several steps. First you need to open the gearbox, then remove the old grease, lay a new one and check the correctness of the application.

To disassemble the Ushm gearbox, you will need to unscrew 4 screws on its lid.

After removing the lid, you will see two conical shocking gears. Large and small. The small is anchored and drives a large. The latter, in turn, is planted on a secondary shaft, to which a cutting or grinding disk is attached.

A disassembled gearbox must be cleaned well of the old lubricant. He no longer performs his functions and has accumulated solid particles of wear of moving parts.

Gearbox lubrication BRUSH CUTTER / how much? How often? How to lubricate?

The exhaust lubricant is removed with a rag or paper towel. You can also remove the parts and rinse them in gasoline or solvent, and then dry thoroughly.

When cleaning and washing the gearbox body, be careful with the rear bearing of the spindle. If it is needle, do not wash it and do not lubricate it. Needles can fall out of a worn separator or outer clip. Thus, there can be a lot of problems. Up to the need to replace the bearing.

When washing the gearbox body, hold the grinder with the engine up so that the dirty solution does not flow through the rotor shaft into the bearings and electric elements.

Before applying, a new lubricant, it must be mixed. Lumps or extraneous impurities in it should not be. On the gear lubricants are distributed with a thin layer so that it completely covers the teeth.

It is more convenient to introduce lubrication inside the bearings with a syringe. The composition is also stuffed into the gearbox body. This is necessary for “insurance”. If the lubricant flies off the gears or it turns out to be too little, the details will not work for dry.

The last step during the maintenance of the angle grinding machine is to check the correctness of the application and distribution inside the gearbox of the lubricant. When the gearbox is assembled, the power tool is included without load for several minutes, while there are no extraneous sounds, smell and other things. When they occur, the grinder is immediately disconnected from the network.

In addition, the heating of the gearbox is checked. The lubricant should distribute heat evenly, so the temperature of the gearbox should not be too high.

The better to lubricate the gearbox Ushm

Any power tool contains in its design rotating parts subject to increased wear as a result of friction. It is possible to prevent premature destruction and extend the life of the instrument if you prophylaxate the rubbing parts in a timely manner. In the Bulgarian, the main wear is subject to gear gearboxes. You can reduce the harmful effect of friction by applying lubricants to the surface of parts. Consider what kind of grease for the gearbox is better to buy.

With intensive daily use of a grinding grinding, a lubricant in the gearbox should be carried out at least once a year. Often, users do not adhere to certain periods of preventive maintenance of the tool, and regulatory work is carried out after the manifestation of extraneous sounds during operation. This is a completely incorrect method for leaving the gearbox.

The prophylactic examination of the gearbox begins with the separation of its casing from the rest of the grinder. To do this, just unscrew the four fasteners.

The next photo shows that the lubricant in the case is present, but gathered on one side of the case, and it is not enough.

This is because Ushm (angle grinding machine) works At high speeds. Under the influence of centrifugal forces, particles of oil strive to move away from the axis of rotation. With prolonged operation, the surface of the gears become completely dry, and without lubrication the metal is erased. In this case, it is enough to lubricate the gear tooths with the existing composition, then close the gearbox and work until the next prevention.

Often in the gearbox you can see grains of oil mixed with dust. During operation, the Bulgarian heats up, and these grains soften, solid particles prevent the operation of the mechanism. Such a lubricant must be replaced.

Lubrication of domestic manufacturers for bearings and gearboxes of Bulgarians

With an increase in for foreign lubricants, especially the lubricants of domestic manufacturers have become in demand.

Russian manufacturers of lubricants have learned to produce high.Quality lubricants suitable for any tools.

Lubricants have been developed for gearboxes of grinders, perforators, drums.

Particularly popular is the products of Nanotek metal plaque Electra. The manufactured series of lubricants with this company allows you to choose the lubricant you need for each assembly

Ushm lubrication for bearings

Three bearings are installed in the design of the angle grinding machine. Two bearings are installed on the rotor of the tool, one bearing is mounted on the shaft of a led scooter of the gear of a larger diameter.

In the Ushm, bearings are used, already filled with grease. But from improper operation, overheating of the lubricant tool.

How to choose the right grease for bearings of the grinder?

Lubrication for bearings should satisfy the following requirements:

- Increase sliding;

- Reduce friction between the component parts of the parts;

- Evenly distribute heat and perform the role of coolant;

- Prevent corrosion;

- Protect against pollution and dust from entering;

- Work in the required temperature range up to 150C;

The working conditions of the electric motor bearings cast from the working conditions of the gearbox bearing, not only due to temperature requirements, but also operating modes, load modes, frequency and speed of rotation.

The lubricant for bearings of the electric motor should have protective properties that prevent the ingress of dirt, dust, moisture on the parts of the bearing.

The Russian market presents a wide range of foreign lubricants intended for bearings operating in different conditions. But their cost makes you look for cheaper, not inferior in quality, domestic lubricants.

From domestic lubricants, we recommend that you pay attention to the lubricants of the CITIMI-221, VNIINP-246 (GOST 18852-73), VNIINP-235. Lithium lubricants have proven themselves well

Lithium lubricants have proven themselves well.

With high water.Repellent properties, they have a wide temperature range. The role of the thickener in them is performed by organic and inorganic substances. For closed bearings, it is best to use the lubricants of the CITIMI-203, VNIINP-242.

Of the pigment lubricants for the electric motor bearings, VNIIIMP-246 and dark purple ointment VNIINP-235 were distributed. The first lubricant due to the high price is less common than the second.

In today’s Russian market, domestic manufacturers of lubricants are widely represented.

Lubrication for the gearbox Ushm

Lubrication for the gearbox grinds differs from the lubrication for bearings with the main feature, increased adhesion. She should firmly hold on the gearbox tooths with a large rotation.

In general, the process of lubrication of the gearbox in angle grinding machines occurs due to small spraying of the lubricant and its suspension. The gearbox works, as it were, in oil fog. Therefore, lubrication requirements for gearboxes are slightly different.

In addition to increased adhesion, lubricant for gearboxes should have high heat resistance and not relaxed at elevated temperatures.

DIY grease for the gearbox with your own hands

But is it possible to make a lubricant for a gearplay gearbox with your own hands?

And there is an affirmative answer to this question.

Gear reduction gearbox repair blow moulding extrusion gearbox pinion gear ZLYJ types of gearbox

Since the main technical characteristics of the lubricants for Ushm gearboxes are presented above, they can be taken as the basis for making lubrication of the necessary characteristics with their hands.

The basis of homemade lubrication for gearboxes should be a lubricant with high adhesion. She should hold tightly on contacting details.

High adhesion has a lubricant for cries. Shrus, this is a hinge in a front.Wheel drive car, operating in conditions of increased pollution, shock loads, temperature fluctuations and humidity.

Сцепление. Как оно работает?

Having taken as the basis, the lubricant for the crows, it is necessary to add liquid lubricant (MS-20) to give a lot of the desired consistency. MS-20 oil must be served drops, thoroughly kneading the mass with a homemade mixer.

Good results are given by a mixture of lubrication of CITIMI-221 and TAD-17, where the basis is cyatim.

How to lubricate a trimmer gearbox

Almost every motorcosa gearbox is equipped with a small technological hole, which in the mode of operation is drowned out by a special bolt. After thoroughly cleaning the node from the remains of grass and debris, it is necessary to unscrew the screw and enter the gearbox into the cavity of 1.5 to 3 ml of lubrication depending on the brand of the tool. For the convenience of dosage, you can use a traditional medical syringe. During the operation, it is impossible to allow foreign particles and objects inside the gearbox, since this can lead to intensive wear of the gear gear, as well as its jamming.

Experts recommend, when completing the mowing season and long.Term storage of the tool without work, to disassemble the gearbox, flushing gears and bearings, as well as re.Lubricating the node.

How to replace a lubricant in a grinder gearbox

Ushm gear lubrication can be performed in the workshop or personally.

With independent work, one should not forget that only the liquid and substances are allowed to take into the work.

How to lubricate the gearbox grinds?

The power tool is disassembled: a circle, shield is removed, the case is opened. The removable part of the gearbox gets. The old substance is removed. It may contain metal particles. The inside of the case and all parts (gears, shafts and stiffeners) are laundered from the old lubricant. The purified surfaces are laundered by a suitable liquid. Gasoline is optimal.

During the drying of the parts, lubrication is prepared. It is laid out to eliminate lumps, unnecessary impurities are removed from it. A new substance is applied to dry and clean details. Lubrication must be covered with all contacting parts.

The grinder is going back and checked in idle mode for a couple of minutes. When overheating or lower speeds appear, the grinder should be sorted out by removing a little lubricant.

Removing the old lubricant

Before applying a new lubricant, it is necessary to remove the old. In the gearbox and teeth, there should not be used old substances. It is substances. In the course of frequent changes in heating and cooling, lubrication is divided into fractions. Particles of metal and small shavings accumulate in it, inevitable with repeated mechanical contact of metal parts. First, with a solid tool, and then rags are removed, which will lead to normal work.

Interflon Gearbox Lubrication

Be sure to degrease and refresh the surfaces. If old particles remain, the lubricating characteristics of the new lubricant will not benefit.

After cleaning, you should definitely wait until gasoline dries. He can begin to dissolve compounds, which will worsen the work of a new substance.

Approaching a new lubricant

The procedure for direct application of a new substance to the gearbox of the grinder is simple.

Before use, you need to mix it. The purpose of this action is to eliminate heterogeneities and extraneous elements. If a fairly solid object falls between moving and connecting at high speed to teeth, a breakdown may occur.

Application is optimally performed through a syringe. Pointily and without unnecessary costs. Lubrication is carried out in relation to bearings, teeth of the gears and lower cavity of the gearbox body. The substance is impressed manually into the body. For sealing, and so that the apparent volume does not turn out to be air. In the latter case, the lubricant can hang on the walls during operation, and the teeth will be “dry”.

The amount of lubrication

Nuance of quantity is important because too much can slow down the rotation of the shafts. In this case, the substance will be squeezed out of the body and begins to get dirty all around.

Optimal. Without binding to the brand or features of the device. It is considered to fill in approximately half the internal volume. The manufacturer always indicates in more detail and accurately, in the instructions for the operation of the power tool.

In this case, all spaces should be filled. Press into the bearing, tighten to the ribs of the stiffness of the case and apply to the teeth with a small layer.

When flowing during the check, you need to disassemble the gearbox again and remove a small amount. It is defined as the excess walls formed on the walls.

When noise appears, the lubricant must be added. Noise arises due to “dry” dough gear. Therefore, lubricate the grinder carefully and carefully.

How to lubricate the gearbox grinds

There are several options for a lubricant-chipper used. A fairly wide list of substances is used in corner grinding machines. Which of them is considered suitable in certain conditions, the user decides. Than to lubricate the gearbox?

- Special lubricants for a particular brand or model of a grinder;

- Ordinary solidol or littes;

- Compositions suitable for any electric tool;

- Independently made a mixture.

Each manufacturer produces certain consumables for his equipment, including lubrication. It is optimal in that it suits specific materials of the gearbox and body. It is also created taking into account the working conditions of the device. The cost may seem significant, but it is less than the cost of the new Ushm.

Litol (solidol) available in each garage are not considered the right decision. They are not designed for temperatures to which toothed gears are heated. Therefore, the lubricant does not work, and instead of a positive effect, it creates difficulties. When working, it will be leaning from the body, and the rubbing parts will fail faster.

Universal lubricants may also not take into account certain speeds and temperatures of the gearbox. Also, this option is bad in that such a lubricant may not work for a particular steel used. A certain effect will appear, but not more than the best than from special lubricants for the grinder.

Manually created lubrication will help out with urgent need for lubrication. The basis is advised to take a car lubricant for a shrug. It is a stand to the loads, humidity, heating fluctuations. In order to obtain the desired density, oil is added-for example, MS-20. The mixture is mixed to complete mutual dissolution. Alternative: “Cyatim” TAD-17. Different masters and thematic forums can offer a lot of compositions, which should be used with caution. Buying a new power tool, especially the professional level, will become a significant investment of funds and time. It will be cheaper to buy the appropriate composition.

What lubricant to use for a grinder gearbox, solve directly to the user. But you need to remember the main thing: all the requirements are set out in the instructions. Information can be on the site: for example, the RU tool can recommend actions and lubrication for the Makita brand.

Homemade mixtures

Situations when there was an acute need to lubricate the elements of Ushm, are not uncommon. And at the same time, as luck would have it, to get a lubricant suitable for these purposes, there is no way. Then the owner may try to make the tool with his own hands from the available materials.

To ensure the desired level of adhesion, a lubricant for car crock is taken as a basis. In addition to excellent penetrating properties, its use for operation in conditions is allowed:

- Significant loads;

- High humidity;

- Temperature fluctuations in a wide range;

- Significant heating;

- Exposure to solid pollutants.

To thin the material and obtaining the consistency necessary for the reducer, it is recommended to add oil MS-20. The liquid is based on the basis gradually, preferably with drops, with constant mixing of the formed composition with a mixer.

The use of home-made material based on “Citiam-221” with the addition of TAD-17 is no less effective.

And what lubricant for the gearbox do you use? Have you ever had to make a lubricant yourself? Share your experience with us, please.