How The Chain Should Be On A Chainsaw

For sharpening chainsaw chains. PRACTICAL RECOMMENDATIONS FOR CHAIN SHINING FOR Stihl CHAINSAW

Sharpening a saw chain with the appropriate knowledge and skills is not difficult, but it requires adherence to certain rules. Let’s consider the most useful and necessary.

During prolonged use of the saw, it is necessary to periodically grind its cutting part during the day, since all cutting teeth must first of all have the same length, sharpening angle and depth gauge position.

To do this, first we find the shortest tooth, take it as the reference point and, in the process of sharpening, adjust all the other cutting teeth of the chain to its length. If it is in the right row of teeth, then we fix the guide rail in a vice with an end sprocket to the left, if in the left row, then we turn the tire with an end sprocket to the right. Then place this tooth in the sharpening area and apply the chain brake. Sharpening is carried out with a round file of a certain diameter, depending on the pitch of the chain (see Table 1), keeping it at right angles to the plane of the tire in the vertical direction and at a sharpening angle in the horizontal direction. For cross-cutting wood, the sharpening angle is usually 30 °, and for longitudinal. 10 °.

For this reason, two types of saw chains are produced. transverse and longitudinal, differing in sharpening angle.

When working with a file, 20-25% of its diameter should protrude above the upper edge of the cutting tooth. Remember that the file grinds the metal only when moving away from itself, and when moving backwards, it should be lifted. In addition, the file must be periodically rotated slightly around its axis to prevent uneven wear. After two or three forward feeds, check that the steel is evenly removed from the sharpened tooth. If the removal occurs in places, then either you are using the wrong file, or you are driving the file too high or too deep. It is necessary to grind the cutting edge until the light strip disappears on it.

When a good cutting edge of the sharpened tooth has been obtained, first release the brake, move the chain to the next tooth on the same side of the bar, and reinstall the brake before sharpening. Grind the rest of the cutting teeth on this side to the same length, then rotate the tool 180 ° and file all the teeth on the other side in the same way. Recall that all of them need to be ground down to the length of the initial tooth. If the cutting teeth of one row are longer than the other, then align them with one or two additional sharpening movements.

Compliance with the above recommendations helps to obtain correct and equal values of the rake angle and sharpening angle at the same height of all cutting chain links.

Now you need to adjust the depth stops, since the differences in the heights of the upper points of the cutting edge and the plunge stop decreased as the teeth were grinded, and not the same, because the teeth had to be aligned.

To check this value, it is convenient to use a filing gauge corresponding to the chain pitch and determining the cutting depth (see Table 1). It is a template for controlling the position of the cutting depth limiter, it is applied to the cutting tooth, and if the cutting depth limiter protrudes above the upper plane of the gauge, then this excess must be removed with a flat file. The file must not touch a sharpened cutting tooth. Count the number of file feeds for the first depth gauge and file the rest of the cutting teeth approximately the same number of times, remembering to round the front edge of the depth gauge to reduce vibration and reduce the risk of kickback.

In conclusion, hand sharpening a chain saw pays off in maintaining the performance of the tool during intensive use throughout the working day. What’s more, STIHL offers a wide range of accessories to make this sharpening easier and more efficient. These are special guides, various sharpening devices, control gauges, etc. After 3-4 manual sharpenings, we recommend that you carry out a professional mechanized sharpening of the saw chain in a specialized service center to guarantee high productivity and excellent cutting quality.

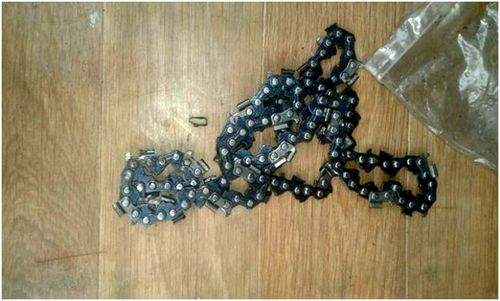

How to untangle a chainsaw chain

When removing an old chain or putting a new chain on the guide bar of the chainsaw, it can become tangled. It can also happen with careless transportation. When the chain is tangled, it folds into rings.

Due to the lack of flexibility in the transverse direction, it is very difficult to untangle it with bare hands, because when you try to untangle one ring in another place, a new ring is formed.

It is necessary to put the chainsaw chain on a horizontal surface and unwind the rings in different directions, while pulling the blade in such a direction that the diameter of the rings increases. Sooner or later, the chain will unravel into its natural position.

There is another way. you can rivet one link of the chain and straighten it, then connect it into a ring and rivet the riveted links back.

What to do if the chain sags

If the chain slack, there is a risk of injury to the operator. the saw blade could break or simply fly off the guide sprockets. Of course, modern chainsaws have safety and emergency stop systems, but these systems do not always work correctly.

It is important not to install a chain with defective or damaged saw links on a chainsaw, in addition to the danger of breaking at any time, such a chain will sharpen the guide grooves of the bar, which will lead to its distortion, uneven cut and failure of the guide bar.

Due to which the chain can sag during even short-term operation?

- There may be problems with the guide bar. Sometimes, due to an oversight of the operator or due to severe wear of the threads of the fixing bolts in the place where the guide bar is attached, vibration may occur, which causes the chain to loosen. Check the condition of the fixing bolts and, if necessary, replace them with new ones. When the bolts are tightened enough, these problems do not arise.

- With enough careful handling of the chainsaw, over time, any chain can wear out. Trying to repair it or collect one from several is a useless exercise. If the chain headset has stretched due to natural causes, then it is best to get a new one.

- The asterisk is skewed. Sagging can occur due to the misalignment of the sprocket teeth. In this case, it would be best to contact a service center to repair and adjust the position of the guide sprocket. It is quite difficult to fix the drive sprocket in the correct position, because you will have to dismantle many small parts, remove the guide rail, and then assemble everything in the reverse order.

Why does the chain come off

Many, even the most experienced users of chainsaws, have encountered in their life a situation where the chain jumped off the guide bar during operation. The most common cause is insufficient chain tension or wear.

In 80% of cases, the stretched chain links slip from the teeth of the drive sprocket, and it flies out from the guide under the action of centrifugal force. Although sometimes the problem appears due to the incorrect position of the sprocket relative to the axis of rotation or a loose saw bar on the chainsaw.

CIRCUIT PARAMETERS

The main geometrical parameters of the saw chain are the pitch, the height of the profile and the shape of the cutting tooth, the thickness of the driving link, the number of links. A step is half the distance between the centers of three consecutive rivets.

It is customary to measure it in inches, and each has a symbol (see Table 1). Saw chains on the height of the tooth profile are divided into low and high profile. So, for powerful chainsaws, STIHL provides Rapid chains with a higher tooth, and for less powerful ones. Picco chains with a lower tooth. The number of links determines the length of the chain, depends on the power of the engine installed in the saw, as well as the type of work performed and corresponds to the size of the bar.

The thickness of the drive link is measured in millimeters (mm) and must match the groove width of the tire used (see Table 2). The last digit of this thickness is stamped as a symbol on each driving link of the chain.

See also: How to properly sharpen a saw sharpener

Saw chains can also differ in the shape of the cutting tooth. STIHL chains have two such forms. Micro (M), Super (S). Without going into the intricacies of the design, we note that the saw chain with the shape of the cutting tooth Micro is universal, it combines high cutting performance, ease of use, long service life and easy maintenance.

Meets the requirements of construction, agriculture and forestry. The Super saw chain combines maximum cutting performance, high plunge efficiency and low feed force to meet the most demanding professional forestry tool requirements. These chains cut faster and are good for chopping hard or frozen wood. There are certain features when sharpening the Super saw chain.

In addition, STIHL has a Duro saw chain with carbide-tipped teeth. It combines the highest wear resistance, ease of use and good performance. Resistant when working with dirty wood or short contact with the ground, when sawing planks from formwork or scaffolding after finishing work.

Highly effective when used in forest areas damaged by fire. Duro chains last up to 10 times longer than non-carbide saw chains. Such chains are much more expensive, and they are sharpened by an electric sharpening machine with a diamond grinding wheel in specialized service centers.

Cutting teeth work like a planer: they cut the wood chips off. The penetration depth of the cutting tooth into the wood and thus the chip thickness is determined by the distance between the depth stop and the top of the cutting tooth. If this distance is not enough, then the saw chain will not pick up the chips (that is, saw), but will only slide along the wood. Conversely, the greater the difference in height between the stop and the tip of the cutting tooth, the thicker the chips, but at the same time, the greater the vibration produced by the chain, and also the higher the load on the drive mechanism. Therefore, it is necessary to achieve an optimal balance of chain vibration and performance, and in all models of STIHL saws this ratio is matched.

Saw chain replacement and adjustment sequence

It is not technically difficult to change the chain of a household and professional chainsaw on your own. The key to the successful implementation of the adjustment work will be strict adherence to the recommendations of the attached instructions.

Due to the thermal expansion of the metal, the chain is installed on the chainsaw and the subsequent adjustment is made only on a cold tire.

- In the classic solution, the technology provides for the inclusion of a lock against accidental engine start, unscrewing the threaded fasteners, dismantling the tire and cleaning the guide groove from sawdust.

- Next, you should make sure that the dimensions of the shanks correspond to the width of the groove, determine which side to put the chain on the chainsaw, fix the tire and adjust the chain in the sequence indicated by the instructions.

- Before putting the chain on the chainsaw, you should make sure that the direction of the chain on the chainsaw meets the stated requirements, and that the chain tensioner has sufficient free play.

After adjusting the new chain, it is recommended to run the saw at medium speed for 2-3 minutes, then check the chain tension again. This moment can be combined with visual inspection of the lubrication system.

Negative consequences of incorrect chain adjustment

Checking the condition and tension of the chain is included in the mandatory list of preparatory work.

It depends on how much you manage to put the chain correctly:

- The duration of its subsequent operation;

- Safety of cutting operations of increased complexity;

- Resource of the engine and chainsaw in general.

An over-tightened headset dramatically reduces work performance, initiates excessive loads on the power unit and transmission. Tire overheating and excessive fuel consumption also occur.

A loose chain can fly off the bar or break. The formation of traumatic moments is partially or completely eliminated by emergency stop systems and catchers, which allow, with more or less success, to unravel the chainsaw chain and determine its suitability for subsequent operation.

Installing a part with damaged or deformed links can lead to uneven wear of the tire guide groove and other undesirable consequences.

Tensioners

The classic budget-class chainsaw chain tensioner is usually a threaded bolt with an adjusting component, standard or side-mounted. The chain tension is adjusted with the included wrench or screwdriver.

expensive models are equipped with easy-to-use devices that allow you to tension the chain with one movement of the lever or by turning the adjusting disc.

In the first case, the degree of tension is fixed with a locknut, in the second, the tire and the chain tensioner are locked in a given position by installing the cover. In both versions, reliable fixation of the chain in a given position is guaranteed, the possibility of compensating for its extension with minimal loss of working time.

Features of manual and mechanized sharpening

Dull cutting edges of the saw chain appear:

- A noticeable decrease in productivity;

- Ejection of small chips;

- The appearance of a characteristic smell of burnt wood.

To restore the cutting properties of the chains, several types of sharpening devices are used.

In the simplest version, it is a holder mounted on a rail complete with a set of special files, in the other. a sharpener with a power drive. Both technologies have their own advantages and disadvantages.

Low-performance and time-consuming manual chain sharpening helps to preserve its resource. The mechanized method provides good performance, but the lack of an individual approach to each cutting link of the chain negatively affects its durability.

Advantages of making a chain set

The chain and the bar are included in the list of interchangeable equipment, so the sawyer, depending on the peculiarities of the work, can use several sets of different lengths and productivity. Average service life of wear-resistant branded tires allows the service life of three saw chains.

The cutting edges of the saw chain links need to be sharpened periodically. The indisputable advantages of using a set of several chains are uniform wear of the drive sprocket and good compatibility with the chains included in the additional set.

Reasons for premature failure of saw chains

Accelerated elongation of the part occurs during the running-in phase and in the last quarter of the service life. During these time slots, the headset needs special attention and careful maintenance.

- The reason for the rapid stretching of the saw chain can be the poor quality of the material of the budget model, the mismatch of the configuration of the crown and excessive wear of the drive sprocket, a malfunction or ineffective operation of the lubrication system.

- The full operation of the chainsaw chain also largely depends on the condition of the tire and the drive sprocket, the quality of the chain oil and the performance of the lubrication system, the timely and competent sharpening of the edges of the cutting links.

According to professional sawers, the operator’s style of work and the level of operational stress affect the durability of the headset. The chains of the budget group are more susceptible to stretching; the more expensive branded assortment has no comments on technical and operational properties.

Chainsaw design

The chainsaw consists of several large independent units.

- The internal combustion engine is designed to generate mechanical energy that is used to drive the chain saw.

- The gearbox transmits the torque from the engine to the cutting tool. It is a set of gears and countershafts.

- The clutch is an intermediate link between the gearbox and the chain. It is used for short-term breaking of the chain "reducer. chain". Keeps the chain saw motionless when idling. Interrupts or weakens the transmission torque in abnormal situations (for example, braking the saw to a complete stop), which allows the engine to run without stalling.

- An automatic brake interrupts the operation of the chain when it breaks, rebounds from the tree being processed, or abnormal operating modes occur.

- Bar. guide for chainsaw.

- Chain tensioning mechanism.

- Chain lubricator and other elements.

Chain tensioners for the Stihl MS 180 chainsaw

How to choose a plaster trowel

X Annual international competition of Internet resources "Electrosite of the Year-"

Tile adhesive consumption per 1 m2

Pumps for increasing water pressure

Chain lubrication mechanism

The chain must be lubricated with oil for stable operation. This role is played by a special unit. the lubrication mechanism. During operation, interruptions in its operation may occur:

- Lack of oil in the reservoir, as a result of which a small amount of lubricant will flow to the chain. it is necessary to replenish the oil level;

- Clogged outlet channels. it is required to clean and replace the filter;

- Small outlet diameter is adjusted with a special screw.

During normal operation of the chain lubrication system, traces of oil can be seen if you bring a working saw to a light, uncontaminated surface, for example, to a fresh cut of a tree (stump).

The amount of oil supplied to the chain depends on the operating conditions. With dense, sticky or damp wood, the oil consumption should be higher. Dry material will require less lubricating fluid.

How to install a chain on a chainsaw?

The chain can be installed and tensioned by unscrewing the main screw and sliding the links onto the drive sprocket and guide bar. It is important to watch out for the tails falling into the groove so that they do not fall off again.

Before tightening the chain of your Husqvarna chainsaw, it is worth looking at its condition and, if necessary, replacing it with another one. After removing this part, you need to carefully inspect the guide groove along which the links go. This is where dirt accumulates, absorbing oil and interfering with the tension of the cutting part. This place is cleaned with a thin metal object. If this is not done, oil may not get on the bottom of the bar, and after installing the chain, the links will slip worse, which affects the sawing efficiency.