How the motor block carburetor works. How to adjust the carburetor on a walkbehind tractor?

Motoboblock adjustment: carburetor, valve, fuel system

The adjustment of the motorogue carburetor should be carried out periodically in order to operate the mechanism. A possible cause of changes in the operation of the motor block may be a carburetor. To do this, the device is disassembled, cleaned and regulated (set up). Regardless of the carburetor brand and from which device it is installed on, the principle of regulation for everyone is the same. The difference can only be among the revolutions.

What should you pay attention to during the interruption of the motor? If the carburetor malfunction occurs, the first thing you need to check the fullness of the fuel tank and the oil level. If the fuel and oil are enough, then they proceed to the examination of the candle. To do this, it is unscrewed and the spark is checked by ignition. Next, test gasoline to the carburetor. For this purpose, the hose is removed from the fitting and monitor the fuel intake. If the fuel does not appear, then, most likely, the filter mesh mesh is required. For this, the fuel valve is unscrewed and all the parts are washed with gasoline. The same thing is done with the potpel jet.

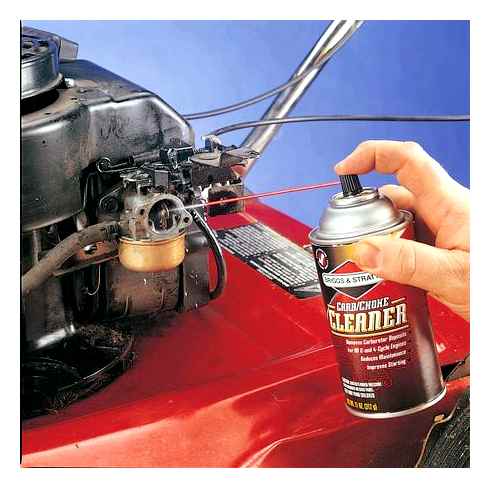

Carburetor cleaning is as follows. To clean the device, to start it, you need to remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the details on which it holds.

So, remove the carburetor and pour gasoline out of it. Gently separate all the details of the device (nozzle, float) for further purge and cleaning. This manipulation is performed by a special cleaner.

See also: The lineup of the chainsaw forestry. Preparation for operation. Typical malfunctions of the chainsaw

After cleaning, thoroughly dry all the details and boldly proceed to the assembly. After assembly, adjust the carburetor for the walk.Behind tractor.

Install the cleaned device using the standard pad, and fasten it with nuts. Do not forget about the air filter, revolutions and a gasoline supply hose.

The tuning of the motorogue carburetor is to adjust it. In order to independently adjust the carburetor, you need to take the following steps:

How to: Clean a Carburetor (Small engine)

- Small and full gas screws need to be twisted all the way.

- Turn the screws of small and full gas for one and a half turn (set the throttle to the shutter in such a position that the gap of the corresponding size forms between the base and the duct).

- Start the motor and wait until it warms up.

- When working motor, the control lever is put at minimum turns.

- Achieve uninterrupted operation of the engine. To do this, you need to make minimum storage of idle, using the throttle screw screw.

- Set the idle speed to the maximum using a small gas screw.

- Set the idle speed to a minimum with a screw of the throttle.

- Repeat 6 and 7 step until the continuous operation of the engine begins.

- The engine control lever is put on gas.

- If the interruption occurs, unscrew the screw that regulates the quality of the mixture, no more than 2.5 revolutions.

I would like to note that the adjustment of the carburetor on the Neva walkover is made clearly according to the above instructions. Neva installed on the Neva walk-behind device K-45 is a single-chamber and horizontal. The float camera is located in the central part. Throttle. Flat.

On the Neva walkover, the DM-1K engine is used, which is available on. The manufacturer categorically does not use Chinese.Made engines. This also applies to the production of a motor cultivator.

Operation Rules

The device will last a long time if you follow the following recommendations.

To preserve the mechanism in working condition, it is important to monitor the composition of the applied gasoline. It should not have mechanical impurities in it. Before starting repair work, it is necessary to process parts with the same fuel. It is not recommended to use the solvent, as it is able to reduce the elasticity of rubber spare parts, damage the washers. Dry details are best using compressed air purge. Do not clean the small holes, for example, using a needle or wire.

- The final assembly, installation of parts evenly. So you can avoid deformation or bends of parts of the carburetor.

- Make sure that the float camera is tightly connected to the body. The future success lies precisely in their tightness.

- Before starting the mechanism, check how the air filter is connected. It is worth fearing fluid leaks.

- To avoid leakage, the fuel valve must be opened, then block the air damper, the control of the lever is tight, open the throttle to 1 \ 8-1 \ 4. The drowner should be squeezed before the appearance of fuel drops (if the temperature decreases to 5 degrees).

- When starting the air damper, you need to open a little. As soon as the motor warms up, open to the full.

Adjustment

If the walk.Behind tractor does not start, stalls or works unstable, there is no need to take it to the service. You can repair it with your own hands. To help a beginner mechanics. Videos, where it is shown in detail how to adjust the carburetor on a walk.Behind tractor. This does not need special tools, all operations are performed in the field.

- Warm the motor for at least 5 minutes. Adjustment is carried out on a heated and operating engine.

- Twist to the stop of the needle (screws) of the minimum and maximum revolutions.

- Loosen the screws for 1.5 turns

- Install the gear lever for the minimum value.

- Weakening and twisting the throttle screw, you should install the minimum speed at which the motor works stable, without interruptions.

- Adjusting the small gas screw, set the maximum idle speed.

- Drown out the engine and turn on again, checking if adjustment is correctly performed. If the motor works unstable again, repeat the operation.

Incorrect tuning of the motorogue carburetor is the cause of the vast majority of malfunctions. By learning to adjust the device yourself, you can eliminate these malfunctions on the spot without dooming the equipment to downtime, but the farm for losses. But if there is no self.Confidence or the device does not manage to fix the device, then, of course, it is worth contacting specialists.

Motobobok carburetor adjustment is a detailed description of the procedure

There are a number of signs indicating the need to adjust the built.In motor block carburetor.

- A sharp drop in the power of the walk.Behind tractor;

- An increase in the number of produced exhaust gases;

- Starting the motor block with subsequent spontaneous shutdown;

- Unstable operation of the engine of the unit at idle;

- Swift increase in the amount of fuel consumed.

Reasons all these malfunctions can be several. Among them are the use of a motor block for excessive loads on its mechanisms, as well as a long simple unit without practical use. In any case, the timely tuning of the carburetor of the used agricultural machine will help to solve these problems.

Yourself to set up a carburetor of an agricultural machine is quite simple. Before adjustment, you will need to start the engine and let it work for 5 minutes. After that, you need to directly adjust the carburetor on the walk.Behind tractor.

The procedure is performed in the following sequence:

- After preliminary heating, you need to drown out the engine and install a walk.Behind tractor in a stationary position. Next, rotate the screws that regulate the full and small gas to the stop, and then turn them out for 1.5 turns in the opposite direction;

- Next, you will need to start the engine again and warm it up. This should take at least 5 minutes;

- Then it will be necessary to install the engine adjustment lever to the position of the lowest revolutions. While the engine should work;

- After that, you need to turn the settings screw position position of the throttle in the position in which the engine of the walk.Behind tractor will work most stable;

- Next, you need to rotate the screw settings screw for the carburetor to the most extreme maximum position;

- Then you will need to turn the throttle screw to the minimum position;

- The last two procedures should be performed until the engine starts to work without failures;

- After that, you need to set the engine control lever to the maximum gas position;

- At the end, you will need to turn the screw responsible for adjusting the maximum revolutions by 2.5 revolutions in different directions to check the stability of the engine operation. You can find out in more detail about setting a carburetor from the video.

After the setting of the carburetor of the walk.Behind tractor with your own hands, you need to check the operation of the unit. If the engine began to work without failures and consume less fuel, then the carburetor adjustment was performed correctly.

Features of the operation of the walk.Behind tractor after adjustment

The duration of the use of the carburetor of the motor block cascade depends not only on the knowledge and skills of adjustment, but also on understanding how to use it after setting.

First, it is advisable to periodically monitor the operation of the engine. Similar control is carried out by the sound of the motor.

- To get started, you need to start the engine and warm it for 3-5 minutes.

- Observe the sequence of speed switching, namely not to jump over them.

- It is equally important to observe the boundaries during the use of a walk.Behind tractor for arable land, because if the plow gets to the hard ground, the gearbox begins to work at maximum power.

- Monitor the level of gasoline in the fuel tank and not allow it to fall below the minimum mark.

- Carry out periodic observation of the oil level in the engine.

In the event that the established requirements are complied with, the owner of the cascade does not have problems with the operation of the unit.

Features of the device

Motoblock is a fairly powerful unit with great power, but at the same time medium size equipped with multifunctional equipment. Basically, the equipment is produced with a gasoline, diesel or electric engine. The latter, by the way, are extremely rare. So that the added fuel is ignited by the carburetor. The manufacturer represents the following types:

- Rotary-the simplest in structure, they are equipped mainly by small-sized engines for 12-15 cubic inches;

- Plunger. In this case, the design is complicated, therefore it is used to assemble powerful motoblocks.

Carbury is carried out using the main details:

So, the process begins with the piston moving upstairs, as a result of which a vacuum is created. The carburetor absorbs air, and it subsequently moves along the Venus tube. The fuel movement (from the tank) is directed towards the engine, this is done using connecting fitting, which acted due to the created vacuum. The liquid goes around the main needle, flows along the absorption nest, falling into the Venuria tube. Pressing the gas lever, fuel is released due to the needle of low speeds. Further, the first needle is responsible for the stream of gasoline.

Among domestic masters and agricultural workers, the technique of Russian brands “Neva”, “Oka”, “Agro”, “Morning” is especially popular. It is characterized by optimal configuration, high.Quality, powerful carburetor. Especially Russian buyers appreciate the Neva motor blocks K-45 for reliability, durability. The KMB-5 model is an older unit, so before buying, consult a specialist who will provide a product that meets your requests.

Carburetor of the walk.Behind tractor

The rated capacity and stable operation of the gasoline factory engine largely depend on the initial quality of fuel refueling into the motorcycle unit, namely on the ratio of fuel and air in the ICE cylinder. The carburetor of the agricultural carrier is responsible for the enrichment of the fuel in the required air in the required proportion. Its working continuous work guarantees a high torque of the factory engine, its durability and low volumes of emitted exhaust gases.

Knowledge about how exactly the carburetor is arranged for the walk.Behind tractor will help to independently eliminate any of its malfunctions, as well as clean and timely adjust the standard fuel unit.

Structurally, the mechanism consists of:

- Float, which is connected to the built.In needle locking steel valve;

- Float metal chamber with chrome internal cavities;

- Additional chamber required to mix fuel with air;

- Fuel distribution structures equipped with a diffuser;

- Adjustable throttle damper;

- Fuel and standard air tubes made of technical rubber.

Depending on the manufacturer and the purpose of the walkways, their carburetors can be equipped with additional elements. But regardless of this, fuel hools work according to the same principle.

One of the most important elements of the mechanism is a float, the main function of which is initially in adjusting the number of fuel, necessary for the good operation of the walk.Behind tract. The fuel itself is in the float chamber, and as soon as its volume is reduced, the float opens the built.In needle valve. Through it, the missing volume of refueling enters the chamber, after which the float rises and slowly closes the valve.

The carburetor on the walk.Behind tractor is equipped with an output channel, which is located in a float chamber. For the normal operation of the fuel node, the amount of fuel in a standard float chamber must be continuously kept at a level, which is several millimeters below the output channel.

Farmall H Carburetor Adjustment

The sprayer initially plays the role of a kind of fuel distributor, which falls with a chrome floatic in a steel mixing chamber. The latter is needed directly to enrich combustible air. Pre.Purified air flows fall into it through the built.In input pipe.

How to adjust the carburetor on different motoblocks?

It is recommended to adjust and configure the dosing node when the first interruptions appear in the engine operation. The process of configuring the carburetor depends on the brand of the walk.Behind tractor.

How To Adjust the RPM Speed on a Lawn Mower

Fix carburettor in 1988 Toyota.

In general, the process of adjusting the revolutions of the Neva motor blocks involves the sequence of actions:

- Twisting to an obstacle to the screws of small and full gas;

- Installation of a throttle to form a gap between the base and the duct;

- Launch of the motor;

- Installation of a control lever for minimum turns;

- Adjustment of the throttle screw until the minimum idle speed is reached;

- Adjustment of a small gas screw until the maximum idle speed is reached;

- Alternation of a minimum and a maximum until the continuous operation of the engine is obtained;

- Transfer of a power control lever for gas unit;

- Adjustment of the screw responsible for the quality of the mixture.

This scheme is suitable for K-45 carburetors, which are placed on the Neva model MB-1 and MB-2.

Ufa small agricultural machinery units are also popular with domestic farmers. They are valued for the high quality of components, a small price and an uninterrupted work in work. A powerful UMZ-341 engine operating with a single-chamber K-45R carburetor is put on the mechanisms of the brand “Agro”.

The principle of operation of the dosing unit is very simple: when idle, the supply of gasoline is minimal, in the working mode. Power according to the instructions to maintain the working capacity of the walk.Behind tractor. With unstable engine operation, you need to configure the carburetor:

- Run the motor and warm it up for several minutes.

- Unscrew the screw that controls the idle speed to the state of an almost stalling engine.

- Twist the screw, having achieved the stable operation of the motor.

- Adjust the position of the throttle, receiving a minimum gap between it and the body of the dosing node.

- By changing the position of the “quality screw”, to achieve maximum speed of the internal combustion engine.

- Again adjust the position of the throttle.

An indicator of the serviceability of the internal combustion engine will be stable operation of the engine at idle and at working speeds.

MTZ-09

The technique of the Minsk Tractor Plant is valued by domestic farmers for operation stability. However, she can also fail over time. If problems have outlived the engine, especially if the unit was idle for a long time, you have to configure the carburetor.

- Run the engine and wait for it to warm up.

- Screw the maximum and minimum gas-bolt to the maximum, and then unscrew them for one and a half to two turns.

- Translate the control lever into mode XX (at least revolutions) and make sure that the motor does not stall.

- Using a small gas screw to adjust idle speeds. There should not be extraneous noise in the engine.

- The maximum power regulator to align the limit frequency of rotation of the crankshaft.

- Using fuel screws, configure the fuel supply.

- After receiving the optimal indicators of the ICE, tighten all the screws.

The period of operation of the carburetor coincides with the operational course of the motor itself. Setting up this node and it then allow you to extend the life of the engine. After adjusting the dosing node, you can achieve stable operation of the equipment and reduce fuel consumption.