How the teeth of cross-cutting saws are sharpened

SHARPENING AND ADJUSTING SAWS.

Saws on the device are divided into onion, two-handed, hacksaws, and relatively not so long ago appeared chain sawsTwo-handed saws, through a certain number of cutting teeth, from time to time make teeth, throwing out sawdust. They don’t sharpen those teeth.

I will tell you my personal worldview on crosscut saws as they relate to hiking. All of the above listed saws were tested by me in hiking criteria. Maybe my worldview is wrong, based on my long-time habit of using certain saws.

Bow saws. For bow saws, the blade is tensioned with a tree stand or iron beam, making it easy to saw one. Actually this is the end of the convenience. The assembled construction is not convenient to carry in the backpack because of its bulkiness. It is possible to carry disassembled, but the possibility of loss or breakage of parts increases. Later, I have some internal aversion to prefabricated structures. in transit perfectly, but every day to collect and disassemble even just. no way I tried to carry only the cloth, and the bow to do on the spot from a branch. Didn’t like it either. Even in taiga you can’t find a branch that suits you quickly, and then you have to cook it and assemble the saw. It is troublesome somehow, and practically unreal in winter. damp branches on frost break as dry ones. Still inconvenience: there is a necessity to saw a fallen tree from below (when sawing from above, a tree clamps the saw). the bow will not pass through everywhere.

Two-handed saws. Sawblade with 2 handles. The best saw for forest hikes in the cooler seasons. And in the summer it’s nice to have a two-armed saw for long layovers. If weight and volume are not critical, it’s better to leave it as it is, not to transform it into a tourist variant. For long hikes it would be good to reduce the size of the saw a little. But it’s necessary not to overdo it, not to make a very narrow and boring blade, not to turn it into a jigsaw saw. I have a two-handed saw, length from handle to handle 800mm, width 90mm. With this size saw you can cut logs up to 30-35 cm in diameter. Saw doesn’t ask for preparation. took it out of the backpack, unpacked, and you saw stupidly. no need to assemble and think about it in the cold. In winter, when making firewood often takes place in the gloom. a simple design does not hurt. You can saw with a two-handle all by yourself. Cover. a strip of thick fabric folded in triplicate and stitched. There are three knitters sewn to the sheath. The cloth cover is more practical. PVC and rubber hose covers freeze. Such a saw takes up absolutely no space at all in a backpack. I put the saw vertically in the backpack, on the side.

Hacksaws. Single-handled sawblade. I have a home-made hacksaw from a piece of two-handled saw. For use in cold weather and in summer. In autumn, with overnight stays by the fire. In winter, on my solitary forays into the woods. In summer, when rafting on rivers in the taiga. It’s easy to cut trees fallen in the water with the hacksaw, sitting in the boat. It is possible to saw from virtually any position. The only limitation for hacksaw implementation is huge cross-section logs. A hacksaw is comfortable for cutting snow bricks. It has a sheath made of tarpaulin.

Chain saws. Saws, consisting of a huge number of link-teeth connected to each other by rivets. Small size and weight are the pluses of the saw. The ability to cut alone. in fact, this is apparently what it was created for. Important drawback: narrow specialization. The chain is good for cutting logs 6. 12 cm. There’s no sense in sawing the smallest logs. it’s easier to chop with an axe. Big cross-sections are not physically feasible for the sawyer. When felling a log alone, the tree tends to fall on the sawyer.к. Sawing is done from the back side of the tree. I have to stop sawing from time to time and check how strong the undercut is. Almost all saw’s reliability depends on the quality of the rivets. over time, the rivets can wear down and fall out. It is convenient to use a top hat under the chainsaw cover.

For all saws I decided to do a test run, so to speak, in the laboratory. in my yard. For the test I took a dry pine log with the cross section of 14 centimeters. not thin and not thick. One by one, using different saws, I sawed off one piece at a time. I sawed, not hurriedly, I think I was doing it in the woods, when I was getting firewood. All saws are sharpened. Rational working conditions for every saw. I used an onion, a two-handled saw, and a hacksaw to make cross-cutting saws. For the chain, I put the log on the ground with one edge resting on the block. Did the timing with a stopwatch. This is what came out:

Hacksaw, 46 seconds. Blade with a big tooth. It is fully comfortable to cut.

Two-handed saw. 52 seconds. Sawing alone, without using pull ropes or other tools. Two people would obviously be sharper. I felt it was easier to cut with a two-handle than with the other saws, even on my own.

Onion. 53 sec. A blade with a small tooth. Sawing is relatively easy.

Chain saw, 56 seconds. It felt like it took the most effort.

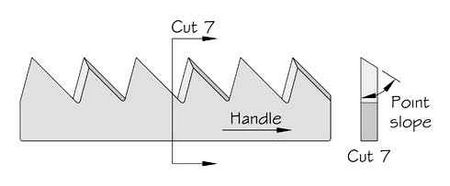

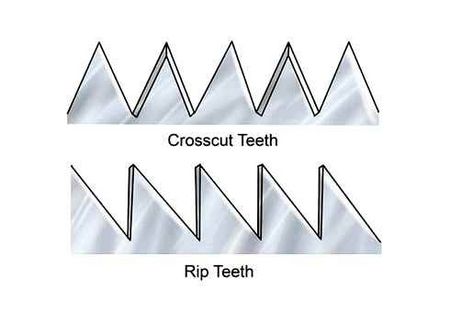

Saws for longitudinal and crosscutting types of wood have different tooth shapes. For cross-cutting sawing, the saw teeth are made in the shape of an isosceles triangle. For longitudinal sawing, it’s a slanting triangle with a wolfsbane. There are also teeth for mixed longitudinal and crosscutting sawing. Actually there is no need to cut wood alongside the grain on hiking trips. The main task is to pile up the dried timber and cut it into the required number of blocks (logs). The effort spent on sawing depends almost entirely on the sharpening and setting of the saw’s teeth. As you saw, the teeth get blunt, i. e.е. the tooth edges are rounded. The teeth are blunted most often. Sawing with such saw is a big ordeal. it takes much time and effort to saw a log even of small cross-section.

Before to begin preparation of saw to work, it is inspected. what is the condition of teeth, is there a separation. Blunt teeth have a bright stripe along the edge, while sharpened teeth do not have a bright stripe along the edge. In the same way it is possible to determine “by eye”, sharpness of even any other cutting tool.

If the saw is old and the height of teeth is very different, they are smoothed with a razor, clamped into a special wood block. The teeth are smoothed, of course before sharpening, after setting.

Tooth setting. To make the saw blade move freely in the kerf, the teeth are set apart. Tooth alternately bent to different sides by the same amount with the adjustable setting. Bending the tooth with the adjustable wrench about halfway up the tooth. Setting tool is a device for setting saw teeth in the shape of a slotted plate. The sharpening of the teeth can be done with the adjustable wrench. It is advised to set more teeth for soft wood and less for hard wood, but it will hardly suit us. there are different density and humidity of trees in the forest. You need to experiment a bit with the setting, to find the best one, about 0.3-0.5 mm per side. In any case we have to set the tines not more than the thickness of the leaf on the both sides. The setting is best done before sharpening.

Sharpening saws. Sharpening saw teeth with a triangular rake. This process is not hard, but it demands patience. The saw blade is clamped in a wood or iron vice. If you do not have a vice, hold the saw against a stationary object, such as the edge of a table or stool. The teeth are sharpened through the tooth, at first on one side of the blade and later on the other side. The metal is chamfered off from both tooth flanks, at about a 60 degree angle. to the blade, which corresponds to the profile angle of the triangular rasp. With all that, little more metal is removed from the top of the tooth than at the base. The ratchet is only depressed when it is moved forward. The reverse stroke is free, pulling the rasp off the surface a bit. Do not run your finger along the tooth to test its sharpness. the rasp bar will slip over the grease film on the metal. Fortunes)

Why turn and when

Constant use causes the teeth to lose their sharpness and wear out the cutting edges, reducing the quality of the cut and increasing the time required to complete the task.

Buying a new one will not remedy the situation for long, and it will take no more than half an hour to restore the old blade.

Timely sharpening of hacksaw will restore cutting ability of cutters and allow to have a serviceable tool at hand at all times.

To correct the sharpness of the cutting edges is worthwhile at the first signs of wear, which can affect local areas and the entire working surface.

The dimensions of the cutters change as well, and this leads to jamming during work.

How to choose a wood hacksaw

At the amateur level in a home workshop, it is advisable to take universal hacksaws with a sharpened and hardened tooth

Buying unground “dummy” without sharpening you should be sure that you can do these works yourself, plus it is useful to check the quality of steel of the blade

Tools

Wood. A fantastic material, as it can take after simple manipulations any kind, which is limited solely by a person’s imagination. And just one of the tools that are designed for this case is a wood hacksaw. It is no less popular than the electric and gasoline chain saws, electric jigsaws and sabre saws we all know. In the arsenal of home tools should be such a hacksaw, and it is useful for every man to know how to sharpen a wood hacksaw with his hands.

Purpose of a hacksaw for metal

There are a great many types and shapes of metal saws. Metal hacksaws can be two-handed or one-handed. Two-handed saws with the advent and spread of gas and electric saws are now quite rare, but one-handed saws are available in almost every home.

The blade of a one-handed saw is in the form of a knife with many teeth. It is rigid, resilient and strong enough to maintain its shape without different tensioning devices. Such a hacksaw for metal has a handle that can be held with one hand when sawing material. Moving the saw back and forth over the object to be sawn, the teeth are driven deeper and deeper into it. With each movement, the teeth of a hacksaw cut through several millimeters of material.

A wood saw is used for cutting wood, boards, logs, particle board and other wood materials, installing wooden structures and joinery work, trimming tree branches and other work that involves cutting different types of wood. You can also use a wood saw if you plan to work with laminate.

The teeth of these hacksaw blades come in three varieties, large, small and medium, and are measured by the number of cutters per inch. The more teeth per inch you have, the better the cut will be. The number of teeth per inch on a wood toothed hacksaw blade is labeled TPI. Remember that for quick and rough cuts you need a hacksaw with a long blade and a large tooth. And if cutting quality is very important to you, then it is better to take a hacksaw with a fine tooth.

Saws with large teeth (3-6 teeth per inch) and a tooth spacing of about 4-8 millimeters are most useful for cutting logs and thicker logs, and a hacksaw with a tooth spacing of up to 3-3.5 millimeters is good for cutting medium-sized boards. Small wood is easiest to work with with a saw with a 2 to 2.5 millimeter tooth spacing.

In the case where the hacksaw has straight teeth, the tool will be designed only for cross-cutting wood, but if you have to cut wood lengthwise, the best option would be a hacksaw with forward sloping teeth. And it is better to have several hacksaws instead of one hacksaw for different types of woodworking.

Sharpening your hacksaw

Any cutting tool will work well if only it is sharp. A hacksaw is not an exception in this case. The cutting element in a handsaw is the teeth that are cut into wedges on the blade. During the operation these very teeth get blunt, i.e. there is a rounding of cutting lateral and front edges, because of this the hacksaw becomes heavy and therefore it needs to be pressed hard.

Sawing with a blunt hacksaw. It’s a pain in the ass. It takes a lot of effort and time, it is difficult to make a right angle cut with such a saw. An improperly sharpened saw moves away from the mowing line of the kerf, it gets jammed and wedges in the cut. You can tell how sharp a saw is by the sound and shine of its cutting edges. To restore the cutting ability of the teeth, the wood hacksaw is sharpened, giving them sharpness while maintaining their parameters: the size of angles, height and pitch.

But remember that not all hacksaws can be sharpened. Saws with hardened teeth cannot be sharpened. To identify a sharpened tooth, you need to look closely at its color. If the tooth is hardened, it’s black with a distinctive bluish cast. To sharpen teeth that are not hardened, use a fine-toothed file.

Hacksaw tooth setting

Before sharpening a wood hacksaw, the toothing should be checked. To move the saw freely in the material and to avoid jamming of the instrument in the kerf, its teeth are set as it gets deeper, i.e. they are alternately bent by the same amount in different directions. As a result, the kerf width becomes larger than the thickness of the toothed hacksaw blade, and on both sides there are free gaps.

As a result the saw will move back and forth, with its blade barely touching the kerf surface, the cutting edges will gradually remove material layer by layer. When setting the saw it should be remembered that the wider the set is, the wider the cut will be and therefore the less chance of the hacksaw jamming. But too much camber in the teeth makes the cut too wide and you need a lot of strength to push the hacksaw into the wood.

Hacksaw set for wood hacksaw should be about 1.5 to 2 times the thickness of the saw blade, which is usually 1.5. 2 millimeters. Therefore it is common practice to bend the saw teeth by 0.25-0.5 millimeter on each side if the saw has to saw dry, hard wood and by about 0.51 millimeter if the saw has to saw wet or soft wood.

In order to bend back the teeth of the saw to the same value, a special device called a setting is used, which is a metal plate with a slit cut in it, which is larger in width than the thickness of the hacksaw blade. The set construction often lets you choose the amount of set to one side using the adjustment screw, which ensures the same amount of teeth bending.

For the parting, as a rule, the blade of the saw is clamped in the vise in such a way that the teeth from it protrude only slightly, and the device itself is fixed on the working table. Bend the teeth alternately in opposite directions along the cutter bar, which is about half their height. Remember not to bend the tooth all the way back, because if you do, it will break at the base.

After such manipulations it is recommended to check the correctness of making adjustments, because it may happen that some teeth protrude more than others when bending on the side, they will slow down when sawing, reduce the quality of the kerf and will quickly become blunt. Look at the mowing line of the tines in the light, and if you see that some tine is bent too much or not enough to the side, you need to correct it.

sharpening rules for wood hacksaw sharpening

Sharpening the saw blade is somewhat of an art, which requires attention, good judgement and correct hands. It is not difficult to learn this business, the main thing is to adhere to the following rules when working:

- Securely locked in place. The blade should be firmly fixed in a special device made of wood, which should also be stably installed in a well-lit workplace, as shown in the video on sharpening hacksaw on wood. Tooth sharpening on your lap or on stools does not work well!

- Using a Quality Tool. Use your own personal file, with further cleaning of the sharpened tooth edges with a nail file or fine velvet file. Of course it is important that the file is sharp and new. You can also use a used one, but it must be brushed with a steel brush and rubbed with charcoal to keep the file from getting blunt and clogged.

- Removing the metal layer. While sharpening a tooth file has to engage in its metal and remove the necessary layer of metal, depending on the amount of pressure. And if it suddenly slips on the tooth, while not removing metal, it means that the file is wiped out or the teeth of the hacksaw are overhardened. It is then necessary to re-sharpen with a different file. If it still slips on the tooth after a file change, another hacksaw should be used.

- Pressure on the cogs. clamp the file handle with the right hand and hold the end of the file with the left hand and guide the file to the saw teeth. The file pressure on the teeth must be even, smooth and, of course, in one direction. The file must not touch the cogs when returning to its initial position.

- Correct file handling. try to file metal of about equal thickness from tooth flanks, always use the file an equal amount of times with equal pressure to keep the pitch, height, and angle of the tooth after sharpening.

- Deburring. Burrs are formed on the saw tooth edges on the exit side, they make the teeth less sharp and if you do not remove them, they will break off when the saw is in use, after which the teeth will become significantly blunt. To remove burrs, the tooth flanks are sharpened using a file with a velvet notch, and also removed from the side edges of the blade with a wet burr.

- Checking the Quality of the Work. After sharpening the teeth, be sure to check their sharpness. Look at the edge of the razor blade and the point of the needle: they do not shine in the light if they are sharpened. And if they are blunt, then the edge of the blade and the tip of the needle appear, of course, rounded surfaces that reflect the light and shine well. Checking the sharpening quality of the teeth of a hacksaw is built on this. For this purpose, it is placed in front of the eyes, looking along the blade at its teeth. If their cutting tips and edges are not shiny, it is an indication that the saw’s teeth have been sharpened. And if suddenly some of the teeth are shiny (it happens often), it is necessary to sharpen them with a file with a velvet notch, that is to remove burrs and check again the reflection of light over their tops and edges.

Sharpening a hacksaw with your hands

When sharpening a certain type of wood hacksaw, it is worth paying attention to certain features of this procedure. Let’s understand how to sharpen each type of wood hacksaw.

Crosscut saws

To sharpen the teeth of crosscut hacksaws use a three-edged file with a fairly fine notch and an angle of close to 60 degrees. To sharpen the teeth clamp the hacksaw in a special device that allows its blade to set at an angle of 45-50 degrees to the surface of the working table. Lead your file at an angle of 60-75 degrees to the blade parallel to the work table and sharpen the left edge in the first tooth this way.

In several steps sharpen the teeth of the saw. First traverse the left edges of the odd teeth that are in the far row with the file, setting your hands in the same motion. Next, the file is passed over the right edges of the same odd teeth, thus completing the sharpening of the cutting edges with sharp peaks.

After you have sharpened the odd teeth of your saw blade, turn the saw blade in the sharpening device to sharpen the even teeth that are in the far row. when sharpening crosscut saw teeth it is necessary to observe carefully that in each tooth there are sharp cutting edges with angle of 60-75 degrees, that is sharp top and short cutting edge.

Longitudinal saws

For sharpening longitudinal saw teeth with angle less than 60 degrees use files with coarser or diamond-shaped files with fine cuts, and files with triangular shape with angle of 60 degrees at the top are not suitable for sharpening. To sharpen the teeth of the longitudinal saw blade it is set in the clamping device vertically, after that the device is fixed on the work table. Here are two ways to sharpen reciprocal saw teeth that differ in the sharpening angle.

The first method is straight, when the file or file at an angle of 90 degrees is directed horizontally to the blade and a small layer of metal is removed from the back and front faces of the tooth, to sharpen the cutting edge. All teeth in the back row are sharpened this way. Then the blade is inverted in the clamping device and the teeth of the other row are sharpened. Many modern carpenters and hobbyists use this method when sharpening the teeth of such longitudinal hacksaws.

The second method is oblique and differs from the first one only in the direction of the tool itself in relation to the hacksaw blade. sharpening angle in the range of 80 degrees. Also sharpen the back and front edges of the teeth, to begin with one row and then the other. By sharpening the teeth in this way, you get the same kind of side edges as you would get when sharpening a bow saw.

Saws for mixed sawing

If you decide to buy a mixed wood saw, you should know how to properly sharpen it. To restore the quality of the cutting teeth, they are sharpened using coarse-cut files or a fine-cut diamond file. Just like when sharpening a slitting saw, there are two known ways. oblique and straight, and they differ from each other by the value of the sharpening angle (90 and 75-80 degrees).

Attachments for hacksaw sharpening

Hacksaw blade for sharpening teeth is installed in a special clamping device, which is then fixed on the work table. Let’s consider the scheme of the clamping device that is used when sharpening the teeth of hacksaw blades for wood and makes it possible to set them at an angle of about 45-90 degrees in relation to your work table.

Such a device consists of a base, made of plywood with dimensions of 550×200 millimeters and a thickness of about 20 millimeters. On the basis of the installation of two guiding rectangular triangles (with equal cathetuses), which are made of steel strip with a section of 20×30 millimeters. To install at the base of the device guide triangles, there are 4 studs, which are screwed on PVA glue.

Further, to the guiding triangles with bolts with wing nuts set the supporting and clamping strips, which are interconnected by hinges (size 400×150 millimeters), made of plywood, which thickness is 15 millimeters. For sharpening the saw is placed with the teeth up between the bars.

Before you start sharpening wood hacksaw yourself, set its blade in such a way that the teeth protrude over the pressure plate by about 15-20 millimeters. This clamping device makes it possible to set the hacksaw to be sharpened at 45 degrees and 90 degrees. When sharpening teeth of mixed and longitudinal saws set at an angle of 90 degrees, and when sharpening teeth of cross tools at an angle of 45 degrees. If the fixture is set at a 90-degree angle, it is used to level the height of the teeth as well as to set them apart.

Let’s also look at the clamping device for sharpening large-sized hacksaws and two-handed saws. This device consists of two cross bars about 550 millimeters long and a section of 40×30 millimeters, two stands 1100 millimeters long and 60×40 millimeters in section, as well as two clamping bars 450×150 millimeters in section, which are made of plywood 15 millimeters thick. The crossbar and the uprights are connected to each other with screws.

Assemble the device as follows: screw the lower crossbar to the posts at a small height from the floor, then put the right leg on it, and then mark the place of the second crossbar so that the knee of the right leg rests on the second crossbar.

This ensures the rigidity of the uprights, which are then leaned against the workbench or table. To sharpen the wood hacksaw blades, place them upside down between the clamping bars and then clamp them with thumbnuts. After sharpening one side of the saw, do not take the saw out of the clamps, turn the device over and continue sharpening the other side as well.

Now you know how to sharpen a wood hacksaw at home. Carefully follow the instructions and adhere to the rules described above, and remember to keep an eye on the hacksaw and determine when it has blunted. Be sure before the procedure of sharpening a hacksaw blade determine what material you will usually work with, as well as conduct the procedure of setting and alignment of the teeth of the hacksaw blade.

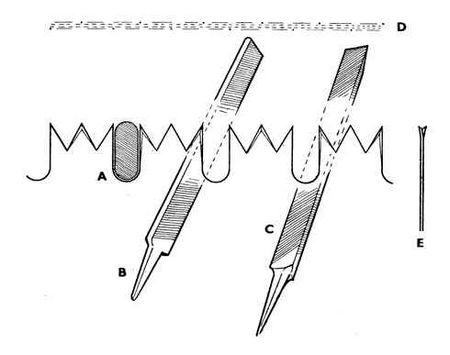

That’s why saws should have teeth for longitudinal, cross and mixed cutting.Slit saws have an oblique tooth shape with a slight slant to the sawing side.Work such a saw in the direction from yourself. Saws for mixed sawing replace two saws of longitudinal and cross sawing simultaneously, the teeth are shaped as a rectangular triangle and saw with them only from themselves. Saws with teeth in the shape of an isosceles triangle are used for cross-cutting (fig. 1, a) such saw saw cuts both ways, i.e. backwards and forwards.

In all saws the spaces between the teeth are called slots. troughs. The saw slots are designed to collect sawdust and eject it as it leaves the kerf. Teeth of saws come in different heights and pitches. This data determines the size of the teeth. Tooth pitch. is the distance between the tips of teeth next to each other. Tooth height. is the distance from the top of the tooth to the base, measured perpendicular.

Each saw tooth has three cutting edges. In the teeth of a longitudinal saw, the leading edge is called the breast edge and the trailing edge is called the back edge. the short edge formed by the breast and back is the cutting edge, and the side edges of the breast undercut the wood fibers from the sides of the kerf, and the kerf becomes cleaner. Mixed saw teeth also work. Cross-cutting saws cut the wood fibres with their flanks, while the fibres are delaminated by the leading edge, i.e. the tip of the tooth. Note the angle of sharpening of teeth for soft wood: for crosscut saws it is 40-50, for hard wood.70; in mixed crosscut saws. 50-60 and 60-70 respectively.

Effective cutting angles for crosscut sawing. 60-80. for mixed. 90 and for the crosscut. 90. 120, Every saw blade must be deburred, smoothed and sharpened.

If you don’t make a setback, the saw will move with great force through the kerf, get hot, and the working. quickly fatigue. For clean, even cuts, set teeth must be perfectly aligned, in exactly the same plane. Even cut is obtained with cone-shaped or trapezoidal saw blades. Such saws do not require setting and the cut is clean.

To set up the band saw blade proceed as follows. Take a steel saw band 1.5-2 mm thick. A wide file is sharpened like a planer knife, but with a very steep chamfer, and inserted into a planer (or make a special) shoe. holes are drilled in the saw blade at the ends and counterbored on both sides. Fasten the band to the evenly planed board and plan the band with a planer on a cone or with a trapezoidal widening so that the edge of the saw is half thinner than the side with teeth (fig. 1, г). A planed blade is clean and smooth.

Some joiners grind strip personal files, which are fixed in a wooden bar, but such a cloth is obtained less smooth than the planed.

Over extended periods of sawing, the set teeth gradually shrink and need to be set anew. Some teeth bent slightly more than others must be straightened or aligned beforehand.

Set the blade so that the teeth bend no more than one and a half times. double the thickness of the saw blade. For dry wood it can be set to 1/4 of the saw’s blade thickness, for wet wood it can be set. be greater than double thickness.

There are different kinds of saw tooth setters for setting. from the simplest (from a piece of steel with slots) to special ones with a tooth stop. When setting, the tooth is grasped at 1/3 of its height and bent back to the necessary size (fig. 1, д). bend only the tip, not the whole tooth, which may cause it to break. Set the saw teeth in a wooden vice (fig. 1, e) by clamping the saw blade close to the mowing line at the base of the teeth.

Tooth setting can be done with a chisel or screwdriver, in a vice. Put a tool between the teeth and. turn it to one side so that the tooth bends back. Often, when diluting, some tines protrude more from the overall mowing line than others, so they are corrected, or straightened. If the vice is available, the saw blade with the teeth is clamped in the vice by the necessary distance and the saw is dragged through, pressing up the protruding teeth several times.

If there is no vice, then two large nails are hammered into a thick board so that the distance between them is equal to the thickness of the split. A saw is inserted between the nails and advanced several times (Fig. 1, ж). After that they sharpen the saw, having it in a wooden vice or in a specially made clamp (fig. 1, h) consisting of two slats, clamped in the pads with wedges. it is better to sharpen the saw with a file with fine notches (velvet file).

The teeth of the crosscut saw (fig. 1, i) is sharpened so. Mentally mark the teeth on the odd. 1, 3, 5 etc. д. and even 2, 4, 6 and t. д. Hold file at an angle of 45 to the saw blade. First sharpen the teeth one row at a time, each tooth on both sides so that the apex of the ground tooth faces the inside of the split. It is better to guide the file all the teeth in one direction from the top of the tooth downwards. After sharpening the teeth on one side (odd-numbered), for example, proceed to the other side. even side.

Tooth flanks of miter saw (Fig. 1, j) grind tooth by tooth, file at right angles (90) to the saw blade. Sharpen both tooth flanks to form a leading short: cutting edge. Metal is filed in forward and backward motion.

The teeth of a mixed saw (fig. 1, l) are also sharpened tooth by tooth, as well as for the longitudinal saw, but hold file against the saw blade at 50-60. Sharpen both sides of the teeth by grinding metal with a forward and backward file motion. A small bevel is created on the front, short cutting edge of the tooth.

Aligning and notching saw teeth.

The wrong tooth point makes the teeth unequal in height and they need to be smoothed because the saw jumps when sawing. It happens that when you undo, some of the teeth are caught by the undoing almost all the way down and break. In this case the saw teeth are cut off and the blade is ground and new teeth of the needed shape and height are cut.

Leveled, or ground, teeth as follows. In two pieces of bars or boards cut holes according to the size and shape of a file and fasten everything together so it does not fall out. The saw-blade with the teeth upward is clamped in a vice or wooden clamps. Lower the file on the teeth, take the wooden block by hand, pushing, and drive it back and forth until the teeth are aligned (Fig. 1, o) and then they are sharpened.

If several saw teeth are broken, all of its teeth are chopped off with a chisel, the chopped side is smoothed and the notching or pulling of the teeth with a file is begun.

For notching use a machine tool, consisting of a die and a punch (Fig. 1, n), made of strong steel, capable of notching the sawing steel. The matrix and the punch are bolted together. The teeth are notched as follows. Mark a spot on the saw blade to determine the height of the teeth. The risk should be clearly visible. Put the band saw blade in the machine so that the punch end is near the risk, strike the punch with a hammer cutting through the band saw blade. This is how all the teeth are notched, set, aligned, and sharpened.

Sharpened saws need to be adjusted, i.e. the saw blade must be set up correctly in the machine and tensioned so that it does not vibrate during sawing. The band saw blade should be tightened without skewing to avoid its breakage and wrong sawing. If correctly mounted, the saw blade can be recognized by eye as a thin thread (fig. 1, о). If the thread thickens in places it means that additional adjustment is necessary. At the end of the working day the bowstring is loosened. After sawing wet wood the band saw blade should be wiped with dry rag and if stored for a long time it is recommended to oil or fuel oil with a thin layer of oil to prevent it from rusting. Before working, remove the lubricant from the blade with a clean rag and then saw a piece of dry wood, completely removing the lubricant.

Keep any tool well sharpened, so that. in case of urgent work not to spend time for tool pointing.

How to sharpen a hand hacksaw for wood and set the teeth

Sooner or later any cutting tool blade will wear out and become blunt. In such a case, there is no need to change the entire tool. Correct sharpening is enough. You can do it with the help of those tools, which are already available at home (most often). Of course, nothing will work unless you know how to do everything correctly. In this article, the master plumber will tell you how to sharpen a hand wood hacksaw and set the teeth.

To ensure a high quality cut, you need to understand the mechanism by which the teeth edges of the hacksaw affect the material you are cutting. Unlike steel or plastic, wood is not a homogeneous material and, for this reason, several kinds of saws have been developed with different tooth profiles, sharpening angles and degree of camber. All sorts of wood hacksaws, their characteristics and technical data are specified in GOST 26215-84.

Basic types of wood saw teeth: 1. for cross sawing Type 1; 2. for cross sawing Type 2; 3. for longitudinal sawing Type 1; 4. for longitudinal sawing Type 2; 5. for universal sawing

There are three types of hacksaw: cross-cutting, longitudinal, and universal. The main difference lies in the principle of cutting: when sawing wood across the fiber on the tooth path there are fragments of different density. On the one hand, this fact plays into hands: the chips formed are smaller and are easily removed from the contact area, which allows both sides of the tooth to be sharpened for sawing, both in forward and reverse feed direction. On the other hand, cutting across the grain is partly impact cutting, so blunt edge angles are needed.

Sawing wood alongside the grain can be described as repetitive micro planing cycles. The force exerted on the tooth in this case is uniform, so the teeth are asymmetrically shaped and point in the direction of cutting. The edge formed at the tip of the tooth is perfectly perpendicular to the blade surface. Sawing lengthwise produces elongated chips that are difficult to remove from the contact area. Also, longitudinal cutting produces greater release of moisture, resins, and sticky substances, which, in combination with the first factor, prevents sawing in both directions. Chips are removed with a straight cut: the perpendicular cutting edge direction causes sawdust to be ejected in the sawing direction. The reverse movement removes chip residues and cleans the edges.

All types of hacksaw teeth are set, they are alternately tilted in different directions from the longitudinal axis of the blade. This creates a sort of dovetail in the longitudinal profile of the saw’s tooth row, with two sets of cutting wedges formed by the tips of the cutting edges of the teeth. Accordingly, the hacksaw forms two grooves at the bottom of the kerf, thus ensuring an evenly stepped cut and efficient chip evacuation.

Qualified professionals know the following signs that indicate a saw is about to fail:

- The hacksaw begins to sound differently when cutting wood;

- Visually, it becomes apparent that the tooth tips have rounded and lost their sharpness;

- The color of the tines changes;

- Sawing effort increases;

- The direction of the saw blade is poorly controlled;

- Frequent jamming of the teeth in the wood.

Tooth separating must always precede the sharpening process. When setting, the teeth should be deflected from the plane of the hacksaw to the left and right at a certain angle. Too small an angle too far will cause the teeth to “bite” into the wood. Conversely, too great an angle of deflection of the teeth makes the kerf too wide, increases the amount of waste (sawdust) and requires too much muscular energy to pull the hacksaw. The purpose of sharpening the teeth is to restore the following tooth geometry:

Hardened teeth cannot be sharpened. They are black in color with a bluish cast.

To do the sharpening with minimal loss of time and quality, you need to use special devices and tools such as:

Saws Part 2: Sharpening a Cross Cut Saw & Setting the Teeth

- Workbench;

- A locksmith’s vice;

- Pliers;

- A sharpening block; ;

- A protractor and a caliper;

- A hammer;

- It is possible to use a jig to clamp the hacksaw blade at an angle of 90 or 45 degrees.

It is mandatory to use the following files:

When sharpening a wood hacksaw, both simple vises are used, which is rather uncomfortable and long, and the vises of multicoordinate type, because their bed is rotated and fixed at the necessary angles to ensure the movement of the tool strictly in the horizontal plane. It is recommended to arrange additional lighting of the workspace with electric lights. Throughout the sharpening process the file / file must move without jerking, a constant pressure must be ensured, and the movements must be made without deviations from the constant angle. The sharpening process is carried out only with file movements “from yourself”. The file/sand file must be returned in the air and there must be no contact with the hacksaw.

Hacksaws are used for a variety of applications. The wood is sawn lengthwise or crosswise. Accordingly, the teeth will also be different.

Sharpening a hacksaw blade is, in a sense, an art that requires attention, good judgement and correct hands. This case is not difficult to learn, the main thing when working to adhere to the following rules:

- Firm fixation. The blade must be firmly fixed in a special fixture made of wood, which should also be stably installed in a well-lit workplace, as shown in the video on wood hacksaw sharpening. Tooth sharpening on bended laps or on stools does not produce a positive result!

- Using a Quality Tool. Use your own personal file, with a nail file or fine velvet file to clean off the sharpened tooth edges. Of course it is important that the file is sharp and new. It is also possible to use a used one, but it should be cleaned with a steel brush and rubbed with charcoal, so that the file is not blunt and clogged.

- Removing the metal layer. While sharpening a tooth file has to engage in its metal and remove the desired layer of metal, depending on the amount of pressure. And if it suddenly slips on a tooth without removing the metal, it means the file is worn out or the teeth of the hacksaw are overhardened. If this is the case, sharpening should be repeated with another file. If even after a file change, it slips on the tooth, you should take another hacksaw.

- Tooth pressure. clamp the file handle with the right hand, hold the end of the file with the left hand and guide the file onto the saw teeth. The pressure of the file on the teeth must be even, smooth, and of course to one side. the file must not touch the teeth when returning to its starting position.

- Correct handling of the file. Try to grind metal of about the same thickness on all tooth flanks, using the file an equal amount of times with equal pressure to keep the pitch, height, and amount of the tooth angles after sharpening.

- Deburring. Burrs form on the saw tooth edges on the exit side, they reduce the sharpness of the teeth and if you do not remove them, they will break off while the saw is in operation and the teeth will become considerably dull after that. To get rid of burrs, the tooth flanks are sharpened with a file with a velvet file, and the flanks are removed from the side edges of the blade with a wet burr.

- Checking the quality of work. After sharpening the teeth, be sure to check their sharpness. Look at the edge of the razor blade and the tip of the needle: they do not shine in the light if they are sharpened. And if they are blunt, then the edge of the blade and the tip of the needle appear, of course, rounded surfaces that reflect the light and shine well. Checking the Quality of a Hacksaw Tooth Sharpening is based on this. For this purpose, it is placed in front of your eyes by looking along the blade at its teeth. If their cutting tips and edges do not shine, it is an indication that the saw’s teeth are sharpened. And if suddenly some of the teeth shine (it happens often), it is necessary to sharpen them with a file with a velvet notch, that is to remove burrs and check again the reflection of light over their tops and edges.

When sharpening a certain type of wood hacksaw, you should pay attention to some peculiarities of this procedure. Let’s understand how to sharpen a wood hacksaw of each variety.

To sharpen the teeth of cross cutters use a triangular file with a rather fine notch and an angle of about 60 degrees. To sharpen the teeth clamp the hacksaw in a special device that allows its blade to set at an angle of 45-50 degrees to the surface of the work table. Drive the file at an angle of 60-75 degrees to the blade, parallel to the work table, and sharpen the left edge in the first tooth in this manner.

Sharpening saw teeth in several steps. Start with the file on the left hand side of the odd teeth in the far row, setting your hands in the same motion. Then pass the file over the right edges of the same odd teeth, thus completing the sharpening of the cutting edges with sharp peaks.

After you have sharpened the odd teeth of your saw blade, turn the hacksaw blade in the sharpening machine to sharpen the even teeth that were in the far row. When sharpening the teeth of crosscut saws, it is necessary to make sure that each tooth has sharp cutting edges with an angle of 60-75 degrees, i.e. a sharp tip and a short cutting edge.

To sharpen saw teeth with an angle of less than 60 degrees you need coarse or fine rhombic files, but files with a triangular angle of 60 degrees are not good for sharpening.

To sharpen the teeth of a longitudinal hacksaw blade, it is set vertically in the clamping device, and then the device is attached to the work table. Here are two ways to sharpen the longitudinal saw teeth, both of which differ in the angle of sharpening:

- The first method is straight, when the file or file at an angle of 90 degrees is directed horizontally to the blade and at the same time remove a small layer of metal from the back and front edges of the tooth, to sharpen the cutting edge. All teeth in the back row are sharpened this way. After that in the clamping device the blade is turned over and the teeth of the other row appearing in the far row are sharpened. Many modern carpenters and hobbyists use this technique when sharpening the teeth of such longitudinal hacksaws.

- The second method is oblique, and it differs from the first only in the direction of the tool itself in relation to the hacksaw blade. sharpening angle in the range of 80 degrees. Also sharpen the back and front edges of the teeth, first one row and then the next. By sharpening the teeth in this way, you get the side edges that are used for sharpening the archer saw.

If you have decided to buy a mixed wood hacksaw, you should know how to sharpen it correctly. To restore the quality of the cutting teeth they are sharpened using coarse-cut files or a fine-cut diamond file. As with the sharpening of a slit saw, there are two known methods. The difference between them is in the angle of sharpening (90 and 75-80 degrees).

During the saw’s separation it is necessary to remember about the uniformity of bending of all the teeth under the same angle, so that there is no increase in resistance to broaching and high wear of metal. Starting to bend the tines in the middle. Trying to bend them back at the base can damage the blade. The teeth are deflected from the blade one by one, i.e. every even tooth to the left and every odd one to the right. Only an experienced carpenter can visually and without tools determine the setting. This skill comes only after many dozens of hacksaws have been deburred.

In the absence of such experience the special tool comes to the rescue. The most affordable option is an ordinary flat plate made of steel. A slit is cut into it, in which the hacksaw blade needs to fit with almost no play. The process of setting is carried out as follows:

- The hacksaw is clamped so that the teeth are slightly visible above the clamp;

- Each tooth is clamped by the groove of the set and bent toward the middle;

- The setting angle should be checked at all times;

- Every even tooth in a row bends to the left, then every odd tooth to the right, or in reverse order.

If the height of the teeth varies, wood will not be sawn effectively, because higher teeth will wear more because of the higher load, while lower ones will not function at all. The blade pulls will be uneven, twitchy. Accuracy of sawing and quality of cut surfaces will also be a complaint. The height of the teeth must be adjusted before sharpening. Check the height as follows:

- The teeth are pressed against the paper, which lies on a flat surface;

- The web is imprinted on it;

- Tooth height is determined by the impression profile.

To align the teeth with a difference in height, the blade should be clamped in a bench vice and the excess metal should be ground. If the teeth have a big difference in height, you need to choose the average value and try to align as many of them as possible to it.

In the story. Sharpening of hand saw with the angle grinder in five minutes

It can be said that to process (set and sharpen the teeth) such a simple tool as a hacksaw at home is not so difficult. Observing the general rules, having certain practical skills and the simplest devices, it is quite possible to give the tool with your own hands a second life and avoid additional costs, buying a new carpenter saw.

How to sharpen a hand wood hacksaw and set its teeth

Sooner or later any cutting tool blade gets out of order and becomes blunt. It is not necessary to change the whole tool in this case. Correct sharpening is sufficient. You can do it with the help of those devices that are already available in the house (most often). Of course, nothing will work, if you do not know the correct technology to perform all the actions. In this article, the master plumber will tell you how to sharpen a hand hacksaw for wood and set the teeth.

To ensure high quality cutting you need to understand the mechanism of impact of the teeth edges of the hacksaw on the material to be cut. Unlike steel and plastic wood is a heterogeneous material, and for this reason several types of saws have been developed, differing by tooth profile, sharpening angle and degree of cleavage. All varieties of wood hacksaws, their characteristics and technical data are specified in GOST 26215-84.

Basic types of wood hacksaw teeth: 1. for cross-cutting Type 1; 2. for cross-cutting Type 2; 3. for longitudinal Type 1; 4. for longitudinal Type 2; 5. for universal sawing

There are three types of hacksaw: cross, rip and universal. The main difference lies in the cutting principle: when sawing wood across the fiber, the tooth path encounters fragments of different densities. on the one hand, this fact plays into hands: the chips formed are smaller and are easily removed from the contact zone, which allows the presence of the sharpening on both sides of the tooth for sawing, both in the forward and reverse feed direction. cross-cutting cuts on the other hand are partly impact cuts, which means that a blunter cutting edge angle is required.

Sawing wood along the grain can be characterized by repetitive micro planing cycles. Even force is applied to the tooth, so the teeth are asymmetrically shaped with the tip pointing in the cutting direction. The edge formed at the tip of the tooth is perfectly perpendicular to the blade plane. Sawing along the fibers produces elongated chips that are difficult to evacuate from the contact area. Also, during longitudinal cutting, more moisture, resin and sticky substances are released, which, in combination with the first factor, prevents sawing in both directions. Chips are removed with a straight cutter infeed: Perpendicular cutting edge direction promotes sawdust ejection to the sawing side. The reverse movement removes residual chips and ensures that the edges are self-cleaning.

Teeth of all hacksaw types are set, they are alternately tilted in different directions from the longitudinal axis of the blade. as a result, a sort of dovetail is formed in the longitudinal profile of the buzz saw teeth, with two sets of cutting wedges formed by the tips of the cutting edges of the teeth. Accordingly, the hacksaw forms two grooves at the bottom of the kerf, which ensures uniform stepped removal and efficient chip evacuation.

Qualified technicians know the following signs to indicate a saw is about to fail

- When cutting wood, the hacksaw starts to sound different;

- Visually, it becomes apparent that the tooth tips are rounded and have lost their sharpness;

- The color of the teeth changes;

- Sawing force increases;

- The direction of the saw is poorly maintained;

- Frequent jamming of the teeth in the wood occurs.

Tooth setting must always precede the sharpening process. When setting, the teeth must be deflected from the plane of the hacksaw to the left and right at a defined angle. Too small a tooth angle will cause the teeth to “sink” into the wood. Conversely, too great an angle of deflection of the teeth makes the cut too wide, increases the amount of waste (sawdust) and requires too much muscular energy to pull the hacksaw. The purpose of resharpening the teeth is to restore the next tooth geometry:

The hardened teeth cannot be sharpened. They are black with a bluish cast.

To do the sharpening with minimal loss of time and quality, you need to use special devices and tools such as:

- Workbench;

- Locksmith’s vise;

- Pliers;

- A sharpening block; ;

- A protractor and a caliper;

- Hammer;

- It is possible to use tooling that allows the hacksaw blade to be fixed at an angle of 90 or 45 degrees.

It is imperative that the following files be used:

When sharpening a wood hacksaw, simple vises are also used, which is rather uncomfortable and long, as well as multi-axis vises, because their bed is rotated and fixed at the necessary angles to ensure the movement of the tool strictly in the horizontal plane. It is recommended to organize additional lighting of the working space with the help of electric lights. Throughout the sharpening process, the file/super file must be moved without jerking, a constant pressure is necessary, and the movement must not deviate from a constant angle. Sharpening is only done with backward motion of the file. The file/nadfill must be returned by air, and there must be no contact with the hacksaw.

Saws are used for a variety of applications. Wood is sawn lengthwise or crosswise. Accordingly, the teeth will also be different.

Sharpening a hacksaw blade is in some sense an art that requires attention, good judgement and correct hands. This case is not difficult to learn, the main thing in the work to adhere to the following rules:

- Secure locking. The blade should be firmly clamped in a special fixture made of wood, which should also be stably installed in a well-lit workplace, as shown in the video on sharpening hacksaw blades in wood. Sharpening teeth on your lap or on stools does not produce a positive result!

- Using a good tool. use your own file with further cleaning of the sharpened tooth edges with a nail file or a file with a fine velvet notch. Of course it is important that the file is sharp and new. You can also use a used one, but it should be cleaned with a steel brush and be rubbed with charcoal, so that the file is not blunt and clogged.

- Removing a layer of metal. While sharpening a file it has to grip into the metal of the tooth and remove the necessary layer of metal, depending on the amount of pressure. And if it suddenly slips on a tooth without removing metal, it means that the file is worn out or the teeth of the hacksaw are overhardened. If this is the case, another file should be used to sharpen it. If it still slips on the tooth after a file change, you should use a different hacksaw.

- Tooth Pressure. The handle of the file is gripped with the right hand and the end of the file is held with the left hand and the file is guided to the saw’s teeth. The file pressure on the teeth should be even, smooth and, of course, in one direction. the file should not touch the teeth when returning to its initial position.

- Proper handling of the file. try to file metal of about equal thickness from tooth flanks, using the same amount of pressure to keep the pitch, height, and angle of the tooth after sharpening.

- Deburring. Burrs are formed on the saw tooth flanks on the exit side, they make the teeth less sharp and if you do not remove them, they will break off while the saw is working, and then the teeth will become significantly dull. To get rid of burrs, file teeth with a velvet file and use a wet burr on the side edges.

- Checking the Quality of Your Work. After sharpening the teeth, be sure to check their sharpness. Look at the edge of the razor blade and the point of the needle: they will not shine in the light if they are sharpened. And if they are blunt, then on the edge of the blade and the tip of the needle appear, of course, rounded surfaces that reflect light and shine well. Checking the sharpening quality of hacksaw teeth is based on this. For such a purpose, it is placed in front of the eyes, examining along the blade its teeth. If their cutting tops and edges are not shiny, it indicates that the saw’s teeth are sharpened. And if suddenly some of the teeth shine (it happens often), then it is necessary to sharpen them with a file with a velvet notch, that is to remove burrs and check again the reflection of light over their tops and edges.

When sharpening a certain type of wood hacksaw it is worth paying attention to certain features of this procedure. Let’s understand how to sharpen a wood hacksaw of each variety.

To sharpen the teeth of cross hacksaws use a triangular file with a fairly fine notch and an angle of close to 60 degrees. To sharpen the teeth, clamp the hacksaw into a special device that allows its blade to set at a 45-50 degree angle to the surface of the work table. Drive your file at a 60 to 75 degree angle parallel to the blade, and sharpen the left-hand edge of the first tooth.

Sharpen saw teeth in several steps. Start with the file on the left hand side of the odd teeth in the far row, setting your hands in the same motion. Next, the file runs along the right edges of the same odd teeth, thus completing the sharpening of the cutting edges with sharp tips.

After sharpening the odd teeth of your saw blade, flip the hacksaw blade in the sharpening device to sharpen the even teeth, which were in the far row. When sharpening cross cutters it is necessary to observe carefully that in every tooth there are sharp cutting edges with angle of 60-75 degrees, i.e. sharp top and short cutting edge.

To sharpen longitudinal saw teeth with an angle of less than 60 degrees use files with coarser or rhombic files with a fine notch, and files with a triangular angle of 60 degrees at the apex are not suitable for sharpening.

To sharpen the teeth of the longitudinal saw blade, it is set in the clamping device vertically, after that the device is fixed on the working table. Here are two ways to sharpen the teeth of a longitudinal saw, both of which differ in the angle of sharpening:

- The first method is straight, when the file or file at an angle of 90 degrees is directed horizontally to the blade and at the same time a small layer of metal is removed from the back and front faces of the tooth, to sharpen the cutting edge. All teeth in the back row are sharpened this way. Afterwards the blade is turned over in the clamping device and the teeth of the other row are sharpened in the far row. Many modern carpenters and hobbyists use this method when sharpening the teeth of such longitudinal hacksaws.

- The second way is oblique and differs from the first one only in the direction of the tool itself in respect to the hacksaw blade. The angle of sharpening is within 80 degrees. Also sharpen back and front tooth flanks, to start with one row and then the other. With this method of sharpening the teeth you get the side edges, which are used when sharpening the archer saw.

If you’ve decided to buy a mixed-cut wood hacksaw, you should know how to properly sharpen it. To restore the quality of the cutting teeth, they are sharpened using coarse-cut files or fine-cut rhombic files. Just like when sharpening a longitudinal saw, there are two known ways. Angle of sharpening: 90 and 75-80 degree angles of sharpening are different between straight and diagonal.

While setting the saw, you should not forget to bend all the teeth evenly at the same angle, so that there is no increase in broach resistance and high metal wear. It is necessary to begin to bend out the teeth from the middle. If you try to bend them back at the base, you could damage the blade. The teeth are deflected from the blade one by one, that is, each even tooth to the left, each odd tooth to the right. Only an experienced carpenter can visually and without using tools determine the setting. This skill comes only after many dozens of hacksaw teeth have been bent.

In the absence of such experience a special tool comes to the rescue. The most accessible option is the usual flat plate of steel. A slot is made in it, into which the hacksaw blade should enter almost without a gap. The deburring process is done as follows:

- The hacksaw is clamped so that the teeth are slightly visible above the clamp;

- Each tooth is clamped in the set groove and bent toward the middle;

- The angle of dilution should be under constant control;

- Every even tooth in a row is bent to the left, then every odd tooth to the right, or in reverse order.

Sawing in wood will not be efficient if the height of the teeth varies, because higher teeth will wear down more easily because of the higher load, while lower ones will not function at all. The blade pulls will be uneven, twitchy. To the accuracy of sawing and the quality of the cut surfaces will also be a complaint. Height alignment of teeth is necessary before sharpening. The height is checked as follows:

- The teeth are pressed against the paper, which lies on a flat surface;

- The blade is imprinted on it;

- The height of the teeth is determined by the profile of the impression.

To align teeth with height differences, the blade must be clamped in a bench vice and excessive metal ground. If the teeth have a big difference in height, it is necessary to choose an average value and try to align as many of them as possible to it.

In the story. Sharpening a hand saw with an angle grinder in five minutes

We can say that it is not so difficult to handle (set up and sharpen the teeth) such a simple tool as a hacksaw at home by yourself. Observing the general rules, having certain practical skills and the simplest devices, it is quite possible to give the tool with your own hands a second life and avoid additional costs, buying a new carpenter saw.

With constant use, the teeth lose their sharpness, the cutting edges wear out, worsening the quality of the cut and increasing the time for the task.

Buying a new one won’t remedy the situation for long, and it won’t take more than half an hour to restore the old blade.

Timely sharpening of hacksaw blades will restore cutting ability of cutters and will allow to have a serviceable tool at hand at all times.

Correct the sharpness of cutting edges at the first signs of wear, which can affect localized areas and the whole working surface.

Cutting edge dimensions also change, and this leads to jamming during operation.

Necessary tool for sharpening a hand saw

It is recommended to arrange additional lighting of the work area with electric lights.

Throughout the sharpening process the file / file must move without jerking, a constant pressure must be applied, and the motion must not deviate from a constant angle. Sharpening is done with backhanded filing only. The file/sand file must be returned in the air, without making contact with the hacksaw.

After sharpening with a hacksaw the saw teeth should have the right shape. This is shown in the picture below.