How to Adjust a Valve on a Four-Stroke Trimmer

The engine is the most important part of the car on which the operation of the car is completely based. That is why it is important to monitor the condition of the engine, carry out diagnostics, and also change consumables in a timely manner. The cause of many malfunctions in a car (for example, knocking, power loss) may be the valve. Therefore, it is important to know how to properly adjust the valves.

Valve adjustment – why is it needed?

Each vehicle has either 8 or 16 valves. Their number depends on the number of cylinders – either one valve on one cylinder or two. The first is responsible for launching the combustible mixture into the combustion chamber, the second is responsible for opening the exhaust outlet for exhaust gases. Such a mechanism that regulates the distribution of the mixture and gases is called gas distribution or valve. It is worth noting that different systems are installed on the diesel and injector.

When the motor is heated, the metal expands. Thus, there should be gaps on the engine that have a fixed size. The consequences of improper valve adjustments include reduced motor efficiency and rapid wear of parts.

For example: if the gap is insufficient, the valve will burn, if the gap is too large, the valve will not fully open and emit a metal knock.

How often to adjust the valve?

When changing the size of the gaps, they must be adjusted.

Signs of incorrect valve adjustment

There are a lot of signs that the gaps are broken. First of all, engine power and its efficiency are reduced. Perhaps the appearance of an unpleasant metal knock, noise, smell of burning, etc. A knock appears mainly during loads or at idle. As a result, engine parts undergo rapid wear.

The above signs of unregulated valves are an alarming symptom. If at least one of them appears, check the valves and adjust them.

Valve Adjustment Result

Valve adjustment: what is it for?

Ultimately, with the correct adjustment of the valves, the stability of the motor is restored, the power and wear resistance increase. The engine will run smoother and more stable at both low and high speeds.

Is it possible not to adjust the valve?

In modern cars, so-called hydraulic lifters are installed. In conventional engines there are camshafts or “pushers” that push the valve. As for hydraulic lifters, they themselves find the necessary clearance for the release of gases at high oil pressure. They ensure optimum valve performance in all cases. Many people ask: “If you do not adjust the valve, what will happen?” If there are hydraulic lifters on the car, then valve adjustment is not necessary. Otherwise, adjust and check the valves periodically.

How to adjust the valve?

How to properly adjust valve clearances

Many car owners try to adjust the valves themselves without contacting technical service.

It is necessary to set the dimensions of the gaps on the engine in the cold state, since the factory settings were made on cold metal. In this case, it does not change its size, and they remain standard.

It is worth noting that adjusting the valves is exactly according to the recommendations and instructions, otherwise the gaps will not be configured correctly.

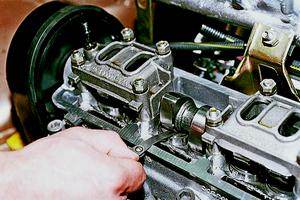

First, the cylinder piston is installed at the dead center of the compression stroke at the top. The cylinder clearance will be determined by the adjustment probe. This will ensure the closure of both valves, as well as rocker rocker within the specified limits of the gap. Manufacturers usually put labels on which to install the piston in this position.

The adjustment itself is made by turning the rocker screws in the right directions. Turn the crankshaft in the sprocket only clockwise. Many apply their labels to determine the position of each of the cylinders. The marks must match on the bearing and crankshaft.

Next, release the locknut on the bolt or screw. The clearance must be set to the limit, in which case the probe is. Then fix the position by tightening the nut. This should be done carefully, taking into account the tightening force, since you can knock down the set gap. To check the gap, you need to insert the probe, it must pass, but with effort. If the probe does not pass, you need to repeat the adjustment.

Video: How to Adjust a Valve on a Four-Stroke Trimmer

The crankshaft is rotated only by the start handle (crank handle), or by the screw that secures the alternator drive pulley and only clockwise.

Here you definitely need a probe or a special tool to adjust the valves.

In special books on engine repair, the adjustment procedure is fully described. Another feature is the installation of a clearance on the intake and exhaust valves. The boost pressure control valve has a clearance different from the gas outlet. In addition, different clearance may be required for different cylinders. All this is described in the car repair manual.

Necessary tools

What you need to adjust the valves

As mentioned earlier, a probe or special device is required. If you choose the right one, you can work with the adjustment plates. Often use a rail to adjust the valves, which provides greater accuracy compared to plates or probe. However, the adjustment process itself is different, it does not correspond to the above method.

You can use the indicator. It is a special device for adjusting valves with high accuracy.

Thus, the valves are responsible for the distribution of the combustible mixture in the engine, the timely exit of exhaust gases. The dimensions of the valve clearances must be regularly monitored and, if necessary, adjusted. You can adjust the valves yourself, without resorting to the services of car services. It is important to accurately measure valve clearances, as they provide stability and engine efficiency.

Many owners of scooters periodically complain of an unpleasant sound coming from the cylinder head, resembling a clatter or clicking. Or they feel that their scooter is slowly gaining momentum at the factory. This is a sure sign that the scooter engine is living out its last weeks, and maybe days.

It is advisable to adjust the valves on the scooter immediately after purchase or after the first run of 500 km

Normally, this phenomenon occurs after a run of 2500-3000 km, and in order not to aggravate the position of the scooter, it is necessary to timely adjust the valve clearances located in the engine. This procedure must be performed immediately after purchase (if the Chinese scooter), then after the first run of 500 km and further in accordance with the table of professional work, which is located in the instruction manual.

How to adjust the valves on a 4-stroke (four-stroke) scooter

Video tutorial from our auto mechanic:

I would like to warn in advance that in the summer you should begin adjusting only after the engine has completely cooled down, otherwise the consequences will not be most pleasant. But in winter the engine should be slightly warmed up. Now for work we need to prepare the following set of tools:

- Phillips screwdriver

- Pliers

- 8, 9 and 13 mm keys

- Probe for adjusting valve clearances by 0.1 and 0.05 mm

First our step will be to prepare small containers for scooter parts. This is necessary in order not to accidentally lose them during disassembly. Four of these tanks will be enough.

Second step: Carefully remove the seat with the boot by unscrewing the four nuts in the boot with an allen key and a screwdriver. Now we have access directly to the engine itself.

Third step: You need to remove the plastic lining of the generator’s fan by unscrewing the two nuts with an 8 mm wrench. So you can find the “dead point” in order to adjust the gaps.

Fourth step: Unscrew the four M10 bolts and two nuts that hold the metal fuel pipe, remove the cylinder head cover from the inside. Then, determining where the inlet and outlet valves are located (inlet at the top, outlet at the bottom), we look for the top dead center (TDC).

In summer, the adjustment of the valves of the 4-stroke scooter engine should only begin after the engine has completely cooled, in winter – the engine should be slightly warmed up

What is TDC? This is the place where the cylinder piston is permanently fixed in the upper position, tightly, so to speak. Finding it is easy. To do this, use the 13 key to turn the hexagon clockwise, located on the generator cooling impeller, until the “T” sign on the flywheel coincides with the side protrusion of the flywheel.

Now take a look at the camshaft sprocket. There should be three holes and it is clear that two valves are closed. The holes must be arranged so that the piston is at top dead center (a large hole on the outside of the cylinder head, and two small holes parallel to the fastening of its cap).

Fifth step: direct valve adjustment. Insert a 0.05 mm probe between the inlet valve and the adjustment bolt. If the clearance is too narrow or too wide, loosen the lock nut of the adjusting bolt. You can increase the gap by turning the key counterclockwise, and decrease it clockwise. The probe should enter this gap tightly, but not end-to-end so that there are no scratches on it when moving. Now you can tighten the locknut back and check the gap width again.

To adjust the exhaust valve, you need to take a 0.1 mm probe. However, it will be much harder to get to this valve

The same operation is performed with the release valve, only for it you need to take a 0.1 mm probe. It will be much harder to get to this valve, but do not despair.

All! The four-stroke scooter valve setting is done! Now carefully assemble all the parts back by tightening all the nuts and bolts, and do all the steps back. Do not forget about caution when working with plastic in the cold: if you carelessly handle it, it can simply fall apart.

Features of how to adjust the valve on a scooter with a volume of 50-150 cubic meters

The size of the probes for adjusting the gaps on scooters of 50-150 cubic meters varies greatly depending on the size of the engine. And in many Chinese scooters (Viper, Geely, Reggy, Daelim, C Moto, etc.) you do not need to remove the rear plastic from the scooter to get to the engine. This greatly facilitates the work.