How To Adjust Rpm On An Angle Grinder

Advantages and disadvantages

Angle grinders with adjustable speed Presented on the construction market in a huge range. Depending on the design features and technical characteristics, they can have both pros and cons. So, household models are compact and lightweight, but their functionality is limited. In such devices, productivity is also reduced, during operation they quickly overheat and require constant stops.

As for professional tools, they are very powerful and endowed with additional functions, which allow them to be used for a long time without overheating the mechanism. These angle grinders are of excellent quality, easy to operate, and are designed for both cutting and grinding workpieces. The disadvantages of these models are the high price and high weight, since the frame of the device and additional components are made of durable material.

Models and their characteristics

Today, angular grinders equipped with speed control are in great demand among craftsmen. This type of tool is well suited for cutting, polishing and grinding workpieces. The construction market is represented by an angle grinder manufactured by both domestic and foreign companies. Models from several brands have proven themselves well.

- Bosch GWS 850 CE. This device is lightweight for easy handling. The machine has a power of 850W and is good for polishing marble and granite. The set of the tool includes a disc speed regulator with six positions. The minimum speed of revolutions is 2800, the maximum is 11000 per minute, a special nozzle designed for high speed is used for processing wood with a machine. The manufacturer additionally equips the device with a handle, a wrench, discs and washers for attaching nozzles.

- Makita GA5030. It is the lightest grinder (weighs 2 kg) and is designed for simple household work. Using the device, you can easily cope with cutting, grinding and polishing various materials. Thanks to the additional handle, the workflow is greatly simplified, this model can be used for discs with a diameter of 115 and 125 mm. The tool has a power of 1400 W, thanks to the speed control it is classified as a professional model. In addition, the angle grinder has a turn-on lock, a speed stabilization system, in order to protect the device from overheating during intensive work, it is recommended to turn it off periodically.

- Metabo WEV 10-125 Quick. This modification is produced with the ability to change the speed and maintain a power of 1200 W, the design provides for an electronic engine overload protection system. The speed of rotation of the cutting wheel automatically changes depending on the type of work and is fixed at varying loads. Of all the 125 mm machines produced, this model is the best, it features a large number of revolutions and variable speeds. The angle grinder also has a safety clutch and replaceable brushes, which turn off when there is a voltage drop in the mains. In addition, the manufacturer has supplemented the tool with an overheating indicator, a stabilizer and a long cable.

The review of the popular angle grinder with adjustable speed can be completed by the modification of Hitachi G13SS. Due to its high power indicators and the possibility of using it with discs with a diameter of 150 and 230 mm, it takes a high rating among the types of this equipment. The device is perfect for both renovation and construction work. The device can cut metal workpieces and cut parts from different materials. A distinctive characteristic of the device is its narrow delight and light weight, which makes it comfortable to operate.

Features:

The angle grinder with speed control is a versatile and multifunctional tool that makes it easy to cope with any task in construction and renovation. The main difference between such an angle grinder is the ability to independently set the speed of rotation of the disk, depending on the type of material being processed. Manufacturers produce a device with an electric motor, the power of which can range from 500 to 1500 watts. For cutting workpieces, you can choose machines with an average capacity of 800 W, but if you plan to carry out grinding, it is recommended to give preference to more powerful models, since the area of contact with the surface of the material being processed is larger in this case.

angle grinder with adjustable speed is an absolutely safe device to use, since all models are equipped with a full range of protective systems to prevent injury. Let’s list the main.

- Soft start device. It is responsible for the smooth operation of the tool after pressing the start button. This device can also act as an inrush current limiter, which extends the life of the device.

- Safety clutch. In the event that, when processing the material, the disc of the angle grinder begins to “bite” or wedge, this device starts an emergency stop.

- Emergency brake. When machining hard material, the tool can twist and pull out of the hand. The brake helps to stop the disc rotation in 3 seconds.

- Coil impregnation with a special compound. Since cutting and grinding of the material is accompanied by the appearance of abrasive dust, its penetration into the device is prevented by additional processing of the coil with a protective layer. This avoids short circuit problems.

- Heat dissipating slots. Protect the device from overheating during intensive work.

- Balancing system. The circles of the machine may be ground unevenly, after which trembling and beating of the machine may occur during the processing of workpieces. Smooth work is helped by special automatic balancing.

- Overload fuse. When the cutting part heats up to a temperature above 160 degrees, the automatic system is triggered, and the rotation speed of the disc first decreases to 200 rpm, then completely stops.

angle grinders with speed regulator weigh from 2 to 5 kg, their performance depends on the diameter of the disc and the number of revolutions. Mini models are very popular among craftsmen, which are suitable for working with 115 and 125 mm wheels. In them, the number of revolutions is from 10,000 to 11,000 rpm. Angle grinder with 115 mm discs is generally used for cutting material up to 28 mm thick and is well suited for sanding wood, tile, porcelain and glass. Devices with 125 mm discs are considered the most popular, as they perfectly cope with grinding the surface of any material and cutting parts with a thickness of 30 mm. If it is necessary to cut and grind steel pipes, bricks and concrete, then it is recommended to use a device with a circle of 150 mm, while metal processing should be carried out at high speeds, and stone at lower speeds.

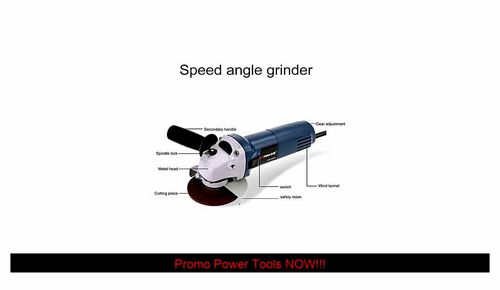

The attachment of the cutting disc to an angle grinder with speed control is carried out using a spindle stop and a safety key, in some models there is also a self-clamping system. Additionally, manufacturers also equip the tool with a casing, which protects the craftsman from dust, sparks in the eyes and breaking the circle on the go.

Tips for choosing

The angle grinder with speed controller is one of the most popular and widely used tools. Since this tool is represented by different modifications, it is difficult to make the right choice in favor of this or that device. The first step is to decide how the device will be used for domestic or professional purposes. In the event that infrequent and simple work is planned, then a small low-speed machine will do. For the simultaneous implementation of high-quality cutting and grinding of the material, it is best to opt for professional models.

In addition, it is worth paying attention to the following characteristics of the device:

- Performance:

- Minimum and maximum number of revolutions;

- Additional functions;

- Disc parameters that can be used with the instrument.

An important criterion when choosing is the frequency of operation of the device. For constant and intensive work, it is necessary to buy models in which the outer case is made of durable metal and supplemented with brass inserts. When installing the pipeline, it is advisable to use devices with the maximum level of protection against water and dirt.

What is the adjustment for??

The quality of cutting and grinding of the material directly depends on the set speed of rotation in the angle grinder. Since hard and thick workpieces lend themselves well to cutting at maximum speed, and aluminum, on the contrary, can melt when heated, then when working with them, the speed of rotation of the disk should be adjusted. Control of operating modes is provided only in models equipped with special regulators. This function is useful and used in several cases.

- When processing stone. This material is well cut and polished at low speeds; for each type of stone, its own disc speed is selected separately.

- For finishing fragile surfaces that require careful handling. At high speeds, such products can deteriorate.

- When replacing one circle size with another. In this case, a speed adjustment is needed.

- When using in the work of crowns and discs with diamond dusting. To avoid their overheating and breakage, workpieces must be processed at low speeds.

If the tool is only planned to carry out threaded operations, then there is a need for a speed controller. When used universally, the angle grinder is irreplaceable. The speed control system in the angle grinder is represented by integrated microcircuits. They are reliable in use, function with a soft start system and a tuned module.

angle grinder with speed control: models, characteristics, subtleties of choice

Every master has at hand such a reliable tool as an angle grinder. With the help of this device, you can not only perform high-quality cutting of material, sand the surface, but also sharpen kitchen knives. Since for SEPARATE types of work minimal rotation of the disc is required, it is recommended to purchase a device with a speed control.

How to use?

Despite the fact that all models of the variable speed angle grinder serve flawlessly, they still require proper care and operation. Therefore, it is necessary to periodically replace the working attachments and contact brushes, add oil to the gearbox and clean the engine compartment from dirt. In addition, a technical check of the tool is also provided, it should be carried out at least once a month.

When replacing the disks, the device must be turned off, the gearbox must be locked with the button, then the old nozzle must be removed and a new one put on, tightly pressing it with a nut. Filling with oil is simple: to do this, remove the gearbox cover, having previously unscrewed the mounting bolts. As for cleaning the case from dust, it is carried out using a vacuum cleaner.

Working with an angle grinder must be carried out in accordance with all safety regulations. The technician must wear protective gloves, goggles or a face shield. Do not start cutting material with a broken or cracked blade as it could cause injury. Grinding with a cutting disc is also not allowed, and cutting with a stripping.

For cutting and polishing various materials, a certain speed of rotation of the disc is required, it can be adjusted using a special automatic system, which is controlled on the body by moving a lever. Thus, the revs can be easily decreased or increased. In addition, you can reduce the speed by using large diameter discs.

For information on how to properly adjust the speed in an angle grinder with your own hands, see the following.

Features:

The angle grinder with speed control is a versatile and multifunctional tool that makes it easy to cope with any task in construction and renovation. The main difference between such an angle grinder is the ability to independently set the speed of rotation of the disk, depending on the type of material being processed. Manufacturers produce a device with an electric motor, the power of which can range from 500 to 1500 watts. For cutting workpieces, you can choose machines with an average capacity of 800 W, but if you plan to carry out grinding, it is recommended to give preference to more powerful models, since the area of contact with the surface of the material being processed is larger in this case.

angle grinder with adjustable speed is an absolutely safe device to use, since all models are equipped with a full range of protective systems to prevent injury. Let’s list the main.

- Soft start device. It is responsible for the smooth operation of the tool after pressing the start button. This device can also act as an inrush current limiter, which extends the life of the device.

- Safety clutch. In the event that, when processing the material, the disc of the angle grinder begins to “bite” or wedge, this device starts an emergency stop.

- Emergency brake. When machining hard material, the tool can twist and pull out of the hand. The brake helps to stop the disc rotation in 3 seconds.

- Coil impregnation with a special compound. Since cutting and grinding of the material is accompanied by the appearance of abrasive dust, its penetration into the device is prevented by additional processing of the coil with a protective layer. This avoids short circuit problems.

- Heat dissipating slots. Protect the device from overheating during intensive work.

- Balancing system. The circles of the machine may be ground unevenly, after which trembling and beating of the machine may occur during the processing of workpieces. Smooth work is helped by special automatic balancing.

- Overload fuse. When the cutting part heats up to a temperature above 160 degrees, the automatic system is triggered, and the rotation speed of the disc first decreases to 200 rpm, then completely stops.

angle grinders with speed regulator weigh from 2 to 5 kg, their performance depends on the diameter of the disc and the number of revolutions. Mini models are very popular among craftsmen, which are suitable for working with 115 and 125 mm wheels. In them, the number of revolutions is from 10,000 to 11,000 rpm. Angle grinder with 115 mm discs is generally used for cutting material up to 28 mm thick and is well suited for sanding wood, tile, porcelain and glass. Devices with 125 mm discs are considered the most popular, as they perfectly cope with grinding the surface of any material and cutting parts with a thickness of 30 mm. If it is necessary to cut and grind steel pipes, bricks and concrete, then it is recommended to use a device with a circle of 150 mm, while metal processing should be carried out at high speeds, and stone at lower speeds.

The attachment of the cutting disc to an angle grinder with speed control is carried out using a spindle stop and a safety key, in some models there is also a self-clamping system. Additionally, manufacturers also equip the tool with a casing, which protects the craftsman from dust, sparks in the eyes and breaking the circle on the go.

angle grinder with speed control: models, characteristics, subtleties of choice

Every master has at hand such a reliable tool as an angle grinder. With the help of this device, you can not only perform high-quality cutting of material, sand the surface, but also sharpen kitchen knives. Since for SEPARATE types of work minimal rotation of the disc is required, it is recommended to purchase a device with a speed control.

Models and their characteristics

Today, angular grinders equipped with speed control are in great demand among craftsmen. This type of tool is well suited for cutting, polishing and grinding workpieces. The construction market is represented by an angle grinder manufactured by both domestic and foreign companies. Models from several brands have proven themselves well.

- Bosch GWS 850 CE. This device is lightweight for easy handling. The machine has a power of 850W and is good for polishing marble and granite. The set of the tool includes a disc speed regulator with six positions. The minimum speed of revolutions is 2800, the maximum is 11000 per minute, a special nozzle designed for high speed is used for processing wood with a machine. The manufacturer additionally equips the device with a handle, a wrench, discs and washers for attaching nozzles.

- Makita GA5030. It is the lightest grinder (weighs 2 kg) and is designed for simple household work. Using the device, you can easily cope with cutting, grinding and polishing various materials. Thanks to the additional handle, the workflow is greatly simplified, this model can be used for discs with a diameter of 115 and 125 mm. The tool has a power of 1400 W, thanks to the speed control it is classified as a professional model. In addition, the angle grinder has a turn-on lock, a speed stabilization system, in order to protect the device from overheating during intensive work, it is recommended to turn it off periodically.

- Metabo WEV 10-125 Quick. This modification is produced with the ability to change the speed and maintain a power of 1200 W, the design provides for an electronic engine overload protection system. The speed of rotation of the cutting wheel automatically changes depending on the type of work and is fixed at varying loads. Of all the 125 mm machines produced, this model is the best, it features a large number of revolutions and variable speeds. The angle grinder also has a safety clutch and replaceable brushes, which turn off when there is a voltage drop in the mains. In addition, the manufacturer has supplemented the tool with an overheating indicator, a stabilizer and a long cable.

The review of the popular angle grinder with adjustable speed can be completed by the modification of Hitachi G13SS. Due to its high power indicators and the possibility of using it with discs with a diameter of 150 and 230 mm, it takes a high rating among the types of this equipment. The device is perfect for both renovation and construction work. The device can cut metal workpieces and cut parts from different materials. A distinctive characteristic of the device is its narrow delight and light weight, which makes it comfortable to operate.

Advantages and disadvantages

Angle grinders with adjustable speed Presented on the construction market in a huge range. Depending on the design features and technical characteristics, they can have both pros and cons. So, household models are compact and lightweight, but their functionality is limited. In such devices, productivity is also reduced, during operation they quickly overheat and require constant stops.

As for professional tools, they are very powerful and endowed with additional functions, which allow them to be used for a long time without overheating the mechanism. These angle grinders are of excellent quality, easy to operate, and are designed for both cutting and grinding workpieces. The disadvantages of these models are the high price and high weight, since the frame of the device and additional components are made of durable material.

What is the adjustment for??

The quality of cutting and grinding of the material directly depends on the set speed of rotation in the angle grinder. Since hard and thick workpieces lend themselves well to cutting at maximum speed, and aluminum, on the contrary, can melt when heated, then when working with them, the speed of rotation of the disk should be adjusted. Control of operating modes is provided only in models equipped with special regulators. This function is useful and used in several cases.

- When processing stone. This material is well cut and polished at low speeds; for each type of stone, its own disc speed is selected separately.

- For finishing fragile surfaces that require careful handling. At high speeds, such products can deteriorate.

- When replacing one circle size with another. In this case, a speed adjustment is needed.

- When using in the work of crowns and discs with diamond dusting. To avoid their overheating and breakage, workpieces must be processed at low speeds.

If the tool is only planned to carry out threaded operations, then there is a need for a speed controller. When used universally, the angle grinder is irreplaceable. The speed control system in the angle grinder is represented by integrated microcircuits. They are reliable in use, function with a soft start system and a tuned module.

Tips for choosing

The angle grinder with speed controller is one of the most popular and widely used tools. Since this tool is represented by different modifications, it is difficult to make the right choice in favor of this or that device. The first step is to decide how the device will be used for domestic or professional purposes. In the event that infrequent and simple work is planned, then a small low-speed machine will do. For the simultaneous implementation of high-quality cutting and grinding of the material, it is best to opt for professional models.

In addition, it is worth paying attention to the following characteristics of the device:

- Performance:

- Minimum and maximum number of revolutions;

- Additional functions;

- Disc parameters that can be used with the instrument.

An important criterion when choosing is the frequency of operation of the device. For constant and intensive work, it is necessary to buy models in which the outer case is made of durable metal and supplemented with brass inserts. When installing the pipeline, it is advisable to use devices with the maximum level of protection against water and dirt.

How to use?

Despite the fact that all models of the variable speed angle grinder serve flawlessly, they still require proper care and operation. Therefore, it is necessary to periodically replace the working attachments and contact brushes, add oil to the gearbox and clean the engine compartment from dirt. In addition, a technical check of the tool is also provided, it should be carried out at least once a month.

When replacing the disks, the device must be turned off, the gearbox must be locked with the button, then the old nozzle must be removed and a new one put on, tightly pressing it with a nut. Filling with oil is simple: to do this, remove the gearbox cover, having previously unscrewed the mounting bolts. As for cleaning the case from dust, it is carried out using a vacuum cleaner.

Working with an angle grinder must be carried out in accordance with all safety regulations. The technician must wear protective gloves, goggles or a face shield. Do not start cutting material with a broken or cracked blade as it could cause injury. Grinding with a cutting disc is also not allowed, and cutting with a stripping.

For cutting and polishing various materials, a certain speed of rotation of the disc is required, it can be adjusted using a special automatic system, which is controlled on the body by moving a lever. Thus, the revs can be easily decreased or increased. In addition, you can reduce the speed by using large diameter discs.

For information on how to properly adjust the speed in an angle grinder with your own hands, see the following.

How to assemble a regulator with your own hands?

A simplified and rather reliable in operation frequency converter for an angle grinder is constructed with your own hands from available electrical parts. Below is a diagram showing all the required components for mounting on a printed circuit board of the device of interest to us.

So, we need:

- Symmetrical triode thyristor (or TRIACOM, triac) DIAC (DB3)

- Resistor (resistance) R1 (its parameters should be 4.7 kOhm);

- Additional TRIACOM VT136 / 138 (TRIAC)

- Capacitor C1 (400 V, 0.1 μF)

- Additional resistance VR1 at 500 kOhm.

A similar scheme operates according to the following method.

- The charging time of the capacitor is modified by an auxiliary resistor (it is called the trimmer). When voltage is applied to the circuit, the triacs are in the gate position, and a zero voltage value is observed at the output.

- In the process of charging the capacitor, an increase in voltage is noted on it, which leads to the opening of the DB3 triac. As a result of this, the voltage falls on VT136 / 138. This thyristor element also opens, and an electric current flows through it.

- After that, the symmetrical components are closed again and remain in a similar status to the absolute recharge of the capacitor in the opposite direction.

- Ultimately, at the conclusion, we acquire a deterministic signal of finite energy, complex in configuration. Its exact range is determined by the period of performance of the functions of the circuit capacitor. auxiliary resistance. resistance R1.

Triacs are usually located on a printed circuit board. It is easy to create it from textolite (multilayer extruded plastic is used, consisting of heat-insulating fiber and foil). Individual craftsmen cut the board with a cutter. It is practiced to place the circuit elements using the hinged mounting method. Triystres are mounted only on an aluminum or copper heat exchanger. It plays the role of a good heat sink.

The test of the assembled device is carried out using an ordinary 40-60 W incandescent lamp. Connect it to the circuit, start to regulate the glow power. If the brightness changes, then you have done everything correctly. Now you can start installing the regulator in the shell of the angle grinder. This is not very easy to do, since it is necessary to ensure that the auxiliary device does not interfere with you when using the angle grinder.

You will need to calculate the place of installation of the homemade control device yourself, in accordance with the design features of the angle grinder. Installation of the scheme is performed:

- In an additional box mounted on the unit body;

- Into the handle of the holder;

- Into a small, empty niche (designed to cool and circulate air masses) in the rear area of the angle grinder.

The very connection of the circuit to the device is made by integrating it into the electric supply channel of the angle grinder. I suppose you won’t have any difficulties with this.

For what purpose is the angle grinder low speed?

The integrated wheel speed control option will enable the gentle handling of materials such as wood or plastic. At lower speeds, comfort and safety are increased. The most practical similar option in radio and electrical installation business, service station and studio engaged in restoration.

In addition, among professionals who use power tools, there is a judgment that the more trivial the device is arranged, the more reliable it is. And it is advisable to take the additional service “stuffing” outside the boundaries of the angle grinder. With this approach, equipment maintenance is greatly simplified. In this regard, some companies deliberately produce portable individual electric controllers that are connected to the network cable.

What is the angle grinder for smooth start and speed controller?

In modern angle grinders, 2 necessary options are used that increase the characteristics and safety of the equipment:

- Speed controller (frequency converter). a device designed to convert the engine speed in different modes of operation;

- Soft starter. a circuit that provides a leisurely increase in engine speed from zero to the limit value when the unit is connected.

They are used in electromechanical equipment, in the structure of which an alternating current electric motor with a collector is practiced. They help to reduce the wear of the mechanical parts of the unit when switched on. Reduce the stress on the electrical components of the machine, putting them into operation smoothly. As studies of the properties of materials have revealed, a particularly strong development of contacting nodes occurs in the process of a sudden transition from a stationary state to rapid activity. For example, one start of an internal combustion engine in a car is equal to the wear of the piston and a group of sealing rings to 700 kilometers.

When power is applied, an abrupt transition is made from a stationary state to the rotation of a circle with a speed of 2.5-10 thousand revolutions in 60 seconds. Therefore, anyone who has used an angle grinder knows the feeling that the tool just “flies out of hand”. Just at this moment, most of the accidents associated with the mechanical part of the unit happen.

The rotor and stator windings are NOT less stressed. An alternating current electric motor with a collector starts up in a short circuit mode, the EMF already pushes the shaft forward, but the inertia force does not yet allow it to rotate. A jump in the starting electric current arises in the coils of the electric motor. Despite the fact that by design they are Designed for such work, over time a moment comes (for example, with a voltage drop in the mains) when the winding insulator is NOT able to withstand and a short circuit occurs between the turns.

With the introduction in the electrical circuit of the instrumentation of the schemes for adapting the soft start and the change in the frequency of rotation of the motor, all the above-described troubles spontaneously disappear. In addition, the issue of a sudden and significant decrease in voltage in the general power grid during the start of the tool is being resolved. Hence, it is clear that household electrical appliances are NOT at risk of failure. And the automatic switches for electricity meters will NOT work and turn off the current in an apartment or house.

The soft start scheme is used in angle grinders of the middle and high price segment, the speed control unit is more and more in professional modifications of the angle grinder. The speed control makes it possible to process soft materials with an angle grinder, to carry out delicate grinding and polishing, since at high speeds the wood or paint will simply burn out. The auxiliary electrical circuit increases the cost of the toolkit, but extends the service life and the degree of safety in use.

How to make a speed controller for an angle grinder with your own hands?

If you have an old angle grinder in your inventory, don’t rush to get rid of it. Using a simple wiring diagram, the tool can be improved by adding an option for adjusting the speed. At the expense of a conventional control device, which you can create with your own hands within a few hours, the functions of the tool will expand significantly. Reduced the number of rotations per unit of time, the angle grinder can be used as a sharpening and grinding unit for different types of materials. There will be additional possibilities for using auxiliary equipment and attachments.

Electronic device testing

Before connecting the block to the angle grinder, check it. Take an electrical outlet. Insert 2 wires into it, one of which connect to the board, and the other to the network cable. Another wire Connect to the network board. As you can see, the regulator is connected in series in the electrical circuit. Connect a light bulb to the electrical circuit and test the device’s performance.

Installation of the regulator in the cavity of the angle grinder housing

The electronic device, assembled separately from the angle grinder, is encased in a dielectric material as all components are energized. A portable electrical outlet with a cable is fixed to the body. The handle of the variable resistance resistor is brought out. The regulator is connected to the mains, and the tool is plugged into a portable power outlet.

Connecting the regulator to the angle grinder

The frequency converter is connected to the instrument in series. If there is free space in the handle of the angle grinder, then this device can be placed there. The surface-mounted circuit is glued with epoxy, which will serve as an insulator and vibration protection. Variable resistance resistor with a plastic handle brought out to adjust the speed.

How to make a regulator from a dimmer?

A very effective and easy solution to this issue will be the creation of an external frequency converter. In the role of a converter, you can use a dimmer. a device for regulating the level of illumination. When creating, you need an electrical outlet and a plug. I must say that the implementation of such a device can be performed in different ways. Particularly simple are 2: with and without the introduction of an automaton.

- Screw 2 wires to the ends of the electrical outlet so that one is longer. Then connect the long end to one of the pins on the plug. The end of the 2nd wire We fix on the contacts of the dimmer, and connect its other output to the 2nd contact of the plug.

- When using the 2nd option, it is required to make a number of modifications to the circuit, namely to place an automatic machine on the cord between the plug and the dimmer. Basically, ordinary switches are provided in the dimmers, but we need an automatic one, which, if something goes wrong, will turn off our device from the mains.

So, the frequency converter of the angle grinder is ready, and for practicality it can be placed in a specialized case or fixed on a wood panel. It should only be taken into account that such a device is homemade, and when working with the power grid, one must be careful.

Device manual

The basic rule when operating an angle grinder with a home-made speed controller is to observe the mode of work and rest. The fact is that the engine operating at the “regulated” voltage is especially hot. When grinding at reduced speeds, it is important to take frequent breaks so that the collector windings do NOT burn out.

It is also highly discouraged to turn on the tool if the speed controller is set to minimum. the voltage drop is NOT enough to spin the rotor, the collector lamellas will remain in short-circuit mode, and the windings will start to overheat. Unscrew the variable resistor to the maximum, then turn on the angle grinder, from below the speed to the desired value.

In addition, it should be understood that the adjustment of the speed of rotation on the angle grinder is based on the principle of a water tap. The device does NOT increase the number of revolutions, it can only lower them. It follows from this that if the maximum passport speed is 3000 rpm, then when the speed controller is connected, the angle grinder will operate in a range lower than the maximum speed.

Features of mounting a finished block

When buying and installing a factory regulator inside an angle grinder, most often you have to modify the case. cut a hole in it to output the adjusting wheel. However, this can adversely affect the rigidity of the casing. Therefore, it is preferable to install the device outside.

The numbers on the adjusting wheel indicate the number of spindle revolutions. Meaning This is not absolute, but conditional. “1”. minimum speed, “9”. maximum. The rest of the numbers are for guidance when regulating. The location of the wheel on the body is different. For example, on a Bosch PWS 1300-125 CE, Wortex AG 1213-1 E or Watt WWS-900 angle grinder, it is located at the base of the handle. In the second models, such as the Makita 9565 CVL, the adjusting wheel is located at the end of the casing.

The connection diagram of the regulator to the angle grinder is NOT complicated, but sometimes it is not so easy to pull the cables to the button, which is located on the second end of the device body. The task can be solved by selecting the optimal wire section or bringing it to the surface of the casing.

A good option is to install the regulator on the surface of the device or fasten it to a power cable. Everything does not always work out on the first try, sometimes the device has to be tested, after which some adjustments are made. And this is easier to do when access to its elements is open.

Why the angle grinder is low speed?

The built-in disc speed control function allows you to delicately handle materials such as plastics or wood. Comfort and safety of work is increased at low revs. This function is especially useful in electrical and radio installation work, in car services and restoration workshops.

In addition, there is a strong belief among professional users of power tools that the simpler the device is, the more reliable it is. And the additional service “stuffing” is better to take out of the power unit. In this situation, the repair of equipment is greatly simplified. Therefore, some companies specially produce separate external electronic regulators, which are connected to the power cord of the machine.

How to assemble a regulator circuit with your own hands

The simplest power regulator, suitable for an angle grinder, soldering iron or light bulb, easy to assemble by hand.

Assembly order

-

An electrical circuit is assembled on a printed circuit board or surface-mounted.

Soft start plus and engine speed control. Installing a homemade board

There are no ready-made installation recipes. Anyone who decides to equip an angle grinder with a regulator positions it according to their purpose and tool model. Someone inserts the device into the handle of the holder, someone into a special additional box on the case.

The space inside the housing of the angle grinder may vary from model to model. Some have enough free space to install the control unit. Secondly, you have to take it to the surface and fix it in a different way. But the trick is that, as a rule, there is always a certain cavity in the back of the instrument. It is designed for air circulation and cooling.

Usually this is where the factory speed controller is located. A DIY scheme can be placed in this space. To prevent the regulator from burning out, the thyristors should be installed on the radiator.

Speed controller and soft start. what are you needed for

In modern angle grinders, two important functions are used to increase the reliability and safety of the tool:

- RPM regulator. a device designed to change the number of engine revolutions in various operating modes;

- Soft start. a scheme that provides a slow increase in engine speed from zero to maximum when the device is turned on.

They are used in electromechanical tools in the design of which a collector motor is used. They help to reduce wear on the mechanical part of the unit during switching on. Reduce the load on the electrical elements of the mechanism, starting them up gradually.

When the power is turned on, there is an abrupt transition from the rest state to the rotation of the disk at a speed of 2.5-10 thousand revolutions per minute. Those who have worked with an angle grinder are well aware of the feeling that the machine is simply “pulled out of hand”. It is at this moment that the overwhelming number of breakdowns occurs associated with the mechanical part of the unit.

The stator and rotor windings are not less stressed. The collector motor starts in short-circuit mode, the electromotive force is already pushing the shaft forward, but the inertia still does not allow it to rotate. There is a jump in the starting current in the coils of the electric motor. And although structurally they are designed for such work, sooner or later a moment comes (for example, during voltage surges in the network) when the winding insulation does not withstand and an interturn short circuit occurs.

When you include soft start circuits and changes in engine speed into the electrical circuit of the instrument, all of the above problems automatically disappear. Among other things, the problem of voltage “dip” in the general network at the time of starting the hand tool is solved. This means that the refrigerator, TV or computer will NOT be exposed to the danger of “burnout”. And the safety devices on the meter will NOT work and cut off the current in the house or apartment.

The soft start scheme is used in angle grinders of medium and high price categories, the speed control unit is used mainly in professional models.

Additional wiring diagrams increase the cost of the tool, but increase the service life and the level of safety during work.

How to connect the device to an angle grinder, options

The connection of the regulator depends on which type of device is selected. If a simple circuit is used, it is enough to mount it in the mains supply channel of the power tool.

Smooth start and speed control

Smooth start-up of power tools is the main guarantee of its longevity. Remember when a light bulb burns out? Most often at the moment of switching on. Because after connecting to the electrical network, the load increases sharply. The worn-out places of the spiral DO NOT withstand and it burns out.

The same processes take place in the angle grinder. At the moment of switching on, the current rises sharply, because the driving forces need not only to move the armature, but also quickly gain the required speed. The effect of such a hard start can be the most deplorable. a winding break.

To reduce the likelihood of tool failure due to a hard start, it is necessary to modify the angle grinder and equip it with a small built-in soft starter.

Another improvement is the rotation regulator. From their own practice, everyone knows how inconvenient it is to work with a tool, which does not have a rotation adjustment. If the electric drill is equipped with a camera, it is difficult to find the rotation speed and drill feed. This will either cause the drill to jam or break.

The lathe works in a similar way, in which there is a whole set of Special gears for adjusting the spindle rotation. This largely determines not only the safety of the cutter, but also the quality of material processing.

You can combine two advantages. smooth start-up and shaft speed control using an electronic circuit. It is quite possible to assemble it yourself and install it directly into the car body. With such a circuit, it will start smoothly, and not create overloads in the windings and the network. And with the same scheme, it will be possible to adjust the speed in order to select the mode of operation with any material.

If you cut metal with significant thickness and hardness, then you need to maintain high speed. But when processing surfaces of low-melting materials, high speed will do more harm than help the cause. It needs to be reduced. It is dangerous to work with stones or tiles at high speed. And here it is necessary to Slow down.

Even when the disc is wobbling, the rotation speed must be proportionally changed because the linear speed of the disc edge will decrease. You cannot do without a speed controller when working with a diamond cut disc, because at high temperatures it breaks down very quickly.

Everything suggests that if an angle grinder does not have a speed controller, then it must be made and installed in the machine.

Speed controller for angle grinder: how to reduce speed and make a smooth start

The power tool in our workshop Occupies one of the main places. Each electrical device performs all functions in accordance with technical data. What else would you like? I really want the tool to NOT break down for a longer time or not break at all. As a person gets used to the second. a dog, so he gets used to the instrument.

One of the basic tools is the angle grinder, which we call the angle grinder. This is a versatile tool, which is capable of cutting, grinding, cleaning the surface, dusting the boards and it can be adapted to many operations.

How to make a speed controller with your own hands

In order not to complicate the perception of the principle of operation in complex terms, the principle operation of the circuit can be explained simply. It has a sensitive element that reads the load. Depending on the read value, this element controls the locking device.

The principle of operation is similar to that of a water tap. In this case, you are the sensitive element that controls the water tap. The flow of water, depending on the need, becomes more or less. The same process happens with the current.

It is necessary to correctly understand the moment that we will NOT be able to increase the rotation speed more than that which is indicated in the characteristics of the angle grinder. We can only reduce the turnover. If the maximum rpm is 3000, then the range in which we can adjust the rpm will be below this value.

In the simplest version, you can use a thyristor-based regulator circuit. He will feel and regulate. Two in one. This diagram has only five parts. It is very compact and fits easily into the case. Such a regulator will not work from zero rpm, but this is not necessary for an angle grinder.

If lower speeds are needed in the work, then it is necessary to use a different circuit on an integrated circuit, where the triac will be the locking element. Such a scheme will be able to regulate the speed from almost zero to the desired value.

And in that, and in another scheme, the main load falls on the shut-off element. It must be rated for voltages up to 600 V and for currents up to 12 A. If your grinder is more powerful than 1 kW, then the locking element must withstand a load of up to 20 A.

All the details of the thyristor circuit can be placed on a printed circuit board or simply by surface mounting. According to the second option, the parts are soldered onto the printed circuit board. The printed circuit board can be manufactured in different ways. It can be etched from foil-coated PCB, you can even cut a cutter, but it will turn out very roughly. In principle, she can be asked to make a familiar radio amateur for a very modest remuneration.

When the finished board is ready, you need to choose a convenient place in the angle grinder case to install it. It is desirable to install it so that it is convenient to use, and so that it does not interfere in the process of work.

Before installing the circuit in the car, you need to check it. To do this, instead of an angle grinder, an ordinary incandescent lamp must be connected to the output. An example with a power of 60. 40 W at 220 V will do. The efficiency will be obvious by changing the glow of the bulb.

Now it remains to mount the device in the selected place and make a test run of the angle grinder. It will stop breaking out of your hands during start-up, and the speed will be smoothly regulated by rotating the regulator.