How to adjust the carburetor on a Husqvarna 365 chainsaw

Adjusting the carburetor on a Husqvarna chainsaw

The company, called “Husqvarna” was based in 1687. “Husqvarna” (Husqvarna) is a favorite in the market of production and garden equipment. Run by a Swedish group of companies. Producing different types of equipment, from small sewing machines to impressive quad bikes.

“Husqvarna has a very wide range of specialty products and equipment for our customers. In recent years, the company has increased the number of patented innovations. “Husqvarna is committed to progress.

Husqvarna products make hard work easy, without harming people or the environment.

Husqvarna 137 chain saw is part of the “forest professional” category. Together with this model, the manufacturer also produces universal chainsaws, blowers and pruners. All manufactured machinery is characterized by small size and ease of operation. All Husqvarna chain saws offer three features. the ability to absorb excessive vibration, an advanced air filtration system and plenty of power.

Features of the Chinese chainsaw carburetor

Their design and parameters are different, depending on what power and model of chainsaw they are designed for. All are virtually identical to the original carburetors in design, but not always in quality. Not all Chinese products today are 100% junk. In turn, according to their quality, they can be divided into three groups:

- Poor quality. Unsuitable alloys are used, which oxidize, crumble and break. No exact fit, calibrated holes are not as required, leading to over or under fueling the combustion chamber. Responsible parts fail quickly. Plastic parts quickly become coarse or on the contrary soften from gasoline and stop working. Axles and wire rods bend, fastener threads break. These products are the cheapest of all. They are made in semi-industrial factories, on adapted equipment. They are usually nameless and unmarked.

- Medium quality carburetors. These are factory assembled products. Here they do not skimp on alloys, and in-line production with quality control is arranged. These are perfectly serviceable carburetors, which can have a lifespan even longer than an entire chainsaw.

- Quality carburetors. First of all, these are products of world manufacturers whose facilities are located in China. According to geography, they can be considered as Chinese, but they are made according to the technologies of the company, the brand owners, who value their reputation. For example, the Japanese carburetors Walbro are produced in China.

over, among the Chinese manufacturers appeared those that focus on high quality. They invest heavily in powerful production, register their own brand and work on its reputation.

Specifications of the Husqvarna 240 chainsaw

The basis of the Husqvarna 240 saw is a 2-stroke engine with a carburetor. Runs on gasoline-oil mixture. Engine life is increased by improvements of crank and connecting rod assembly and special coating of the cylinder. Fuel savings of up to 20% thanks to the innovative X-Torq system, which also reduces harmful exhaust gases. Generously sized fuel tank and low fuel consumption allow extended periods of use, without refueling.

Otherwise, the saw has the following technical specifications:

- capacity. 2L. с.;

- chain pitch. 3/8 inch;

- fuel tank capacity. 300 ml;

- oil tank. 200 ml;

- Busbar length. 40 cm;

- weight 4,7 kg.

How to adjust the carburetor on the Husqvarna 240 chain saw?

Every machine is subject to breakdowns from time to time. The Husqvarna 240 chain saw breaks down the carburetor, other parts of the fuel system, the oil pump. If the oil pump breaks, the chain for the Husqvarna 240 chain saw stops turning due to lack of lubrication. Also, damage to the gas tank or fuel hoses may be the reason why gasoline is leaking from the saw. If the chain saw does not start at all, first of all you should check the quality of the fuel mixture and check the spark plug ignition. If necessary clean or replace the spark plug with a new one and adjust carburettor.

You also need to adjust the carburetor if your chainsaw starts poorly, stops when loaded, or if the fuel type or operating conditions change. Carry out adjustment of the carburetor after preliminary cleaning of air filters and warming up of the engine.

Then proceed as follows algorithm:

- Turn screw L to maximum. Then turn the screw back a quarter turn immediately.

- Hold the throttle trigger and turn the H screw a quarter turn.

- Release the throttle and turn the T screw clockwise until the chain starts to move. Then immediately turn the screw back until the chain stops.

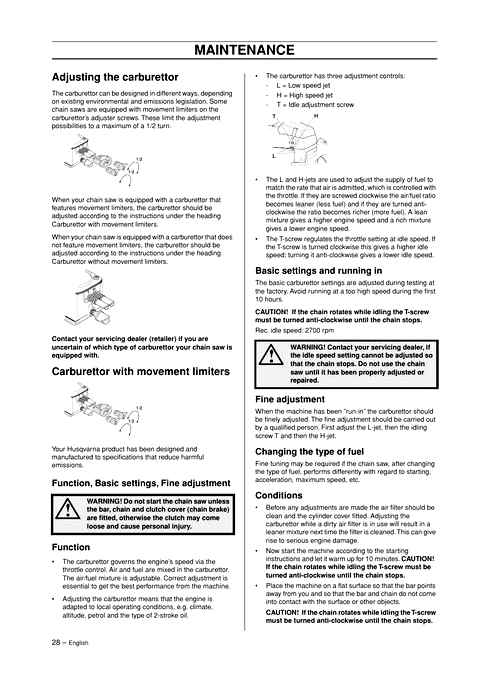

The layout of the corresponding screws is shown below:

Modern chainsaws have a complex system and consist of several major components that require periodic maintenance and adjustment. In this article we will talk about how to adjust the carburetor on a Husqvarna chainsaw.

When to adjust the carburetor?

The reasons why it is necessary to adjust this unit, you can list for a very long time.

Among the main faults are the following:

- Increased revolutions at idle speed;

- The appearance of a large amount of smoke during operation;

- Deterioration of starting properties;

- Not enough power to the tool when cutting.

This is not a complete list of all known faults. Sometimes it is necessary to adjust the carburetor on a Husqvarna chainsaw after a complete overhaul of the power unit or after maintenance.

The developers of Husqvarna 137 write in the datasheet that carburetor adjustment should always be performed before and after running-in the tool.

How the carburetor on the Husqvarna 137 chain saw works?

Most of these chainsaws are equipped with a Walbro carburetor ex works. Before you can adjust the carburetor on your Husqvarna chain saw, you must have a basic understanding of its construction and know how it works.

What is responsible for the fuel and oil mixture

For a precise delivery of fuel with oil is used the work of the fuel pump, which is driven mechanically from the crankshaft. The carburetor itself is equipped with a diaphragm and a special needle valve, which are responsible for regulating the pressure in the system. Thanks to them, proper operation of dosing chambers and pump is arranged, which improves chainsaw performance.

Fuel mixture preparation

When operating a chainsaw, a fuel mixture of gasoline and oil in a ratio of 15:1 by volume should be used, t. е. Add 1 liter of oil to 15 liters of gasoline and mix the mixture well. The amount of gasoline and oil in the fuel mixture is shown in this table:

| Gasoline.л | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Oil, l | 0.06 | 0.13 | 0.20 | 0,26 | 0,33 | 0.40 | 0.46 | 0.53 | 0.60 | 0,66 |

| Fuel mixture, l | 1.06 | 2,13 | 3,20 | 4,26 | 5,33 | 6.40 | 7.46 |

ATTENTION! Use of oils: Lukonoi-2T; TNK-2T OIL: AZMOL Sport 2T GD” and Dr., and waste oil in the fuel mixture will lead to failure of the connecting rod needle bearing.

What is responsible for the air supply

Two flaps mounted on the diffuser chamber are responsible for the air supply. The first can regulate the amount of air when the gas pedal is depressed and is called a throttle valve, while the second restricts airflow when the chainsaw is cold-started. To make starting easier, the damper is closed, which means the mixture becomes rich as it is saturated with more fuel. It is easier to operate in this mode, but since it increases fuel consumption, this mode is not used throughout operation. The saw is a wear-and-tear machine.

To spray fuel into the cylinders, a nozzle with a check valve is used.

The principle of operation is simple: it limits the return of the mixture back into the chamber. All the main malfunctions of chainsaws, most often manifested by improper operation of this mechanism.

- The most common mistake is storing the tool for too long. The thing is that with prolonged inactivity the valve gets stuck and either fills the cylinder with fuel or simply does not open.

- The second problem is an increase in the amount of air in the mixture, caused by its suction from the outside, if the valve does not work properly. Regulate it is already impossible, because in this case only helps to repair the valve or replace it, because the adjustment screws will not respond to the saw.

In contrast to the car, the adjustment of the carburetor chainsaw provides three adjusting screws responsible for the quality of the mixture, the number and the nominal revolutions of the crankshaft of the engine Husqvarna:

- L screw. is intended for adjusting the amount of revolutions when operating in middle conditions and adjusts the low revolutions;

- The H screw. adjusts the number of high revolutions and the thrust of the rig;

- T. is designed to adjust the total amount of fuel and adjusts the operation of the throttle assembly.

It is not recommended to touch the first two screws without special skills. The problem is that if you adjust them incorrectly, then the carburetor will not be able to start the engine, or even start it in the wrong modes of operation. This kind of adjustment of the screw can lead to its fastest wear and failure. This principle is inherent in many devices.

Parameters of the settings are not given in any table. It is therefore not necessary to look for this data in special literature, just follow the instructions clearly. The table in the data sheet has only informative value concerning the characteristics of the engine.

How the carburetor on a Husqvarna 137 chain saw works?

Most chain saws of these models are equipped with a Walbro carburetor ex-works. Before adjusting the Walbro carburetor on the Husqvarna chain saw, you should have a basic understanding of its construction and know how it works.

What is responsible for the fuel-oil mixture

For a precise fuel and oil supply, it uses a fuel pump, which is mechanically driven by the crankshaft. The carburetor itself is equipped with a diaphragm and a special needle valve, which are responsible for regulating the pressure in the system. Thanks to them, the proper operation of the metering chambers and the pump is organized, which improves the performance of the chainsaw.

Preparing the fuel mixture

When operating the chainsaw, a fuel mixture of gasoline and oil in the ratio of 15:1 by volume must be used, i.e. е. add 1 liter of oil to 15 liters of gasoline and mix the mixture thoroughly. The amount of gasoline and oil in the fuel mixture is given in this table:

| Gasoline.л | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Oil, l | 0.06 | 0.13 | 0.20 | 0,26 | 0,33 | 0.40 | 0.46 | 0.53 | 0.60 | 0,66 |

| Fuel mixture, l | 1.06 | 2,13 | 3,20 | 4,26 | 5,33 | 6.40 | 7.46 |

WARNING! Application of oils: “Lukonoi-2T; TNK-2T OIL: AZMOL Sport 2T GD” and Dr., and used oil in the fuel mixture will lead to failure of connecting rod needle bearing.

What is responsible for the air supply

Two flaps on the diffuser chamber are responsible for the air supply. The first can regulate the amount of air when the gas pedal is depressed and is called a throttle valve, and the second restricts the amount of air when the chainsaw is cold-started. To make it easier to start, the choke is closed, which means the mixture becomes rich as it becomes saturated with more fuel. It is easier to work in this mode, but because it increases fuel consumption, this mode is not used throughout the work. The saw is working too hard.

To atomize fuel in the cylinders, a nozzle with a check valve is used.

How it works is simple: it stops the mixture from flowing back into the chamber. All major chainsaw malfunctions, more often than not, are caused by improper operation of this mechanism.

- The most common fault is storing the tool for too long. The fact is that with prolonged inactivity, the valve jams and either fills the cylinder with fuel, or simply does not open.

- The second problem is an increase in the amount of air in the mixture, caused by air suction from the outside if the valve does not work properly. Adjustment is no longer possible, because only the valve can be repaired or replaced, because the adjustment screws will not work.

Unlike a car carburetor, there are three adjustment screws for the carburetor, which are responsible for the mixture quality, quantity and nominal revolutions of the Husqvarna engine crankshaft:

- screw L. designed to adjust the number of revolutions when working in medium modes and regulates low revolutions;

- H screw. adjusts the amount of high revolutions and the thrust of the unit;

- T is for adjusting the total amount of fuel and adjusts the throttle.

It is not recommended to touch the first two screws without special skills. The problem is that if you adjust them incorrectly, the carburetor will not be able to ensure the start of the engine, or even start it in the wrong modes of operation. Adjusting the screw in this manner can lead to premature wear and failure. This is the principle behind many devices.

No adjustment chart is available for this setting. So do not look for this data in special literature, but just follow the instructions clearly. The table in the datasheet is for informational purposes only and relates to the performance of the engine.

What you need to adjust the carburetor Husqvarna with your own hands?

In order to properly carry out the adjustment of the carburetor of a chainsaw, it is necessary to have the appropriate tools in advance.

- The most common screwdriver with which to unscrew or tighten the adjusting screws;

- A tachometer designed to count crankshaft revolutions. Has to when adjusting the idle speed, as it is quite problematic to determine the number of revolutions per minute by ear;

- Phillips screwdriver. It is needed to be able to unscrew the screw (T);

- A compressor with a special gun connected to it. Blower helps get rid of excess dirt and grime, because the carburetor must always be clean.

Many Husqvarna chain saws use adjustment screws with a special section. In advance, look at what you have installed and buy the appropriate set. This will help to avoid many difficulties at the initial stage.

The saw must be warmed up for at least 10 minutes, set on a level surface for accurate adjustment. The bar should be facing away from the person making the adjustment. At the initial stage, you should find the highest value of the idle speed. Adjusting the chainsaw carburetor is done in the chainsaw should work. To do it, turn the L screw slowly from left to right and then back. When the maximum rotation has been determined by experiment, turn the screw L counterclockwise to the value of 1/8 to a quarter of a full turn.

Tools required for the work

Before you start adjusting the Husqvarna carburetor, you should take care to have all the tools you may need. To perform this type of work yourself, you will need:

An ordinary slotted screwdriver will not work for this adjustment. к. The adjustment screws on Husqvarna chain saws may have different cross sections. You will have to buy a special, this is a feature of Husqvarna chain saw repair, they have made everything so that the saw can be repaired only in a specialized service center Husqvarna.

Algorithm and description of adjusting the Husqvarna carburetor

Adjust the Husqvarna carburetor the same way as with other makes of chain saws.

Just before adjustment it is necessary to make a full diagnostic of the chain saw and make sure that there is no choking and no air sucking into the carburetor. Also make sure that the air filter is clean and if necessary replace it with a new one.

- With the saw stopped the Husqvarna carburetor is set to the factory settings.

- Start the engine and warm up the saw for a few minutes.

- By turning the screw (L) clockwise, there is a position in which the engine develops maximum RPM, after which the screw should be turned back to 1⁄4. If the chain of the chain saw rotates, the idle speed should be reduced by adjusting the propeller position (T).

- The next step is to adjust the power of the Husqvarna at maximum rpm and correct the number of revolutions. For this purpose, the tachometer is connected to a running chainsaw, the gas knob is squeezed to the full, and then the tachometer readings are checked. If the maximum rpm differs from the maximum recommended by the manufacturer, change the setting of the screw (H) and check the revolutions of the tachometer.

Adjusting the carburetor on your Husqvarna chain saw

Like all other saws, the Husqvarna has the same carburetor adjustment algorithm. Therefore, the instruction will also be relevant for other tools and chainsaw models such as the Husqvarna 142. 236. Before you start, make sure the air filter is clean and everything else is working properly. The fuel supply to the float chamber must run smoothly and the ignition system must be correctly set and have a fresh spark plug.

- Set the factory settings of the carburetor. This should be done with the engine stopped.

- Now you can start the engine and be sure to warm it up for a few minutes. Adjust the idle speed of the Husqvarna 137 carburetor only when the engine is warm.

- Turn the L screw clockwise to set the crankshaft to the highest rpm and then turn it back a quarter turn. Use the T screw to adjust the crankshaft RPM so that the chain does not rotate. It must not be driven without depressing the gas pedal.

- Now you need to set the maximum rpm and its power. Just connect the tachometer to the ignition system and set the maximum possible RPM with the gas pedal. Compare it with the specifications. If they are different unscrew or tighten the screw H. By changing the range, limits can be created to make the saw efficient and preserve the life of the motor.

What you need to pay attention to?

Once the adjustment of the Husqvarna carburetor is finished, check that the engine is stable and that the saw easily gathers and releases necessary rpm. The rotation of the chain at idle is considered an abnormal phenomenon, so it is necessary to re-adjust its connection to the clutch using the H screw. Do not forget that the unit is not adjusted immediately: you need to wait for some time, because the Husqvarna chain saw does not immediately respond to a change in the position of the screws. This time can range from 5 to 15 seconds. This time is not prescribed by the table, so you can only find out experimentally.

If after adjustment you notice that there is a large amount of smoke from the machine, adjust the fuel and oil mixture. For this purpose turn the L screw.

What is the Husqvarna chainsaw carburetor factory setting?

In order to ensure that the chainsaw will still start even if it is set incorrectly, the factory H and L screw positions are used. Most Husqvarna chain saws can be started by loosening both screws exactly a turn and a half. Only then can you change the screw positions to get the right amount of fuel and maximum performance. The idle speed is also adjusted after these manipulations.

If you have questions about adjusting the carburetor on the Husqvarna 137 chain saw and other models of this line, I recommend that you take a look at this

Owner’s Manual

The manufacturer emphasizes that the chain saw should not be used until the chain has been treated with a sufficient amount of oil. Before you start working you should read the manual because it also informs you about safety measures at work.

For example, if you improperly combine the chain and the saw bar, it will increase the likelihood of kickback. But even if you familiarize yourself with the manual, it is impossible to foresee possible situations when working with the saw, so the operator should be careful, guided by common sense. Use protective headphones, a special helmet, goggles, and protective clothing when working.

Advantages and disadvantages of the Walbro HD 6B carburetor

Undoubtedly, this carburetor has many advantages. Here are some of them:

- High-quality carburetor construction and reliability. With proper and timely carburetor care, this chainsaw will give you years of reliable service. Numerous reviews on the internet only attest to this.

- Comfortable carburetor design. The diaphragm in the impulse chamber allows you to pump fuel while working in any position of the chainsaw, whether it’s horizontal, vertical or lateral sawing. It is very convenient, unlike gasoline-powered saws with float-type carburetors, where the fuel flows by gravity into the carburetor and the saw just shuts down on the side cut.

Of the disadvantages I would like to note the absence of a primer on the carburetor or a heating system for it. In Russia, it is often necessary to operate the saw during the winter months. When there is a lot of frost, you sometimes have trouble starting.

When choosing a carburetor there is a chance of getting a fake one. To avoid buying a counterfeit, before buying watch the following video which shows in detail how the factory packaging and the Zama carburetor itself looks like for a Husqvarna 365 chainsaw.

How to set ignition on your Husqvarna chainsaw

Parts for chain saws and trimmers with delivery nationwide cash on delivery.

Choice of models

- Gasoline saws

- Parts for Chinese Benzopilas 45, 52Kcube.see

- Parts for Chinese Husqvarna 25 Cc Gasoline-Powered Saw.see

- Spare parts for Chinese Bowsaws 25KW.See

- Spare parts for Chinese STIHL 660

- Parts for Partner 350, 351, 352, 371

- Parts for Partner 340S, 350S, 360S

- Spare parts for Husqvarna 137, 142

- Spare parts for Husqvarna 230, 235, 236, 240

- Spare parts for Husqvarna 365, 372

- Spare parts for STIHL 180

- Spare parts for STIHL 210, 230, 250

- Spare parts for STIHL 290

- Spare parts for STIHL 361

- trimmers for grass

- Parts for Chinese grass trimmer 33, 43, 52 cc.cm

- Spare parts for Chinese grass trimmer 26cc.see

- Spare parts for Husqvarna 125, 128

- Spare parts for Favorit Т283, Т284

Ignition coil (magneto). Checking and Adjusting the Ignition Coil Gap.

It is not uncommon to encounter situations where tool users come with faulty ignition. it is often the ignition coil that is at fault, but often the ignition coil has nothing to do with the tool’s malfunction. How to adjust ignition on STIHL chain saw, Husqvarna and other chain saws. Here are the steps to check the ignition coil.

How to evaluate current coil condition.

Before you deal with coil ignition, check the serviceability of the circuit. How to change the drive sprocket in a Husqvarna chain saw, on the clutch. Follow up: