How to adjust the carburetor on a lawn mower

Petrol Lawn Mower Care.

Petrol Lawn Mower Care.

A few simple steps to take care of your lawn mower will extend its life for many years.

Regular annual maintenance of your lawnmower will keep your gasoline engine running and running smoothly. Plus, regular maintenance will prolong the life of your car. You should also pay attention to extraneous sounds, uneven operation or decreasing engine power. If any interference occurs, stop operation immediately and rectify the problem as soon as possible, or seek professional advice.

In order to keep the mower in good condition, only a few simple manipulations need to be done on easily accessible engine parts.

Replacement of gasoline. Engine problems arise due to the fact that gasoline remains in the tank for the whole winter. Over time, it becomes runny and clogs the carburetor. To avoid clogging of the carburetor, after the last autumn mowing of grass, gasoline and oil from the tanks must be drained. Throughout the season, you should always use only fresh gasoline and do not pour a lot of fuel into the car.

Oil change. Every gasoline powered lawnmower needs good oil. It is required to change the oil in a new mower after 5 hours of operation, later after every fifty hours of operation of the mower. If you mow the grass once a week, then I recommend changing the oil twice a season.

Sharpening knives. Sharp knives will help prevent rapid engine wear. If the lawnmower stops cutting the grass evenly, then it’s time to sharpen the blade block. It is best to unscrew the block and give it to a specialist to sharpen it. Whoever sharpens knives himself with a file must ensure that the knives are equally well sharpened and balanced. The result of uneven sharpening is an imbalance that occurs, which leads to vibration of the device during cutting and significant damage.

Removing dirt. Regularly clean the painted surfaces of the machine and the underside of the mower’s undercarriage from grass and soil. Always check the air filter and if it is clogged, replace it with a new one.

If the mower has a two-stroke engine, it needs a mixture of gasoline and oil. Do not use pure gasoline as this will cause irreparable engine damage. Once a year, the wheel bearings must be lubricated with grease. To do this, the wheels must be removed and filled with grease in the bearing bores. Whenever you turn the mower on its side for maintenance work, try to put it with the exhaust pipe facing up. This prevents the oil from entering the carburetor, where it contributes to the release of fuming smoke during combustion.

List of maintenance work for the lawn mower:

Replacing the spark plugs:. pull out the spark plug plug and unscrew the spark plugs using a special spark plug wrench. Screw new spark plugs into the car and tighten them tightly with a special spark plug wrench. Clamp the spark plug plugs firmly. Now check if the lawn mower engine starts.

First aid in case of breakdown:

Fill the tanks with fresh gasoline and oil in the spring. If gasoline and oil have been in the mower all winter, have a specialist inspect the mower if possible. Check air filters. Mount a new or sharpened knife block. Regularly check the air filter for clogging during the summer lawn mowing season. Before each mow, check the mower for oil. Keep the underside of the mower clean. In the fall, at the end of the season, drain the oil and gasoline. To do this, lay the mower on its side. Which one depends on the design of the lawn mower.

Carburetor adjustment for Briggs and Stratton engine

To extend the life of the lawn mower, we do preventive maintenance, as it reduces the likelihood of serious damage. Good luck to you. and you can find the necessary lawn mower in our ONLINE STORE

Source: http: // super-sad. info / uhod-za-benzinovymi-gazonokosilkami / 962.php

How to clean a carburetor on a lawn mower

The section is devoted to motorized equipment for gardening, parks and earthworks. Here you will find information about the brands under which lawn mowers and tillers, chainsaws and cultivators are sold, everything that makes the work of summer residents, gardeners and communal workers easier. The equipment is subdivided into gasoline and electric (powered by accumulators and batteries as well). We have long been accustomed to tillers and cultivators; almost every second owner of a country house uses a chainsaw. In the section “Gardening equipment” you will find information about many other devices that will make your work pleasant and easy, and your site. an object to follow.

Trimmers. petrol or electric lawn mowers are wheel and hand-held. The mower is one of the trimmer options, adapted only for a certain type of grass. The shredder converts trash and wood waste into a homogeneous mass for compost and mulching. A garden vacuum cleaner is useful both for cleaning areas covered with vegetation, and for cleaning paved areas and paths. Any summer resident knows about the purpose of a sprayer and an electric hoe, but many only guess what a verticutter and a scarifier are. The verticutter removes the dense top layer that forms on the soil in early spring and late autumn. Scarifier (another name. aerator), in addition to cleaning the packed layer, makes grooves in the soil. Information about where, how and under what brand all this is produced is also in this section.

Source: http: // www. id4.ru/top/?r=sadovaya-technikau=stihl#44622

How To Adjust The Carburetor On Your Lawn Mower For Optimum Performance?

This is a very delicate matter. adjusting the carburetor, not every master will be able to adjust it by ear, you need to look at the adjustment on the tachometer and, based on the readings, adjust the optimal speed.

The carburetor is regulated in each lawn mower according to different parameters, so in order not to mislead you, I will omit the numbers and just tell you the basic adjustment diagram:

First, the engine starts and warms up, then the speed is adjusted to a certain speed by tightening the nozzle adjusting screws (if you get in there at least once, until you adjust the entire carburetor, the lawn mower will not work properly)

So, having set the revolutions with the jet by adjusting the fuel supply to a certain speed, we proceed to adjusting the idle speed, for this we also take readings from the pressure gauge and adjust it in accordance with the technical data of the tool.

In some models, the enrichment of the mixture is regulated by two screws. low speed and high speed, while the low speed is controlled first.

At the beginning, I would like to note some important things.

The carburetor is adjusted for optimal operation at the factory, if there are no problems with the lawn mower and with the carburetor in particular, then there is no need to adjust anything additionally.

Carburetor adjustment is done using instruments such as a tachometer

This work requires a lot of experience, carburetors (professionals), even in an average city, can be counted on one hand.

Lawn mowers are different, carburetors are naturally the same.

If you still decide, then at the beginning you need to perform a number of actions.

Change the candle, change the air filter (you can just clean it), eliminate other “little things” that can affect the operation of the entire apparatus.

Only after that we proceed to adjust the carburetor.

Naturally, the lawn mower needs to be driven a little, the carburetor is not regulated on a cold.

Next, look at your carburetor, maybe you have three screws there (there are other options), the screw marked “L” is responsible for low rpm.

Jet “N”, for high speed.

“T”, idle speed (marking may be different, you must look exactly at your instructions).

At the beginning we adjust the jet “L”, slowly turn the screw slightly to the left and right sides, looking for maximum idle speed.

As soon as they found the same screw was turned a quarter of a turn counterclockwise and so far.

Now we adjust the idle screw, everything is clear here, we increase the speed clockwise, we decrease it counterclockwise, our task is to make the lawn mower work steadily even when it is cold.

We will follow the adjusting the screw of high speed.

The throttle is completely on ourselves, as soon as we hear that the revolutions have reached their maximum value, we turn the screw (again slowly) counterclockwise, we hear that the revolutions are not stable, now clockwise until the engine starts to work steadily.

That’s basically all, but I still advise you not to adjust the carburetor yourself.

Source: http: // www. remotvet. ru / questions / 1408-kak-otregulirovat-karbjurator-na-gazonokosilke-na-optimalnuju-rabotu. html

How to properly clean and adjust the carburetor

Quick check of carburetor functions. Carry out the following checks, air filter inlet heating system.

Heated intake manifold (hedgehog), throttle body, thermal switches and. thermal valves, idle solenoid valve. turn on the ignition. Disconnect. supply wire. clicks should be heard when the valve is actuated.

Accelerator pump. press the pressure lever with the throttle valve. a continuous continuous jet should be emitted from the sprayer.

Partial load valve (economizer)

trigger control diaphragm. check for air leaks

automatic machine spring. pump, trigger and starting parts

air damper. check the smoothness of opening.

Without diaphragm. check for gasoline leaks and replace defective parts.

Throttle Accuracy and Fit. Check for Wear.

Secondary Throttle Actuator. Check for Excessive Wear.

Check the CO level, if possible, in the exhaust gas at idle. If the CO level is out of range, try to adjust it. Please note where the result will be within the permissible specifications. the mixture will be enriched or depleted. Check CO and CH levels at 2000 rpm. min. At these speeds, the CO level should be approximately 50% lower than at idle. Remember which result will be obtained. rich mixture or poor.

Check CO and CH levels at 3000 rpm. min. At these rpm, the CO level should be slightly lower than at 2000 rpm. min. Again, remember at what quality of the mixture the result was obtained.

Open the throttle quickly at 1000 rpm. Watch for possible failures in the engine and the operation of the accelerating pump, pay attention to the CO level. if it falls, then there is no enrichment of the mixture, if it rises, then the mixture is enriched correctly.

Check the ability of idle to recover (when the throttle is released).

The results of the obtained analyzes of the composition of the exhaust gases should indicate the nodes of the carburetor responsible for the enrichment or depletion of the mixture.

It is hardly a rarity. hanging of the slightly open throttle valve of the secondary chamber at idle speed. This often causes a very rich mixture, gasoline leaking out of vias or crevices. Black soot from the exhaust pipe. This is due to the formation of a carbon ring around the secondary throttle valve, which prevents it from closing completely against the stop in the adjusting screw. The screw is adjusted so that the flap is closed but does not get stuck in this position.

Dips or uneven operation of the engine

Check the ignition system and spark plugs thoroughly.

Check the ignition timing at idle, make sure the vacuum and mechanical ignition timing are working properly.

Check the operation of the accelerator pump.

Check for air intake.

Adjust the carburetor to a slightly richer mixture than specified in the Specifications.

Carry out a gas analysis of the exhaust, paying particular attention to CO at 2000 rpm. min and 3000 rpm min.

If the gas analysis results are significantly greater or less than the permissible specifications, service the carburetor and check the cleanliness of the jets.

If the mixture is too lean and after servicing, change the idle jet or the fuel jet of the main metering system to a slightly larger one.

Cold start and warm-up problems

Check the condition of the intake air heating system. Make sure that all vacuum hoses are properly connected, the integrity (or presence) of the corrugated hose for heating the air from the exhaust manifold to the air cleaner body. The air damper in the air cleaner housing should be open to allow hot air to enter at air temperatures under the hood below 15 ° C (usually) and gradually closed with an increase in the engine compartment temperature. Hot air access in most systems should be closed at temperatures above 25 ° C. If the action of the damper is broken, check the operability of the thermostat of its actuator, which is usually installed in the air cleaner housing.

Let the engine cool down, remove the air cleaner and move it to the side with the vacuum hoses attached.

If a semi-automatic suction is installed, cock the system by lowering the throttle by smoothly pressing the accelerator pedal a couple of times.

The flap should close off the carburetor inlet. If not, check the connection of the bimetallic spring to the choke control lever. Adjust the spring to close the choke when the engine is cold. If the spring housing is turned all the way down and the flap is still not closed, the spring may be defective. It can also be the reason for the incomplete opening of the damper with the engine warming up. There is a way out. replacing the spring.

Start the engine.

Make sure the starting speed is correct.

The mechanism for opening the dampers during cold start should work as expected.

With the engine warming up, the throttle should open slightly and the speed should gradually fall to idle. It may be necessary to stimulate the opening of the choke by lightly depressing the accelerator pedal and releasing it to release the crank cam.

If the operation of the actuator is not satisfactory, check for a jam, wear, or damage to the actuator. Also check for electrical heating and heating from the cooling system. If the engine stalls immediately after starting, or barely turns, try to change the angle of the throttle position with your finger. If the engine runs more fun, check the trigger adjustment. If the adjustment is within the prescribed range, adjust the mechanism so that the starting system works satisfactorily. Many engines require a leaner or, more often, a richer mixture with age.

Checking the thermal switches in the cooling system

Thermal switches provide power to components such as the choke switch, intake manifold heating and throttle body heating when the engine coolant has not yet reached operating temperature. When the engine (and, accordingly, the coolant) reaches the operating temperature, the switches are triggered and turn on the power. One switch must serve several components, each component can be operated from one switch. The switch is usually installed in the coolant hose or in the intake manifold cooling channel. In some systems, the heating of the throttle and the control of the machine does not depend on the thermal switches

All circuits are different, so in each case, refer to the wiring diagram of a particular car.

Both manifold and carburetor heaters operate on the principle

positive temperature coefficient of resistance, with an increase in temperature, the resistance of the heater increases, the current decreases.

A quick check of the heaters is possible if you turn on the ignition and touch the intake manifold or the throttle body with your hand; they should heat up quickly. Be careful to avoid burns. On a warm engine, these parts should not overheat.

On a cold engine, turn on the ignition.

Connect a voltmeter between the carburetor ground and the thermoswitch hot wire. If the battery does not supply power, check the connection of the carburetor body to the negative battery, then power from the ignition switch to the switch.

Connect a voltmeter between the switch executive contact and ground. If there is no power, replace the switch.

Now connect a voltmeter between the heating element supply lead and ground. If there is no power, check the wiring from the switch to the element.

Start the engine and warm it up.

Connect a voltmeter between the thermal switch executive contact and ground. When the engine reaches operating temperature, the voltage at the operating contact of the switch should disappear. If not, replace the thermal switch. If the trigger temperature of the switch is unknown, it should trip when the engine is fully warmed up.

The thermal switch can also be checked with an ohmmeter. An open thermal switch should indicate infinity, a closed one. zero.

If all voltages are present, and the system does not work, check the quality of the connection between the carburetor housing and the negative battery terminal.

Disconnect the electrical connector from the choke machine.

Connect a test lamp between the positive terminal of the battery and the terminal of the suction heating element. If the lamp does not light, replace the “suction” heating element.

Heated intake manifold

Connect an ohmmeter between the thermocouple hot lead and ground. Resistance should be within 0.25. 0.50M.

Throttle body heating

Disconnect the electrical connector from the heater.

Connect a test light between the positive battery terminal and the heater. If the lamp does not light, replace the heater. When assembling the heater, be careful, incorrect assembly will lead to a short circuit.

Source: http: // www. autoshcool. ru / 384-kak-pravilno-pochistit-i-otregulirovat-karbyurator. html

DIY lawn mower repair

A lawn mower is a very popular technique among owners of suburban areas. The larger the plot, the more often gasoline lawn mowers are used on the farm. This is not surprising, because gasoline cars are more powerful, more efficient, they can be used to process a much larger lawn in less time. In addition, the gasoline tool is not tied to the power source by an electric cord, which makes it much more maneuverable.

However, any gasoline equipment sooner or later begins to require repair, no matter how reliable and expensive it is. In the case of lawn mowers, malfunctions can begin after three to four seasons of active operation, and most often they appear after the equipment has been hibernated in unheated rooms. These problems manifest as follows: the mower may stop starting, the engine may intermittently run, or stall soon after starting. Often mower owners complain that after several years of use, the engine does not start working at full capacity, and the efficiency and productivity of the equipment decreases. All these problems in 90% of cases can be quickly corrected by yourself, and in this article we will consider the main causes of the listed problems.

It should be noted right away that the main reason for improper engine operation is the clogging of the engine carburetor with combustion products due to the long operation of the lawn mower or poor fuel quality. It is quite possible to cope with cleaning the carburetor on your own, but first you need to study the materiel. The volume of this article, unfortunately, will not allow us to consider the cleaning procedure in detail, but, however, the network has detailed step-by-step instructions for cleaning the carburetor, we recommend that you study it at the link: “Do-it-yourself lawn mower repair.” By cleaning the mower carburetor following the instructions mentioned above, normal engine operation will most likely be restored. If this does not help, you need to check some other possible causes of the problems.

Uneven operation of the mower engine can be caused by poor fuel quality. This is especially true if the gasoline has overwintered in a tank in a cold room. It is recommended not to use equipment filled with such fuel, it is better to drain it and fill the tank with fresh gasoline. In addition, a drop in engine power can clog the air filter. In this case, you need to replace the old filter or at least clean it with a vacuum cleaner. If the mower won‘t start and show no signs of life, it’s probably a candle. You need to unscrew the spark plug and check if it gives a spark of proper quality. A normal spark should be clearly visible even on a sunny day.

Having dealt with the reasons mentioned in this article, you will surely restore the normal operation of your lawn mower, which is quite capable of serving you for more than one season. In addition, you will gain the skill of self-repairing gasoline equipment and save on garden equipment services.

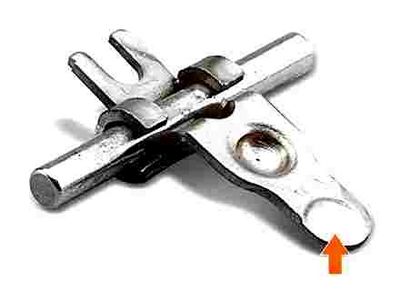

Adjustment lever defective

This breakage occurs when the contact surface of the lever wears out.

The abrasion of the contact surface occurs due to the presence of abrasive particles in the gasoline or due to strong vibration of the engine during operation. This defect in the adjusting lever causes problems with the intake, as well as improper idling of the engine.

Throttle and choke shaft wear

The air and throttle shaft can wear out for the following reasons:

- insufficient and improper maintenance of the air filter;

- the air filter is damaged;

- the air filter is not suitable for this unit.

Due to the ingress of poorly cleaned air, the shaft wears out and can break. Broken shaft parts can enter the combustion chamber or crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace the defective filter or flush the existing (serviceable) one. The filter must be washed in soapy water and dried.

Intake Adjustment Lever Problem

This problem can occur if the adjusting arm is not properly installed or if it is bent before installing. As a result, the contact surface takes the wrong position, which disrupts the additional fuel supply.

How to properly adjust the trimmer carburetor

On trimmers, in addition to electric motors, gasoline internal combustion engines are installed. This mechanism requires special attention to itself, since if it is incorrectly configured, it will either refuse to work, or it will work intermittently and loss of power. Basically, engine tuning is about adjusting the fuel flow, and this is done using the carburetor trimmer.

Common carburetor malfunctions

Failure of the trimmer carburetor occurs due to the use of poor quality gasoline, a damaged air filter and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair the carburetor with your own hands. Listed below are typical lawn mowers carburetor malfunctions.

Damper wear

The throttle and choke valves are mainly subject to wear due to the presence of abrasive particles in the air. Defective dampers look like they have been sandblasted.

As a result of valve wear, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder coating wear out.

When to adjust

Carburetor adjustment is necessary in the following cases:

- the new engine was run-in (4-5 liters of fuel mixture were used);

- the composition of the fuel has changed (brand of oil and gasoline);

- the weather has changed (it became hot, cold);

- the rarefaction of air has changed (applies to mountainous regions);

- after long-term storage;

- increased load on the engine (after tool change, etc.);

- due to vibration, the adjustment screws spontaneously unscrewed;

- fuel consumption has increased, the carburetor overflows fuel;

- carbon deposits quickly appear on the spark plug electrodes (while the fuel mixture is prepared correctly);

- the engine starts and immediately stalls or gains momentum poorly;

- no gasoline enters the cylinder;

- large amount of exhaust gases.

The principle of operation and adjustment of the carburetor

Many, sooner or later, for some reason, face the need to adjust the carburetor. But not everyone knows how to do it correctly. This article may be useful to you in such a situation.

At first glance, the carburetor looks like a complex device, but a little theory and it will be easier for you to cope with its setting.

The first thing you need to know is at least the basics of the principle of operation of the carburetor and its main controls and adjustments.

Let’s start from scratch.

Let’s consider the principle of operation of the carburetor using the example of Figure 1:

The hole in the carburetor, through which the air-fuel mixture (the mixture that ignites in the combustion chamber and causes the piston to move up and down) is fed into the intake manifold, as shown in the figure with arrow 1 (the intake manifold is the pipe that connects the carburetor to the engine) and then enters combustion chamber. When the engine is running, the pressure in the intake manifold decreases relative to atmospheric pressure, which also leads to a decrease in pressure in the carburetor. Naturally, since the atmospheric pressure is higher, then from the side of the carburetor, shown by the blue arrow, air will begin to flow into it and, accordingly, through the intake manifold and bypass channels into the combustion chamber. Air passing through the carburetor will capture fuel from the fuel chamber and mix with it, thereby creating a fuel-air combustible mixture.

Figure 1 shows that air enters the carburetor through a gradually narrowing channel. It is like a river bed. You probably noticed that in the place where the river narrows. the current increases. The same happens in the carburetor: the air movement is accelerated, which leads to an even greater discharge. The chamber where the fuel is located is connected to the atmosphere, so the pressure in it is higher, and the fuel rises up the tube and mixes with air. The result is a fuel-air combustible mixture. The lower the pressure in the carburetor. the more fuel enters and mixes with the air.

Now let’s go deeper. How to regulate the supply of fuel with air? Probably all of you noticed that there is a throttle on the steering wheel of the scooter on the right? : o) Here she also controls the carburetor. Consider Figure 2 below:

The throttle grip on the handlebars is directly connected to the air damper and the metering needle attached to it. When the gas is released, the needle almost completely closes the fuel supply channel from the float chamber (why the float, we will describe below) and the air damper. blocks the air.

How does the needle block the fuel channel? It’s very simple! After looking at Figure 3, you should understand everything at once. The more you add gas, the higher the spool needle rises and the more the fuel supply channel opens. Together with the needle, the air damper rises. The amount of the combustible mixture increases proportionally and is fed into the combustion chamber, where the spark of a candle ignites.

How to Adjust The Carburetor On A 4- Cycle Engine in 2 Minutes

How does idle work? Why is it needed? It is needed for the stable maintenance of low engine speed during the time when the scooter is not traveling, so that the engine does not stall, as well as to save fuel. The combustible mixture in this mode is rather lean and enters through a separate channel. The principle of operation is shown in Figure 4.

When the throttle knob is released, the spool needle closes the main fuel supply channel, only the air damper 3 remains slightly open, supplying a little additional air for idle speed (hereinafter, we will reduce the idle speed. XX). The hole through which the fuel mixture for XX is supplied is located behind the air damper and the air-fuel mixture through it begins to flow into the cylinder only when the vacuum in the carburetor increases greatly, i.e. when the air damper blocks the air too much.

The combustible mixture at XX is prepared in this way: fuel from the float chamber is supplied through channel 4 and is mixed with air entering through a separate air channel shown by the blue arrow. The quality of the mix is regulated by the mix quality screw XX 2, i.e. the more you tighten the screw, the more you block the air channel, then the mixture becomes richer (there is more fuel in it), the more you unscrew the screw. the more air comes in and the mixture becomes leaner (there is more air in it). Thus, by tightening and unscrewing the quality adjustment screw XX, you achieve the optimal proportion.

Higher or lower engine speed is achieved by slightly raising or lowering the main air damper 3. For this, a special speed screw is installed on the side. By twisting it, you raise the air damper, unscrewing it. letting go.

For the correct dosage of fuel and air, nozzles are installed in the places where they are taken. What is it, jet?

Schematically in section, it looks as shown in Figure 5:

Hole 1 in it is selected with a certain diameter and does not allow more fuel or air to be consumed. The nozzles are installed at the inlets to the fuel supply channels for the main and idle speed. Also, sometimes, instead of the air mixture quality adjusting screw XX, a jet is installed at the inlet to the air channel. The advantages of this design. no need to adjust the quality of the mixture, cons. with wear over time or other factors, you cannot adjust anything.

What is a float chamber? This is the container in the carburetor where the fuel is located. With the help of a plastic or iron float, the level of gasoline in the chamber always remains stable. As soon as the fuel begins to decrease, the float is lowered and the needle to which it is connected opens the fuel supply hole from the gas tank. Gasoline starts flowing, the float rises again and the level stabilizes. It is worth mentioning that when the engine is cold, it does not have enough fuel to start properly and needs a richer mixture. Agree, turning the screws and changing the jets is not very convenient for this: o) For this, an additional channel for supplying the fuel mixture has been created, very similar to the main one, only of smaller dimensions. There is also an air damper and a needle, only the damper is controlled in basically two ways:

one). Manual control. There is a lever on the steering wheel. On a cold one, you turn it, an additional channel opens and an additional mixture comes in. As it warms up, turn the lever to its original position.

2). Automatic control. The needle and the shutter are connected to a device that is forcibly heated. Heating is often done with a coil (similar to a boiler) connected to a generator. In this case, the material that heats the spiral expands and pushes the stem to which the air damper with the needle is attached. The warm-up time is optimally calculated, and after a certain time (approximately 3 to 7 minutes) the channel closes completely.

It should be noted that the carburetor adjustment should only be carried out on a well-heated engine. On a cold engine, the additional fuel supply flap that has not closed will interfere, the engine will not work properly due to its incomplete warming up. Start adjusting immediately after you ride the scooter or after 10-15 minutes of warming up.

Also, before adjusting, check, and preferably change to a new spark plug. Check if the air filter is dirty (read here), clean it or replace it with a new one. Make sure the exhaust system is clean, which you can read about here. It is also advisable to rinse in gasoline and blow out all channels and jets in the carburetor with compressed air.

Only after that you can start adjustments.

And now the carburetor adjustment itself.

The needle in the choke valve can move relative to it within a small range. To do this, the needle has grooves into which the corkscrew ring is inserted. We put this ring in the middle groove. Screw the screw for adjusting the quality of the mixture until it stops and unscrew it back by 1/2. 1 turn. We start a scooter.

If there is no idle speed, they are too low or high, by adjusting the idle speed screw, we increase them, if high, then we decrease.

Then again, by adjusting the mixture quality screw, we achieve maximum idle speed and screw it back by 1/4. 1/2 turn.

We are trying to go. If there are dips during acceleration from standstill, tighten the mixture quality screw by another 1/4 turn. After each adjustment with the quality screw, we adjust the idle speed of the engine with the idle speed screw.

In case of excessive consumption of fuel, you need to lower the spool needle by one notch and make the adjustment again, as described above. If, on the contrary, the scooter still does not have enough fuel, there are gaps, raise the needle upward and repeat the adjustment from the beginning.

To some extent, the correct carburetor adjustment can be determined by the color of the spark plug insulator. If the color is brown. means in general the quality of the fuel is normal. Read more about candles here.

Basically, the principle of operation and the device of all carburetors are the same, so it doesn’t matter what brand of scooter you own.

Of course, only an experienced specialist can adjust the carburetor very accurately and correctly, but thanks to this article you can do it well yourself.

Adjusting the carburetor on a scooter. how to adjust the carburetor correctly

Check the carburetor for debris before adjusting. If there is, then we clean and wash with water. Initially, the engine should be warmed up. this is the main condition before starting the adjustment.

The carburetor needs to be insisted in several stages, which include:

- Idling, its correction;

- Checking the composition of the mixture and its quality, due to the screw;

- Checking the composition of the mixture using a needle;

- Adjusting the fuel level in the float chamber.

Each item should be considered in more detail.

Idle speed correction.

This part is found in every scooter carburetor. Thanks to the screw, the scooter runs stably when it is standing. First you need to warm up the engine.

We will look at the position of the adjustment screws on different models.

Honda has this location:

- The first is the idle speed control screw;

- The second is a screw that regulates how high-quality the mixture is.

Carburetor made in China:

- idle speed adjustment screw

- fuel intake

- a fitting that helps to drain fuel from the float chamber

- screw in the form of a plug, which is located in the float chamber.

Checking the quality of the mixture.

- Ventilation pipe;

- The screw that produces revolutions during idle;

- Air-fuel mixture structure, its correction.

The speed will increase as the screw is tightened. If you unscrew it, it will decrease. The scooter needs to be warmed up for 15 minutes, and this screw will help to achieve confident idling.

Adjusting the mix quality

The main point is that the fuel mixture is suitable for the standards that are supplied by the manufacturers when the device is released. A poor mixture will break the scooter, it will often overheat and lose power. A rich mixture increases fuel consumption, an impurity forms in the combustion chamber and the carburetor gets wet. The properties of the composition of the mixture are regulated by a screw or with a throttle needle in the damper.

Turning the screw to adjust the mixture in a clockwise direction, the mixture is enriched, turning the opposite. it becomes lean. You can also watch the needle. Rises. the mixture is enriched, falls. becomes poorer. The ability to use both methods in tuning will help you achieve better results. However, carburettors such as Suzuki Sepia, Suzuki Assress lack the first option, so only the needle and its movement have to be used.

At the beginning of the carburetor setting, the scooter engine must be warmed up. This will take 10-15 minutes. Then clean the device itself. Engine operation will be considered ideal if the screw, which monitors the quality of the mixture, is unscrewed in the interval of 2 revolutions. The range of indicators may vary, it all depends on the engine, how worn out or other malfunctions.

During normal operation, the scooter accelerates without jerking or gaps. If you do not observe stable operation of the device, then you need to get the choke out of the carburetor and raise or lower the needle. To do this, you must first remove it from the valve and move it to the retaining ring along the grooves.

The color of the candle and its deposits on the electrodes in the scooter can determine the quality of the mixture, which makes it possible to understand how to properly adjust it. A black candle means a rich mixture with a predominant amount of carbon deposits. A white candle means that the mixture is poor, and the electrodes are overheated and melt.

Adjusting the fuel level in the float chamber

A transparent tube located at the bottom of the carburetor makes it possible to check the fuel level in the chamber. To do this, unscrew the drain screw. To begin with, you need to lift the tube up so that it is on the opposite side of the carburetor and is above it. Note that the fuel level control procedure is carried out only in the operating state of the engine. If the level reaches the edge of the lid, there is sufficient.

However, if there is a lot or not enough of it, it is necessary to remove the cover and adjust the locking needle at the moment when it works. You need to bend the tip of the needle that holds it, but in small gaps.

Also, before adjusting the operation of the scooter, you should make sure that:

- the carburetor was cleaned on time;

- channels and jets do not contain debris and other contaminants;

- the quality of the filled gasoline contains an octane number that corresponds to the factory one, or lower than that required by the manufacturer

- the parameters set by the manufacturer are fully compatible with the jets and other parts

If all the necessary conditions are not met, this adjustment will be temporary, without the expected result.