How to adjust the carburetor on a Partner chainsaw

The main malfunctions during the operation of gasoline saws

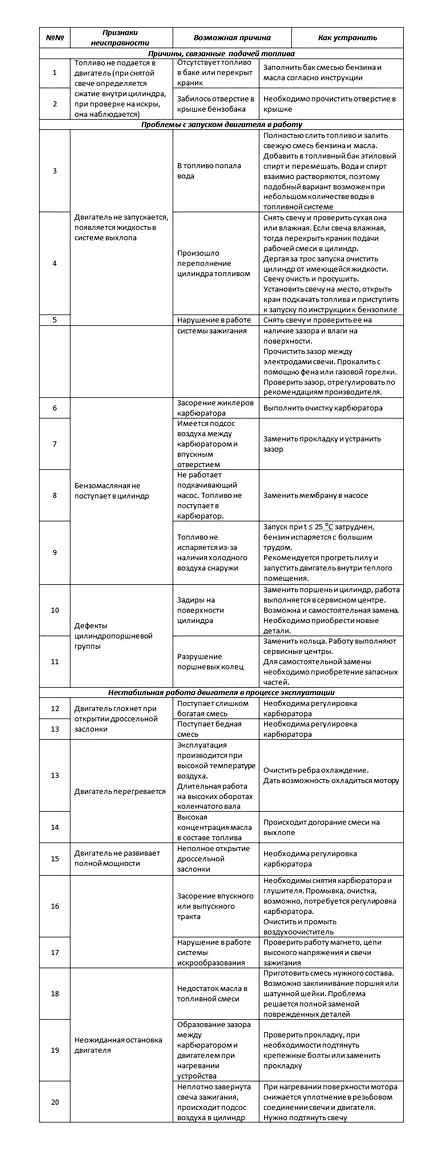

You should start adjusting the carburetor only after making sure that the cause of the malfunction is due to a malfunction in its operation. Therefore, you should analyze the possible causes of a failure in the operation of a gasoline engine. Table 1 shows the main malfunctions and causes, their occurrence in most models of gasoline tools.

Users note the main symptoms when the carburetor settings are violated:

- Engine starts with great difficulty or cannot be started at all.

- During operation, dips are observed when pressing the throttle control lever.

- The motor cannot develop the required power, with full throttle opening, a stop is possible.

- Excessive smoke level, increased noise during operation, accompanied by shots in the intake tract.

- Unstable work in different modes.

- Low speed of the chain drive when setting on the automatic maintenance mode.

- Increased consumption of gasoline while performing work. The sign is very subjective, based on a comparison of indicators in different periods of operation.

- Clogged intake system when removing the air cleaner. Clogging of the material used for air cleaning is possible.

- Wear of the cylinder-piston group. Carburetor adjustments will have a temporary effect.

Attention! If dirt gets into the power system, then it will not only have to be regulated. There will be a need to rinse individual units and parts.

The proposed video shows a variant of the simplest purging of the intake system:

How to remove the carburetor?

- In order to remove the carburetor, you need to unscrew 2 nuts.

- Key 13 used.

- The levers are detached from the cables.

- The feed hose is removed from the gas tank.

- Swinging the carburetor to the right and left, take it out.

- The inlet to the engine must be closed with a plug or a clean cloth.

- The fuel hose is kinked. You can put a nut on it, as shown in the photo. Then gasoline will not flow out.

Ural adjustment

It differs slightly in that it should not be carried out at sharp maximum rpm, but make sure that the chain picks them up quickly, but smoothly, without moving along the bus.

In any case, it is worth taking the adjustment very seriously, because if it is carried out incorrectly, the saw will not stay with you for a long time. Take care of your tools and if you are not confident in your abilities, it is better to take it to a professional.

Any of them, even a strong friendship, needs attention and care. And then the chainsaw will be your faithful assistant for many years to come.

Chainsaw stalls when pressing on gas. How to adjust the carburetor

When purchasing a HUS365 chainsaw, you should be prepared for the fact that after a month of using it, you will not want to deal with any saw other than this brand. This is explained by its reliability, affordability, and most importantly. ease of management.

Step by step setup

“Partner 350” is regulated similarly to many models of chainsaws.

- Low rpm. L

- High. H

- Singles. T.

Once released from production, these chainsaws are tuned to deliver more mix than necessary. This should be the case only in the first hours of work.

When the motor warms up, it is best to re-tune it. At idle, turn the screw T counterclockwise until the chain stops, after which we adjust each of them in the order: L, H, T.

Screw L must be turned counterclockwise ¼ turn at the moment when the largest turns begin at idle.

Adjust the screw H as follows: warm up the convertible and turn it counterclockwise ¼ turn. To determine if everything is in order, you will need a tachometer. The revolutions must be the same as the maximum ones indicated in the chainsaw passport.

Your actions should lead to the fact that the engine immediately accelerates and makes a noise like four times.

The Husqvarna carburetor is adjusted in the same way.

Partner 351 differs only in that its factory settings initially supply the optimal amount of the mixture, that is, everything should work correctly at once. But, if necessary, the instructions above will help you set up the carburetor correctly.

Adjustment of carburetors of Russian and Chinese-made chainsaws Ural, Druzhba, Forte and Champion

In 1997, the manufacturers of gasoline units agreed on a unified marking system for adjusting devices at different units. Before that, Chinese-made chainsaws had significant differences depending on the copied brand.

Nowadays, even the landing dimensions of carburetors, exhaust pipes and a number of other assemblies are made the same. In 2001, Russian manufacturers joined this charter. Now most of the components and assemblies can be installed from different manufacturers.

- The screws for the maximum shaft speed are designated by the letter L (Л in Russian-made devices).

- Mix quality screws are marked with the letter H.

- Idle Screws. T (LA).

All adjustments are carried out in the same way.

Partner chainsaw not adjusting screw H and adjusting the quality of the mixture

The screw H on the carburetor does not work.At the same time, a dip is observed when pressing the gas.

And now let’s take a look at the features of adjustment on different models, both more modern and domestic, and more familiar to us.

Chainsaw Partner P340S. tool device

The standard equipment of this amateur model includes everything you need for continuous comfortable work on the site. The engine of the gasoline-powered tool is a 1-cylinder, running on a fuel mixture of 92 gasoline and oil for lubricating 2-stroke engines. The proprietary Japanese Walbro carburetor is responsible for the continuous enrichment of fuel with oxygen and its supply to the cylinder, the walls of which are covered with a continuous layer of protective chrome-plated alloy.

To ignite the fuel in the engine cylinder, the ignition system is responsible, which consists of a coil and a spark plug located above the engine. The principle of starting the motor is manual. For this, the Partner chainsaw is equipped with a starter and a pump for pumping fuel into the cylinder before starting a cold internal combustion engine. A separate cover is responsible for protecting the spring and the starter coil on the left side of the chainsaw, which is attached with several screws.

For a continuous connection between the motor and the saw headset, the Partner chainsaw is equipped with a reinforced clutch, all parts of which are made of hardened steel. This material allows the mechanism to work under higher loads without the risk of blue disc clutch discs.

For sawing wood, the Partner P340S chainsaw is supplied from the factory with a high-quality saw set. It includes a reinforced metal bar with grooves for grease and a forged chain. designed to work at elevated temperatures. An unregulated oil pump is responsible for supplying oil to the saw bodies in the Partner chainsaw device, which operates in a fully automatic mode.

To protect all the internal components of the chainsaw, the manufacturer has equipped it with a durable housing made of several layers of plastic sheets. In the back of the case there are switches and a power button for the model. The chain inertia brake lever is in the middle, and the handle and starter cable are on the left side of the body.

Adjusting the carburetor of the Partner 340 chainsaw with your own hands

Initially, the carburetor on the Partner 340 chainsaw was adjusted by the manufacturer to operate at maximum power and economy. Additional adjustment may be necessary if the traction characteristics deteriorate, which is possible with sudden changes in air temperature or when filling the tank with another fuel.

Before adjusting, it is necessary to clean the carburetor of the chainsaw from dust and dirt (it is better to use a compressor with an air nozzle for this purpose).

The carburetor adjustment algorithm itself is performed as follows:

- For access to the screws of quality (marking H) and quantity (L) on the chainsaw there are special holes on the left side. For convenience, you need to remove the protective cover.

- We tighten both screws to the end, and then we unscrew each one 1/5 of a turn.

- We start the chainsaw and warm up the engine for 5-10 minutes.

- We adjust the idle speed. To do this, turn the screw T counterclockwise until the engine starts to work as steadily as possible. At the same time, we make sure that the chain does not rotate (if it does, we smoothly tighten the screw until it stops). If the engine stalls at idle, the T screw must be slightly unscrewed again.

- We adjust the power of the motor and the quality of the mixture. Smoothly pressing on the gas, we wait for the engine speed to rise to the maximum. According to the manufacturer’s data, the maximum speed falls at 11.5 thousand rpm (for an accurate determination, use a portable electronic tachometer). If the revolutions do not increase, it is necessary to turn the screw L counterclockwise by 1/8 of a turn. Do not allow exceeding the maximum speed higher than the recommended ones, because this can lead to ignition problems. In this case, turn the screw H counterclockwise, thereby reducing the maximum speed

If you don’t have a tachometer at hand, you can determine if the carburetor is visually adjusted correctly. When the engine emits a lot during operation (the mixture is enriched), screw L must be slightly tightened. In the case when the engine heats up and picks up speed by itself, the screw H must be unscrewed counterclockwise by about ¼ turn.

Sometimes it happens that the adjustment does not help. The motor does not develop revs or stalls. A clogged filter or air intake may be the cause. It is enough to clean and re-adjust the carburetor, if necessary.

Partner 351 chainsaw fails,fixed bad starting.

Popular among gardeners, the Partner P340S portable chain saw is well suited for a variety of gardening tasks, logging and felling small fruit trees. The main advantages of this model are high power, ergonomics and ease of use. Garden tools in this configuration do not require special maintenance, so any novice user can start their intensive use.

Carburetor device

The carburetor body of the Partner 340 chainsaw is made of aluminum alloy. It has technological channels through which a mixture of fuel and oil moves and a diffuser. The task of the latter is to mix air with gasoline, thereby forming a combustible mixture.

The main elements of the carburetor are:

- fuel pump;

- main chamber with membrane;

- throttle and air dampers;

- screws (adjusting quality, quantity, idling);

- needle valve;

- fuel jets.

Step by step setup

“Partner 350” is regulated similarly to many models of chainsaws.

- Low rpm. L

- High. H

- Singles. T.

Once released from production, these chainsaws are tuned to deliver more mix than necessary. Before adjusting the carburetor of the Partner chainsaw, adjust less. This should be the case only in the first hours of work.

When the motor warms up, it is best to re-tune it. At idle, turn the screw T counterclockwise until the chain stops, after which we adjust each of them in the order: L, H, T.

Chainsaw “Partner” 351. a worthy representative of the household line of chainsaws from the “Partner” brand. According to its technical capabilities, it is focused on garden work and simple tasks for sawing wood. Simplicity of design, ease of operation and maintenance allowed this model to be on a par with other famous chainsaws from the brands “STIHL” and “Husqvarna”.

The Partner 351 chainsaw has a standard design. The set of the tool includes a reliable gasoline 2-stroke engine with a cylinder volume of 38 cm3 and a power of 1.4 kW. To start the motor, the manufacturer has provided a trouble-free manual starter, the resistance of which has been reduced by 30%. The modern assembly and layout of the starter makes it possible to start the Partner 351 chainsaw at any time of the year, providing a minimum load on the engine and other mechanisms of the tool. An efficient forced air system is responsible for cooling the motor.

The Partner 351 chainsaw is equipped with a durable ignition system and a proprietary Bosch WSR 6F spark plug. Good assembly of the ignition system and its optimal combination with the clutch makes starting and operating the tool more stable and efficient.

The working bodies of the model are represented by a bar and a chain. A separate sprocket located on the side of the model is responsible for the chain tension. Free access to the sprocket makes it possible to quickly adjust the chain tension without the use of tools.

All internal parts of the Partner 351 chainsaw are housed in a robust housing. It is made of high-quality multi-layer polymer, which gives the case the ability to successfully withstand drops from low heights and accidental impacts on foreign objects.

The body of the model is designed in such a way as to give the operator free access to the main consumable elements of the model. Thanks to this, the feller can quickly make tool repairs right in the field.

The Partner 351 chainsaw has good technical performance. Model features include:

- power. 1.9 liters. from.;

- the capacity of the tank for filling fuel. 380 ml;

- capacity of the tank for filling oil. 200 ml;

- the recommended length of the bus used is 35–40 cm;

- chain pitch. 3/8 “;

- the number of links in the saw chain. 56;

- weight in ready-to-use form. 4.7 kg.

The Partner 351 model stands out for its modest dimensions and low weight. This makes it possible to confidently use it at height without additional insurance for the operator. An important advantage of the instrument is its low noise level. When the saw motor is running at maximum speed, this parameter is 106 dB.

- saw chain and bar;

- spark catcher screen;

- brake mechanism and cylinder-piston group;

- front handle;

- ignition system switch;

- safety device and extinguishing system;

- oil drain hole;

- fuel compartment cover;

- throttle valve;

- fuel suction button;

- chain catcher;

- protective case;

- stop tooth;

- air filter cover;

- tubular handle.

The features of the device are in safety devices:

- Chain mechanism with low risk of kickback. Helps Reduce the Risk of Injury.

- Spark arrester screen. Essential for trapping soot in exhaust fumes.

- Protective hand guard. Helps protect hand from injury if it slips off the tool handle.

- Ignition switch. Stops the engine instantly in case of an emergency.

- Fuse. Prevents accidental acceleration.

The units of the Partner 351 chainsaw (their location and structure) are identical to devices of other models, they consist of the following elements:

- link chain, chain guard (hand protection), chain brake lever;

- tire, ignition off switch, spark arrester;

- front handle, fuses, rear handle;

- starter outlet. handle, tubular handle, persistent tooth;

- oil filling hole, fuel tank;

- starter cover (housing), nuts (protecting), muffler;

- spark plug, carburetor (air) choke knob;

- air filter cover, chain catcher, throttle valve;

- fuel suction (button);

- throttle trigger, protection cover, chain tension adjustment screw.

The Partner brand chainsaw in the 351st modification does not differ much from other models of this well-known brand. Its signature device is based on a durable 2-stroke petrol engine, consisting of an enlarged chrome-plated cylinder and a forged piston. To ensure that the air entering the engine is cleaned, the Partner 351 chainsaw is equipped with an innovative cooling system. The engine is equipped with a 380 ml fuel tank.

The garden tool is equipped with a wear-resistant clutch system to connect the engine to the saw set. The ignition, consisting of a coil and a Bosch WSR 6F spark plug, is responsible for the timely ignition of the fuel in the cylinder. Free access to the spark plug makes it easy to dismantle the part for cleaning or do-it-yourself replacement.

For more convenient operation of the model, its basic device includes an effective vibration and noise damping system. To suppress the vibrations of the engine, the manufacturer has equipped the garden tool with 6 powerful steel springs that take the load from the motor onto themselves. Thanks to this, the vibrations of the engine on the handles of the model are practically not felt.

The Partner 351 chainsaw is equipped with a factory saw set consisting of a 35 cm metal bar and chain with a 3/8 “pitch. Lubrication of the working bodies is carried out using an automatic oil pump, free access to which simplifies the operation and manual repair of the unit. The side chain tensioner is responsible for adjusting the chain on the tire, which can be used without hand tools.

To reliably protect the internal components of the model from damage, the Partner 351 chainsaw is equipped with a shock-resistant plastic case. It is made taking into account all the requirements for the ergonomics of the tool, and its assembly gives the operator the opportunity to independently eliminate any malfunctions of the gasoline saw.

At the rear of the Partner saw body, the manufacturer has provided all the levers and switches necessary for operating the saw. The middle part of the garden tool is equipped with a chain inertia brake shift lever. For better grip, the model is equipped with rubberized handles.

How to adjust the carburetor on a Partner chainsaw

Setting up the carburetor of a Partner chainsaw with your own hands requires the preparation of the following tools:

- tachometer (electronic counter of the crankshaft speed);

- slotted screwdriver;

- set of filters (their replacement is part of the adjustment process).

You can only adjust the carburetor on a Partner 352 chainsaw or another model if you first clean it from dirt. The best way to do this is to use an air-cushion compressor. The adjustment itself is performed in several stages:

- The cover must be removed to access the adjusting screws. They can also be accessed through special holes on the left side of the carburetor. It should be remembered that the left screw is the quality screw (marking H), and the right screw is the quantity (marking L).

- After that, the screws must be fully tightened, and then loosened by ⅕ turn.

- Then the chainsaw needs to be started, since the carburetor can only be adjusted when the engine is hot.

- After that, the amount adjusting screw must be tightened clockwise to the maximum engine speed. Upon achieving this result, the screw must be unscrewed counterclockwise by ¼ turn. After that, the chainsaw should idle. If there are too few or too many revolutions, then the throttle valve is used.

- Now, using the quality screw, the maximum speed is set. This parameter is determined by a tachometer. The maximum possible value is easy to see in the instructions. For example, for the Partner 350 chainsaw, this value is 12,500 rpm.

If there is no tachometer, then the quality of the adjustment can be determined visually. If the tool emits a lot during operation, then the amount screw must be slightly tightened. Another option is also possible. The chainsaw can work well at idle, but poorly at maximum. The situation can be corrected by tightening the quality screw, while the gas must be kept completely clamped.

Need for adjustment

Adjustment of the carburetor of the “Partner-350” chainsaw is sometimes required, often obstacles appear, expressed in the wrong flow of fuel or engine wear. However, there are now signs that the mechanism needs to be adjusted, here are a few. When I managed to start the engine, it immediately stalls.

Sometimes users do not have a basis at all to start it, and the reason lies in the lack of fuel or an excess of oxygen. A discrepancy arises if the passage of an increase in fuel consumption, the result is an increase in the volume of exhaust gases. This sometimes happens due to oversaturation of the consistency with fuel.

In order to understand how the Partner-350 chainsaw is adjusted, it is best to familiarize yourself in more detail with the device of this unit at the first stage. If you understand the principle of operation and the constituent elements, you will be able to independently determine the cause of the breakdown. The carburetor acts as one of the main parts of the engine, which is necessary for the preparation and subsequent supply of fuel, the latter consists of fuel and oxygen. If the ratio of these ingredients is violated, then the motor may start to work incorrectly, and subsequently fail.

Adjustment of the carburetor of the Partner-350 chainsaw is required in the rarest cases, more often obstacles appear, expressed in the wrong flow of fuel or engine wear. But there are signs that the mechanism needs to be adjusted, here are some of them. After I managed to start the engine, it immediately stalls.

If you have a Partner-350 saw, the carburetor can be adjusted independently, without the involvement of specialists. After evaluating your capabilities and experience, proceed to the disassembly, the recommendations for which were presented above. Then you can carry out the setting and subsequent adjustment.

It is necessary to distinguish between three screws, it is in this amount that the “Partner” saw has them, but in some models the screw is installed in a single copy. The manufacturer has designated each with its own letter, which will allow you to understand what the element is intended for. Thus, the screw under the letter L must be used when setting low rpm.

Adjustment of the carburetor of the Partner-350 chainsaw is required in the rarest cases, more often obstacles appear, expressed in the wrong flow of fuel or engine wear. But there are signs that the mechanism needs to be adjusted, here are some of them. After I managed to start the engine, it immediately stalls.

When it is necessary to adjust the carburetor if the chainsaw suddenly Partner 350, though. In some cases, users cannot start it at all, and the reason lies in a lack of fuel or an excess of oxygen. A discrepancy may appear in the event of an increase in fuel consumption, the result is an increase in the volume of exhaust gases. This can happen due to oversaturation of the consistency with fuel.

If you have a Partner-350 saw, the carburetor can be adjusted independently, without the involvement of specialists. After evaluating your capabilities and experience, proceed to the disassembly, the recommendations for which were presented above. Then you can carry out the setting and subsequent adjustment.

It is necessary to distinguish between three screws, it is in this amount that the “Partner” saw has them, but in some models the screw is installed in a single copy. adjusting the carburetor on the chainsaw Partner (partner) the Partner p350s chainsaw and. The manufacturer designated each with its own letter, which will allow you to understand what the element is intended for.

In order to understand how the Partner-350 chainsaw is adjusted, it is best to familiarize yourself in more detail with the device of this unit at the first stage. If you understand the principle of operation and the constituent elements, you will be able to independently determine the cause of the breakdown. When you need to adjust the carburetor on your chainsaw, Partner 350, although.

The carburetor acts as one of the main parts of the engine, which is necessary for the preparation and subsequent supply of fuel, the latter consists of fuel and oxygen. If the ratio of these ingredients is violated, then the motor may start to work incorrectly, and subsequently fail.

Adjustment of the carburetor of the Partner-350 chainsaw is required in the rarest cases, more often difficulties appear, expressed in the incorrect flow of fuel or engine wear. But there are signs that the mechanism needs to be adjusted, here are some of them. After I managed to start the engine, it immediately stalls.

Additional recommendations

If you purchased a Partner-350 saw, the carburetor can be adjusted during operation. Before carrying out these works, you must remember that the factory settings are optimal. Using the screws described above, you can adjust the operation of the motor in special situations, among them different climatic conditions can be distinguished. It is necessary to use the screws under the letters L and H when adjusting. To increase the speed, turn them clockwise.

To reduce the speed, the screws are turned in the opposite direction. It is also important to take into account the sequence of using the elements, which looks as follows: L. H. T. If during the adjustment you encounter difficulties, then it would be best to contact a specialist, because an incorrect setting can damage the motor.

Ignition adjustment

Those people who have a Partner-350 saw adjust the ignition quite often. At the first start, the idle speed needs to be checked, in order to perform it, it is necessary to turn the screw responsible for adjusting the idle speed clockwise. As soon as it rests, it should be turned counterclockwise 4.5 turns.

Those people who have a Partner-350 saw adjust the ignition quite often. At the first start, the idle speed needs to be checked, in order to perform it, it is necessary to turn the screw responsible for adjusting the idle speed clockwise. the chainsaw stalls on Partner 351 does not idle, the stroke of the carburetor-blew rpm.

As soon as it rests, it should be turned counterclockwise 4.5 turns. Adjustment of the partner 351 carburetor. The Partner 351 chainsaw contains partner 351 in the chainsaws. If, after carrying out these manipulations, the motor runs without rotating the chain, then everything is in order. Otherwise, you need to contact the service center, as it can be dangerous to work with such a saw.

Partner 351 Specifications

- Fuel consumption is minimal thanks to the installed air filter, which operates on the CCS system.

- The motor service life of the Partner 351 has been increased by means of a double air cleaning system. The chain operates at the highest possible speed.

- The Partner chainsaw is designed for long, uninterrupted use.

- The device has a vibration damping system.

- Safe working with Partner 351 guarantees instant chain brake action.

The solid factory parameters of Partner’s 351st model make it stand out from other household chainsaws.

Garden tool metrics include:

- the power of the standard gas engine is 1.9 liters. s. / 1.4 kW;

- the speed of rotation of the crankshaft at idle / maximum speed. 3000/12000 rpm;

- the possible length of the bus used for work is 35–40 cm;

- number of chain links. 56;

- sound pressure on the operator. 98 dB.

One of the main advantages of the proprietary Partner 351 model is its relatively low weight. When the fuel and oil tanks are fully filled, and with the saw set installed, this parameter is 4.7 kg.

In the segment of non-professional chainsaws, Partner 351 (Partner 351) takes its rightful place. Lightweight, powerful and reliable, the saw allows you to perform a wide range of wood sawing tasks at the household level.

The Partner 351 chainsaw is a device designed for logging and felling small trees.

As a Husqvarna company, a subsidiary of Patrner specializes in a wide range of power tools and chain saws in various capacities.

Among the models of the brand demanded by domestic buyers, the Partner 350 s chainsaw occupies a leading position.

The household model is widely used in private households, in dachas and garden plots, in carpentry workshops to perform the following tasks:

- pruning branches and branches;

- tree care and crowning;

- felling trees of small diameter;

- cleaning the area from unwanted growth;

- sawing trunks, branches, boards, beams;

- preparation of firewood for the winter.

The Partner 350 chainsaw can also be used for private construction (for the construction of log cabins, saunas, alcoves, gazebos, wooden houses).

| Construction type | Manual |

| Tool power | 1.8 horsepower |

| Chain device pitch | 3.8 inch |

| Bus length | 35 cm |

| Rotation speed of mechanisms | 10,000 rpm |

| Engine displacement | 34 cm³ |

| Fuel tank volume | 0,4 l |

| Oil tank volume | 0.2 l |

| Chain brake | there is |

| Automatic chain lubrication mode | there is |

| Chain thickness | 1.3 mm |

| Number of link elements | 56 |

| Noise level | 106 dBA |

| One-handed operation option | there is |

| Idling speed | 3000 per minute |

| Tensioner type | Instrumental |

| Anti-vibration system | there is |

| Inadvertent activation blocker | there is |

| Rubberized handles | there is |

| Dimensions (edit) | 422629 cm |

| Launch system | Easy Start |

| Weight | 4.7 kg |

The Partner 351 saw good performance and performance, despite its compact size and weight of 4.7 kg:

- motor power 1400 W (1.9 hp);

- tire 35 cm. It is possible to install a tire at 41 cm;

- 56-link chain with 3/8 ” pitch;

- spark plug. Bosch WSR 6F;

- fuel tank capacity 380 g;

- oil tank for 200 gr;

- noise level just over 100 dB.

The CCS air filter significantly reduces fuel consumption. The double air purification system increases the engine resource of the Partner 351 chainsaw. The chain operates at high speeds.

Sophisticated ergonomics and reliable vibration damping system allows you to use the tool for several hours without interruption.

The chain brake is instantly responsive, which makes working with the chainsaw even more comfortable and safe.

Chainsaw starting instructions

The Partner 351 chainsaw works on the same principles and has a similar structure as other tools with gas engines:

- Before the first use, all components of the Partner 351 chainsaw are securely screwed on, the integrity of the body is checked.

- The chain tension is checked before each start. If necessary, the chain is tensioned or relaxed using the adjusting screw.

- The amount of oil is checked before each start.

- The chainsaw can only be started from a hard surface. The foot should firmly press the tool to the ground.

- Before starting, the damper is placed in the “open” position.

- The start button is moved to the “on” position. after which it is necessary to press the primer 5 times and start pulling the starter cord. The main thing is to start the chainsaw smoothly, without jerking.

- After starting, the engine should idle for 60 seconds. Then you can start working by adjusting the power with the throttle.

The user manual contains recommendations for maintenance, which is carried out as follows:

- Cleaning the air filter. It is necessary to remove the air filter cover by loosening the mounting bolts. Pull out the filter element, wash it in clean water and soap and allow to dry completely. Reinstall all elements.

- Fuel filter. It is necessary to remove the filter from the reservoir, and then install a new filtering mechanism, insert the end of the filter into the opening of the reservoir. After the steps taken, you need to fill in a new fuel fluid.

- Spark plug. Turn off the engine, remove the head that secures the air filter cover, disconnect the high-voltage wire, unscrew the spark plug and install a new one in its place.

- Spark arrester screen. It is necessary to dismantle the muffler, remove the fastening screw, discard the worn screen and install a new one.

Setting up the carburetor

If you have purchased a Partner-350 chain saw, carburetor adjustment may be necessary during operation. In order to perform these actions correctly, you must also familiarize yourself with the principle of operation of this piece of equipment. The fuel is atomized in the diffuser by a jet of air, which creates a mixture that is forced into the cylinder.

The Partner 351 chainsaw has several working mechanisms that require periodic inspection and maintenance. One of them is a carburetor.

It is not recommended to repair the carburetor of the Partner 351 chainsaw with your own hands, but it is possible to make a small adjustment. There are two main breakdowns that can be eliminated by adjusting the carburetor with your own hands:

- Spinning the chain while the engine is idling. To eliminate the malfunction, you must use the adjusting screw. First, turn it fully clockwise. Then make 4.5 turns counterclockwise. The malfunction should disappear.

- Incorrect supply of the fuel mixture. There may be several reasons. From misalignment of adjusting screws to breakage of carburetor parts. In any case, the adjustment takes place according to the same scheme.

There are three adjusting screws for adjusting the carburetor: L. for high revs, H. for low revs, T. idling of the Partner 351 chainsaw.

Chainsaw Carburetor Adjustment | How to Tune ‘Correctly’. by Craig Kirkman

- The adjustment starts with screw T. To do this, start the saw, and turn the adjusting screw counterclockwise until the chain stops.

- Then screw L is turned counterclockwise a quarter of a turn. During idle adjustment, there should be the largest turns.

- Turn screw H a quarter of a turn counterclockwise.