How to adjust the centrifugal regulator on a walk-behind tractor

topic carburetor tuning. | Topic author: Ramani

Roman (Commodore), in addition to the idling screws and the quality of the mixture, you also need to adjust the carb needle. The cartridge on the carb needle has 5 slots. Best for 3 slots, when you rearrange the needle, you need to adjust the mixture quality screw with the screw. The slots on the needle are counted from the top. In this photo the needle is not from the cartridge and therefore there are 4 slots on it.

Roman (Commodore) is rearranged neatly with pasatizh, “DISK” which is on the needle.

Roman (Commodore) must be set up so that, at the stall stroke, turn the throttle handle by half and it quickly dials up, and not stalls.

Anton (Jennica) Roman, I have long wanted to know how the carb is regulated, thanks for the info And another question on how to properly adjust the quality of the mixture??

Roman (Commodore) is not all. here this “cover” is removed there is a spring, a damper and a needle. in the photo the carburetor is not from the cartridge.

Vasily (Avidror) Roman, how to properly adjust the float chamber? and screw the quality of the mixture by how much to turn it?

Roman (Commodore) Vasya, you can’t just twist the screw of the mixture quality.

Vasily (Avidror) Roman, this engine has some kind of carburetor that is not finished yet, no matter how you set it up, it stalls or foams up when the gas is suddenly twisted

Roman (Commodore) is not satisfied with the stock carburetor, put a vacuum one. for 125 cubes cost: 1500 rubles. it’s much better with him.

Vasily (Avidror) Roman, did you set yourself? and how does it work? I saw pictures there was not found drosel

Roman (Commodore) yes, I have a vacuum one. works awesome. only I have 250 cubes and the vacuum cleaner is a little different.

Vasily (Avidror) Roman, okay, maybe I’ll take myself somehow) but you can throw a link?

Roman (Commodore) http://scooter77.ru/product/karbjurator-Honda-gy6-125.

Vasily (Avidror) Can you explain how this vacuum carburet works, if not difficult? I don’t understand how it works and why wires are needed?

Mikhail (Gafar) Vasya, take a long time to explain, just type something in Yandex, yes there is)

Damir (Zuleika) Roman, How did you put it? is there a branch pipe that goes to the other cylinder? and to the air connection the filter is also different? do you need to redo a lot? thanks in advance for your reply.

Roman (Commodore), the inlet pipe must be cut and thrown out the part with the attachment to the carb, and instead of it, tighten and clamp the rubber pipe with a clamp, well, for example, the radiator pipe from the VAZ 2121, it fits perfectly. this way the vacuum carb can be taken out anywhere. air filter nozzle: if you drive only on asphalt, then you can not take a steam bath and just put a zero-wheel, and if off-road, you need to solder it into the native air, take the air out from sunrise to the side, cut a hole in the lining and connect it with a pipe that is made of the corrugation of the plug sunrise, so it is done for me.

Roman (Commodore) the result is worth the rework.

Alexander (Claude) cold engine seizes and immediately stalls hot starts normally what is the reason.

Tags: How to adjust the centrifugal regulator on a walk-behind tractor beam

Centrifugal regulator on a walk-behind tractor | Topic author: Vasily

I have a single-axle tractor MB-1 Stanislav, I installed another carburetor. Question: if you fix the rod of the centrifugal regulator in the upper or lower position, what will happen? The engine is not covered?

Zoya Put the Lifano engine on. Price 6tch. rub.

宮 | CARBURETOR. FAULT DIAGNOSTICS | Topic author: Odion

LIKE WHERE DEFINED THE FAULT AUTO 20:47 12:36 16:48 38:52

Ignition system malfunctions affect all engine operating modes.

When checking it, special attention should be paid to the gaps of the spark plugs, the ignition timing, the cleanliness of the high-voltage wires, the condition of the ignition coil and the distributor connector, the serviceability of the vacuum and centrifugal regulators.

It is necessary to wash the carburetor from the outside without disassembling it. Particular attention must be paid to the cleanliness of moving joints, damper axles, levers and rods. It is recommended to completely disassemble the carburetor to flush the chambers and channels. When partially dismantled, dirt from the outer surfaces can enter the interior of the carburetor. For this, kerosene or special flushing fluids and a brush with moderately stiff bristles are used. You can rinse individual parts of the carburetor with acetone. Gaskets, diaphragms and rubber seals are not solvent resistant. These parts must be removed and washed separately and only in gasoline.

If there are old deposits in the channels of the carburetor, its body parts can be immersed in detergents for several hours.

For the final removal of deposits, all channels after flushing must be blown out with compressed air at high pressure (6-8 bar).

It is not recommended to wipe the carburetor parts and cavities with a lint cloth. Even the smallest fibers separated from it enter the channels and jets, which can lead to subsequent adhesion of dirt on them, reducing their throughput or clogging.!

Vladimir (Gealya) DIFFICULT STARTING A COLD ENGINE may be caused by improper starter adjustment. Incomplete closure of the air damper leads to a depletion of the mixture and, accordingly, to the absence of flashes in the cylinders, and its insufficient opening after starting the engine over-enriches the mixture, and the engine becomes “baked”.!

Vladimir (Gealya) DIFFICULT STARTING A WARM ENGINE Most often associated with a “rich mixture” entering the cylinders due to an increased fuel level in the float chamber. Cause. either a violation of the adjustment of the float mechanism, or the tightness of the fuel valve. The quality of gasoline plays an important role, since poor-quality gasoline boils earlier, vapors re-enrich the mixture. You can start after purging by pressing the gas and the clutch at the same time to the stop when cranking with the starter.!

Vladimir (Gealya) ENGINE IS UNSTABLE IDLE OR STALLS. Solenoid valve is loose. Clogged idle fuel or air jet. Air is sucked in in the intake tract. The sealing ring of the “quality” screw is damaged. Faulty EPHH system If all other carburetor systems are working properly, this is possible due to: clogging of the nozzles and idle channels; incomplete tightening or malfunction of the solenoid valve; malfunctions of the control unit or other elements of the EPHH; damage to the rubber sealing ring of the “quality” screw. Since the transition system of the first chamber is combined with the idle system, at unstable idle speeds, the engine may fail and even stop when the vehicle starts moving smoothly. The clogging can be eliminated by flushing and blowing out the channels after partial disassembly of the carburetor. Defective parts are replaced.!

Vladimir (Gealya) INCREASED OR DECREASED IDLE SPEEDS Idle speed adjustment is faulty. The level of fuel in the float chamber is violated. The solenoid valve is not tightly wrapped. Clogged fuel or idle air jets. The air damper is not fully open. The throttle valve is not closed completely. The rubber ring of the “quality” screw is damaged. Incorrect idle speed adjustment; increased or decreased fuel level in the float chamber; clogging of the fuel or air jets, air leaks into the carburetor or intake manifold at the joints or through the connecting hoses; incomplete opening of the air damper. Unstable engine idling can be caused by too lean mixture adjustment.!

Vladimir (Gealya) INCREASED FUEL CONSUMPTION. Increased resistance to vehicle movement. Air filter element clogged. The starting system is defective. Fuel leaking from the fuel pump. Fuel leaks from the supply or return lines. The fuel level in the float chamber is violated. The EPHH valve is not tightly wrapped. Faulty EPHH system. The economizer valve is not sealed or its diaphragm is torn. Elements of the carburetor do not correspond to this modification Elimination of this malfunction is most difficult due to a large number of probable causes. First, you need to make sure that there is no increased resistance to the movement of the car, which is facilitated by the braking of the pads on discs or drums, violation of wheel alignment angles, loading the car, deterioration of aerodynamic characteristics when transporting cargo on the roof. Driving style plays an important role in fuel consumption. Such carburetor malfunctions can lead to increased consumption, such as: clogged air jets; malfunction of the EPHH system; loosely wrapped solenoid valve and, as a result, fuel leakage between the nozzle and the channel walls; economizer malfunction; incomplete opening of the air damper, leading to a constant over-enrichment of the mixture. If the increased fuel consumption appeared after the carburetor was repaired, it is possible that jets with large bore diameters were mixed up or installed.!

Vladimir (Gealya) DEEP FAILURE, BEFORE THE ENGINE IS STOPPED when opening the throttle valve of one of the chambers, may be caused by a clogged main fuel jet. When the engine is idling or at low loads, the engine’s fuel consumption is low. When you try to reach full loads, fuel consumption increases sharply, the patency of clogged fuel jets is not enough, and a failure occurs in the engine.!

Vladimir (Gealya) EASY MAINTENANCE OF THE CAR IN MOTION, SLOW ACCELERATION WHEN Smoothly PRESSING THE GAS PEDAL, most often it can be caused by too low fuel level in the float chamber due to improper adjustment of the float mechanism.!

Vladimir (Gealya) FAILURES, JUNCTIONS, SWINGING OF THE VEHICLE. The fuel pump is faulty. A vapor lock has formed in the power system. Accelerator pump, econostat or economizer defective. Air is sucked into the fuel supply line. The carburetor mesh filter or fine fuel filter is clogged. The carburetor body is deformed by excessive tightening of the nuts of its attachment to the intake manifold Occur at increased loads and disappear when switching to idle; associated with interruptions in fuel supply. This may be caused by leaking fuel pump valves, clogging of the mesh filters of the fuel intake, fuel pump, carburetor, increased resistance to the passage of fuel through the fine fuel filter, or air leaks into the power system.!

Vladimir (Gealya) FAULTS ARISING AT SHARP PRESSING OF THE “GAS” PEDAL and disappearing when the engine is running for 2-5 seconds in the same mode, are caused by a malfunction of the accelerating pump.!

Vladimir (Gealya) ENGINE WON’T START OR START DIFFICULTY There is no fuel in the float chamber :. ■ fuel has evaporated during long-term parking. ■ the strainer is dirty. ■ defective fuel valve (stuck closed). ■ the fuel supply system is faulty

Air is sucked into the intake tract :. ■ damaged gasket between the carburetor and intake. ■ pipeline. ■ the gasket between the inlet pipe and is damaged. ■ cylinder head

The fuel level in the float chamber is violated :. ■ the fuel level in the float chamber is not adjusted. ■ the fuel valve is not sealed. ■ hitting the floats on the walls of the chamber

Starting system defective (with manual drive) :. ■ the adjustment of the starting system is broken. ■ the air damper rod is stuck or cut off. ■ the fastening of the air damper drive rod is loose. ■ the choke axle is seized

Defective starting system (with automatic starting device) :. ■ the adjustment of the mechanism is broken. ■ the installation of the bimetallic spring is broken. ■ loss of elasticity of the bimetallic spring. ■ loss of mobility of the launcher rods joints. ■ the diaphragm of the automatic starting device is damaged

The carburetor jets or passages are clogged: ■ resin deposits in carburetor jets and passages. ■ mechanical impurities in the fuel

The water in the carburetor is frozen (water in the fuel)!

Vladimir (Gealya) ENGINE STARTS, BUT STALLS IMMEDIATELY Starting system is faulty. we set the air damper gap or check the membranes. Fuel supply to the float chamber is interrupted. check the needle valve Clogged carburetor jets or passages Read, like!

Vladimir (Gealya) ENGINE DOES NOT WORK AT IDLE Fuel or air passages or jets clogged EPHH system faulty: solenoid valve defective EPHH control unit contact of the screw tip “quantity” with wire or “ground” is broken Air is sucked into the intake tract!

Vladimir (Gealya) BREAKING FAILURES ENGINE DOES NOT DEVELOP FULL POWER Outlet of the transition system clogged Low fuel level in the float chamber The engine is not warmed up Fuel level in the float chamber is faulty Inlet air thermostat is faulty The filter element of the air filter is faulty The fuel pump is faulty or the tank is faulty carburetor Throttle valves do not open fully Economizer or econostat defective The dosing elements of the carburetor do not correspond to this modification.!

Vladimir (Gealya) THE ENGINE DOES NOT START OR STALLS IMMEDIATELY AFTER STARTING. This may be caused by a lack of fuel in the float chamber or a violation of the composition of the mixture (the mixture is too rich or, conversely, insufficiently rich). The presence of fuel in the carburetor float chamber can be checked by removing the air filter housing cover and looking into the mixing chambers. We turn the throttle valve drive sector two or three times. This will activate the accelerating pump. If there is fuel in the carburetor, it will be injected from the accelerator pump sprayer into the intake tract. If fuel enters the cylinders, but the engine does not start. most likely, the composition of the mixture is broken or the ignition system is faulty. If the float chamber is empty, we find out why the fuel does not enter the carburetor. To do this, turning with the starter, we install the crankshaft so that the manual pump drive is in the working position. In this case, when you press its lever, the resistance of the diaphragm and the return spring will be felt. Remove the hose from the carburetor fuel inlet and use the hand drive lever to activate the pump. A pulsating jet of fuel should appear from the hose. If it is not there, we check the presence of fuel in the tank, the flow of fuel to the pump, as well as the serviceability of the pump. If fuel does not flow to the pump, it is possible that the fuel supply line is clogged or kinked, the fuel intake strainer is clogged, the ventilation of the fuel tank is impaired (due to a malfunction of the double-acting valve). The fine fuel filter may also be clogged. If fuel is supplied to the pump, but not to the carburetor, the pump or its drive may be faulty, the fuel supply hose to the carburetor is clogged or pinched.!

Vladimir (Gealya) LACK OF FUEL IN THE FLOAT CHAMBER WHEN IT IS PRESENT AT THE INLET TO THE CARBURETOR. The carburetor mesh filter may be clogged or the fuel valve needle is stuck in the closed position. We take out the mesh filter, rinse it in acetone, blow it with compressed air and put it back in place. To return mobility to the valve needle, it may be enough to lightly tap the carburetor body with a wrench. But at the first opportunity it is necessary to replace the valve, since the needle sticking will be repeated periodically.

IF THERE IS A SUSPECTED FUEL PUMP MALFUNCTION.First, we check for a vacuum in the suction cavity of the pump. Close the suction connection of the pump hermetically with your finger and press the manual drive lever several times. In a working pump, a vacuum is created in the suction cavity, which can be felt with a finger. If no vacuum is generated, the pump is defective. Having removed the fuel pump from the engine, we once again check its performance. We lower its suction fitting into a container with kerosene or diesel fuel and manually pump the liquid. In a serviceable pump, a pulsating jet with a diameter equal to the opening of the outlet fitting will appear from the discharge connection. After making sure that the pump is supplying fuel, we check its valves for leaks. To do this, having typed fuel into the pump, tightly close the discharge connection with your finger. Using a manual drive, we create fuel pressure in the pump cavity and wait a few seconds, after which we release our finger. A jet of fuel should spray out of the fitting, indicating the presence of pressure and, accordingly, the tightness of the valves. If, during the check, the pump is running, but after installation on the engine, it is not, then the drive is faulty. Most likely, it will be enough to adjust the amount of protrusion of the pusher.

TO LEANING THE MIXTURE, AS WHEN THE ENGINE IS STARTING, AND WHILE IT IS RUNNING. Low fuel level in the float chamber, suction of extraneous air into the intake pipe at the joints of the carburetor with the pipeline, the pipeline with the block head, as well as through the hose of the vacuum brake booster, damaged sealing screw ring of “quality”, etc. Violation of the composition of the mixture can be caused by an incorrect position of the air damper, which is possible when the damper axis, lever or thrust of its drive, malfunction of the vacuum diaphragm mechanism, automatic starting device (for modifications “31”, ” 35 “and” 62 “), incorrect adjustment. At negative temperatures, water can freeze in the channels of the carburetor and the fuel line and clog them with ice plugs, as well as freeze the mixing chambers in the diffuser area. A drop in engine power is observed. To remove icing, it is enough to stop, turn off the engine and wait a few minutes until the ice melts.

FUEL TANK VENTILATION MALFUNCTION. If, when the tank plug is removed, fuel flows through the fuel line to the pump, and after installing the plug, gasoline supply interruptions begin after a while, the double-acting valve is faulty. The flow of fuel through the fuel line to the pump can be checked by removing the hose from the fuel pump suction fitting. Using a tire pump, through the union of a double-acting valve, we create a small pressure in the tank (no more than 0.5 bar), while simultaneously observing the appearance of fuel in the inlet hose of the fuel pump. You can also extend the hose with a transparent plastic tube about 0.5 m long.Mouth, being careful, create a vacuum in the fuel line until fuel appears in the transparent tube.!

Vladimir (Gealya) The technical condition of the engine also plays an important role. Camshaft cam wear, valve timing, incorrect adjustment of thermal clearances, valve burnout, uneven or low compression in the cylinders. result in loss of power, vibration and increased fuel consumption. With a worn-out cylinder-piston group, crankcase gases with resinous substances and oil vapors, getting into the cavity above the carburetor, clog the filter element of the air filter, settle on the jets and other elements of the carburetor, making their work difficult.!

Vladimir (Gealya) USEFUL INFORMATION ON REPAIR AND MAINTENANCE OF VAZ

Murzilka: http://www.autoprospect.ru/vaz/ Description of repair and advice on the operation of cars of the VAZ family.

Vladimir (Gealya) History, photo repair VAZ

Tags: How to adjust the centrifugal regulator on the Neva walk-behind tractor

How to adjust the centrifugal regulator on a walk-behind tractor

I will try to summarize and place in one place information from various sources in the article. I apologize to the authors of the articles for not indicating links to them. I just don’t remember where I got the information from. I do not claim to be 100% accurate yet of all the information, tk. I draw some conclusions based on my own guesses. Perhaps someone will correct me. Let’s practice, together we will create a small set-up instructions. Service center specialists, of course, know everything, but they will not share their knowledge. The less information, the more profitable it is for them. After all, the Neva has been produced for a long time, but there is no literature on repair and adjustment. And it won’t. As in my case, they will answer you: “Bring it to us”! And if this is another state, or thousands of kilometers to the service workshop, then how. I’m not alone. I read it in different forums, people are interested in how it works and how to fix it. So I’ll try from the simplest. For some it will be clear and so, but for beginners, maybe it will become clearer.

I just ran into a problem with setting up the Neva MB-2 walk-behind tractor. During operation, I wiped the thrust of the centrifugal regulator with a rag and, apparently, the bolt was not tightly tightened. in general, it turned. After that, I tried to fix it for a long time, until it worked. I will try to describe how I regulated, how it works.

I’ll start with a centrifugal regulator. Its purpose is to maintain a constant engine speed when the load on the shaft changes. Those. so that the single-axle tractor does not stall when you, for example, plow. At the same time, through the wheels, gearbox, pulley, belt, engine pulley, the engine begins to slow down and if it were not for the centrifugal regulator, the engine stalled. After all, we do not have the ability to press more and more on the gas like a car. The design is thought out very competently.

Click on the picture to enlarge

After the engine is started, the weights of the regulator are unwound. Due to centrifugal force, they disperse, opening like a flower, and on the stem moves forward, turning the regulator lever. Now, if we load the engine, the rotation of the engine will start to slow down. In this case, the speed of rotation of the weights will also decrease, they will begin to fold (cover like a flower) and the regulator lever will begin to return back, which will lead to a turn through the centrifugal regulator lever, traction, throttle valve of the carburetor to increase fuel consumption, i.e. add gas. Those. having put the throttle stick in a certain position, we can now not worry that the engine will stall under load. As soon as we reduce the load, the weights diverge again and turn the throttle valve through all the rods to decrease the throttle. There is another spring in this entire line. With an increase in gas, it stretches through a cable and a bracket in the shape of the letter “G” and counteracts the rotation of the throttle valve in the direction of decreasing gas.

Click on the picture to enlarge

Further. Because rpm “walk” when the air damper is fully opened, then a lean mixture comes out. It needs to be adjusted. We screw in the idle mixture adjustment screw until it stops. Now we unscrew this screw by one and a half turns and start the engine. The carburetor device is such that when screwing in the screw, we block the air channel and increase the amount of gasoline in the engine. That is, we enrich the mixture, and if we unscrew the screw, then we add more air, so we make the mixture lean. Now, with the air damper fully open, we try to achieve the maximum stable rpm by rotating the screw, reduce the gas to a minimum and again try to achieve the minimum low, but stable engine rpm.

Now we look at another important part. the throttle stop screw. With the gas removed, it should rest against the carburetor board. Now we smoothly unscrew it and achieve the minimum speed. This screw allows the throttle to close at a certain angle. Now you can test a single-axle tractor. Having allowed it to warm up under load, you can find out by the candle whether the working mixture is correctly adjusted. Since after idling, you will not see this.

Identifying engine problems by looking at spark plugs.

We hope this article will help you choose the right spark plug and determine the condition of your engine.

By the appearance of the spark plug electrode, you can determine the condition of the engine, the suitability of the glow number of the spark plug, as well as whether the carburetor and the ignition timing are properly adjusted.

- Wet spark plug electrodes (Figure 1-2) can be caused by one of the following:

(a) Very rich air / fuel mixture (high fuel, low air).

(c) Ingress of oil into the combustion chamber (worn out: piston rings or valve guides).

Adjustment of the carburetor of the walk-behind tractor should be carried out from time to time in order for the mechanism to work properly. A likely prerequisite for changes in the operation of the motor-block motor is the carburetor. For this purpose, the device is disassembled, cleaned and adjusted (tuned). Regardless of the brand of carburetor and how correctly you can choose the studio, on which device it is installed, the principle of regulation is the same for everyone. The difference you will like best is solely in the number of revolutions.

Where do you need to find out in due time a motor breakdown? When a carburetor malfunction occurs, the most important thing is to check the fullness of the fuel tank and the oil level. If there is enough fuel and oil, then they run over to the inspection of the candle. For this purpose, it is turned inside out and the spark is inspected using ignition. Next, they test the flow of gasoline to the carburetor. For this purpose, remove the hose from the fitting and track the flow of fuel. If no fuel appears, then most likely the filter mesh will need to be cleaned. For this purpose, the fuel cock is unscrewed, all parts are washed with gasoline. Do the same with the carburetor jet.

The carburetor is cleaned in this way. To clean the device, you must first remove it. To effortlessly remove the carburetor, it is necessary to closely examine the body of the device and unscrew the parts where it is held by our client.

What is needed, remove the carburetor and pour out the gasoline with its use. We carefully separate what remains for our client to do with the details of the device (jet, float) for the upcoming blowing and cleaning. This manipulation is performed with a special cleaner.

Use a compressor for stubborn dirt.

After cleaning, we painstakingly dry our client with the parts left and boldly proceed with the assembly. After assembly, adjust the carburetor for the walk-behind tractor.

We install the cleaned device using a standard gasket and fasten it with nuts. Remember the air filter, speed regulator and gasoline hose.

IDLE SPEED ADJUSTMENT AT THE MOTOR UNIT

Setting up the carburetor of the walk-behind tractor is to adjust it. To be able to adjust the carburetor without the help of others, you must take the following steps:

- The screws at low and full throttle must be tightened in full.

- Unscrew the screws at low and full throttle by one and a half turns (set the throttle valve in such a position that a gap of the corresponding size forms between the base and the air duct).

- Start the engine and wait until it warms up.

- With the engine running, set the control lever to low speed.

- Achieve smooth motor operation. For this purpose, it is necessary to make the idle speed as low as possible using the throttle screw.

- Set idle speed to maximum with idle screw.

- Set idle speed to theater-like with throttle screw.

- Repeat steps 6 and 7 until the motor starts to run continuously.

- Set the engine control lever to gas.

- If an interruption occurs, unscrew with a screw that regulates the quality of consistency, less than 2.4.5 turns.

I would like to note that the adjustment of the carburetor on the Neva walk-behind tractor is done correctly according to the above annotation. The K-45 device installed on the Neva walk-behind tractor is single-chamber and horizontal. The float chamber is in the very center. Throttle body. flat.

On the Neva walk-behind tractor, the DM-1K engine is used, which is produced at the Krasny Oktyabr Neva plant. The manufacturer categorically does not use Chinese-made engines. This also applies to the production of a motor-cultivator.

Gasoline supplied to this device does not necessarily contain mechanical impurities. Our client is left with parts processed only with gasoline. Do not use a solvent, because the elasticity of the washer and rubber parts is damaged.

Use compressed air to dry the parts. It is not recommended to clean small holes with a wire or a needle. Installation after repair or cleaning should be carried out sparingly so that no twists and deformation of parts come out.

I will try to summarize and place in one place information from various sources in the article. I apologize to the authors of the articles for not indicating links to them. I just don’t remember where I got the information from. I do not claim to be 100% accurate yet of all the information, tk. I draw some conclusions based on my own guesses. Perhaps someone will correct me. Let’s practice, together we will create a small set-up instructions. Service center specialists, of course, know everything, but they will not share their knowledge. The less information, the more profitable it is for them. After all, the Neva has been produced for a long time, but there is no literature on repair and adjustment. And it won’t. As in my case, they will answer you: “Bring it to us”! And if this is another state, or thousands of kilometers to the service workshop, then how. I’m not alone. I read it in different forums, people are interested in how it works and how to fix it. So I’ll try from the simplest. For some it will be clear and so, but for beginners, maybe it will become clearer.

I just ran into a problem with setting up the Neva MB-2 walk-behind tractor. During operation, I wiped the thrust of the centrifugal regulator with a rag and, apparently, the bolt was not tightly tightened. in general, it turned. After that, I tried to fix it for a long time, until it worked. I will try to describe how I regulated, how it works.

I’ll start with a centrifugal regulator. Its purpose is to maintain a constant engine speed when the load on the shaft changes. Those. so that the single-axle tractor does not stall when you, for example, plow. At the same time, through the wheels, gearbox, pulley, belt, engine pulley, the engine begins to slow down and if it were not for the centrifugal regulator, the engine stalled. After all, we do not have the ability, like a car, to push more and more on the gas. The design is thought out very competently.

Click on the picture to enlarge

After the engine is started, the weights of the regulator are unwound. Due to centrifugal force, they disperse, opening like a flower, and on the stem moves forward, turning the regulator lever. Now, if we load the engine, the rotation of the engine will start to slow down. In this case, the speed of rotation of the weights will also decrease, they will begin to fold (cover like a flower) and the regulator lever will begin to return back, which will lead to a turn through the centrifugal regulator lever, traction, throttle valve of the carburetor to increase fuel consumption, i.e. add gas. Those. having put the throttle stick in a certain position, we can now not worry that the engine will stall under load. As soon as we reduce the load, the weights diverge again and turn the throttle valve through all the rods to decrease the throttle. There is another spring in this entire line. With an increase in gas, it stretches through a cable and a bracket in the shape of the letter “G” and resists the rotation of the throttle valve in the direction of decreasing gas.

Click on the picture to enlarge

Further. Because rpm “walk” when the air damper is fully opened, then a lean mixture comes out. It needs to be adjusted. We screw in the idle mixture adjustment screw until it stops. Now we unscrew this screw by one and a half turns and start the engine. The carburetor device is such that when screwing in the screw, we block the air channel and increase the amount of gasoline in the engine. That is, we enrich the mixture, and if we unscrew the screw, then we add more air, so we make the mixture lean. Now, with the air damper fully open, we try to achieve the maximum stable rpm by rotating the screw, reduce the gas to a minimum and again try to achieve the minimum low, but stable engine rpm.

Now we look at another important part. the throttle stop screw. With the gas removed, it should rest against the carburetor board. Now we smoothly unscrew it and achieve the minimum speed. This screw allows the throttle to close at a certain angle. Now you can test a single-axle tractor. Having allowed it to warm up under load, you can find out by the candle whether the working mixture is correctly adjusted. Since after idling, you will not see this.

Identifying engine problems by looking at spark plugs.

We hope this article will help you choose the right spark plug and determine the condition of your engine. By the appearance of the spark plug electrode, you can determine the condition of the engine, the suitability of the glow number of the spark plug, as well as whether the carburetor and the ignition timing are properly adjusted.

- Wet spark plug electrodes (Figure 1-2) can be caused by one of the following:

(a) Very rich air / fuel mixture (high fuel, low air). (b) Malfunction of the ignition system. (c) Ingress of oil into the combustion chamber (worn out: piston rings or valve guides).

- Soot-coated spark plug electrodes (Figures 3, 4 and 5) can be caused by one of the following:

(a) A plug with a too high glow number is used, so the electrodes work in a partial load state and cannot reach a self-cleaning temperature regime (above 400-450 ° C). (b) Using too rich air / fuel mixture (more than 8: 1-10: 1). (c) Malfunction of the ignition system. (d) Malfunction of the cooling system (too much cooling).

- Even spark plugs that are good looking (Figure 6-24) can often be coated with lead due to misfiring.

Cold candle or rich mixture But okay

Cold candle or rich mixture But ok

Cold candle or rich mixture But okay

Hot candle or poor mix But ok

Hot candle or poor mix But ok

Hot candle or poor mix But ok

(a) A plug with a too low glow number is used, so the electrodes operate under an excessively high load and exceed the upper limit of the optimal temperature regime (above 850-1000 ° C). (b) Poor air / fuel mixture. (c) A late ignition timing is set. (d) Abnormal combustion of the air / fuel mixture (detonation). (e) Malfunction of the cooling system (engine overheating).

Too hot spark plug or poor mixture Early ignition

Too hot spark plug or poor mixture Early ignition

Too hot spark plug or poor mixture Early ignition

Too hot spark plug or poor mixture Early ignition

Too hot spark plug or poor mixture Early ignition

Now by looking at the spark plug, you can judge how you adjusted the carburetor.

That’s all I wanted to share. I apologize for having described it unclearly. It is easier for me to explain “on the fingers” or to do it myself.

Adjustment of the walk-behind tractor: carburetor, valves, fuel system

This article describes the adjustment of the walk-behind tractor, namely its main parts: the carburetor, valves and the fuel system. The process is not easy, so we have also attached some photos and videos.

Carburetor for walk-behind tractor: adjustment, repair, maintenance

The carburetor is the element of the walk-behind tractor that is necessary to control the flow of air and fuel.

Thus, the optimization of the motor operation is carried out at a stable load. Like any mechanism, the carburetor needs proper care.

Types and methods of carburetor adjustment

As you know, a uniaxial tractor, like many other units of this type, is powered by an engine. Due to the fact that the engine cannot ignite without supplying oxygen, it becomes necessary to use a carburetor. Two types of carburetors are used for the walk-behind tractor. One of them is rotary, the other is plunger. Naturally, each of the mentioned types has its own advantages and disadvantages, the choice depends on the walk-behind tractor, its performance and the type of work performed.

There are times when there are abnormalities in the operation of the carburetor (the process is unstable). In such a situation, the carburetor needs adjustment. How to adjust the carburetor on the walk-behind tractor? It is quite possible to do it yourself, following a certain sequence of actions.

- First, you need to turn the screws (full and low throttle) until they stop. Then turn them one and a half turn.

- Turn on the engine, give it time to start and warm up.

- Do not shut off the engine and place the motor control lever in the lowest speed mode.

- Next, set the minimum number of revolutions when the device is running stably.

- Then run idle to maximum.

- Shift idle to minimum. Repeat this action, alternating with the previous one, until the engine starts to run smoothly.

- Move the control lever to the “throttle” position.

Following such instructions, you can independently adjust the carburetor of the walk-behind tractor.

Carburetor adjustment. | Topic author: Mitsue

In order to save the engine during the running-in period, the Chinese are reinsured.

Mikhail (Delman) as a common man in the street to make a jet with a lower throughput?

Using (Ramakrisna) Mikhail, solder the old nozzle with tin and drill a smaller hole, or choose a suitable nozzle, which is more correct

Mikhail (Delman) http://www.wagnerland.ru/index.php? topic = 602.msg13410. it will be clearer here

Denis (Vishala) Kostya, Bend or solder the valve foot.

Mikhail (Delman) Another observation: the main jet from the VAZ carburetor is ideal for KDshek carburetors. Tomorrow I’ll go and ask about the sizes. I have a millimeter in diameter. Vprinsepe and it can be adjusted if the native is lost

Farid (Ratnamala) How many revolutions to unscrew the mixture adjustment screw before the first start?

Denis (Vishala) Farid, this is an idle screw. The mixture in this carburetor is adjusted by the position of the needle and the selection of the jet.

Sergey (Volkert) how to understand 80 cube I bought or 50.

Alexey (Eckehard) Unscrew the candle from the cylinder, insert a straw into the hole and lower the piston to the lowest position. now take a 20 cc syringe and pour gasoline into the cylinder. You will be able to count the skok poured)) 49 or more is not 80 for sure, but about that)))

Marat (Aingeal) Alexey, I am plagued by vague doubts if I lower the piston to the lower position and pour gasoline into the cylinder with a syringe, whether gasoline will flow through the exhaust or intake ports of the cylinder into the exhaust pipe and into the engine. Picture 3 shows that the channels are open at the bottom of the piston

Alexey (Eckehard) Marat, Logically !! I did not think about that))) So the windows can be drowned out, for example with plasticine. I need to conduct such a test at my place. The season is over then and I’ll see.

Marat (Aingeal) Alexey, I think it’s easier to find out the diameter and stroke of the piston after which I think it will be possible to calculate the volume of the cylinder.

Vladimir (Achelous) Sergey, Sorry for breaking in without asking, accidentally hitting a link. On F80, the studs for mounting the cylinder are M8, on 50-ke. M6.

Vladimir (Achelous) Alexey, Alexey, so you will fill in 200 cubes. Everything will flow through the windows into the crankcase, and then into the muffler!

Vladimir (Achelous) To optimize the KD carburetor, the first step is to lower the fuel level in the carburetor. To do this, it is enough to disassemble it, unscrew the inlet fitting, remove the gasket from under it, and carefully assemble it back. Without the gasket, the level will drop to (-10). (-11) mm. Solder the nozzle with acid with solder, and blow into it while the solder is melted. Excess solder will fly out, a hole will remain, which must be calibrated with a regular sewing needle with a diameter of 0.65-0.67 mm, pushing it to the middle and pulling it back. Carefully remove excess solder from the widened part of the hole with a drill (MANUALLY!), So as not to damage the jet itself, i.e. calibrated part. The throughput of such a jet will be 72-76 ml / min. Full turns will appear.

Tags: How to adjust the centrifugal regulator on a walk-behind tractor beam video

Adjusting the fuel system of the walk-behind tractor

If the fuel is not supplied to the cylinder, then, first of all, it is necessary to check if there is enough fuel in the tank. You also need to check whether it goes to the carburetor. For this, a hose is removed from the inlet connection of the device. If we are talking about a carburetor of the K45 type, you should press on its quench so that the fuel begins to pour out through the drain hole.

If the fuel does not enter the carburetor, then you need to turn off the fuel supply valve, completely disassemble it and remove accumulations of dirt from the mechanical filter. To achieve maximum cleanliness, all components must be treated with gasoline. The fuel cock is assembled and returned to its original place.

If fuel enters the carburetor, but is not supplied to the cylinders, it is necessary to check the correct operation of the fuel valve, as well as the presence of dirt on the jets.

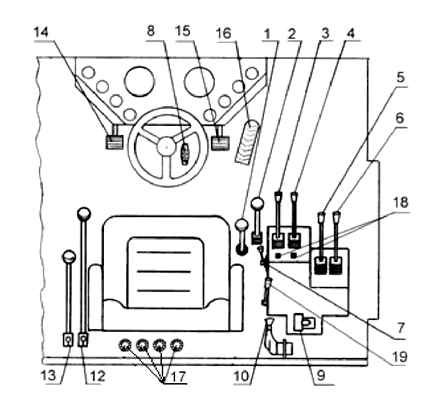

To deal with the carburetor of a gasoline walk-behind tractor of the KMB-5 type, you need to remove it from the engine and pour out the fuel from the float chamber. Through the fitting (see figure), with the help of which the gasoline is supplied, it is necessary to supply the air mixture, having previously installed the carburetor in the operating position. The passage of air should go unhindered, and when the carburetor is turned over, it should completely stop. These features indicate the full performance of the part.

Details in the figure: 1. fuel supply connection; 2. upper body; 3. throttle valve; 4. idle needle; 5. jet; 6. lower body; 7. air damper; 8. screw fixing the tie; 9. maximum gas needle; 10. spraying element; 11. float; 12. fuel supply valve.

The fuel level inside the float chamber can be adjusted using the float tab. Ideally, it should range from 3 to 3.5 centimeters.

To purge the jets, it is necessary to unscrew the screws responsible for full and idle throttle. Cleaning of the carburetor parts begins by unscrewing the screws that hold the upper housing. The lower body is removed, the fuel supply valve is flushed with gasoline, and the dirt from the nozzles is blown out by a pump. It is necessary to check if the float is intact. It is absolutely impossible to use rags in the cleaning process.

After completing the cleaning, the housings are connected. It is necessary to check that the spray tube is clearly inserted into the hole located on the upper body. Open the throttle valve and check how well the assembly is done. The screws that secure the upper case are tightly tightened. After the assembly process is completely completed, the carburetor should be adjusted. This will significantly improve the performance of the walk-behind tractor with attachments, since for correct operation, ideal adjustment of all its parts is required.

If the carburetor DM 1.08.100 is installed on the engine of the walk-behind tractor, then the procedure for adjusting it will be as follows:

- Screw in the screw 10 at idle until it stops and unscrew it half a turn.

- Then you need to tighten the full throttle screw 9, unscrew it completely by 2 turns.

- Unscrew the screw 4 of the minimum engine speed right up to the stop of the lever against the bore of the carburetor body and tighten it 2 turns.

- Start the engine of the walk-behind tractor, then adjust stable operation at maximum speed after warming up with screw 9.

How To Adjust Mechanical Governor On Small Engines

Do not allow the engine control lever to be turned off, move it to the minimum throttle (rpm) position and by unscrewing screw 10 set stable idle rpm.

That’s basically it. The main points of adjusting the main parts of the walk-behind tractor are considered. Enjoy adjusting your single axle tractor!

Grillo Walk-behind Tractor Handlebar maintenance

The scheme of work of centrifugal regulators

Figure 38, a shows a diagram of the operation of a single-mode centrifugal regulator. The regulator shaft 1 is driven by the engine crankshaft. With a decrease in the engine load, the number of revolutions of the crankshaft, and therefore of the governor shaft, increases. When the centrifugal force of the weights 2 exceeds the resistance of the spring 5, which presses the arm of the lever 4 to the sliding clutch 3, the clutch will begin to move and by means of levers and rods will close the throttle valve 7.

With an increase in the load, the revolutions will decrease, the centrifugal force of the weights will decrease, the spring will move all the parts in the opposite direction and slightly open the damper.

The beginning of the action of the regulator depends on the elasticity of the spring: the greater the elasticity of the spring, the greater the centrifugal force must be in order to overcome its resistance. The spring is tensioned when adjusting.

To obtain reduced speed, the manual control lever is used, which can be used to close the throttle valve through the linkage system. In this case, the regulator cannot act on the damper. If the lever is set to the extreme rear position, then the impact of manual control on the damper will cease, the regulator spring will slightly open it.

Figure 38, b shows a diagram of an all-mode regulator. The elasticity of the spring 5 can be changed with the lever 6 within the limits that are determined by the position of the bolts 8 and 9. The position of the stop bolts is set when adjusting the regulator.

Lever of the centrifugal regulator in the Neva walk-behind tractor. 2M

Can you tell me how you can correctly set the regulator lever on the centrifugal regulator. I had such a misfortune. I wiped the carburetor and rods in the walk-behind tractor and turned the regulator lever on the centrifugal regulator, the one that crimps the centrifugal regulator with a bolt and nut. I tried to put it in different ways. It works at very high speeds, then I achieved that it starts up normally when the air damper is closed and the speed does not float, and when I open the air damper, the gas starts to float and if I lower the gas, it stalls. In this case, the throttle valve floats within wide limits. And also foolishly bent the lever with the spring, through which it is connected to the rod that compresses the centrifugal regulator. In general, I’m sitting now and wondering how everything should interact.

Thank you very much, Alexey! I checked my mail and read your answer. I will try it on weekends.

Tinkered at the weekend, but never won. Disassembled and washed, cleaned all holes in the carburetor with a fishing line. Collected, but the result is the same. The forum had a glimpse of replies where the K-45 carburetor was mentioned. Maybe someone disassembled it will tell me about the idle jet. It is located on top, there is also a rubber ring on the screw. So my question is whether it will affect how much it is screwed in, because it has one through horizontal hole and one small jet from below to this horizontal one. I screwed it all the way. Is it correct?

Hello everyone. uniaxial tractor Neva, carburetor 45 bought used, removed and disassembled the carburetor. there is a lot of dirt, but the question is in another 1- the lower bar was removed which goes to the regulator 2- on the regulator itself the lever dangles. apparently the bolt is not tightened well, and the question itself- how to correctly set the bar on the carburetor that controls the damper and how to set and fix the lever on the regulator

Good day! Help, I have the same situation as once before: Lever of the centrifugal regulator in the Neva-2M walk-behind tractor Can tell me how you can correctly set the regulator lever on the centrifugal regulator. I had such a misfortune. I wiped the carburetor and rods in the walk-behind tractor and turned the regulator lever on the centrifugal regulator, the one that crimps the centrifugal regulator with a bolt and nut. I tried to put it in different ways. It works at very high speeds, then I achieved that it starts up normally when the air damper is closed and the speed does not float, and when I open the air damper, the gas starts to float and if I lower the gas, it stalls. In this case, the throttle valve floats within wide limits. And also foolishly bent the lever with the spring, through which it is connected to the rod that compresses the centrifugal regulator. In general, I am sitting now and wondering how everything should interact. There is no book. You have dropped instructions for dokpva by email. If you can help me too. Thanks in advance.

vai72 wrote: Good afternoon! Help, I have the same situation as it was once before: Lever of the centrifugal regulator in the Neva-2M walk-behind tractor Can you tell me how you can correctly set the regulator lever on the centrifugal regulator. I had such a misfortune. I wiped the carburetor and rods in the walk-behind tractor and turned the regulator lever on the centrifugal regulator, the one that tightens the centrifugal regulator with a bolt and nut. I tried to put it in different ways. It works at very high speeds, then I achieved that it starts up normally when the air damper is closed and the speed does not float, and when I open the air damper, the gas starts to float and if I lower the gas, it stalls. In this case, the throttle valve floats within wide limits. And also foolishly bent the lever with the spring, through which it is connected to the rod that compresses the centrifugal regulator. In general, I am sitting now and wondering how everything should interact. There is no book. You have dropped instructions for dokpva by email. If you can help me too. Thanks in advance.

And me, if you can. I will be very grateful

Actually, there is this in the topic about the Neva. There is also something that I’ll post and a description of how to do it, like Gesha laid out. I have such a recommendation.

woldemar wrote: hello everyone. uniaxial tractor Neva, carburetor 45 bought used, removed and disassembled the carburetor. there is a lot of dirt, but the question is different 1- the lower bar was removed, which goes to the regulator 2- on the regulator itself the lever dangles. apparently the bolt is not tightened well, and the question itself- how to correctly set the bar on the carburetor that controls the damper and how to set and fix the lever on the regulator

Regarding the DM engine: We put the traction lever (by loosening the tie bolt) (3) connected to the carburetor damper (2) in place. Then we turn the CRO shaft (regulator) clockwise until it stops (1). Keeping the shaft in the stop position, press the thrust lever (5) until full throttle is obtained. While holding this position, tighten the tie (4). Then put the spring back in place (6). We check the work of the gas. At minimum, the damper is in a free position, with full throttle, the damper opens to full. We start MB, Warm up. CRO always tries to close the damper on XX. With medium throttle, the flap should open halfway. At full to full. Everything else is regulated by the CRO depending on the load.

My thoughts swarm only in my head. Oh, I’ll take the swarm to the dacha, but for the weekend.

All-mode regulators have a number of advantages over single-mode regulators:

- a wide range of regulator action provides the tractor with great versatility, that is, the ability to work at different power and different speed;

- overcoming obstacles on turns, etc., you can change the speed of the tractor without changing gears;

- the economy of the engine increases when it is operated with underload.

If, when working in 2nd gear, the resistance of the trailed or mounted machine is not enough to fully load the tractor, the regulator moves the pump rack back, and the engine runs at a slightly increased speed. Specific fuel consumption is also higher than normal.

In the presence of an all-mode regulator, you can switch to III gear and lower rpm, while maintaining the same speed of the unit. Since this will reduce the engine power, the load will become more complete and the regulator will move the rail forward.

The engine will operate in this mode at a lower number of cycles per minute, but with full fuel supply per cycle, as a result of which heat loss to the cooling water will decrease and specific fuel consumption will decrease.