How to Assemble a Drill Lock on a Hammer

Any tool requires timely maintenance. And the puncher needs this in the first place. Its operation is accompanied by a large number of reciprocating movements and rotations. In this case, the amount of dust emitted from the treated object has a very high concentration. In such working conditions, careful maintenance of the tool and timely replacement of grease is necessary.

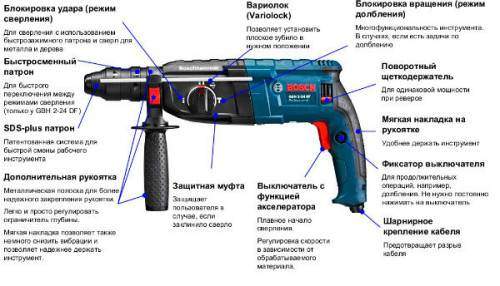

The layout of the external part of the punch.

Many users are sure that if it is present, then you can work with it an unlimited amount of time. This misconception exists among users due to the low level of knowledge of physical laws. Consider the mechanism of lubrication a little deeper.

How to make a soldering iron stand. details>>>

What is lubricant and why is it needed?

It is recommended to change the grease in the punch once every six months.

A lubricant is a viscous mass that is designed to minimize the coefficient of friction between parts. Reduce, not eliminate completely. This means that friction between the parts is almost always present, and with it part of the fine particles is separated from the parts and gets directly into the oil. Over time, this grease enriched with metal dust already ceases to fulfill its main function. First, the viscosity of the grease simply changes, and a little later, it itself becomes the cause of rapid wear of parts. The viscosity of the lubricant is the main parameter that you must pay attention to when buying it. The punch manufacturer must indicate in the accompanying technical documentation all the parameters of the punch and the lubricating fluid that must be used. Particular attention should be paid to the frequency of maintenance, which indicates how long it is necessary to change the lubricating oil.

For a puncher with a quality certificate, it is necessary to use only branded lubricants, otherwise in the event of a device failure, you will lose the right to warranty service. After the warranty period, it is also advisable to use the substance recommended by the manufacturer, but at this point, as a rule, the user uses cheaper domestic counterparts. Solidol or lithol will not harm your instrument in the least. But do not forget that lithol "works" a much shorter period, so it should be replaced more often.

What do you need to lubricate a rotary hammer?

The scheme of the device components of the punch.

Such lubrication is also required for the temperature regime of use. But this does not mean at all that the use of lithol is prohibited. There are facts when, when using a domestic lubricating fluid, the impact force of a perforator only increased and the noise background produced by it increased. This is especially true of the Chinese assembly punch. Users of Chinese products do not hope for warranty service, therefore, they act at their discretion from the very beginning of the use of a punch (or drill). Since the punch of each manufacturer has its own fundamental design features, the general lubrication instructions cannot exist. The main thing that you have on hand:

- product care instructions;

- rags;

- branded grease or its equivalent.

And then, as you may have guessed, we act strictly according to the instructions. Do not forget that the perforator should be as dust-free as possible. And make sure that the lubrication level does not exceed the reference mark. As a rule, a perforator has a special capacity for lubricating oil, so it is not difficult to complete the entire procedure.

Video: How to Assemble a Drill Lock on a Hammer

Lubricating the rotary hammer immediately after work is not recommended, since heated parts, when cold grease gets on them, lose their physical properties. It is also advisable to lubricate the drill shank with solid oil or lithol. If the punch is equipped with an open cartridge, then it makes sense to lubricate the seal. It must first be disassembled and wiped thoroughly. The applied grease will extend the life of the cartridge and will resist dust from entering the hammer.

Is it worth it to disassemble the gearbox yourself?

Disassembly of the perforator gearbox: 1. special ring, 2. releasing sleeve, 3. ring, 4. ball, 5. spring 8. casing, 22. closing spring, 28a. switch, 29. ring, 30. spring, 31. retainer.

The perforator gearbox requires special attention. It’s not so difficult to lubricate the gearbox parts, but you shouldn’t do lubrication yourself before the warranty period expires. You definitely succeed in disassembling the gearbox, but not everyone can assemble it. With the problem of gear lubrication, it is better to contact specialized workshops or a branded service center. This work is very delicate, therefore it is better to entrust it to real experts. It is possible that the nearest such center is far from you, so you decide to lubricate the gearbox at home.

Then it should be recalled that the lubricant must be replaced by first disassembling the gearbox. Both before and after disassembly, thoroughly clean the hammer from dust. Better if you blow through all the details. A compressor helps you quickly remove dust. Any building hair dryer or even an ordinary brush is suitable for this. The main thing is that dust does not get into the gear housing.

When disassembling, pay attention to all the details. Some of them have no lubrication at all. This does not mean that they have been greased. Just part of the gearbox parts is not lubricated. You also do not need to smear them. When disassembling, we try to remember as much as possible the position of the parts and the order in which they are extracted. So, you will not get "extra" parts during assembly. All parts of the gearbox must be thoroughly washed with kerosene (or spindle) and wiped dry with a rag. It is also necessary to flush the gear housing from the inside. There is no need to rush with the assembly: let the case dry.

Causes of hammer overheating

And now we lubricate the parts and assemble the gearbox in the reverse order. We remind you that an excessive amount of lubricant can also affect the quality of work: gearbox heating may increase.

If the punch began to heat more than usual, then this does not mean that there is a problem with lubrication. Most likely, you used the chiselling mode for too long, so the lubricant simply did not reach all the parts of the punch in the required amount.

A second reason may be clogging of the engine cooling openings. There is only one solution: to clean the puncher from dust and transfer it to a different operating mode for a while. If the punch works for 15-20 minutes like a regular drill, the temperature of the case will significantly decrease. The gearbox must have the same temperature in all modes of using the hammer drill.

Subtleties of drill maintenance with punch function

It is much more difficult to maintain a drill, which is also positioned as a hammer drill. Such a hybrid of two tools has a number of disadvantages compared to conventional rotary hammers. Firstly, they do not have special containers for filling grease. Secondly, it’s much more difficult to maintain the mechanism cartridge. Only the tip of the drill needs constant lubrication. The amount of lubrication is minimal: just wipe the drill from dust and apply a small ball of solid oil (the size of a match head) to the tip.

The drill will be very easy to move and will serve you for more than one year. The same requirements apply to the maintenance of a conventional drill drill. Excess grease on the storm will not harm the mechanism, but it will certainly splatter and may cause cosmetic damage to the repair of the apartment. But if the grease is added to the gearbox in excess, then it will simply leak.

Excessive lubricant pressure will surely squeeze out one of the seals, and the heated grease will protrude onto the gear housing.

And this is the same spray and the same problems with the repair. And the gearbox itself will be damaged.

A few words must be said about professional rotary hammers. In personal use of a home master, such a tool usually does not exist. Here, first of all, cost plays a role, therefore, they acquire them much less often. Meanwhile, such a punch is the most unpretentious and easy to maintain. There is no problem with the lubrication of such a tool, since the design of the mechanism is extremely simple. The gearbox also has no features that impede its maintenance. Everything is simple: we open the drain valve, release the used grease into the tank, rinse the hole for greasing the perforator, close the drain hole and fill in new grease to the required level. The gearbox of such a hammer drill is serviced in the same way as previously described.